Everything posted by Zed Head

-

240z bumpers to 280z brackets

Someone took the time to figure out the proper dimensions, put them to paper, get them fabricated or did them themselves, and is offering the results of their work. Try it yourself and come back with your price. Maybe you'll make a few dollars.

-

Just ordered my Rebello 3.0, now what

That seems a little bit vague and general. If you have the 260Z distributor it's set up for carbs, if you have a ZX distributor with the side module it might have a high advance vacuum system designed for emissions engines. If you have one of the 280Z distributors there are essentially two sets of advance curves, high vacuum, low centrifugal for the EGR systems and vice-versa for the earlier non-EGR. Just saying, it seems like there could be more attention there. It's all part of the fun though.

-

Half Shaft Failure - is it a common Z problem?

I think that the early 260Z's might have had R180's. Which might use the plug-in half shafts. Those parts in your link are half-shafts for an R200. The shafts are the same length. It's been studied and verified. The distance between diff and hub is different though, probably where the misconception started. You need to get under your car and see what you have. Pictures will tell the story. And the welded diff would not be helping with parts durability. The early Z axles are kind of weak also. Betamotorsports.com used to have some good information on both the weak 240Z axles and the halfshaft length issue. But the site is gone and the Facebook page doesn't seem to have them either. Maybe johnc could bring them back to life. Edit - actually the stories and pictures might be on Facebook somewhere. Facebook is all about getting you to click ads though so it's difficult to organize. Troll through the content and it might be found. https://www.facebook.com/pages/BetaMotorsports-LLC/143989191670

-

Just ordered my Rebello 3.0, now what

Clutch kit and flywheel. Make a list of the installation steps, in order, and you'll realize what you'll need to replace or upgrade at each step. You might need/want to recurve your distributor also, or at least check that the curves are right. A Rebello motor probably likes different timing than a stock motor.

-

Transmission problem - won't go into reverse

A look in the FSM's shows that they are different. I have a 280Z so kind of forget about the early 4 speeds, which were used with the 3.36 rear diff ratios, generally. 3.592 1st vs. 3.321. They all have a 1:1 4th gear though, so probably quicker but not faster. Here's the ratios from the FSM's (MT chapter), looks like the 260Z 4 speed would be the one, if 3-4 closeness trumps: 260Z - 3.592, 2.246, 1.415, 1 280Z - 3.321, 2.077, 1.308, 1

-

Transmission problem - won't go into reverse

If the 5 speed is pre-1980.5 it will have the same 1-4 ratios as the 4 speed. The 77-80.5 5 speeds were just the old 4 speeds with an extra gear added. If it has two exhaust hangers on the tail-shaft housing it's the pre-1980.5 5 speed.

-

Transmission problem - won't go into reverse

How does 5th gear do? It shares half the shaft, on the backside of the adapter plate, and a shift fork, with reverse.

-

Help me ID these parts

Those are wheel axles, and companion flanges, and an odd part. Looks like the companion flanges might be adapters for turbo ZX four-bolt CV half-shafts. I saw your other post and you might want to re-word it. The half-shaft is the drive shaft between the wheel and the differential. One on each side. Typically has u-joints on each end, up until the later ZX's when they went to CV joints.

-

Where do these connectors go?

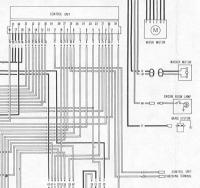

Even if someone suggests a destination for those wires you should check the integrity with a meter. Just to make sure they really go there and that they're not shorted on the way. Meter lead at choke mechanism, meter lead at wire end, lead at defrost mech, at connector, etc. There are wiring diagrams out there on the web. Not the greatest but might get you closer. Datsun Service Manuals - NICOclub Z Tech Tips Electrical (AtlanticZ.ca)

-

Rear wheel bearings and seals

You'll lose points at the concourse with the ZX nuts. But you'll have an easier time in the future if you ever decide to install an adapter flange for CV axles or 5 lug wheels. ZX nuts give you flexibility. Plus the fact, although unlikely, that your new bearings are damaged and need another replacement. You might need to remove them again. I vote for the ZX nuts just in case the axle needs to come out again.

-

Runs rich and high idle after restart

I meant first appearance in 77. It was there for 78, looks like it's gone again for the ZX models, 79 and on. So two years. Could be that CA's stricter emissions standards made it necessary.

