Everything posted by Zed Head

-

Moog ball joints

Their picture shows a Zerk fitting though. Among the parts. So you get a fitting and a nice bolt to seal it up afterward. Looks like picture uploading still isn't working. The picture is in the link above.

-

Moog ball joints

You can re-use them. Take them off the old joint. Or break the bank and buy new... https://www.rockauto.com/en/tools/hardware,grease+fitting,grease+fitting+-+english+thread,172 At least they pre-tapped the hole. That was nice of them. https://www.rockauto.com/en/moreinfo.php?pk=203652&cc=1209226&pt=10070&jsn=378

-

Won't run if tach connect?

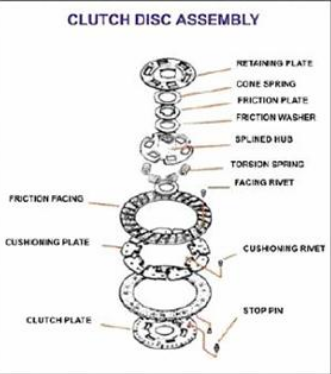

Look at the diagram and do what makes you feel comfortable. If the Crane module fails it will be easier to reconnect the old one.

-

Shifter Rattle

Pretty sure that I've read about doubling up on the roll pins. Pin in a pin. Turns out that you can buy them that way too. Also, coiled spring pins. https://www.jackstransmissions.com/my-cart/store-home/double-roll-pin https://www.grainger.com/category/fasteners/pins/spring-pins

-

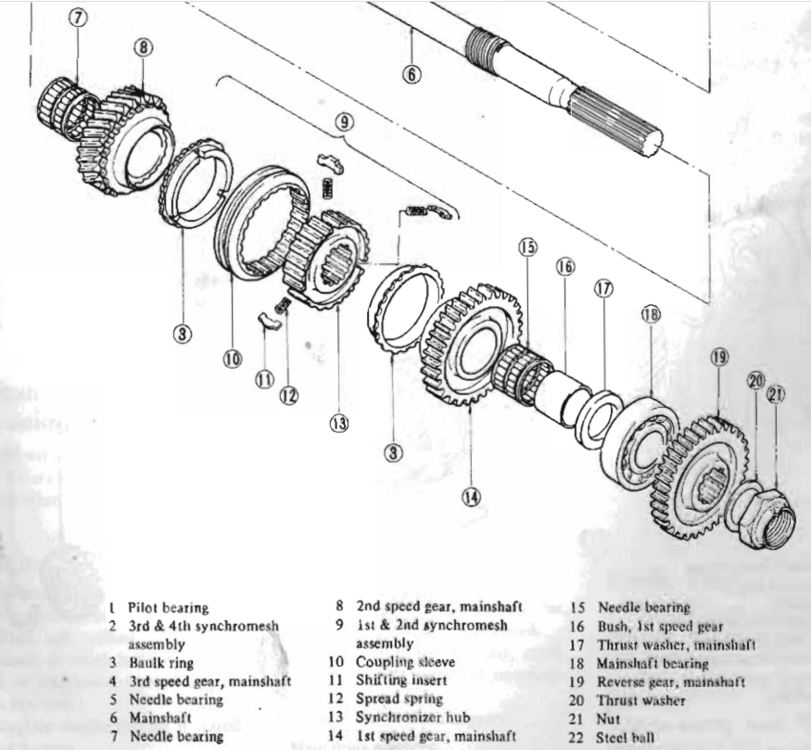

Existing FS5W71B Bearing/Seal Size Inventory?

Found a link. I don't know if this has been uploaded to the site or not. Post #45 has a pdf file you can open.

-

Existing FS5W71B Bearing/Seal Size Inventory?

@EuroDat did, I think. I tried to find it but can't. It should be in the Downloads area somewhere but I can't figure out how things are categorized there. Don't know how to search just the Downloads area either. Anyway, it's out there somewhere.

-

Need clutch disc, not kit

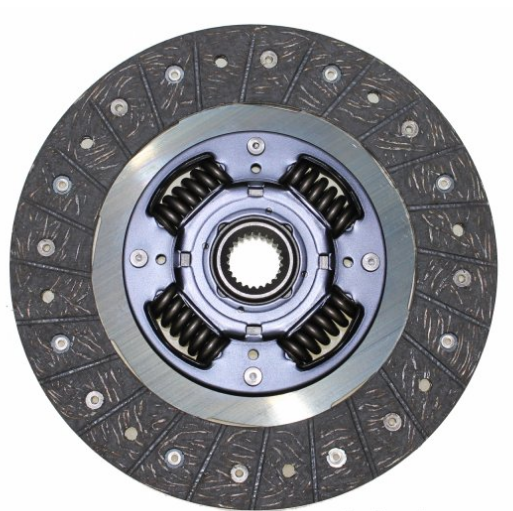

I don't know that there's nothing wrong with it. You might try making a few hard pulls with it and see if the pucks will bed in and behave differently. I had a clutch that chattered when it got hot. It was terrible, had to change it. But it was fine when it was cool.

