Everything posted by Zed Head

-

280zx Distributor Upgrade (240z)

I was just pointing out something real that happened. Always nice to get one or two of those. In my case, the capacitor fixed a problem. When the wire to the capacitor fatigued and broke the problem came back, so it's been verified twice. No capacitor on the coil negative, no tachometer function. Someday I might move the capacitor to another spot just to see how important location is. I can't explain it but it's a real thing. But I can't explain how my tachometer works either, or how injector pulse durations are controlled. If you search "Kettering ignition" you can read all about how capacitors made their way in to points-style ignition systems, and the multiple benefits they have there. Seems like they started out for contact durability, then either the second benefit was a bonus or some electrical wizard did some complex math. Or both, who knows. There are some fascinating writeups out there.. That Kettering guy was pretty smart. The electronic ignition cars still came with capacitors on the alternators, so it's not just a points thing. Maybe they're insurance against a failing sparky alternator, maybe alternators inherently generate RF interference. I don't know, but the capacitors are there.

-

Removal of rear oil seal on the Trany

One trick I've used it to punch a hole in the seal edge with a sharp punch then run a wood or sheet metal screw in to the hole. Clamp on to the screw with some pliers and either pull it out directly or lever it out from the end of the tail shaft. Or use a dent puller if you have one. Might take two holes. Make sure the punch is sharp so you don't just mangle the seal and drive it inward.

-

New owner of '77 280z from Upstate SC

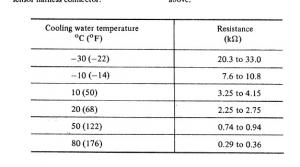

Don't know for sure if your 6 teeth is adjusted to the lean side or not. I think that it makes it lean, tightening the spring. Could be that somebody was trying to fix the rich condition by leaning out the AFM. Pushing the vane in adds fuel, so all you were doing was making it even richer. The first impactful thing you'll want to do is to measure the resistance of the coolant temperature sensor circuit, at the ECU connector in the cabin (Pin 14 to ground?). Compare the resistance you get to the temp. v. ohms chart in the EFI Guide or the Engine Fuel chapter. If it's too high, or even open, the ECU will add a bunch of fuel, because high resistance means cold. If that number is in range, check fuel pressure (check it anyway), and check the color of your injectors. Sometimes people think that installing turbo injectors will add turbo power. They should be light green or tan, not purplish-brown. Found it -

-

What coil resistance to run with zx dizzy upgrade

Nissan spec'ed 0.84 to 1.02 ohms for the ZX system. I'm a big fan of using the factory spec's if they do the job. They also spec'ed .039 to .043" plug gap with that set of parts.

-

78&79 Z

Is it black interior or the more typical butterscotch? An uncracked dash is a rare find. I wonder if it would survive the removal. For non-running cars with decent parts you can estimate what the wrecking yard would pay for the body and get a better idea of what the parts will actually cost you. Pick n Pull will give a number right over the phone after a few questions. They'll even arrange towing from your house after you pick ii apart. Of course towing from Onalaska needs to be factored in also. Drive trains would be very similar. 79 used the early type 5 speed.

-

New owner of '77 280z from Upstate SC

You can do most of the EFI system testing at the ECU connector in the cabin. That lets you test the wires to the components also. The AFM black cover is a press fit, usually with a small amount of sealant around the edges. A wide blade scraper or screwdriver can be used to tweak the edges off until it comes free. There's a bypass screw on the side of the AFM that is used to tune idle. If it's far open it can let the AFM vane close. Don't forget that the engine crankcase is connected to the intake system through the PCV, the valve and the hose from the valve cover. So a split PCV hose or missing oil filler cap or leaking valve cover gasket can let air in. Leaking injector seals can also be hard to diagnose. If the wire in the AFM vane causes the pump to run then it seems like the fuel pump power circuit is in good shape. The vane just isn't moving far enough. Could be stuck. One advantage of taking the AFM cover and starting the engine is that you can see the vane move or not move. Most contact cleaners contain some lubrication. WD-40 does also and it's made for electrical applications. Lots of small things to check. Try to get real numbers when you're testing, the FSM has a "continuity" check method that usually has to be re-run for real ohm measurements later.

-

Any ideas?

