Everything posted by SteveJ

-

Tachometer maxes out when Ignition switched on. Loss of power too! (Help!)

As long as you don't have a dash cover glued onto the dash, it's not too bad to remove the tach. It just involves contorting yourself some. I'm in my mid-50s, and I can do it. Heck, I did it a couple of weeks ago when I was helping with diagnosing a car. There are two wing nuts holding the tach in the dash. You pretty much have to lie down in the footwell and reach up to find them . Once you pull the tachometer out enough, you can disconnect it from the wiring harness.

-

Tachometer maxes out when Ignition switched on. Loss of power too! (Help!)

Well, everything I could find about the tach pegging says that the tach is going bad, and for many it's the failure of a discrete component, like in the thread I linked. The good news is this can be repaired. This place fixed a friend's 260Z tachometer about 11 years ago. https://www.bobsspeedometer.com/

-

Floor temp light

Color me unsurprised. There's only so long a manufacturer can support obsolete technology. I'm usually surprised when something is still available.

-

ZCON 2022 Roll Call

-

Pressure in the gas tank

I skimmed through the EF section of the 74 FSM. I didn't see that valve, and it wasn't described in the theory of operation on EF-32. I would not be surprised if the vent line from the tank was capped at the tank or in the engine bay.

-

Tachometer maxes out when Ignition switched on. Loss of power too! (Help!)

You're right. I was speculating based upon the dropped performance. That's why I revised to dying tachometer once the voltage readings came back.

-

Pressure in the gas tank

He has a 74. I never noticed pressure building up in the tank in my car. Of course, the carbon canister was not hooked up properly.

-

Floor temp light

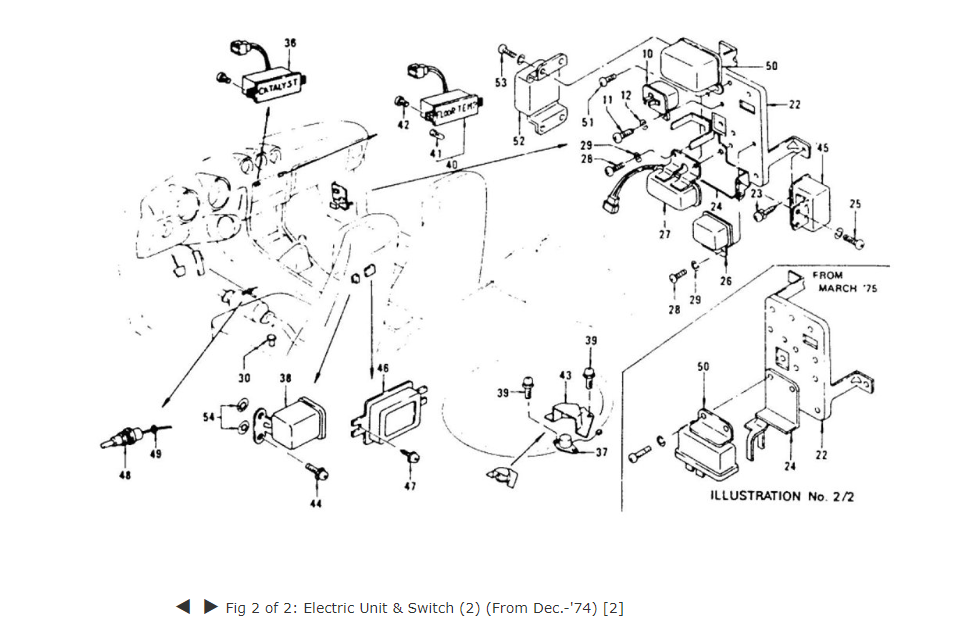

@Dave WM I think you'll find the part numbers on this page: http://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/electric-unit-switch/section-2/280z. Start around part 31 and work your way down. Be sure to go to figure 2 of 2.

-

1973 240Z Horn signal wiring/relay location

An easy way to see if the steering column is grounded is to check continuity from the shaft where the steering wheel mounts and the body.

-

Tachometer maxes out when Ignition switched on. Loss of power too! (Help!)