-

Runs rich and high idle after restart

Took a look through the FSM's and see that the "atmospheric pressure signal" didn't show up until 1977. California models only. Page EF-7 in the 76-78 FSM's (not shown in 76, shown in 77). Pins 12 and 9 on EF-25 in the 77 book (now called an altitude switch, shown right next to the ECU). EF-23 confirms it's just a switch. Weird stuff. What's really interesting is that to "go lean" the ECU looks like it changes the resistance on the pin 9 circuit. Might give a clue on another way to tweak the mixture. Maybe the thing shown in the AFM is the reference resistance for the circuit and decreasing its resistance leans the mixture. I'm guessing that Pin 12 is another resistance, added in parallel to pin 9. Someone else with more electrical would know better.

-

Runs rich and high idle after restart

The two white wires have been discussed before. They're "Control Unit Checking Terminals". Can't remember where the altitude wires come out of the harness. You could probably use them to do the same as lowering fuel pressure though. Quick fix. I think that they just need to be shorted, the altitude "sensor" is really just a normally open switch if I recall right. Edit - Actually, superlen and I had an exchange about the wires in a past thread. Apparently there are extra black wires and extra white wires depending on the harness. Probably best to trace the wires to the pins to know exactly what's what. The FSM describes the altitude switch and probably has the diagram back to the pins. You could probably wire in your own switch if you wanted to try it or jump it with some test leads to check it out.

-

New Strut Inserts - Fill The Strut Tube With Oil?

With the switch to encapsulated shock mechanisms it makes you wonder if you shouldn't drill a small hole in the strut tube to let moisture out. Condensation happens everywhere, along with leakage from the gland nut area and it will sink to the bottom of the oil pool at the bottom of the tube. If I was doing my mine again I'd probably drill a hole (undecided as to where) then grease up the shock body with heavy grease before installation. Leave the strut tube dry and the heat from the hub will probably keep it dry. Just thinking. With KYB's or Tokico's the system is not the same as designed.

-

Runs rich and high idle after restart

I've found that the combination of parts can affect the way the engine runs. By parts, I mean the ECU, AFM, injectors, coolant temperature sensor, grounds, etc. I've had a lean-running engine and a rich-running engine with the same AFM, but various other changes. I'm not positive what exactly made the same AFM give a different air-fuel ratio, since I've improved grounds, changed my power supply set-up, swapped injectors, and ECU's, in between. I put an AFM that used to run rich back on my engine because I had since installed an adjustable fuel pressure regulator (thought I could now go low on fuel pressure and use the better AFM) and found that it was now lean at the same pressure as before (I used a potentiometer to tweak it richer and it works great now). So if I was starting with an unknown system the one modification I would make, to start, would be a good adjustable FPR. Then you can go lean or rich. On a stock engine the curve is probably right, it just needs to be moved up or down, as a whole. An adjustable FPR might be that final fine tune to get you away from rich. Drop the fuel pressure 1-5 psi, it won't have a huge affect on spray pattern since Nissan went with the narrow stream on their injectors.

-

MSA Manifold Nut & Stud Kit

To be clear, you can go to your local Nissan dealer and ask for the nuts and washers for your engine and they will probably have them or be able to get them in a few days. They're about the same cost as the MSA kit. I went through the whole "what should I use" issue and found that my local dealer could get them. Why not go stock? And, expanding on Post #2, I think that Nissan doesn't even use washers, of any kind, on the "yokes" (the thick shaped "washers"). It's just a nut, the yoke and the manifold (study the diagram in Post #2). Lock washers are over-rated and give a false sense of security. I've disassembled a few L6 engines and many don't have washers. If the nuts seem loose after running it's probably the manifold gasket shrinking from the heat and pressure and things moving around after some heat cycles. It's not the nuts loosening. I haven't done a manifold recently but the next time I do I will be polishing up the surface of the yokes so that the nuts can seat correctly (sitting top of rust is bad) and the yokes can self-adjust, and use the stock Nissan nuts. I might even go for a factory gasket, depending on timing and funds.

