Everything posted by Zed Head

-

AC/Heater stuck Mode door

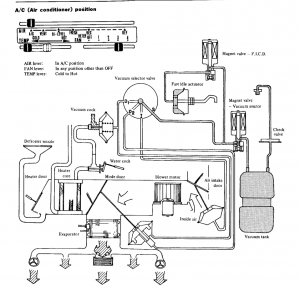

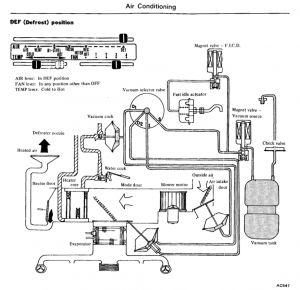

The selector valve directs vacuum to all three actuators in Defrost mode. Water ****, fresh air door and mode door. A leak in any might weaken another. Actuating by hand would at least answer the question of if it's catching on something. You can only generate so much force with a vacuum actuator. Air pressure limited. Maybe a little extra force to break it free would let it work afterward. You don't need to disconnect it either, just give it some help. If you can reach it.

-

Testing the ignition coil per FSM

What kind of meter are you using? All of your numbers seem high. Spec. on the coil is 1.4 ohms. If you don't have an adjustment on the meter, touch the leads together and record that number. Then subtract it from whatever reading you get on the parts. More details on what happened before the engine starts dying might offer a clue. Is the engine still cold or is it hot (ignition module's fail from heat), has it been idling for a while or have you been driving it, is the idle speed low (AFM contact switch), once it starts happening is it repeatable or does it go back to just fine for hours or weeks? Stuff like that. Context.

-

Engine issue

Here's another thought. Related to the loose damper bolt. That should never happen, and really seems like the most significant thing. I've seen where other people have reported their distributor drive spindle has slipped down in the drive gear and the tang no longer sticks out far enough to grab the distributor groove properly. Maybe the vibrations related to that loose bolt, either causing the loose bolt or caused by the loose damper, made other parts move. I would follow that path and see if maybe a woodruff key sheared or moved (there's three of them, right?), or if the quill dropped in the drive gear. Also, why did the bolt get loose? Could be that something else is coming loose inside the engine. I would have broke a sweat when I saw that loose bolt. Just because it seems like a big deal. But that's me, and I've never rebuilt an engine.

-

Engine issue

Is the damper itself still in good shape? Still damping? Maybe the timing mark you're looking at has moved. On the low pressure - different gauges can read different pressures, due to internal volume variation. Low pressure might not be relevant, but does fit changed cam timing. I'm a big fan of the notch and groove for checking that the cam and all of the other parts are in their proper relation to each other. Does the Web cam not use the notch and groove? Cam lobes up is not the most precise. That's what struck me when I read your first post. Also, on spark - current through the coil will determine strength of spark. Changing ignition system parts won't change power supply. Maybe you've got a fried power supply wire to the coil and module.

-

Redwing's Car - An Update

Took a picture of an R200 diff nose on a mount. Everything is inboard of the mount. That rusty crack I circled in that other picture is just something hanging off the body. A broken u-joint might cause some clanking and locking. Or a broken differential.

-

Redwing's Car - An Update

Snipped a copy and circled what I think you're talking about. Haven't looked at a diff lately so not sure what that is.

-

AC/Heater stuck Mode door

A follow-up to zcarnut - AC mode is all spring-actuation and cables. Defrost requires the vacuum pots to overcome the springs. Maybe you've got a stuck magnet valve or split hose, and the springs win the battle. Does the idle RPM increase when you go to Defrost mode, or switching between other modes? That was one of the signs of a split hose for me, the vacuum leak increased my idle RPM.

-

Redwing's Car - An Update

I've had my car on stands, with the wheels hanging, and the half-shaft angles are are too steep for the u-joints with the wheels hanging. I think that was with KYB shocks. They'll make that rat-tat-tat noise even with everything in good shape. The length of the shock at full extension will affect that. So, you might have missed the real problem. I think that you need to get the stands under the control arms so that the wheels and half-shafts are in the normal driving orientation. But if the diff was bouncing around because of u-joint binding that's still not right. The diff should be pretty well held in place by the front mount and the mustache bar.

-

Restoring a 1977 280z! (My first z car)

Well then, Patcon's suggestion is the way. You'll have to twist your way back there or lay on your back to get to the screws. Use a short screwdriver. Take a flashlight and a few other pokey-proddy tools to move the lever. The panel might have some sealant holding it in place, try not to bend it, it's just vinyl-covered cardboard. When you're done, get some stick-on weatherstrip and seal the complete perimeter of the panel. It will keep exhaust fumes out. You can slide the lock holding clip off with the panel off and remove the lock, then actuate the lever from the outside hole, I believe. If you don't have another lock to put in its place.

