Everything posted by SteveJ

-

260z Vin#'s and production info

Okay, after the Kenmeri thread, you KNOW you have to post pics.

-

Hybridz.org is "For Sale"

http://www.datsunworks.com/Blog/ It makes me wish I had a few thousand to spend.

-

[2017] What Did You Do To/with Your Z Today?

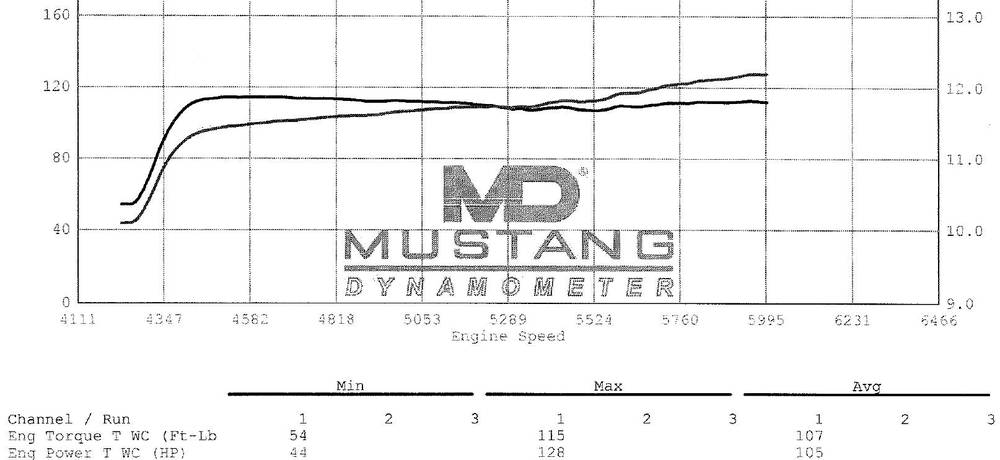

Z31Atlanta organized a dyno day and opened it up to others. It was only $50 for 3 pulls, so I figured I would find out what the new motor was pulling. I played it conservative because I don't really know much about the actual build, telling them to cut off at 6000 RPM. After seeing the results, I would say I might have left some HP on the table, considering the best run was 122.5 HP (128.0 with WCF) at 6006 RPM (88.6 MPH - and me without a flux capacitor). Peak torque was 109.8 Ft-lb (114.7 with WCF) at 4575 RPM (65.5 MPH). The owner of the shop said it would probably top out around 150 HP on a Dynojet dynomometer. So any educated interpretations of the graph?

-

New member introduction - My 76' 280Z in Atlanta

I was helping a friend last weekend sort out the same hack job where someone replaced factory FI with carbs and didn't do a good job on the fuel pump wiring. My friend and I tag-team. He provides the mechanical expertise, and I provide the electrical expertise. I'll send you a PM later.

-

New member introduction - My 76' 280Z in Atlanta

If there was only someone in the Atlanta area who understood the 76 280Z wiring diagram to help you locate the factory wiring and safely modify it to work...

-

510 signal problems

I found the wiring diagram you posted before. The 510 doesn't have the same potential for cross connections as the 240Z. The turn signal switch on the 510 does not affect the brake light circuit. Also the turn signals and brake lights only share a ground. They are in different sockets. The tail light housing serves as the grounding point for the bulb sockets.

-

510 signal problems

Start with the left rear. Remove the bulbs and inspect the sockets. Look for a cracked insulator on sockets that take an 1157 bulb. Look to see if an 1156 bulb was used in a 1157 style base. (Single filament bulb in a dual filament socket) Test with the bulbs out. See if the problem remains. Also post that wiring diagram for the 510 again.

-

Ignition switch

That's why I roll my eyes when I hear someone saying he wants to convert to carburetors because they work better and are more reliable. If I could afford it, I would install FI into my 260Z.

- 1976 280Z Restoration Project

- 1976 280Z Restoration Project

- BRAKES LIGHT AND LEFT REAR FLASHER

-

Something's wrong, headlight switch controls my fan etc

Stupid is making a mistake and never realizing or learning from it.

-

Something's wrong, headlight switch controls my fan etc

Considering your post from a few minutes ago, that was fast. Please share what you found.

