Everything posted by Zed Head

-

Problems leveling my 240z

Sorry, it might just be me but I don't get a picture of what you did. You checked the level but don't say if it was level or not. You took some measurements but not clear when or exactly where. Sorry, not getting it. If you could put things in the terms of "the strut towers were level and the measurement on the driver's side fender was X, the measurement on the passenger side fender was Y", that would make sense. Or "the fenders were even height but the strut towers were X on one end and Y on the other". Something needs to be level though.

-

Problems leveling my 240z

If you get the car level, and the measurements of the fender wells are close/same, then you can focus on the struts. If you find a big difference in strut tower to fender well relationships then some substantial body work has been done in the past. then the frame shop comes in to play. Just trying to separate body problems from suspension component problems.

- Problems leveling my 240z

-

Problems leveling my 240z

I actually have a slight difference side-to-side on my car. I've pondered all of this stuff before. I think that my spring rates, used springs, are different. But, your idea is a good one. Get the strut tower tops level, with the car on a level surface, then measure distance to the ground on each fender well. The suspension mounting points should be level when the car body is. If the strut tops are level, you should get matching numbers from each side of the car. Maybe you have mismatched tires? Who knows.

- Problems leveling my 240z

-

Problems leveling my 240z

If you decide to go to a shop I would go to a Z car shop, not a frame shop. There are so many modern mechanics and professionals that don't understand these cars, and do actual damage just trying to lift them to take a look, it's not funny. Plus if you get the wrong one, you can get spun down a trail of expensive attempts, with no solution, before you realize the guy knows less than you do.

- Problems leveling my 240z

-

Problems leveling my 240z

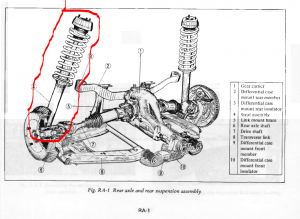

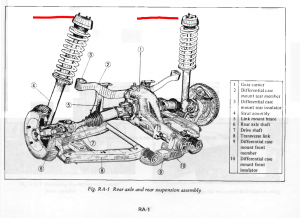

No, I'm suggesting that somebody mixed 240Z and 280Z insulators on the back struts. If you did one strut at a time you might have missed the height difference. The wheels do not spread out as far as they will after rolling. You have to roll the car to get it down to ride height. Everybody does. There is no real frame on the car. It's a sheet steel box with frame elements attached. It's called a unibody, or monocoque chassis. You can't bend it or twist without having big problems like door gaps closing or opening and fenders not fitting. Edit - just saw your reply. I showed 280Z, not ZX, just to be clear. Regardless, it still looks like the driver's side is hanging lower. It shouldn't since the shock shafts extend the same distance. Measure the distance with the tire hanging and see if you have the same 2 1/2" difference. If you dom, that takes some of the potential away from the springs, since they're not doing anything when the tire is hanging. Hope I'm not being too blunt, just trying to get some thoughts across.

- Problems leveling my 240z

-

Problems leveling my 240z

Sorry for the sad story, I didn't expect that. Looking at your latest pictures, it looks like the driver side hangs lower than the passenger, which follows from the original pictures. Assuming that the struts extend to the same length, that implies that the insulator is too tall. Assuming that it's intact, they do fall apart. Here are some pictures I stole from MSA. The 280Z's is taller by about an inch apparently. One thing I didn't see mentioned is that when you lower the car back down after lifting, the wheels are held in by the ground and hold the body up until you roll the car back and forth to let them spread back out. http://www.thezstore.com/page/TZS/PROD/23-4370 http://www.thezstore.com/page/TZS/PROD/23-4382

-

ACK! Battery Cable replacement help!

They're a little more crowded in the engine bay. The bolls are the same though.

-

ACK! Battery Cable replacement help!

It would help if you told what year and type of car you're working on. You can use a transmission mount bolt. The starter bolts to the transmission, so that's a decent ground path. Starter body > starter bolt > transmission case > negative cable. There's also a second mounting bolt, underneath.

-

Problems leveling my 240z

Chasing your own tail is what this forum is all about. It was mentioned that one control arm "bracket" was more difficult to get installed. I'm not really sure what "bracket" means though. Not sure why you would remove a bracket either. But I do know that with the car on the ground I can loosen all of my bushings caps and the control arms won't move. Loosening the caps might show if something is under stress. The system is designed to move smoothly through its range of motion. A picture with a description of what you saw would be a big help.