The voltages look right for a 240Z with points. Unfortunately that probably means your tachometer has seen better days. Read through this thread: Of course, @beermanpete figured out how to fix his. I wish he was still hanging out around here. As for the fog lights, that green/white wire should only be used to control a relay along with a switch. Don't use that wire to power the fog lights. You would need a fused 12 volt source connected to the 87 terminal of a relay with the 30 terminal connected to the red wire. (Relay explanation here: https://fiddlingwithzcars.wordpress.com/2012/12/22/relays-simplified/)

-

Timing Off Runs Bad

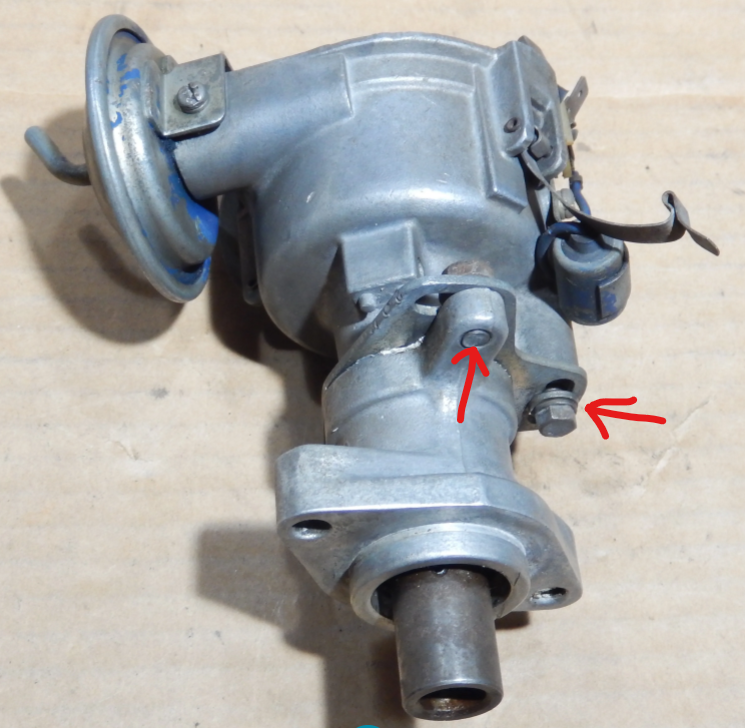

With the 280ZX distributor you will need to buy a 280ZX distributor mount and timing plate. The mounting bracket seems to be pretty rare now, and it's not like they were very common 10 years ago when I last bought one. (People seem to forget about this when they suggest a 240Z owner swap to the ZX distributor.) A 240Z distributor with Pertronix would probably fit in the mount you have now. By the way, Summit Racing seems to have the best price around on the Pertronix right now. I'm not sure what part number Pertronix you would need for the Mallory. Looking at their website, this was the only 6 cylinder, 12VDC, negative ground Mallory kit I saw: https://pertronixbrands.com/products/pertronix-ml-161-ignitor-mallory-6-cyl

-

Pressure in the gas tank

First, locate the vent line in the engine bay. Blow some compressed air at low to moderate pressure into the vent line, and have someone listen at the filler with the gas cap off. The helper should hear the woosh. That also allows you to figure out if someone capped off the vent line in the engine bay. For the plastic panels, you might try some thin weather stripping. https://www.amazon.com/Weather-Stripping-Sliding-Speaker-Dashboard/dp/B07WGTHBSC Or maybe something like this: https://www.amazon.com/Weather-Stripping-Silicone-Window-Transparent/dp/B07XRVBSYC Here's some 1 mm weather strip. https://www.amazon.com/uxcell-Thick-Adhesive-Weather-Strip/dp/B07L6JKJD1

-

Timing Off Runs Bad

As for the bolts to adjust the timing, there's a picture for that. Here's a YouTube video where a guy made a transitorized ignition with a Hall effect sensor. You'll see early in the video that he passes a magnet over the sensor, and you can see the spark. For the Pertronix ignitor, there are magnets in the ring that goes below the rotor. The ring should be indexed to fit over the shaft only one way. Otherwise, I don't have much to add to what @Zed Head said.

-

1973 240Z Horn signal wiring/relay location

Do you have any loose wires around the steering column? (Aside from the key in switch buzzer)

-

Timing Off Runs Bad

There should be two adjustment bolts for timing. Have you played with both? If you have, and what you said still holds, here is what you might do. Put the mark at the first line past the middle and toward retard. Consider that your static zero position. Adjust the oil pump from there to put the rotor at TDC. Still this picture bugs me. In the 240Z, I could swear that when the engine is at TDC, the rotor is near the Hall effect sensor, not 180 out like in your photo. I tried searching for images with your setup, and I tried searching Hybridz. I didn't find anything useful. Maybe someone smarter than I am can chime in about this.

-

Pressure in the gas tank

No, it is not normal to build pressure. Make sure the vent line is not capped off.

-

Timing Off Runs Bad

Edit: Some things got clipped out by mistake. Does your distributor still have a plate like this? Here is how it's lined up on my 240Z. Here's what you might try to do before messing with the oil pump. (Minimize jumping around.) Set the car at TDC. Align the mark on the plate to the middle. Verify that the rotor is at the #1 plug. From there, you'll have a better idea of what way you need to go.

