Everything posted by EuroDat

-

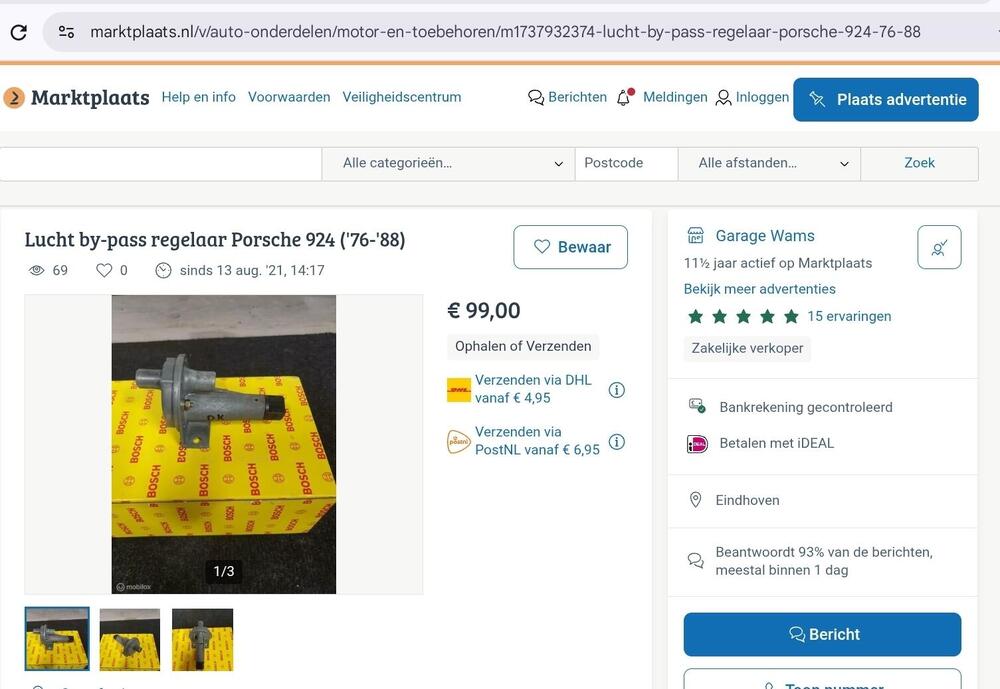

A better Auxilary Air Regulator

If someone is looking for an original Bosch version of the 280Z auxilary air valve here is one in NOS condition. Its for a 1976 Porsche 924, but it's a very similar system. Marktplaats≥ Lucht by-pass regelaar Porsche 924 ('76-'88) — Motor en...Lucht by-pass regelaar Porsche 924 ('76-'88)Lucht by-pass regelaar Porsche 924-Porsche 924, 2.0liter-Voor koude start regeling (lucht)-Bosch-Getest en

-

Making an inspection light lens

Hi Mike, Just back from a holiday in Spain. I have plenty of photo's and I believe I have a video of it bubbling to remove air. Ill see what I can find and post them.

-

Diesel crank

That would bd a good find. Don't see any photos of the engine so I'm wondering: Does it still have the engine???

-

Rebuilding an AC System

I like the Sanden compressor in their kit. It looks visually close to the original Hitachi compressor. The mounting bracket though looks big and cumbersome compared to my original hitachi bracket. If you are spending all the money on the kit for the engine bay, then I would also go the extra for a new evapourator.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Do you have the Apex-Engineered front subframe or have I missed it? With the subframe you could reverse engineer it to work out what you need.

