Everything posted by Zed Head

-

OFFICIAL 280Z "Fuel Damper" thread!

I read a few things. Always good to have a new reason to learn about an obscure part. It's not really clear what the damper is actually for. Some say it's actually there to damp the pump pulses from the original Bosch pump. So if you have an aftermarket pump, maybe it's not necessary. Some say that aftermarket FPR's have built-in damping ability. No proof, just statements from nowhere. Some say you'll have a poor idle if you don't have a damper. Many say that the engineers wouldn't have put it there if it wasn't needed. Seems like the best reason to damp might be to make parts last longer. The hydraulic hammering from injectors opening and closing and stiff fuel lines might make parts wear faster. Either the pump or the injectors. Maybe it's actually there to protect the Bosch pump. Just adding a few things to think about. Good luck.

-

OFFICIAL 280Z "Fuel Damper" thread!

That's probably as close as you'll get. It's actually a Nissan design, for the 280ZX, 810 and 200SX. Click on the FPD26 number in the description here - https://www.rockauto.com/catalog/raframecatalog.php?catalog=154&partnum=FPD26&a=www.google.com%2BSearch%2Bfor%2BSTANDARD%2BMOTOR%2BPRODUCTS%2BFPD26&blanktemplate=true Cheaper too.

-

OFFICIAL 280Z "Fuel Damper" thread!

The newer designs attach right to the fuel rail,with an o-ring seal. But you might try something like this - http://www.summitracing.com/parts/smp-fpd1/overview/ You need 5/16" barbs though, which is small. Check the OEM applications to see if you can find hose size. Or go to OReilly and see if they have one you can measure. You would probably be fine mounting it in the engine bay also, closer to the injectors. Here are some more options - http://www.summitracing.com/search/part-type/fuel-system-pulsation-dampers I know someone who actually tuned their damper using the adjustment bolt. He had someone turn the adjuster while he watched a pressure gauge. When the needle stopped bouncing he was done. But the later models probably have better damping materials or design so don't need tuning.

-

No gas coming out of the tank!

These two things are hard to figure, especially the first one. It implies that everything was sealed up except for the outlet port, and that you pressurized the tank and the pressure was released when you stopped. One the second - how did you blow air in to the tank? Through the return port, or the filler cap, or a vent line? Not clear. I'd try taking off the filler cap and blowing air in to the outlet port. If fuel is covering the other end you'll hear bubbles inside and air will come out of the filler hole. Don't blow too much or you'll the area with fuel fumes.

-

Ever see these valve seals before on a L series?

That's a nice collection. Where'd it come from? I only see Chrysler and GM as USA market, all the others are foreign. No Ford. Maybe the odd ones are installed upside down.

-

What maintains the fuel line pressure when the care is off?

This thread is about maintaining fuel pressure, not fuel dampers. You've inserted yourself in to someone else's thread. And you're not even on-topic. Starting a new thread of your own might get better advice. Try Oscar. http://www.datsunstore.com/fuel-pressure-dampener-7583-p-95.html Any damper from an older fuel-injected car would probably work. Browse the local wrecking yards.

- R180

-

83 280zx turbo half shaft CV's

Why?

-

83 280zx turbo half shaft CV's

That's what I thought you were thinking of. I have a set of 2+2 280Zx CV's in the garage and the companion flanges, from a diff I bought as a spare. But I have a 280Z so they're not much use to me. The 300ZX Trubo shafts are longer than the 280ZX turbo shafts, I believe. I don't think the 280ZX shafts have the length problem. Guess you'll find out.

-

Dirty exhaust normal at startup ?

Cold operation is a transient phase, a region to get through as quickly as possible. That's why the thermostat stays closed and there are temperature operated choke flappers, fast idle mechanisms, AAR's, and timing advance schemes on carb'ed and EFI systems keep the engine running while it's cold. I wouldn't do any "tuning" to change a cold engine observation. Just me. You'd probably change the hot end by working on the cold end.

-

Bearing issue, HELP!

Looks like you got a bad set. I don't think a wide bearing can be used on a narrow journal anyway, so easy decision. Monroe shows some good stuff on page 115 of his Rebuild book. Also mentions that the shells with the holes go in the block. And the size/thickness should be marked on each one. More stuff to look for in your bad set.