-

Steering Rack Disassembly and Refurb

That's some great internet detective work. I wanted to see more pictures though, so I went to my favorite economy site, Rockauto.com, and the pictures didn't look like your EMPI part. So I plugged your EMPI numbers in to the Google and found an EBay link that suggests the car would be a 92-99 Nissan Sentra. Just helping get the most out of your work. Makes me want to go rebuild my rack now. I know I'll be checking the boots/bellows for damage next time I get a chance. Empi 48204 53Y25 Power Steering Rack Boot Kit Fits Nissan | eBay (check the interchange number in "item specifics") Edit - Maybe I'm just muddying up the thread but it looks like that 88-1509 bellows fits several cars. Found another EMPI catalog. Looks like 88-1527 does fit the Miatas. Probably best to just get the EMPI brand 88-1509 part rather than a boot that fits the car. Anyway, thanks for sharing! http://www.empius.com/bcatalog/PDFs/2013_B_Catalog.pdf

-

MSA Manifold Nut & Stud Kit

You could go to the hardware store and get self-locking nuts (steel out-of-round, not nylon). The part number for the original Nissan nuts is in the link in Post #2, but I don't know for sure that they're self-locking (I've never seen new ones). I used the MSA gear on my first gasket change and I had little room for the nuts and hardware also. I used the MSA gasket, which is thick. The studs are only supposed to be finger tight when installing, if you double-nutted them and drove them in to the head you lost room to work. Apparently, if you get the right group of parts, you can mount the exhaust manifold using the three inner bolts, start the nuts and washers on all of the studs, and slip the intake manifold between the washers and the head. I've never had enough room to do that myself, but it's been described.

-

Keep blowing the "IGN" fuse!!!

You do know what you're looking for, right? The wire or component that has zero or very low resistance. Just leave your meter connected to the green and black wires and connect and disconnect things until you find the thing that causes very low resistance. That low resistance is what allows the current to flow that overheats and blows the fuse.

-

Very Cool Ignition Upgrade

I saw that video. Note that it's really a comparison of distributors AND their ignition systems. Maybe old worn distributors using the Pertronix and points systems too (as noted in the comments). If they had installed the Pertronix and points in place of the 123 ignition system, in the 123 distributor, that would be meaningful, comparing ignition systems. It doesn't tell how a new distributor with points or Pertronix would perform. Again, not trying to be a downer, but sales is sales.

-

Right rear tire wearing faster

What kind of wear? Even across the tread, one side only, cupped pattern on the edge, etc. A picture would be good.

-

parts worth grabbing off 83 maxima?

The ignition system might be worth getting. Your 260Z already has electronic ignition though, but the 83 Maxima might be a little more developed (higher energy). It won't have the E12-80 module though, so you'd have swap one in or figure out how to make the other module work (it will have more pins). The brakes are disc, so nothing there. The diff maybe, I think it's an R180, you might have an R200 though, so little benefit. The Maxima uses a different suspension system, trailing link in the back, not sure on the front. Not much to get really, the 5 speeds swap over but you're looking at an auto. You could swap the complete L24E engine and EFI system in (assuming it's not a diesel). It would fit. The exhaust system might need work though.

-

Very Cool Ignition Upgrade

The switchable curves were discussed somewhat in the Hybridz thread - 123ignition - Nissan L6 Forum - HybridZ They're not typical L6 engine curves. Many peak at very high RPM, compared to where the typical L6 Nissan curves peak. Open this link (the manual for the switchable dist.) and go to the bottom and you'll see the options. They appear to be shown in crankshaft RPM (unless they're set up for 9,000 RPM engines). http://www.123ignitionusa.com/123gb6rv.pdf Looks like they're shown for 10 degrees starting point (idle advance).

-

Keep blowing the "IGN" fuse!!!

You could also use a battery and alligator clips with a light at the power wires in the connector. I do it with gauges on the bench. I don't think it will hurt your meter to turn the dial to other resistance ranges while it's connected. Most meters are able to give an actual number, even no resistance has some resistance. On the meter usage - a typical meter test is to touch the two probes together to check the battery and probe connections to the meter. If everything is right you should the very, very low reading or zero, for no resistance. Then you'll know for sure what no to low resistance looks like on the meter.

-

Keep blowing the "IGN" fuse!!!

What brand of meter are you using? 001 might just mean "out of range". You might consider a test light in place of the fuse. Disconnect everything, insert a light in place of the fuse, either built yourself with alligator clips and wire, or one from the parts store, apply power to the system, then reconnect each item. The shorted component or wire will cause the test light to glow the brightest, but the light bulb will protect the circuit from too much current. I didn't follow out the wiring diagrams but it could be something as simple as a shorted gauge bulb, or bulb socket. The little BA9 bulbs have their electrodes in close proximity.