-

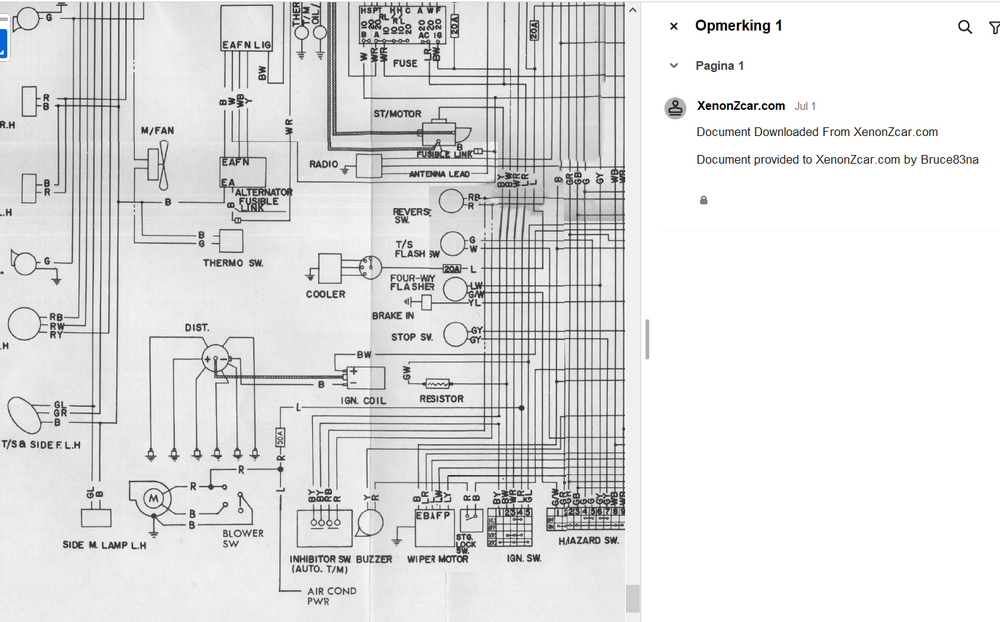

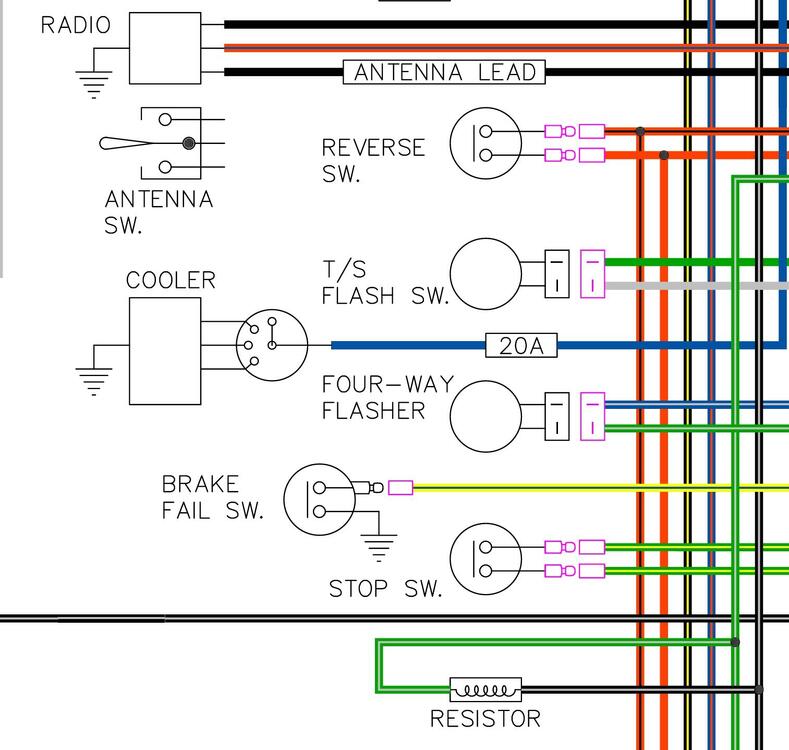

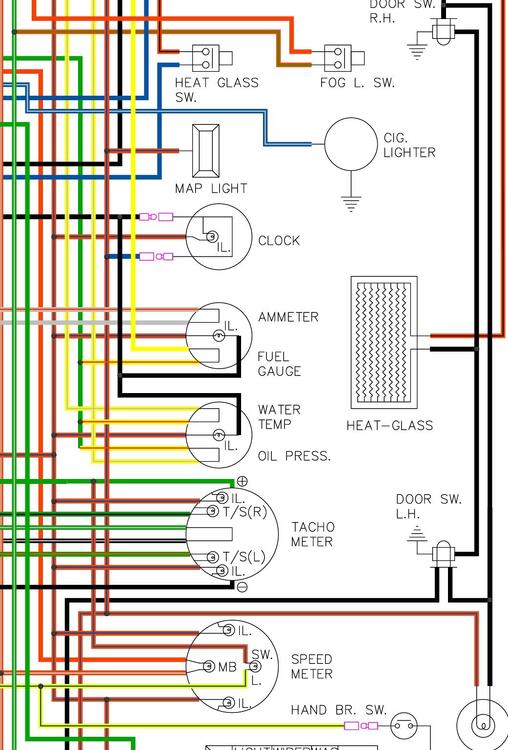

1970 Wiring Diagram

-

1970 Wiring Diagram