-

Problems leveling my 240z

The urethane bushings are't really susceptible to when you tighten the brackets since the inner sleeve rotates, unlike the rubber factory bushings which are bonded to the sleeve. Pictures of the welded area would help a lot. I might guess that the car was in an accident of some kind. Could be that the strut tube is bent and binding. The control arm (transverse link in Nissan-speak) just rotates to where the strut and spring place it. Most of the height is controlled by the vertical member. One thing that can lift a side is the anti-roll bar. Do you have one on your car? Another possibility is that somebody replaced a strut assembly with a 280Z strut. They're taller. But you would have noticed when you replaced the insert/shock/damper/strut. Could also be that they replaced the strut insulator, the big rubber piece on the top with the three studs sticking out, with a 280Z insulator. The 280Z insulator is taller also. Since you checked everything, I'm going to make that my #1. It would be easy to miss, especially if you did one side at a time when you changed struts. Apparently you bought a a car that has been sitting for 17 years? The back story is always interesting for the viewers, if you share.

-

Differential front mount insulator for a 1970 S1 240Z - NLA?

Edit - I was looking at the wrong part. Here's the link. Not good that they're running out. We should all start hoarding. http://www.thezstore.com/page/TZS/PROD/23-4614R Edit 2 - also realized that they are charging $149.95 for a sand blast and paint on some pretty small parts. Seems excessive. Edit 3 - An AFM, with a core sent in, costs $169.95. For reference.

-

ACK! Battery Cable replacement help!

Use a wrench. Or a socket, Not clear what your problem is, that is one of the easiest large bolts to remove on the whole engine. Right hand accessible, big open space to work in, push down to loosen. Explain your situation.

- Problems leveling my 240z

-

REAR MOST EXHAUST MANIFOLD STUD PROBLEM

My suggestions were about making an attempt before removing the manifolds. Might get lucky. For every five "took forever to get the broken stud out" stories, it seems like there is one "the stud came out with a reverse rotation drill bit without even using the EZ-out". Take a shot then remove the manifolds to get the broken EZ-out and destroyed stud stub out. Besides that, if one stud went, there are a few others close behind. Check the front one.

-

Need help sourcing parts

Forum members have worked many people down the EFI problem-solving path. Search through some threads here or post a description of what you're seeing. You can save some money. Hopefully you're using the Factory Service Manul and not one of the simpler help books, like Chilton or Haynes. The Factory book is much more detailed. There's another general EFI Guidebook also, very useful.

-

Need help sourcing parts

The first thing many people who read this will wonder is do you really need an AFM? If it's not missing entirely you may not need a new one. The AFM gets blamed for many problems. MSA sells a good product. I have one on my car. But they need a core. So if you don't have a core you'll have to find one. Core charge is $400. Notice also that what you need is more of a model number, like A31-060-001, not the Nissan part number. I have a 78 AFM in the garage but I'd have to go look to find the number. Can't remember for sure. http://www.thezstore.com/page/TZS/PROD/11-3040 Edit - just noticed the good advice at the bottom of the page I linked. Read everything.

-

REAR MOST EXHAUST MANIFOLD STUD PROBLEM

Do you think the gasket is still in good shape? Did you just discover it broken after hearing a noise or did you try to tighten the nut to fix a noise? If you were fixing a noise then the gasket's already shot and a new stud won't help. Seems like drilling the stud end and trying an EZ-out is the only realistic option since you can only see the broken end of the stud. Build a fixture to keep the drill located and perpendicular and you might have a shot. ​A slim possibility - if there's enough space in the hole a stud removal tool might be able to fit. Basically a socket with internal teeth. Drive it on and hope. Overall, the odds are against you. The studs can be hard to remove even with lots of room to work.

-

No gas coming out of the tank!

Just disconnect the small solenoid wire at the starter and turn the key to Start. The pump should get power. It's actually the method described somewhere in one of the FSM's or the EFI Guidebook.

-

No gas coming out of the tank!

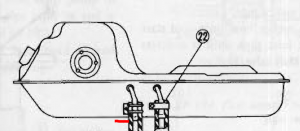

Adding a picture to think about. If the outlet port tube is tweaked upward, or the car is tilted, the siphon problem, and just keeping the inside hole covered, gets worse. These cars are known to suck the line dry on left hand turns when the tank gets down around 1/4.

-

OFFICIAL 280Z "Fuel Damper" thread!

Tried to add that damper to the basket in Rockauto and it says NLA. No luck. All of the old EFI cars used an inline damper though. VW, Toyota, BMW. 99% sure you can run without a damper while you're looking. Cabin noise and, possibly, idle fluctuation, seem to be the major reasons to have one. http://link.springer.com/article/10.1007%2Fs12239-012-0014-7 http://papers.sae.org/2000-01-1086/ http://papers.sae.org/971071/

-

No gas coming out of the tank!

It sounds like you're just losing siphon. You might add a length of hose to the outlet port with end of the hose below the fuel level inside the tank and try again. 5 gallons will spread to a low depth in the bottom of the tank. Or you could just connect the pump, put the end of the exit hose in a gas can and run the pump using the Start trick (disconnect the solenoid). Maybe you just need to suck some snot through the lines.