-

Cranking Engine but no Start...

It sat for a year. Does it have new fuel? Is it still fuel injected, or has it been converted to carbs? Sorry, but now it's just a car that sat for a year and runs poorly, with new "spark plugs, spark wires, cap and rotor". Still missing details. Many of the good suggestions have already been made, above. Just start back at #1, and replace "won't start" with "runs poorly".

-

83 280zx turbo half shaft CV's

You bring up a good point but might be thinking of the 300ZX 4-bolt CV shafts that come with the 86-89 300ZX turbo cars. grannyknot/Chris is using the 280ZX 6 bolt (3x2 pattern) CV shafts. They came on the 280ZX turbos and 2+2's. People use them on 240Z's if they change the companion flange at the wheel. Apparently the 280ZX and 240Z's used the same shaft diameter and spline count at the wheel axle. You can also use them on 280Z's if you get an adapter. But the stock length seems to be okay.

-

83 280zx turbo half shaft CV's

They use a hack saw in the Service Manual.

-

71 wires question

The rear window defrost power connectors are female spade type, for the 76 280Z at least.

-

Collient plug f54 block

I know it's the same size as the elbow in the back of the head that feeds the heater core. I've swapped them.

-

Redwing - Unusual incident

Yes, you can still drive on a bad clutch. It just limits performance. Didn't mean to add to the to-do list, it can wait.

-

Pre-oiler

Seems like a good spot. But I wonder how much oil could flow back through the pump. If oil makes it to the top end though, it seems safe to assume that it's also made it to the bottom end, since the system is designed to be balanced.. So a test with the valve cover off would indicate effectiveness. How do you get the extra oil back out?

-

Redwing - Unusual incident

Great point. Unfortunately the tachometer doesn't work to see the speed - RPM mismatch. For Jai - did engine RPM rise without car speed changing? That much slippage probably means time for a new clutch. A burnt clutch smells somewhat like rubber when it's toast (humor...).

-

Redwing's Car - An Update

-

Redwing - Unusual incident

Kind of sounds like one or both back tires were rubbing. Maybe the steep angle loaded the body down on to the tires. Any unusual noises?

-

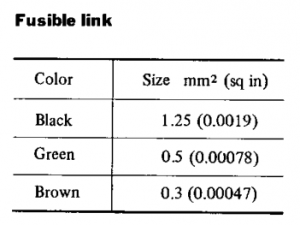

Upgrade from fusible links to circuit breakers

I'll bet no one has done that with the other colors either. So you don't really have a spec. for any of them.

-

Upgrade from fusible links to circuit breakers

-

Redwing's Car - An Update

I'll kick things off with an easy one. Raise the idle speed slightly. Just use your ear since the tachometer doesn't work. If idle speed is too low, the plugs can foul during warmup. At low idle speed the typical Z car alternator can not meet the demands of the electrical system. This could be causing low voltage during warmup, which can cause a variety of problems. It's easy and can't harm anything. The Z EFI system passes through two areas during warmup where idle speed will drop - once when the AAR valve closes and again when the ignition system goes off the second pickup, if it has one. If it doesn't have the second pickup then it sits in a low RPM area for longer. Modern EFI systems monitor RPM and change timing to hold a steady idle. In short - turn that screw counterclockwise a 1/2 turn or more and add some idle RPM. Worst case, your battery lasts longer.

-

HEI Upgrade not working on '78 280Z

I had a 78 parts car that had a similar problem. I'd get click-whir, click-whir until it finally grabbed and would start the engine. When I finally took it apart I found chipped starter teeth. I don't know if they were the cause or a result, but I have that engine and flywheel in my car now with a different starter and no problems. If you want to test the starter solenoid wiring, make sure the transmission is in neutral, take a screwdriver or wrench, and touch it to the main lug on the starter (where the battery cable connects) and the small male connection on the solenoid. That will provide full power directly from the battery through the tool to the solenoid. If the car is in gear it will jump forward so be careful. I also had a starter begin to fall apart. The bushing in the nose had worked its way out of its seat. That starter made a terrible noise sometimes after starting as the shaft wobbled around. I imagine that it if it had broken or came all the way out, the shaft could have got misaligned and caused worse problems. The starter has a mechanical lever and pivot action from the solenoid to the gear drive. Could be that it just broke.