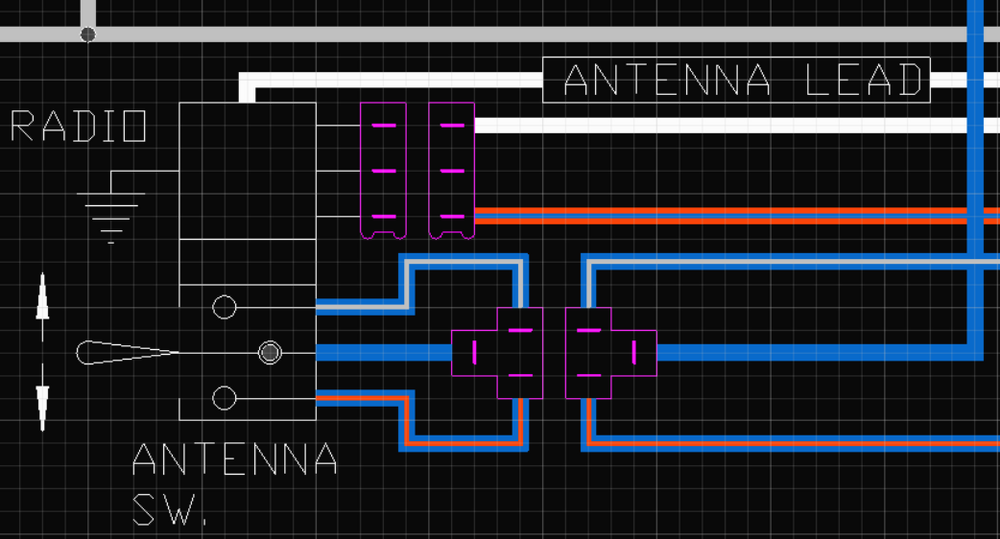

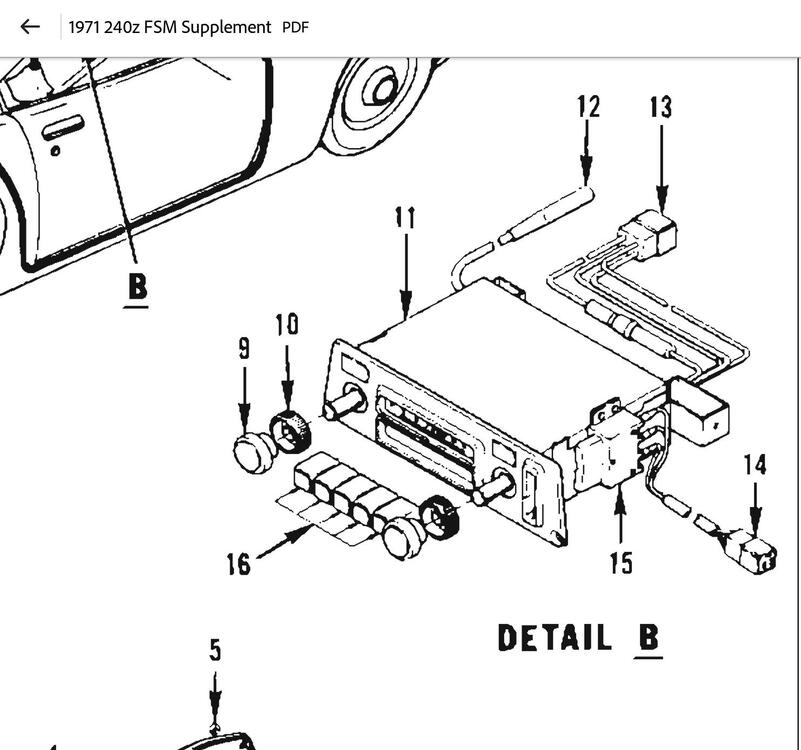

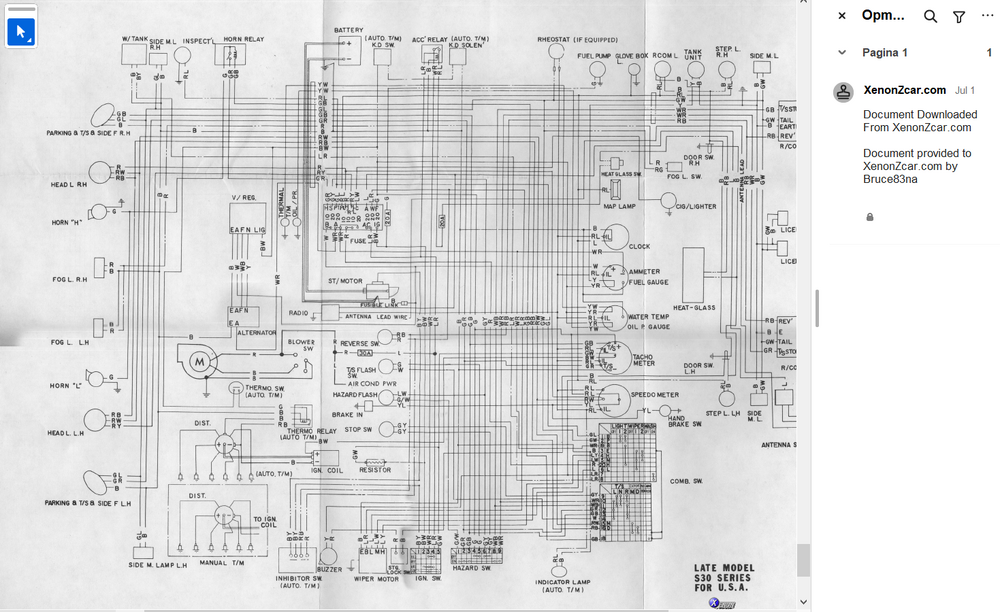

Evreything I find on the internet (ignoring the BS E-bay ads quoting antenna switches to suit datsun 240z to 280zx) seems to point to that type. The wiring diagram is based on the two diagrams in the Xenon website 1971 240z FSM supplement In the detail Pos 14 & 15 seem to match.