-

WTB V-8 converison Z

The Ford swap is not common. Your best bet would be to have someone build one for you. http://www.technoversions.com/MotorMatchHome.html Here's the web site where he documents the swap - http://www.lainefamily.com/240Z_V8_Conversion.htm

-

WTB V-8 converison Z

Kind of an odd set of parameters but you'd probably have better luck on Hybridz. This is Classic. http://forums.hybridz.org/forum/72-cars-wanted/

-

Differential Output Shaft Stub Question

So you're saying that there's a bolt head under there?

-

Differential Output Shaft Stub Question

Could be the old wild-goose chase. Maybe the OP didn't look for the bolt and took bad pictures. I gave the benefit of the doubt. From this post and that Hybridz one though it seems that the CV flange clip-in axles have a different spline count. There doesn't seem to be a clip in u-joint halfshaft option for a Nissan R180. That;s the part I'm wondering about.

-

Mystery wire on Distributor (78 280Z)

I think that you are right and that is just the ground connection for the condenser. The condenser is probably still stuck in your harness somewhere, by the coil wiring. I'd try to find it and use it. I'm not sure that all of the condensers are just for radio noise. Other circuits might be affected by the noise. I know that my tachometer will not work without a condenser, but my ignition system is modified. Here's another wiring diagram that shows a condenser grounding next to the distributor. http://www.atlanticz.ca/zclub/techtips/wiringdiagrams/78_280Z_wiring.pdf

-

Differential Output Shaft Stub Question

The R180s diagram above shows the 6 (3x2) bolt flange. I assume that that's supposed to pop out and the four bolt flange and shaft pops in. Someone on Hybridz had one of those though and the spline count was wrong, apparently. Many ways to get confused with the R180's. http://forums.hybridz.org/topic/123135-stub-axle-confusion/

-

Differential Output Shaft Stub Question

The Nissan FMS's all the way to 1983 show bolt-in axles for the R180, not clip-in. And the Hybriz link shows how to convert a newer Subaru clip-in diff to Nissan bolt-in. But doesn't show a Nissan R180 clip-in diff. Maybe Subari used a clip-in diff on their older models, and you have one of those, and somebody converted a halfshaft. You can convert a half shaft by putting a different flange on the u-joint. If the u-joint size is the same size. So that is a weird one.

- Zed to replaced by XUV

- Recommendation for new radiator and elctrical fan for 280Z

-

Recommendation for new radiator and elctrical fan for 280Z

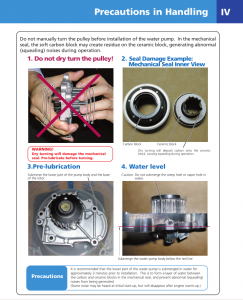

Hey, are you sure that the AISIN has the cast impeller? I notice that they don't show it and their web catalog shows all stamped steel. http://aisinaftermarket.com/uploads/rh4yebzy_CoolingCatalog2013.pdf The catalog is interesting to read, regardless. I replaced my leaking radiator with a cheap Murray brand from OReilly Auto Parts. The mounting holes needed work but it does a great job cooling.

-

L26 blowing back through the carburator

Looks promising. If it was correct, cylinder #1 would have intake and exhaust lobes up, and the damper pulley timing mark (for setting ignition timing) would be on zero. Not sure what you mean with the 4 and 6 comment. You should really get a timing light and set timing. It's time. You can't force a valve open from inside the cylinder.

-

L26 blowing back through the carburator

As madkaw said, forget about the bright links. If you can't see the corresponding link on the crankshaft gear, it's meaningless. If you turn the engine one revolution the link will be somewhere else. So you have a sprocket that was designed to be set up one time, with a new chain and never adjusted. Because there's no easy way to tell if chain/sprocket wear has occurred. I've also read on the old interweb that Cloyes started adding notches to the later sprockets, and only the old ones are notchless. Regardless, you have no way to confirm proper valve events unless you add a degree wheel to the damper and measure valve lift. Kind of a dilemma. Might be easiest to assume the PO knew what he was doing and work on everything else until cam timing is the last possibility. Or replace that sprocket with one that has the notch.

-

Restoring a 1977 280z! (My first z car)

The key turns in the button with no pressure on it, to get to the unlocked position. Then the button can be pushed down. In other words, if you're pushing on the key to try to push the button, that's not the way to do it. Just in case. Could also be the wrong key.

- wheeler dealers - 72 240z.

-

wheeler dealers - 72 240z.

Considering all of the problems people have stopping cam lobe/rocker arm destruction with new or reground cams, the "hard-welding" is surprising. The shop looks iike it's called R&R Cam, or H&R (it's on the side of the building). Probably never worked on a Datsun camshaft. I'll bet many of these car show cars self-destruct after the episode is done, Or the car sits in a storage area somewhere, where nobody can see what they really did to it. I'm a cynic, but they are just TV shows.

- wheeler dealers - 72 240z.