-

Timing Off Runs Bad

Did you retard timing any after moving the wires? It might be too far advanced.

-

Tachometer maxes out when Ignition switched on. Loss of power too! (Help!)

After looking through the wiring diagram, I am guessing that mystery connector is for the fog light switch. You don't have a fog light switch? Well, North American cars are wired for fog lights, but Nissan didn't install a switch. It's just as well. The engineers designed the circuit to come off the parking lights. That circuit already has enough issues without fog lights added.

-

Tachometer maxes out when Ignition switched on. Loss of power too! (Help!)

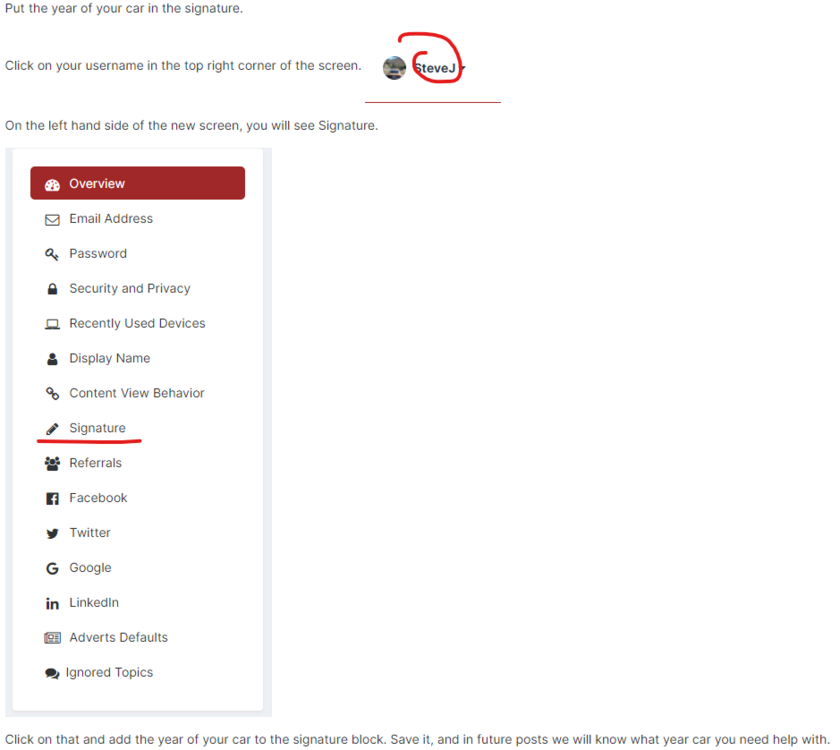

Please make it easier to provide help. Wiring diagrams differ by year. As for why your tachometer is maxing out, I would posit that there is too much current flowing through the tachometer. Maybe the black/white wire from the tachometer has been damaged and is slightly coming into contact with ground. This would cause more current to flow through the tachometer sensor and less to flow out to the ignition. Maybe you reconnected something wrong, though there shouldn't be anything connected to the black/white wire between the tachometer and coil positive. While the car is running, measure voltage to ground at the green/white wire on the ballast resistor and also measure voltage to ground at the black/white wire on coil positive. There shouldn't be much of a difference in voltage between the two. Also measure voltage to ground at the black/white wire on the ballast resistor. Pleas report your results. After you supply the year of your car, I can look at the FSM to try to identify the mystery connector. I'm guessing you have a 72 since I see short pigtails on the fusebox, but I don't see sockets for bulbs around where the control panel goes.

-

1973 Rebuild

Tools from this kit may be more gentle on the paint than an old screwdriver. https://www.harborfreight.com/automotive/auto-body-trim/trim-and-molding-tool-set-5-pc-64126.html

-

Carburetor Conundrum (260Z)

Most people use 20wt oil in the dampers. You should check the level in the carburetors. Also, with the car off, try to lift the piston in each carburetor. The damper oil should provide a fair amount of resistance. I'm wondering if the front carb has enough resistance. Ace Hardware stores typically carry 3-in-One brand oil that is 20wt.

-

ZCON 2022 Roll Call

Well, if anyone is joining me in Birmingham, bring plenty of water and light clothing. It looks like it will be as hot as the Memphis or Austin conventions. https://www.wunderground.com/calendar/us/al/hoover/KBHM

-

Carburetor Conundrum (260Z)

What type oil did you use in the dashpots? Is the oil staying in the dashpots?

-

Carburetor Conundrum (260Z)

I can't download the MOV file. There's something wrong. Can you upload it to YouTube?