-

1970 Wiring Diagram

-

1970 Wiring Diagram

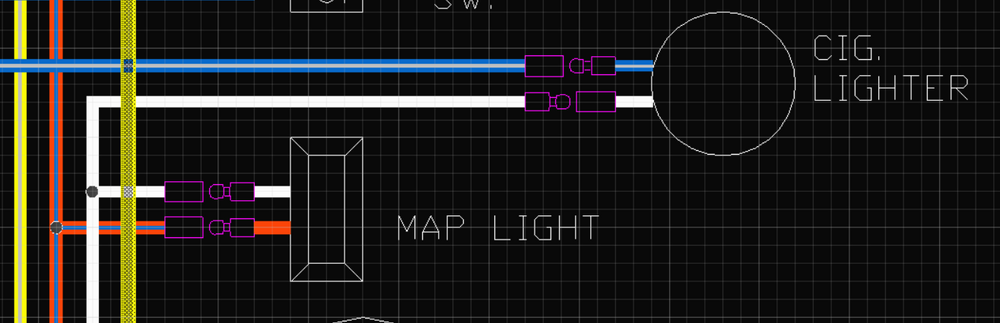

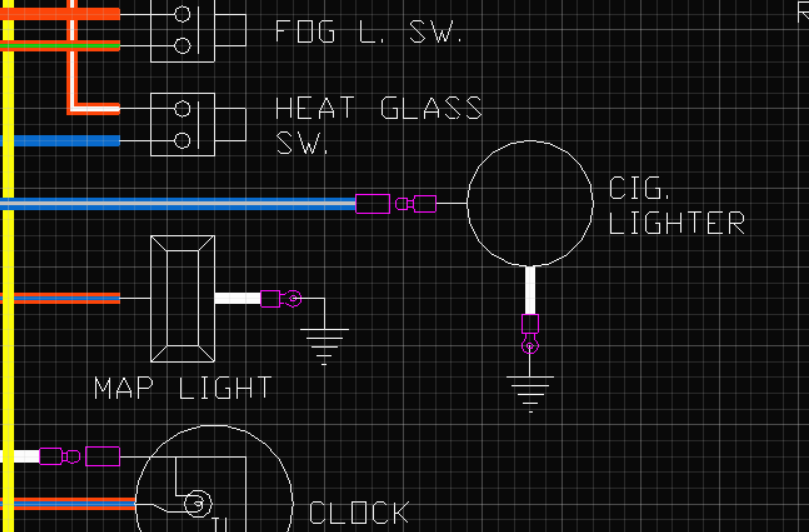

Hi Captain, You have an good eye for detail.😀 I'm not sue if the Map light uses a bullet connector of spade for the power supply? The blower is in the cabin and I think the Cooler is the engine fan maybe? , but I must admit I have never seen an original 240Z with original air-con fitted --> Thr blue branch off wire. The was from a source file I used from XenonZcar 9 years back.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

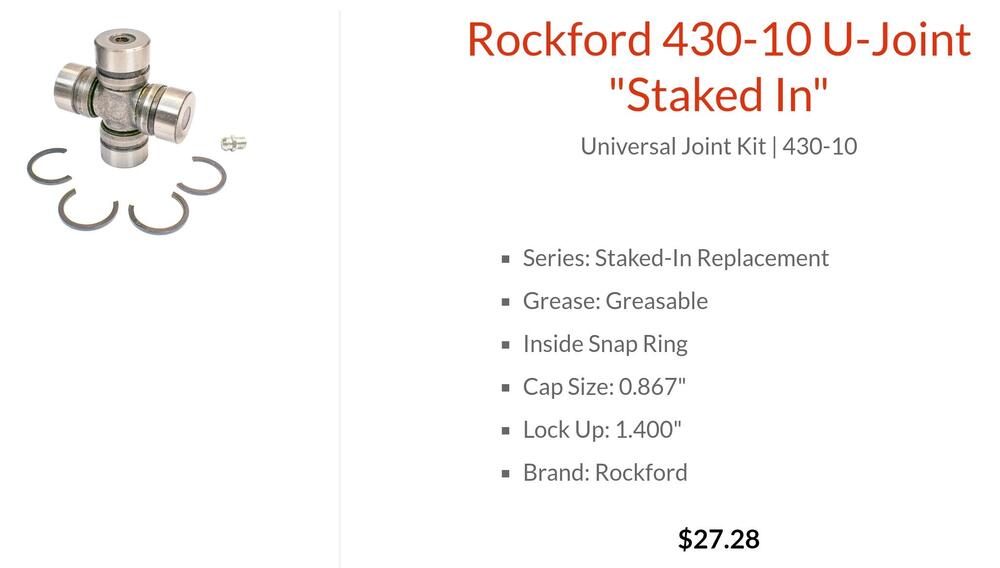

I read the Subaru drive shaft uni-joints were the best replacement for the 280Z and came with inner circlips. Rockford u-joint replacement kit 430-10 "Staked in" replacement. I can't confirm fitment.

