Everything posted by Zed Head

-

260z no start once hot ..all electrical gone when hot

The above, the third part about restarting, does not match a blown fuse. Fuses don't fix themselves when they cool down.

-

Timing kit differences?

I looked in the How To Rebuild book and can't find any sign that there's a difference in the L24 and L28 blocks besides bore. He doesn't mention the different timing chain guides either. Nissan probably did some minor mold clean up when they went to the N42 L28 block but if zcarnut can use the L28 piece on his L24 blocks, the bolt holes must be the same. It's probably a like-for-like piece, just so people get the same as what they're replacing. I've never seen anyone notice that before though. A new mystery. p.s. I was joking on the Kameari kit. Unless you're planning for 13,000 RPM.

-

Timing kit differences?

That is weird. The L28 kit costs more, but wouldn't have the fuel pump drive cam. And if the L28 guide is better, why even sell the weak L24 guide. Maybe people just like to see identical replacements parts in their kits, so MSA gave them that to stop the questions. http://www.thezstore.com/page/TZS/PROD/10-2050 http://www.thezstore.com/page/TZS/PROD/10-2051 Maybe they've been doing it for a while but MSA now has Kameari parts. Upgrade your cam control! For just a few dollars more. http://www.thezstore.com/page/TZS/PROD/10-5470

-

Rear control arms bushings replacement

Actually, one remaining question is "should you replace those bushings with PU bushings?"

-

Reluctor and other distributor parts

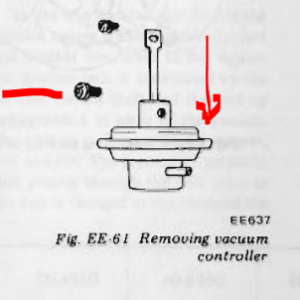

If you do find that the internals of your 76 distributor are rusted and gummed up, the ZX distributor is a good option also, because it uses a high energy ignition control module and coil (so you'd want a newer coil too, projects always grow...). 1976 still uses a low energy coil and ballast resistor. But if the guts are in good shape, it might be worth keeping. I marked up a picture to show another simple way to check the breaker plate. But, they are almost always rusty and need lubrication. They are super easy to take out and replace and you'd have to work to get it in backwards (no offense to those that have managed to do that). It will only install the right way or 180 off, no gear teeth to worry about. It will only go in 180 off if the tang and slot are worn, and you can't distinguish the big half moon from the small one.. Take the big screw out, it might be very tight, gently loosen the vacuum module, it might be very tight, and gently pry it out part way with a screwdriver. It might be very tight. The breaker plate with the pickup coils on it should rotate. But, if you pull too hard you might break the bearing holder under the plate and screw things up. So it's dangerous. Were it mine, I'd loosen that big screw while it's mounted in the engine, give the module a little twisting to break it free, then remove the distributor and take a good look. The breaker plate comes off easily also, and you can check the centrifugal weights. The other way to check operation though, is with a timing light. Connect intake vacuum directly to the module port and see what happens to timing. Edited - backward arrow.

-

Reluctor and other distributor parts

The only part that matters on the reluctor is the very edge of each tooth. That's all the pickup coil sees. You can shine up the rest but it won't affect performance. I'd be leery of any aftermarket reluctor because the precision of the timing depends on the precision of the machining. I'd rather have a rusty factory reluctor than a new aftermarket reluctor. Another way to check the breaker plate vacuum advance is to just twist it with your hands. But eyeball the edges first for rust. If there's any at all, best to take it out and clean it up. The balls will get stuck and the bearing holder will break. Not good. A common problem on the EFI cars is a lean mixture from the ECU. Adding the potentiometer to the coolant temperature circuit will help. Here's a good link, many do it. It's reversible if it doesn't work. http://atlanticz.ca/zclub/techtips/tempsensorpot/index.html

-

Datsun Parts LLC - gone to the dark side?

We should start a poll thread with all known suppliers listed and just keep track of who's good and who's bad. I've started two specific threads about problems but kind of feel bad that we don't recognize the good work. MSA, for example, did swap a bad mirror for a good one, after I called them. This would give anyone who does their due diligence a chance to see some real-time feedback. Everybody wins.

