Everything posted by Zed Head

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Sounds like your AFM is not connected, electrically. Might be that the connector/plug fell off of the bottom. It happens. You can can check via the pins at the ECU connector to be sure.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

I looked around a little bit and it seems like the manufacturers generally went to computer control of a simple fuel pump relay instead of integrating the timer. But it is a hot topic, so of course, people have filled the need. https://www.ebay.com/itm/174274213748?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=NmzUBVTDRzy&sssrc=2047675&ssuid=bBzFtXzvTQO&widget_ver=artemis&media=COPY This on Amazon, below. The words in search should find it. I don't like to copy their links they seem full of extra stuff. Could probably be made to work.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

Define long-term. Hey, you're having fun. Just keep going. There's probably a fuel pump relay out there somewhere with an integral timer. Or try that timer thing in your first post. My 2003 Ford has a timed prime but I think it's controlled by the PCM (aka ECU/computer). EFI is all about emissions so the manufacturers went to great lengths to get everything perfect from the first crank. Have you measured the leak down rate on your system?

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

My good FPR's (edit - and fuel pump check valve) would hold about 20 psi for days. The bad ones would leak down to zero. Carry on.

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

I hope it's not so but that sounds little bit like a bad ECU. When it's running poorly do you smell raw fuel from the exhaust? One test/fix that people do is to bang on the side of it while it's acting up. There can be broken solder joints inside that lose connection. A few kicks or knuckle raps can remake the connection. It's not a permanent fix but it's a clue. Could also be the ignition module. The clue there is the tachometer needle. Does it jump around or read higher than it seems it should?

-

1978 280Z - Won't restart when hot, all interior gauges, fan motor, backlighting not working

Didn't you check fuel pressure using a temporary gauge in the past? And it was correct? If it was mine, I'd pop the cover off of the AFM and make sure the vane is moving with air flow. Simple stuff, no tools required. Any chance you could summarize everything you've done so far with measurement numbers ? Too many pages to go back and read through them all. I see suggestions that I'm pretty sure have already been made. Plus your problem is different now. The title says "when hot" but now it's when cold. The main problem has changed.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

The forum's search engine is terrible, if you've been trying to find things using it. Go straight to Google to get better results. I know that Fastwoman had discussed it in the past. It's not hands-free but it's close. https://www.google.com/search?q=site%3Aclassiczcars.com+fastwoman+momentary+fuel+pump

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

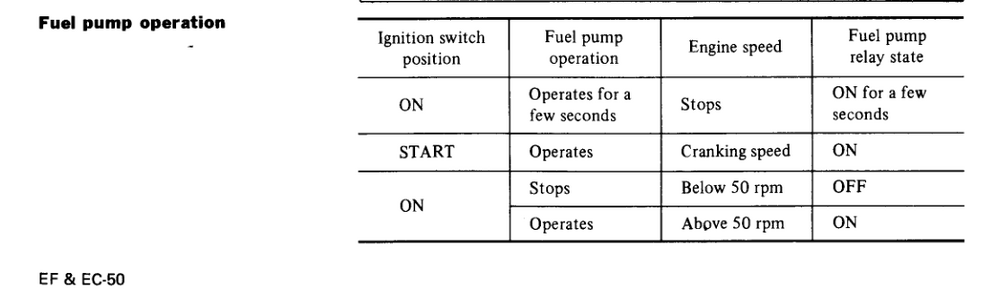

Are you saying that your fuel pressure is leaking down? Nissan added automatic pump priming in the ZX's. It often quit working though. I'd guess the timer is in the relay. Maybe you could retrofit a ZX pump relay. 1982 -