-

1970 Wiring Diagram

I made a low res print in pdf of this last update Rev1.1 The radio connector is not right. It should be 4 pole. See screen shot of the supplement. Connector Pos:13. I think the speaker wires come from pos 13? ColorWiring240Z1971Early_TerminalBlockExample09-aug-2015 Rev1.1.pdf

-

1970 Wiring Diagram

Ill make a list of things I miss. If anyone has parts handy and can take a photo or even out of memory would be a great help. Please don't hesitate to make or suggest any corrections. Like I mentioned, I don't own a 240Z to fact check any of this.

-

1970 Wiring Diagram

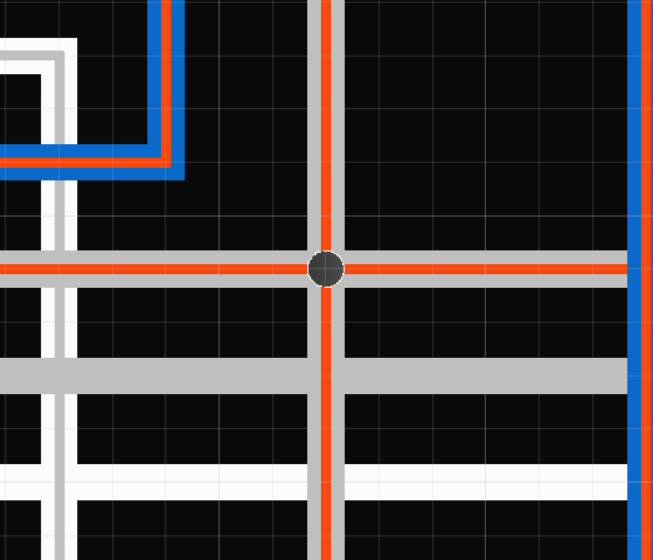

Hi Captain, Communicate mistakes on my diagram or screen shots would be great. Your example is very clear. Thanx I like the early wiring diagrams too. That is why I'm trying to keep it close to the original layout and adding terminals. I also found a dash connector diagram in the 1971 supplement where I can make out the radio connectors. I can't find anything on the Passing relay.

-

1970 Wiring Diagram

Looking through the drawings to see what I was up too 9 years ago🫣 Most of the terminal layouts are from the service manuals and photo's members posted in threads on this site. I made some screen shots of some of the sections still kissing the terminals. I remember working on the antenna switch, but could not find a photo of its terminal block. I think I'll first update the schema with the remarks from @Namerow and @Captain Obvious b

-

1970 Wiring Diagram

Hi all, Just searching through my drawings on the 240Z wiring diagrams. I was buzy adding terminal blocks te the early 71. It also needs some update "thanks to @Namerow for his input back them" I was too slack to finish it. I could work on the "Terminal block version", but I would need help from you guys since I don't own a 240Z and like mentioned in the thread, the manuals have their issues. Here is where it was in 2015. I also had a request to add Line colour text for people that are colour blind. It's all possible, but I don't want to waste my time if no one is interested. My absence in the last 12 months is due to health issues in the family. ColorWiring240Z1971Early_TerminalBlockExample09-mar-2015.pdf

-

1970 Wiring Diagram

Hi guys, Just quickly dropping in to let you know, I'm still around. I'll read through the thread in more detail later the weekend.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

