Everything posted by Zed Head

-

Z's on BAT and other places collection

I'm not sure what you mean. I was just rephrasing Carl Beck's definition. It only uses the VIN as the identifier. He says that Nissan defined two specific ranges of VIN and that those ranges were used to define "Series". Nothing about features. Just VIN.

-

Z's on BAT and other places collection

So, the people that are defining their "Series" by the parts on the vehicle are out of line, speaking nonsensically (no offense intended to anyone). What the "Series" designation really means is that the VIN is within a certain range. The parts (and the build date) don't define the Series, the VIN does. If somebody says that they have a Series 1, just ask for the VIN and you'll know.

-

Z's on BAT and other places collection

HLS30-00000 - 00005 = Series 0. A small group, but still needs recognition.

-

Z's on BAT and other places collection

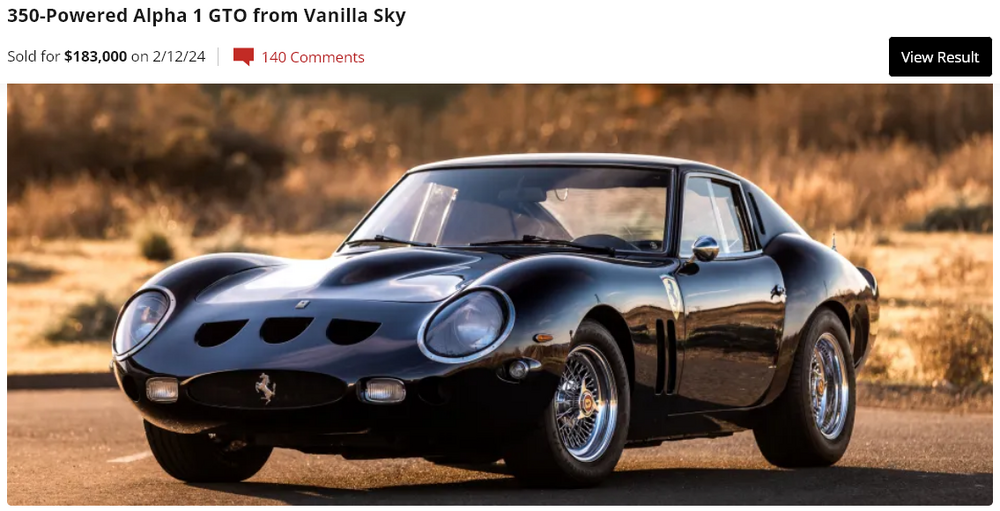

The Tom Cruise Alpha 1 GTO sold. Pretty good money for a 1976 280Z! https://bringatrailer.com/listing/vanilla-sky-ferrari-250-gto-replica/

-

Z's on BAT and other places collection

Weird, I looked on Facebook Arizona and did not find it. Facebook sucks, of course. https://www.facebook.com/marketplace/phoenix/search/?query=240z

-

KYB 361002 shock Won’t fit rubber spring isolator?

You've been conditioned to expect problems. Reprogram!

-

Z's on BAT and other places collection

Facebook? Craigslist?

-

KYB 361002 shock Won’t fit rubber spring isolator?

You need the D to hold the shaft while you tighten the nut. Otherwise it will spin. Did you get four? Are they all that way?

-

KYB 361002 shock Won’t fit rubber spring isolator?

No. I had KYB's and the shafts were D-shaped. Drop-in replacements. Maybe KYB is cost-cutting, or made a mistake, or maybe you got counterfeits.

-

Trans and diff gear oil

I'd go with Pennzoil Synchromesh or Redline MT-90. They're both better than typical manual transmission fluid. Redline has been proven in many situations, solving grinding problems. Search on the forum and you'll find stories. If you use Driven you might be the first. https://drivenracingoil.com/i-30497794-go-80w-90-conventional-gl-4-gear-oil.html https://www.redlineoil.com/mt-90-75w90-gl-4-gear-oil https://www.pennzoil.com/en_us/products/other-oils-fluids-fuel/manual-transmission-fluids-axle-oils/synchromesh-manual-transmission-fluid.html

-

Sudden Running Lean Issue

-

Is my throw out bearing correct?