If I recall right the front case is easy to remove. No need to mess with the shifting mechanism, just remove the circlip on the input shaft bearing (under the front cover), remove all of the bolts that hold the back to the front through the adapter plate and tap the front case off. The back end will be loose and can create a gap but it can just be held on by hand. Here's a link that describes a fairly common front case swap. Your front case half to a newer gear set. I did the swap and never separated the back end, only the front. http://zhome.com/ZCMnL/tech/240SX5spd/transmission.htm I know that EuroDat replied also but my internet is crapping out so I'm just going to hit Submit Reply.

-

Any ideas?

Mark and Euro know the tricks for rebuilding. But if you want to get a head start, and maybe get lucky, remove the front cover. It's the piece that has the snout for the throwout bearing collar. You'll see the input shaft and countershaft bearings under it. The cover can be tough to remove (Nissan glued them on), don't break it. Edit - actually you won't get lucky because EuroDat already confirmed that it's an adapter plate bearing. Were you I, I'd (you'd?) set it aside and find another.

-

Any ideas?

Here's a shot of the adapter plate stripped down with just the outer race. If you have space and some ingenuity, the tear down and bearing replacement shouldn't be terrible. The manual calls for special tools and large presses but people manage without them.

-

83 280zx turbo half shaft CV's

You're probably fine, since people have done that swap before and not reported problems. I was just pointing out things to be aware of. I've tried measuring half-shaft lengths and it's difficult, compressing them and keeping the flanges parallel and getting the tape on it and getting your eyeball in the right place to see the number. If I really wanted to be sure I'd build a fixture of wood with a slot in it that could be drawn together with a long bolt or piece of all-thread. A wood shop vise for gluing boards would probably work great.

-

Any ideas?

Saw the 1970 and assumed 4 speed. I'm losing it. Good luck. Put an ad in the Parts Wanted area. http://www.classiczcars.com/forum/21-wanted/

-

83 280zx turbo half shaft CV's

Found it. Thanks to John Coffey for saving the old information from his Beta Motorsports web site. Scroll waaaayy down to March 5, 2014. https://www.facebook.com/BetaMotorsports-LLC-143989191670/ Actually, this "permalink" might work - https://www.facebook.com/permalink.php?story_fbid=10151884802416671&id=143989191670 I re-read your post and wonder where you're measuring from though. The best measurement is from flange surface to flange surface with them squared-up to the shaft. That gives a number to compare between shaft types.

-

83 280zx turbo half shaft CV's

These are fascinating numbers because they open a very old can of worms. Several people measured a bunch of 240Z and 280Z halfshafts and decided that they were all the same length. You're showing a difference. Are you sure that they were fully compressed. The reason they measured is because when you put an R200 in to a 240Z the halfshafts often bind at full compression. So you're showing that your CV axles are longer than your stock u-joint axles, which should make the problem worse for you. Maybe why Darrel went back to u-joints. You've raised many questions. I'll see if I can find the old info about halfshafts. Many people even modified their u-joint half-shafts by cutting the ends off of the inner shaft.

-

Any ideas?

True, if the event is the top priority. Pulling the transmission itself may knock him out of the event though. Put a tow company number in your phone and just run the event and hope. Assume it's toast anyway. You'll provide entertainment when it starts grinding and self-destructing. A way to make new friends.

-

Any ideas?

Odds are it's a 75-77 4 speed then. Very common. I think that you can see those adapter plate bearings from either the front or the back so splitting it would let you see the damaged bearing. It takes some work to get to it though. Check the 1976 MT chapter of the Service Manual to see what's involved. You can tell by the damage though that the cage got ripped off by some gear teeth. Probably an end came loose, it flapped around a but then got sucked in to some gears. Many paths possible. Tear it down and install new bearings, find a used 4 speed, or take the opportunity to go for a 5 speed (it's a direct swap). http://www.classiczcars.com/files/category/4-manuals/

-

Any ideas?

I just took a guess because I've seen one of those bearings failed. I bought an abused 5 speed and took it apart. All kinds of carnage along with the failed bearing. Some of the balls had fallen out also. Even though the transmission still works well I think that the shaft is now misaligned because the balls can all move to one side. This would let the end of the shaft move to the other side. Close to double the original tolerance, I'd guess, but not quite. This makes the gear surfaces non-parallel and puts odd loads on them, I would think. Four speeds are plentiful and relatively inexpensive. People tend to swap in late model 5 speeds and end up with leftover 4 speeds. You might consider just buying a used unit. Or buy a used unit and rebuild the original. Although, your 1970 might have the "monkey motion" shifter and unique gear ratios. So, might be worth a rebuild anyway, for originality.