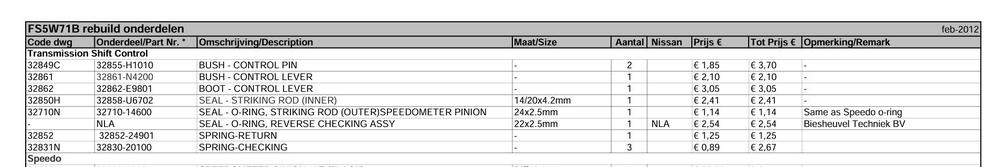

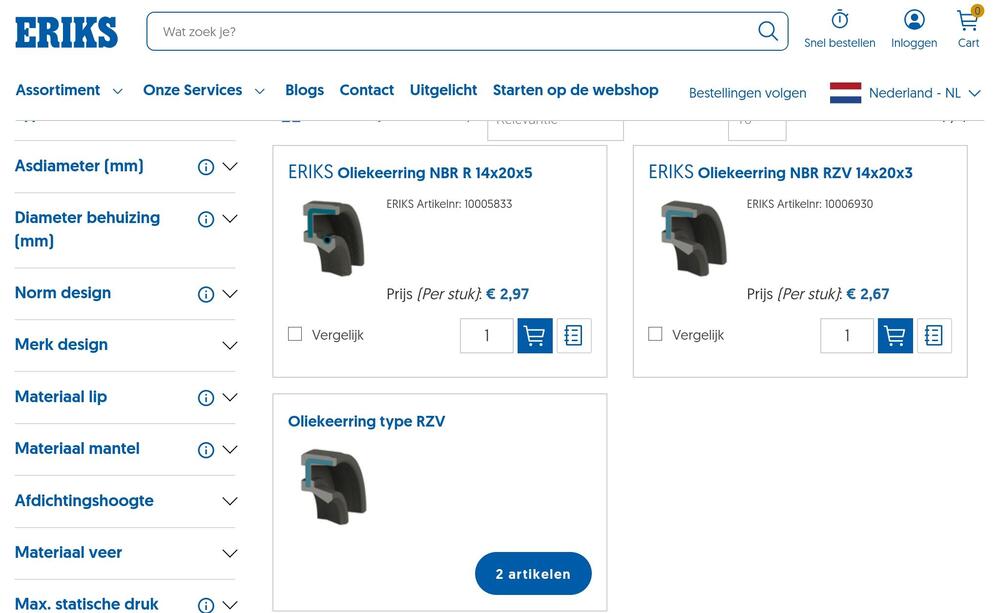

The striking rod oil seal is easy to find in the aftermarket suppliers. Don't use a hydraulic oil seal. They are a different design. The 5mm thick seal will also fit. It needs to have an ID 14mm and OD 20mm. (14/20 x 4.2mm or 5.0mm). Over here they cost a little less than €3.00. I mentioned the size in my list I made back in 2012. Make sure the rear bush is the Omega machine tool variant. It is not for our transmissions, but it is so close to the original that is is a suitable alternatieve. The SKU: 303066 (NIS-62) only fits the stubby FS5W71C transmissions for 4 cyl models. The transmissions with the long rear extension housing never had the option to replace this bush, not through Nissan anyway. I think the stubby transmission housing provided more stress to this bush and it was prone to wearing out. The NIS-62 is also much shorter and has less surface area.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