- Won't run if tach connect?

-

Won't run if tach connect?

Maybe somebody has been in there. Anyway, the old module should still be disconnected. Here's some reading. http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/75_280z_wiring.pdf

-

Won't run if tach connect?

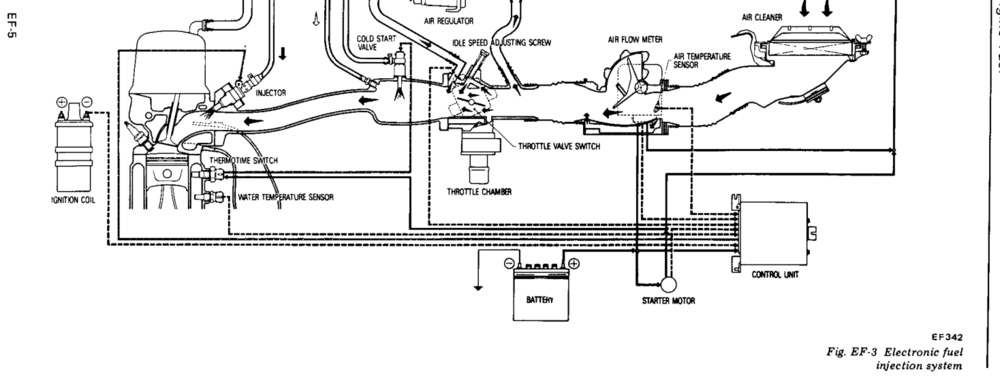

There is something odd about your situation though. I think it's why I got confused. The blue wire also branches to Pin 1 on the ECU to know when to open the injectors. Is he running carbs? An EFI engine should not run if the blue wire is not connected to the coil negative terminal.

-

Won't run if tach connect?

The blue wire will still be connected to the tach. It just won't be connected to the old ignition module which seems to be interfering with the new ignition module's purpose. The wire branches in to two after it leaves the coil, one branch to the tach, one branch to the old ignition module.

-

Need clutch disc, not kit

I'd just keep it to scare my friends. Rev, rev...Beees!