-

Sealing an oil pan

This is a timely thread. I thought I had a rear seal leak but now it looks like the pan gasket. Surprising how much oil can build up around the perimeter of the pan and slowly leak out over time. So did you use no RTV or sealant at all, just the gasket? Dry on a clean surface? Hylomar Blue is good stuff and stays pliable. Stays pliable so no need to worry about the V part of RTV. The transmission rebuild guys love it. http://www.hylomarsealant.com/

-

Intermittent driveability issues

You can get a pressurized air bubble in the filter that doesn't really matter. The float bowls will still fill and that's what counts. But the 11.5 volts is not good at all. 12.6 is standard lead-acid charge. 11.5 is almost dead. But once the engine is running you should be on alternator voltage and that's when your problem happens. But you might be just running on battery power. Verify voltage while running. Low voltage can case weak spark. Found this interesting chart via the Google, post #2 - http://www.solarpaneltalk.com/showthread.php?20997-SLA-Battery-Possible-Discharge-Problem

-

Rear Hub Disassembly and Spindle Pin Removal

The spindle pin removal is a popular topic of discussion. There is a ton all over the internet to look at: pictures, descriptions, horror stories, etc. Not to be too negative but if you had problems with the lock bolts, the spindle pins themselves will be tough. Sometimes they come out easily but not enough. One trick to get things started and allow some penetrating oil to get in is to put an old lug nut n the end of the spindle pin and spin the pin in its bore. After that, you can tap on the nut and see if the pin moves back and forth. From there it's just a matter of how far you can get it to move and what it gets stuck on. Worst case, people cut the pin in to pieces and press them out later. Here's an example, from Blue's work - http://atlanticz.ca/zclub/techtips/suspension/rearend/index.html And here's the hubs, which are also described in the FSM - http://atlanticz.ca/zclub/techtips/rearwheelbearings/index.html And bonus stuff - http://www.atlanticz.ca/index.php/tech-tips.html

-

Datsun Parts LLC - gone to the dark side?

Who is Art Singer and how does one buy parts from him? It's tempting to surf Al's site and find all of the stuff he's marked up (there's a bunch) but if he can offer a proper return policy and respond to people's problems that would be reasonable. But a big markup on RockAuto parts, with no returns allowed is just not right. The Wheeler Dealer show probably gave him a big bump in sales though. Easy money, no conscience required.

-

New member from Oklahoma

Could be running rich, or some oil leaking in to the cylinders Too much of one of those petroproducts, not being burned completely. Hard to be sure until you've tuned everything up. Found you an avatar, for those that haven't experienced the large scary bugs. They fly.

-

Datsun Parts LLC - gone to the dark side?

Really a shame that there's no response here.

-

I've Got Milky Coolant But Not Overheating

If you want to drive it the most cost-effective route is to refill it with the proper water-coolant blend, drive it, and monitor the situation. If you want to work on it, there are myriad paths you can choose to address the ugly coolant. Not being sarcastic, just saying, some of us buy to drive and some of use buy for garage projects. Either way, a refill and some driving will tell you a lot about the situation. Only cost, with proper monitoring, is the coolant. You might find that the coolant maintains its proper color and clarity and the engine runs fine.

-

Computerized data logging

I think that you could easily measure all of those with a scanner, some data-acquisition software and a computer. Very common in the industrial/scientific world. But, maybe expensive. If you did the math you'd probably find that converting to Megasquirt, for data-logging alone, would be the way to go. The tuneable engine management would be a bonus.

-

1972 FSM

I appreciate anybody's efforts to keep these old FSM's available. They are the most important thing, I think, that keeps these old Z's alive. But is your copy different from the Xenons30, or nicoclub copies? 1972 is available there. 1971, though, seems to be unavailable anywhere. On the other hand, maybe we should get copies of all of the FSM's in case those other sites go under, like web sites tend to do. I will ship my paper 1976 original FSM to anybody who will copy it and make it available to classiczcars.com. I don't have that ability. Does anyone know if Kinko's will do that work and how much? Whatever it takes.

- Recommendation for new radiator and elctrical fan for 280Z

-

Transmission mount

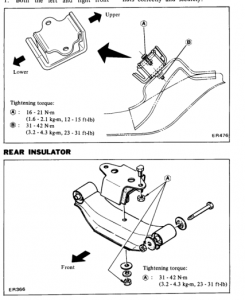

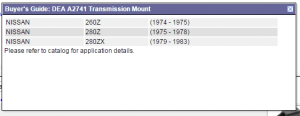

Looks like the ZX uses the two longitudinal bolts, like the later 280Z's. From the 82 MT Engine Removal chapter. Weird that they have a special chapter for it, seems like it would be in Engine Mechanical. The transmission mount is considered the third engine mount. Not clear if you meant the crossmember or the rubber. If rubber, the part numbers should be the same at Rockauto or wherever. I have a ZX mount in the garage somewhere. Edit - added some Rockauto stuff.