-

Any ideas?

That is a bearing ball cage, or separator. Holds the ball bearings separated in the bearing assembly. Not good, it means that one of your bearings is loose and failing. Probably one in the adapter plate. Here's some links and a picture. http://www.globalspec.com/learnmore/mechanical_components/bearings_bushings/radial_ball_bearings

-

Zedyone_kenobi's Nightmare

I see that now too. Sorry about that. Just so easy to get things twisted. HS30-H, to be fair, does have a point in his post. But the "China" issue has been beat to shreds in other threads. No use going over it again. I'm breaking my ignore rule. Back to constructive things...

-

280zx Distributor Upgrade (240z)

Capacitors (aka condensers in the automotive world) can serve many functions. RF noise suppression is a common usage. There's one on most alternators, for example. The function of the one by the coil on the electronic ignition cars is unclear, although I have an extra one on my car to fix a tachometer problem. The tachometer won't work without it. It's not the condenser, it's one of at least two (on the 280Z's), maybe more. Could be that the 280Z condenser filters electrical noise for the tachometer or maybe even the ECU, for injector pulses. I wouldn't worry about it, but keep it in mind if you have problems.

-

Zedyone_kenobi's Nightmare

My mistake. I missed the deviation to another web site. zcar.com. But that's how things go bad when you start paying attention to the negatives. HS30-H started on Blue, Lumens agreed, then deviated. And a whole negativity thing started, bringing up memories best forgotten. It just makes a mess. I tried to stay on the logical, high ground side with Tony D once in what started out as a good discussion, and was doing well as he spiraled down his own bung hole. But at the end I couldn't hold out and the thread ended weirdly. I choose to ignore. Which I will for the remainder of this thread.

-

Zedyone_kenobi's Nightmare

Folks, I think that we're getting distracted. Blue is/was a moderator. Pretty sure he's the only other one besides Mike. He's "the guy". This thread is devolving in to the very thing it's complaining about. We should all stop.

-

New owner of '77 280z from Upstate SC

tool_man's car looks very "untampered with". It even has the original plastic ties on the harness. All I'm saying is check things out before going crazy. He's removing the AFM, but what will he see with it in-hand, that he can't see with it on the car? Here's something though - remove the distributor and give it a good work over before too much use. The breaker plate bearings tend to rust to the rolling surface and break their plastic cage as vacuum tries to move them. Here's another - buy some picks before trying to remove the plug from the AFM, or the injectors, or any of them. They take a little bit of technique to remove..

-

Zedyone_kenobi's Nightmare

People have their positives and negatives. A slight shift in his viewpoint and everybody's on board. Product quality does, in general, seem to diminish as companies try to squeeze more profit out. A rant about the people who waste their money on poor quality products would be reasonable. Ranting about where it's made is just misguided. Who knows, he might be out campaigning. Feel the Bern!

-

Zedyone_kenobi's Nightmare

Pretty sure he said he was just tired of the internet. Too many ads. An objective look will show that the internet can be unhealthy. Not really meant for humanities well-being, it's been hijacked to sell more stuff. Easy to see the need for taking a break.

-

New owner of '77 280z from Upstate SC

Browse through these documents and download the EFI Book 1980. http://www.classiczcars.com/files/category/4-manuals/ The 1977 FSM is available here (sorry Blue, it's the only one missing) - http://www.nicoclub.com/FSM/280z/ Download that also. There may not anything wrong with your AFM, the fact that the wire in the intake kept the pump running shows that the switch is fine, not dirty. EuroDat was suggesting that the spring pre-load may have been adjusted, causing the vane to stay closed, but any air leak in to the intake system might cause the same. But you can tell if that's the case by inspecting the glue blob on the sprocket. And you don't need to remove the AFM to do that. It's actually easier to get the black cover off of the side with it installed. Looks like it's in great shape. Don't get ahead of yourself, taking things apart. rossiz was on point, speaking from our collective experience. It's the small things that will get you. Poke around and ponder, there's quite a few things you've probably never seen before.