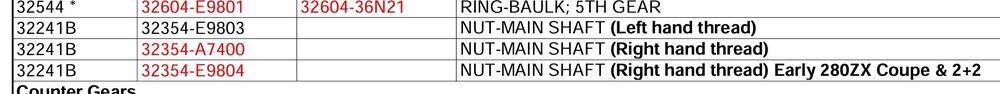

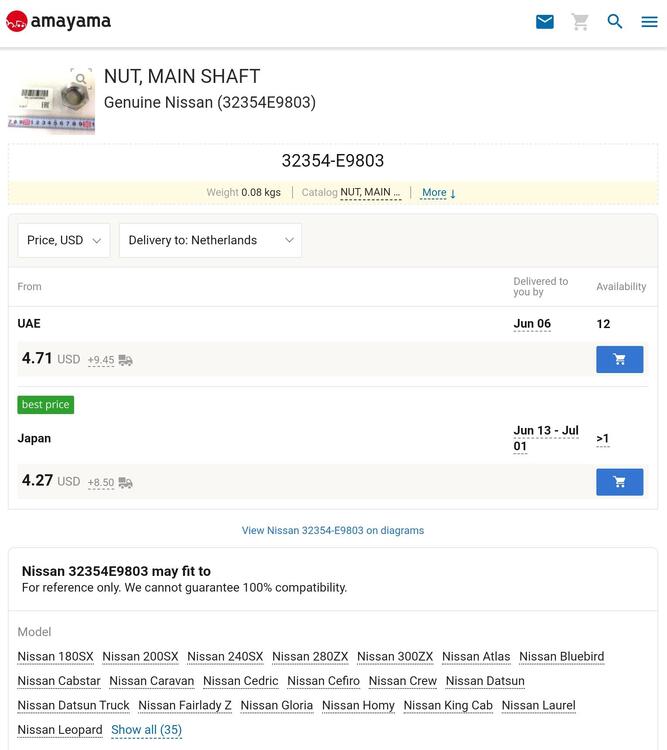

All part numbers 32354-A7400, 32354-E9800, 32354-E9802, 32354-E9804 are Right Hand Threads. Part number 32354-E9803 has a Left Hand Thread. The E9800 was used in the early 200SX 1979 - 1980. Right hand thread and replaced by the E9804.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

All part numbers 32354-A7400, 32354-E9800, 32354-E9802, 32354-E9804 are Right Hand Threads. Part number 32354-E9803 has a Left Hand Thread. The E9800 was used in the early 200SX 1979 - 1980. Right hand thread and replaced by the E9804.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

All part numbers 32354-A7400, 32354-E9800, 32354-E9802, 32354-E9804 are Right Hand Threads. Part number 32354-E9803 has a Left Hand Thread. The E9800 was used in the early 200SX 1979 - 1980. Right hand thread and replaced by the E9804.

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

It's actually the right hand thread that is NLA. They changed when they started making the close ratio transmissions in the 280ZX. The LH Thead M27 x 1.0mm is used in a variety of models like the Urvan, Infiniti, 240ZX, 280ZX, 300ZX, 720 trucks etc. The RH Thread M27 x 1.0mm has been NLA for a very long time. Someone on this forum made some for other members a while back. You can re-use the original nut if you can open the indented section and remove it without to much trouble. When you rebuild and it lines up on the used section of the nut, you have a couple of options: 1. Machine 0,5mm of the nut face, then the nut will turn a furthe 180° or 2. Use 0,5mm shim. Any thickness will do as long as it is not 1, 2 or 3mm.

-

Replacement Throttle Body Linkage Return Spring

Btw: If the wire diameter, spring diameter and materials are the same, the spring with the less coils (green circle) will be a lot stronger, but will have less travel. Based on the law of Hooke. Hookes law: F = kx (F is force, k is spring constant and x is distance travelled.) Wire diameter: When the wire diameter increases, the spring constant also increases. A thicker wire ensures that the spring constant becomes stronger and is even more difficult to deflect. Spring diameter: An increase in the spring diameter will lead to a decrease in the spring constant. Number of turns in the spring: The higher the number of turns, the lower the spring constant. It would have been interesting to test the springs with a weight to determine the k factors.

-

5 speed swap tunnel hole for the shifter

In Wheeler dealers they changed the auto to a 5 speed transmission in a 240Z. They show cutting out the floor piece and installing the shifter. Watching it might help?

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

Congrats on the quick fix. You are lucky to have a Bosch 0 322 514 127 Fiat relay handy. These dual units are getting harder to find since Bosch stopped making them around 2020. Something I found years ago. If you are looking for a Bosch 0 322 514 120, try Beck Arnley 203-0053. It's a Bosch relay, but they just took it out of the Bosch box and put in a Beck Arnley box. It is also hard to find, but the more options increase your chances of finding one.