But, just for fun, it also suggests that the monkey motion transmission was used up through 1976. Lots of confusion out there. https://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/transmission-assembly

-

Is my throw out bearing correct?

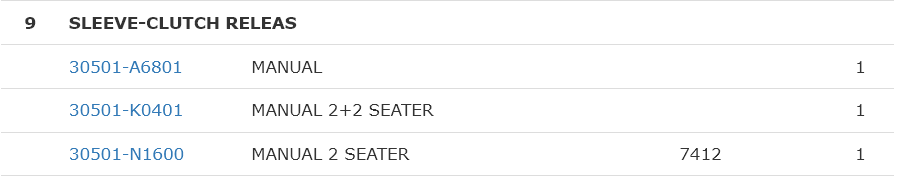

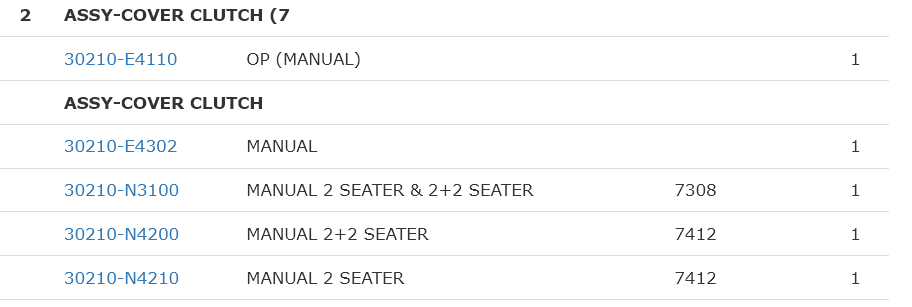

The parts schematic suggests that there are really only three possible sleeves, and four or five pressure plates. The Exedy with the long sleeve sounds like the right combo. https://www.carpartsmanual.com/datsun/Z-1969-1978/power-train/clutch

-

Is my throw out bearing correct?

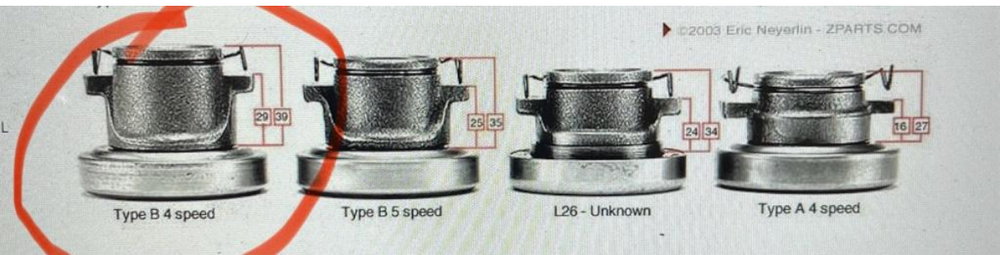

How do you know? The 240Z came with a Type B 4 speed after the Type A monkey motion unit. Feels like the table has turned... For what it's worth, more food for thought, the Type B 5 speed is identical in every way, externally and gears 1 - 4, to the Type B 4 speed. Nissan just added a 5th gear and some shift control mechanisms. The 1 - 4 ratios are identical. In 1978 you could order a 5 speed or a 4 speed. It would be a Type B transmission. Same dimensions. Pretty sure the clutches were identical. Just poiniting out that the labels in that figure don't really tell much.

-

Is my throw out bearing correct?

Odds are good that the sleeve/collar is the one that came with the car. So the typical 280Z 225 mm pressure plate will probably work correctly. Worst case, you take the measurement after you get it and have to wait to get a new sleeve. Your biggest mistake would be installing without taking that measurement. That's where all of the "what's wrong" threads come from. So, at this point you're really just choosing between a "guaranteed" correct fit or maybe having to wait for a new sleeve. Certainty or uncertainty.