-

Need clutch disc, not kit

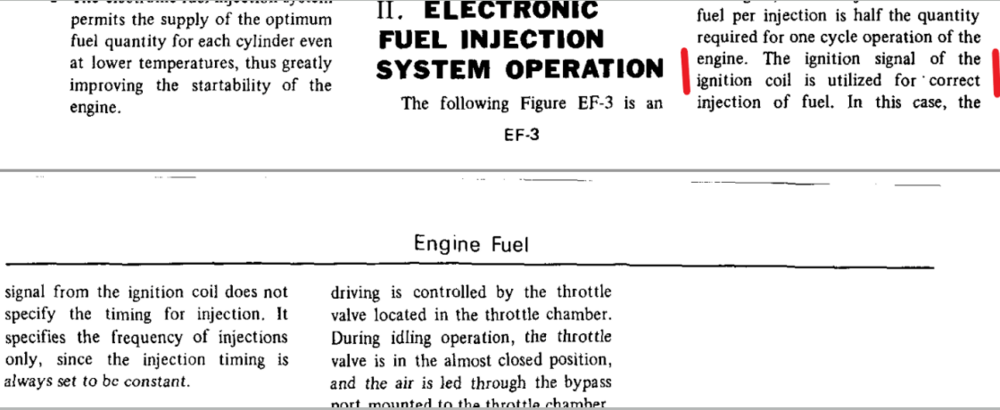

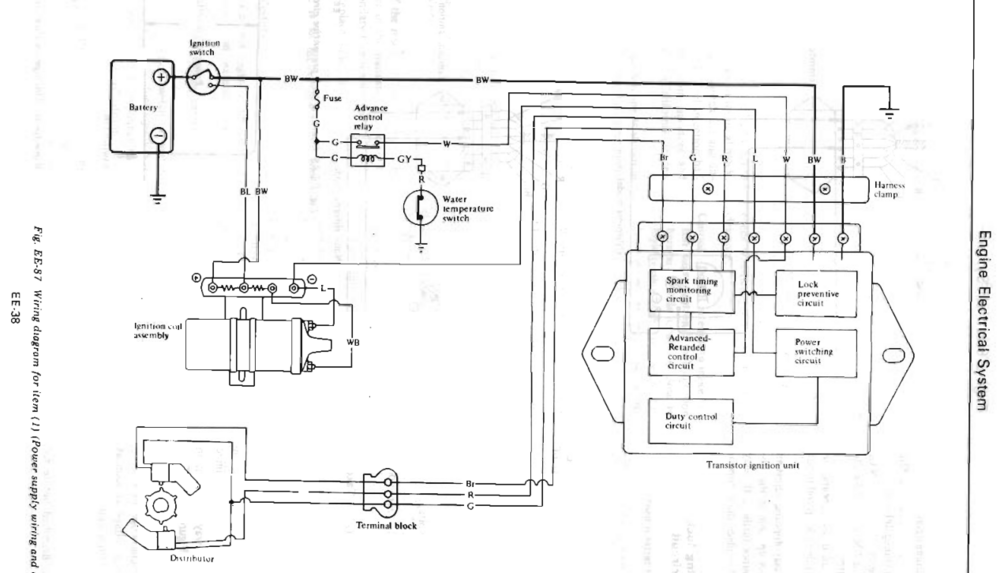

Those puck style discs don't have the marcels, or cushioning plates, between the friction material surfaces. They are prone to chatter. https://www.maximummotorsports.com/Clutch-Disk-Tech-C294.aspx#:~:text=Marcels - A clutch disk with,the flywheel and pressure plate. http://thecartech.com/subjects/auto_eng/Auto_Clutch.htm

-

Won't run if tach connect?

- Won't run if tach connect?

The blue wire is actually the coil "control" wire. The ignition module in the footwell makes and breaks the electrical circuit to the coil. That is its main purpose, not tach sense. You can just unscrew all of the wires at the module. Some of them (two of them?, the blue one for sure) are hot with the key on, can't remember which. So don't bundle the ends together, keep them separate and tape them up. Or check the wiring diagram and isolate the hot ones.- Won't run if tach connect?

I screwed up. I thought you were talking about connecting a wire from the Crane module. Wild guess - the old ignition module is still connected, by the fuse box. When you say "connect the blue tach sense wire" you're talking about connecting the wire at the coil? That also branches off to the old module. You have two modules connected when you connect the blue wire at the coil. You can disconnect all of the wires at the old module and tape them off. The blue tach wire branches off before it gets there.- Need clutch disc, not kit

Usually they put a sticker on that says "flywheel side". I don't see it on yours so it's probably right. And the hub usually pokes in to the hole in the pressure plate which yours does. Looks correct. But, I think that problem might just be related to the fact that you're using one of those high performance clutches. They're not made for comfort. They're made for grabbing and going. Found some stuff - https://www.google.com/search?rlz=1C1SQJL_enUS862US862&q=6+puck+clutch+disc+noise&sa=X&ved=2ahUKEwja17zGup_5AhUXIjQIHVdNDnAQ7xYoAHoECAEQMw&biw=1345&bih=620&dpr=1.19- Need clutch disc, not kit

p.s. it's not clear from your sound bite that the vehicle is completely stationary, like foot on the brake stopped. Might be a clue. Plus, it seemed like I heard some gear grind when you put it in gear. Definitely an odd noise. Everyone should listen to it.- Need clutch disc, not kit

So, if the vehicle is stopped, transmission in gear, clutch is slightly engaged (but vehicle is still not moving), what happens? The pressure plate, disc, and flywheel are pressed together, the main shaft and the gear that is engaged are loaded with force but still not moving. The only parts that are spinning are the flywheel, pressure plate, and throwout bearing. The disc is still static, rotationally, because it is splined to the mainshaft which is engaged with whatever gear is selected, but the disc is still subjected to the spinning flywheel. According to your description in the sound bite the noise happens when the disc is slightly loaded. One part that might buzz is the spring(s) in the disc. What did you buy? Maybe it's some sort of weird resonance that only happens in 1st and 2nd. Are you sure you can't make it happen in 3rd, 4th, or R? Edit - also, the disc could be rattling on the main shaft as the pressure plate spins against it. That might give a spinny buzzy noise. Loose splines.- Need clutch disc, not kit

I deviated from CO's point about nothing moving if the gears are engaged and the vehicle is not moving. My post above doesn't really fit the "vehicle not moving" scenario.- Need clutch disc, not kit

That does sound a like a spinny noise. Too bad you spread your threads around I'm pretty sure I saw one about the pilot bushing. How did the pilot bushing fit? Did you put a dab of grease on it? The noise kind of sounds like what I would imagine a dry and/or loose pilot bushing to sound like. It has a certain wobble to it. But throwout bearing seems possible too. You didn't record third and fourth so I assume that they don't make the noise. Or, maybe the needle bearings around 1 and 2. 1 and 2 also share the same coupling sleeve. The guys that have rebuilt theirs would know more about that possibility.- Z's on BAT and other places collection

- Z's on BAT and other places collection

A couple came up today. A 78 in the 20's. A 72 still climbing. https://bringatrailer.com/listing/1978-datsun-280z-128/ No reserve - https://bringatrailer.com/listing/1972-datsun-240z-232/- Spammers operating on this site !

Here's an actual example.- Spammers operating on this site !

Like this? - Won't run if tach connect?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.