-

Something's wrong, headlight switch controls my fan etc

You'll probably continue to have those problems until you remove the previous owner's modifications.

-

SteveD

Another possibility, though it may be remotely is the resistor is dying or not making good electrical contact. I say remote because resistors usually fail open or closed, not displaying intermittent failures while dying. Sent from my SM-S320VL using Classic Zcar Club mobile

-

New member introduction - My 76' 280Z in Atlanta

Now that's a horse of a different color. If you hold the throttle at a certain position and the engine doesn't maintain speed, it's likely that the engine is running out of fuel. You need to check Fuel pressure Float levels Since you say you have already set the float levels, you might want to check fuel pressure. Here's the gauge I have in my car: https://www.amazon.com/gp/product/B000CIH38M. You will also need this adapter if you are running standard fuel lines: https://www.amazon.com/gp/product/B00093CL3M. You should be running about 3 to 3.5 PSI IIRC. If you have enough pressure, then you probably don't have your float levels set properly. If the pressure is low then it's probably 1 or more of these: Weak/undersized pump Rust/pinholes in the pickup in the tank Kinked fuel line Partially blocked fuel line. Fuel filter that is getting loaded up with crap from the fuel tank. If you get to a point where you want to throw your hands up, I can refer you to a number of people in the area I would trust to resolve your problem.

-

New member introduction - My 76' 280Z in Atlanta

Since carb cleaner or starting fluid is flammable, your engine treats it as fuel. If you have a vacuum leak along say a gasket at the insulator blocks, that leans out the engine. When the carb cleaner gets pulled in through that leak, your mixture isn't as lean. Another method I've used in the past was an unlit propane torch. You barely crack it open, and when you get near the source of the leak, you'll hear the engine speed increase.

-

Tach swap now guage lights don't work?

Make sure the gauge body is in firm contact with the chassis. If you were testing the gauge without having securely mounted it in place, it would not have the ground for the lights. If you did have it attached with screws, examine the gauge and dash mounting points for rust or other debris that would insulate the gauge body from the dash.

-

New Z owner here!

Welcome. Do yourself a favor and download a copy of the factory service manual to start off. It has a lot of the information you will need to maintain your car. You can find a link in my signature, though I'm not sure the signatures show up on mobile devices.

-

Better Headlights Details

Incorrect. The 280Z does NOT have relays in the headlight circuit. All of the current for the headlights go through the contacts in the headlight switch. This means the contacts can foul, just like they do in the 240Z switches. Therefore, the 280Z would benefit from a conversion to relays. The catch is that the connectors changed between the 240Z and the 260Z. While Dave Irwin @Zs-ondabrain was able to source the 240Z connectors, he could not find a vendor that had the 260Z/280Z connectors. That is why there is not a plug and play solution for the 260Z/280Z. Dave has made custom relay harnesses for owners of those cars who have supplied their own connectors. Keep in mind that a voltage drop will severely curtail light output of the headlights. (https://www.danielsternlighting.com/tech/relays/relays.html) About 16 years ago I did a relay conversion to my 240Z. The voltage at the headlights (with the car off) went from 9 to 12 volts. That means the headlights were about twice as bright as before.

-

Plugged return fuel line

10 AWG solid wire: https://www.amazon.com/Ground-Wire-Copper-Listed-SATELLITE/dp/B00JJTPWII You can also get 8 AWG bare solid wire from Home Depot or Lowes for 59 cents/foot. That's a little over 1/8 inch in diameter. It should fit inside the return line easily.

- BRAKES LIGHT AND LEFT REAR FLASHER

- BRAKES LIGHT AND LEFT REAR FLASHER

-

Something's wrong, headlight switch controls my fan etc

Or I have a 73. The 73 was the first with intermittent wipers, so the combo switch has a 9 pin connector on the headlight switch side.

-

Something's wrong, headlight switch controls my fan etc

No problem. Now I can make sure I'm looking at the right wiring diagram. What I'm afraid of is that someone put in more than just the one wiring hack we see in your photos. We already know of one cross-linked circuit. There may be others. It will require a visual inspection on your part to identify where they are and what color wires are involved. The butt splices may help us in locating them. When you took out the dash, were there any connectors already apart? If there were and you remember where, that may help us further.