-

Is my throw out bearing correct?

-

Circuit board

https://en.wikipedia.org/wiki/FR-2 Looks like good stuff. Probably easy to work with. Must be an analog here in the states somewhere. https://gie-tec.de/product/phenolic-resin-paper-laminate-fr2/?lang=en Phenolic resin paper Laminate FR2 Halogen-free laminates (1,5mm) out of phenolic resin paper High dielectric strength, excellent insulator in high-voltage technology Very good processing, high tool life 35µm copper cladding (copper foil, single side) Optionally uncoated or with foto positive coating of the copper foil High quality positive resist with short process times Produces according: – UL: E103670 – VDE: Reg. Nr. 4158 – BSI: 6741 Option: Phenolic resin paper/ Pertinax without copper lamination, Thickness 1,0mm or 2,0mm

-

Circuit board

-

Starter plunger stuck at normal engine temperature

Here's a trick that might tell you something. Connect a light or a buzzer between the starter solenoid wire and the solenoid terminal. When you turn the key to start the starter should work and the light should light or the buzzer buzz. If you turn the key to Start and you get a light or buzz but the plunger doesn't plunge it's a mechanical problem. If you turn the key to Start but there is no light or buzz then it's a heat-induced open electrical circuit. No current flow through the solenoid windings. The ground for the light or buzzer is on the other end of the windings.

-

Is my throw out bearing correct?

I think that the Perfection kit I got might have been on the shelf for a while at the local auto parts store. Bought it in 2009. It was actually Zoom by Perfection if I recall right. Odds are it will work fine. Mine only had problems when it got hot. I got on to Summit and found this. Doesn't say Perfection in the title but does in the video. Who knows. They're probably all made at the same place. https://www.summitracing.com/parts/zzz-mu47594-1a/make/nissan/model/280z/year/1976

-

Starter plunger stuck at normal engine temperature

Or, if everything goes dead when you turn the key, it could be a dirty battery terminal.

-

Starter plunger stuck at normal engine temperature

Then what I wrote applies pretty well. It will be hard to determine is the solenod has an open circuit when it gets hot or if it's sticking. You might try tapping/beating on it when it happens. You said it has voltage. Is your probe on the male terminal itself or on the female wire end when you measure? The female ends get loose and lose contct. Maybe it just needs a good squeeze. .. . .

-

Is my throw out bearing correct?

If you watch the video in his first post you'll see that it's not a typical throwout bearing. In your picture you can see the gap between the part that spins and the part that doesn't. In his you can't see that gap on the back side, it's solid. But the gap is there on the contact side, with the narrow contact surface. And he shows that the bearing spins correctly on the sleeve. It's just an odd bearing. OR maybe it has fallen apart and the actual contact surface is missing. Just thought of that. Maybe it's a broke bearing, installed correctly. This is my new working theory. More broken stuff, to fit with the missing flywheel pins. Notice that the surface you're showing is rounded while his is not. Deosn't really matter much becuase he already said he's getting all new stuff. Just a puzzle.

-

Starter plunger stuck at normal engine temperature

The solenoid plunger can get stuck in the cylinder. All that is causing it to move is the magnetic field created by the solenoid coil. Take it off and see if something is misaligned. Could also be an open circuit somewhere. Are you saying that you don't even hear a click when you turn the key? Check the mounting bolts for the solenoid. Grab the solenoid and see if it's loose.

-

Parts Wanted: 280zx Turbo Distributor

The one-six and the Godzilla are similar but not identical. The Godzilla has two wheels, a 24-1 and a single tooth. The one-six apparently only has the 24-1 wheel. And the one-six is a Hall effect, the GRW is VR. You'd need to know what your engine management system can do and what you want it to do to make the right choice.