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

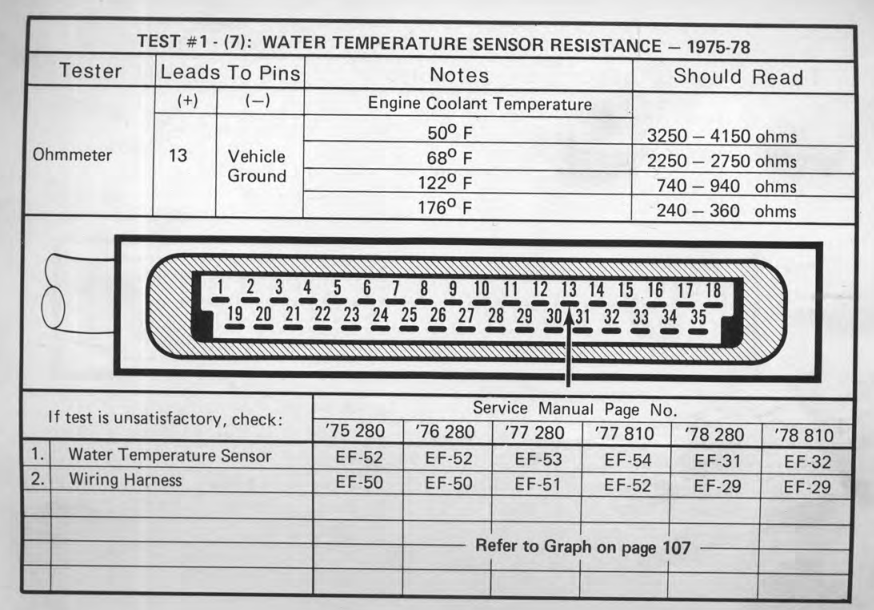

How does it run? The typical no-AFR-gauge sign of a lean mixture is bucking and popping back through the intake manifold at part throttle acceleration. Don't get too focused on the numbers on the LED screen. If you're certain it's lean you could try the resistance tuning for the temperature sensor, that was previously mentioned. You can insert it in between the bullet connectors on the engine and let it hang for a quick test. http://www.atlanticz.ca/zclub/techtips/tempsensorpot/index.html

-

76 280Z Throttle Body bolt spacing

I don't know why they've changed the name to "additive manufacturing" but if you use that search term you can find a lot. Stereolithography > 3D printing > additive manufacturing > goofy. Pick a name and stick with it! Metals are possible. https://www.additivemanufacturing.media/kc/what-is-additive-manufacturing/am-materials

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

I'd check the coolant temperature sensor resistance. Compare to the chart from previous. Check at the ECU connector.

-

Leaking Bellhousing and Hard to shift into first

Could be the front seal or the front cover gasket. Both require removal to fix. Use a piece of wire or a long skinny stick in the fill hole to see how low the level is.

-

"The Brown Z" HLS30-11080

Do it again!

-

Door glass window plate rollers install 280z

Browse through the Knowledge Base area. The articles are oddly categorised, but there's not too many. I found one in Body and Paint, pretty sure there is at least one more. Edit - actually, it's in the same place. Copied link below. https://www.classiczcars.com/articles/

-

Engine rough running - at wits end

-

76 280Z Throttle Body bolt spacing

I'll go ahead and ask before CO does - is your ported port 70 mm across? Doesn't look it. 70 mm would be outside the 60 mm centerline of the screw holes. You'll need an adapter with a neck-down transition. Kind of defeating the point. They make a 60 mm big bore. Looks like it would fit about perfect. One example. There's probably used on eBay. https://zcardepot.com/products/big-throat-borla-throttle-body-60mm-280z-280zx

-

76 280Z Throttle Body bolt spacing

Is this for a factory stock head and intake manifold? Most of the horsepower chasers say that the intake runners and head ports are the significant flow restrictors. One of the reasons I remember that the ZX TB bore is smaller is because it was kind of surprising that they modified the L28 extensively for emissions and power and ended up with a smaller TB bore than the N42 based Z engine. Call me a buzzkiller...

- 76 280Z Throttle Body bolt spacing

-

76 280Z Throttle Body bolt spacing

Oh. Be careful with any information you find or get. I see some bad guesses out there. ZCD is selling a throttle body that he says will fit both Z and ZX. But I know that the bolt patterns are different, I've had both. My memory says that the ZX pattern and opening is smaller. A ZX TB will not fit a Z intake manifold and vice-versa. Surprised that he doesn't know this. https://zcardepot.com/products/big-throat-borla-throttle-body-60mm-280z-280zx?_pos=8&_sid=7968a8baa&_ss=r https://zcardepot.com/products/throttle-body-gasket-70mm-large-280z-280zx

- 76 280Z Throttle Body bolt spacing

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Another thought - a dead spot on the AFM wiper. You might be able to test that by manipulating the throttle by hand until you hit the zone, then moving the vane to see if it goes away.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

Watched the video. The problem seems ready made for a timing light for a plug wire and a noid light for an injector. I don't think that "hunt" is the right word for the problem. Sounds like you're losing either ignition (which will also kill injection), or just injection. You're losing all six cylinders at the same time, not even a sputter. Seems electrical for sure. A noid light in parallel with an injector and a timing light on any plug wire, pointing at your face while you sit in the driver's seat, while you do that test should tell you something.

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

You can wire up the HEI module directly from the distributor wires and the coil power supply right next to the coil. Forget about the ballast resistor entirely, at least for a quick test. Or just use it as a terminal block. The HEI module is current limiting. The stock module is about 4.5 amps, I think, and the high performance ones about 7. But that's just at the beginning of the coil charging cycle. Should be fine. It's all about heat and you can touch the parts to see how they're doing.

-

Bad air flow meter??

Doesn't look like you tried. You said you were on the edge and passed on the next run-through. Therefore.... Keep an open mind. The 280Z EFI system is an excellent learning tool. Good luck.

-

Bad air flow meter??

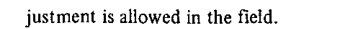

The "proper" way to adjust the fuel-air mixture at idle is with the screw on the side of the AFM, not the spring inside. It's described in the FSM. Edit - actually, it's described that the bypass screw is not to be adjusted. But it is the most direct way to lean out or richen the idle mixture.