-

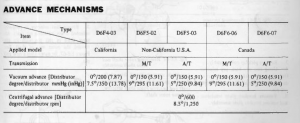

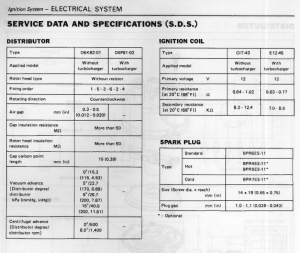

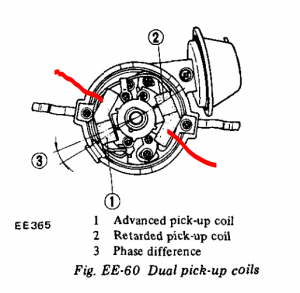

78Z to 83ZX distributor swap

Probably not a benefit. And the vacuum advance curve of the 83 may be different. Looks like it has a dual stage curve, I can't remember exactly how it works. I think it uses the high vac advance when EGR is actuated so you'd probably be on the 10 degree curve if you just use one vacuum port, as opposed to the 15 or 18 degrees of your 78. On the other hand, that 77 distributor will work just fine with your 78 ignition module. If the breaker plate bearings and other parts are good, it would be worth getting, for a spare. Also, note that the 83 probably uses an E12-92 or -93 module (ID should be molded in to the module case), which takes extra wiring to work right, as opposed to the E12-80 module. Of course, if any of the engines use a rebuilt distributor, all of this may be different. The rebuilders don't match specs. exactly. Stuff to think about...

-

Testing the ignition coil per FSM

-

Testing the ignition coil per FSM

Sounds more like a bad electrical connection, or a bad module. The "jumping alive" again part is odd, but does remind me of a problem I've seen described with the wires to the pickup coil in the distributor. The breaker plate moves with intake vacuum and the wires to the pickup coil flex back and forth each time. They can wear through the insulation and short. You might check those carefully. When the engine dies the breaker plate would go back to its starting point and all would be good. You can measure resistance at the terminal block while you twist the breaker plate, or just take the distributor rotor off and look closely. If the distributor is old be careful because the breaker plate bearings get rusty and break their plastic cage. You don't want to do that. If you have a Federal 76, you'll have two pickup coils, one for cold engine and one for warm engine. If you find a bad wire, you can rig things up to use the other. And a cheap but effective ignition module swap is the GM HEI module. Many of us use it. ~$25 and some time.

-

AC/Heater stuck Mode door

The selector valve directs vacuum to all three actuators in Defrost mode. Water ****, fresh air door and mode door. A leak in any might weaken another. Actuating by hand would at least answer the question of if it's catching on something. You can only generate so much force with a vacuum actuator. Air pressure limited. Maybe a little extra force to break it free would let it work afterward. You don't need to disconnect it either, just give it some help. If you can reach it.

-

Testing the ignition coil per FSM

What kind of meter are you using? All of your numbers seem high. Spec. on the coil is 1.4 ohms. If you don't have an adjustment on the meter, touch the leads together and record that number. Then subtract it from whatever reading you get on the parts. More details on what happened before the engine starts dying might offer a clue. Is the engine still cold or is it hot (ignition module's fail from heat), has it been idling for a while or have you been driving it, is the idle speed low (AFM contact switch), once it starts happening is it repeatable or does it go back to just fine for hours or weeks? Stuff like that. Context.

-

Engine issue

Here's another thought. Related to the loose damper bolt. That should never happen, and really seems like the most significant thing. I've seen where other people have reported their distributor drive spindle has slipped down in the drive gear and the tang no longer sticks out far enough to grab the distributor groove properly. Maybe the vibrations related to that loose bolt, either causing the loose bolt or caused by the loose damper, made other parts move. I would follow that path and see if maybe a woodruff key sheared or moved (there's three of them, right?), or if the quill dropped in the drive gear. Also, why did the bolt get loose? Could be that something else is coming loose inside the engine. I would have broke a sweat when I saw that loose bolt. Just because it seems like a big deal. But that's me, and I've never rebuilt an engine.

-

Engine issue

Is the damper itself still in good shape? Still damping? Maybe the timing mark you're looking at has moved. On the low pressure - different gauges can read different pressures, due to internal volume variation. Low pressure might not be relevant, but does fit changed cam timing. I'm a big fan of the notch and groove for checking that the cam and all of the other parts are in their proper relation to each other. Does the Web cam not use the notch and groove? Cam lobes up is not the most precise. That's what struck me when I read your first post. Also, on spark - current through the coil will determine strength of spark. Changing ignition system parts won't change power supply. Maybe you've got a fried power supply wire to the coil and module.