KiddysClassics

Member-

Posts

45 -

Joined

-

Last visited

About KiddysClassics

- User Group: Member

- Member ID: 30023

- Rank: EnthuZiast

- Content Count: 45

- Content Post Ratio: 0.01

- Reputation: 3

- Achievement Points: 461

- Member Of The Days Won: 0

- Joined: 03/06/2015

- Been With Us For: 3339 Days

- Last Activity:

- Currently:

- Age: 35

Clubs

Contact

-

Map Location

Jensen Beach, FL

Social Sites

-

Website

http://www.kiddysclassics.com

Recent Profile Visitors

1,451 profile views

KiddysClassics's Achievements

-

- 34 replies

-

Thank you for watching! If you have any questions, please don't hesitate to ask.

- 34 replies

-

The rails are nice. Although don't reference the photos above as how they will come to you. We added to them to make them look more like the original. We also added plates to the rear frame rail to help reinforce where the frame rail ties into the rear frame cross section. As you can see from the photos below, extensive modifications were done to ensure that the rails properly fit the vehicle.

- 34 replies

-

Yes, they are "Bad Dog". The customer brought them in to have them custom fit to the vehicle.

- 34 replies

-

Although these frame rails were not in horrible shape, the owner of the car has decided to replace the original rails with thicker aftermarket rails to make the body stiffer to support the additional horsepower the car will have once complete. Our job was to make the new frame rails replicate the original to maintain the overall stock look the customer wants to keep.

- 34 replies

-

- 2

-

-

With any patch panel, we look at how much time it takes to make a patch panel vs. how much it costs to buy one - many times, the aftermarket patch panels require a lot of work to make them fit to the body of the car - often taking close to the same amount of time it would have taken to fabricate a completely new one. If we see that the cost of the panel is close to the cost of the labor to create one ourselves, we often go with fabrication over purchase. However, if buying an aftermarket panel is obviously cheaper due to the complexity, we will always head in that direction or try to find a donor

- 34 replies

-

- 1

-

-

The rear wheel well on the passenger's side was badly rusted. We cut away the damaged area and fabricated patch panels to replace it. Currently, we're working on ensuring the contours match the factory look.

- 34 replies

-

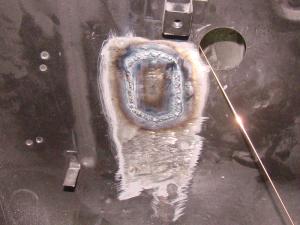

While inspecting the vehicle, we noticed a large rust hole under the cowl. We scraped away the seam sealer and revealed a significant amount of damage compared to the rest of the vehicle. We removed the HVAC duct and repaired it and the surrounding area.

- 34 replies

-

Every panel prior to reassembly is first media blasted clean, if the panel is going to be welded those areas that will be affected by heat are coated in a weldable primer. If the area is not going to be welded and/or will not be affected by the heat of the welder, such as the inside section of the new frame rails below the flange. (we will post pictures of those later after they are finished with them) Then those areas are coated with epoxy. As for our welding methods about 90% of the work we do in the shop is TIG welded. If I can get the back side of the panel to hammer and dollie my weld seam I will always without question reach for the TIG.

- 34 replies

-

Upon inspection of the rear valance, we noticed that the panel was being pushed up between the spot welds - which usually indicates that there is rust beneath the surface. After carefully removing the rusted panel, it was media blasted, repaired and re-installed.

- 34 replies

-

These openings in the firewall were originally made to allow the HVAC lines to be run inside the vehicle. Because the owner no longer tends to use them, we fabricated patch pieces and welded them in.

- 34 replies

-

Compared to most other vehicles that come in, media blasting this 240Z was relatively quick and easy due to the lack of rust. We did find some areas of mild concern that we will be repairing.

- 34 replies

-

That is an absolutely beautiful vehicle! Wonderful job!

- 34 replies

-

When we stripped the paint from this vehicle, we found no visible rust and very little body filler. Those who are familiar with these vehicles, will tell you that finding an almost rust-free Datsun 240Z is near impossible.

- 34 replies

-

It is most definitely a beautiful piece of art. I'll update daily with news and photos of the progress.

- 34 replies