Everything posted by ToolBoy

-

Rear control arm bush alignment

Thanks for forwarding all this great info. Probably won't have the parts for a week but will read this all thru several times and then again while I'm doing it. Bearings and seals for rear stub axles are arriving today. I'm really hooked on the mustache bushing conversation and determined to find a better solution than the pu product at some point. Great that many others are interested in the same. My car was driven into the ground and then parked with the fluids in it for 18 years, fortunately in a garage in phoenix. There is absolutely no rust but everything else is shot. I just acquired a hoist and hope to pull the engine in next month to look at possible electrolysis damage, general condition and get fussy with the engine bay. Most of my Pa. memories are as a little kid. Moved from there when I was 12. Dad was a pretty well known architect in Lancaster. I used to pedal to the book store in the student union bldg. at F and M on a schwinn ram's horn fastback. (Ha Ha) . . . From there to Corrales, New Mexico for almost 10 yrs. and then to L.A. area in 79. Been at same place on Palms in Venice since 97. Yes, we have probably crossed paths at some point. As artist Barbara Kruger said, "it's a small world, but not if you have to clean it"

-

Rear control arm bush alignment

I just ordered 55554-E4100, 55555-E4100 and 55541-E4100 and cut and burned out the old rear transfer link rubber bushings and I'm fixing to press in the new lower ones when I have 'em in hand. (nissanpartsdeal.com seemed to have the best price). The space between them obviously needs to match the corresponding width of the strut assembly but the FSM talks about aligning the two bushings so the spindle will pass thru as though they won't on their own. Can anybody share wisdom on this task? Do I need to have the spindle temp- installed for alignment? Not sure what's happening here? Thanks. Andy

-

Brake Booster Rebuild Help

Thanks for the follow-up. The rod does look good although it might have a few tiny chips in it and I don't remember if I used the plate and seal from the kit or the one that came with the car. The first time I checked vacuum it held and the second time it dropped a little. I cut the gasket myself but given the new info I'll leave it off when I reassemble. You're in Philly? My mom's brother lived in Philly for 30 years and my mom is from Beaver Falls. I'm originally from Lancaster.

-

Brake Booster Rebuild Help

Perfect, I never noticed that passage before. I'm hoping I can get plate/seal/rod to seal well enough.

-

Brake Booster Rebuild Help

I wasn't sure and knew if it wasn't right I would hear about it. Thanks for that. I'll look for that hole too.

-

Brake Booster Rebuild Help

Hey HappyZ, Glad to help out a little as most of the time I'm confused and terrified. After I had mine torn apart I went to the local Z mechanic to find out how the poppett assembly came apart. He said he didn't know as he had never done it and always "sent them out". The guys on this site saved me on that one. When you tear apart the entire unit and study it you see that the vacuum is held inside the front shell between that shell and the big rubber diaphram that is included of the rebuild kit. There are only a couple places vacuum can escape but one is to the front around the plate and seal and thru the pushrod. My suspicion is that if you don't have a perfect seal at the plate and seal, the installation of the master cylinder stops the vacuum after it has been fitted. I think I checked vacuum only after bolting that on. ( I think ).

-

Brake Booster Questions - Please Look :-)

I finally looked at this. When you buy the rebuilt booster there are issues with the threaded rods not lining up at the firewall and they warn that it often needs to be customized to fit your car. I bought the master rebuild kit and it was challenging but I got through it. Mine held vacuum after I was done but I tore it completely apart as my photos indicate. I also cut gaskets for my spacers and plan to silicone them in in case there is a potential vacuum leak there.

-

Brake Booster Rebuild Help

Just occurred to me when thinking of your initial question. The rubber reaction disk "E" that sits against the pushrod can fall inside the housing when the pushrod is removed if one isn't careful.

-

Brake Booster Rebuild Help

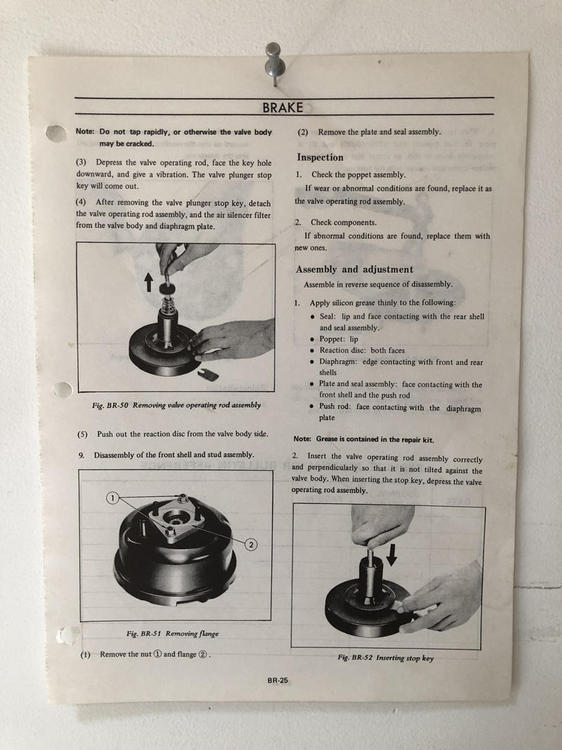

Ah. . . here. See page from FSM that lists parts that get silicone grease. . . calling it "plate and seal". Part can also be seen in second photo first column.

-

Brake Booster Rebuild Help

Not sure if that disk gets glued in, mine's just sealed with grease but might be a good idea.

-

Brake Booster Rebuild Help

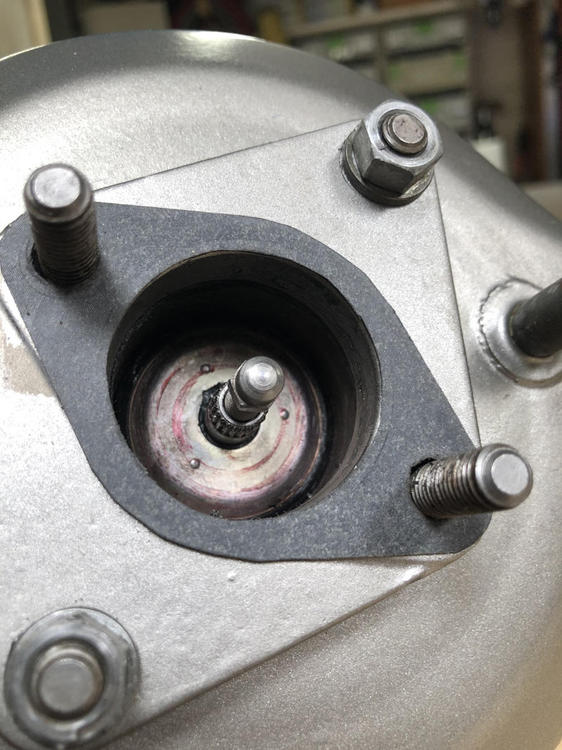

Hey Happy Z, It's been a while but I haven't put the booster back in the car yet so I was able to remove the parts as shown. The push rod "D" is only stuck to the reaction disk "E" with the silicone grease and it's kept from falling out when the master cylinder is bolted in. That push rod "D"seems to be centered with disk "N" that's pressed into the front of "A". I was thinking that Disk "N" needs to seal against "D" but I'm hoping that vacuum will be sealed on the other side after the master cylinder is bolted on. Mine is holding vacuum when tested but I can't really test in the real braking world as I won't have the car running for some time. I've attached a photo of the front pulled apart to Illustrate. I wish I could say I have it assembled correctly but at some point I was winging it as I didn't take as many photos as I should have. Good Luck. . . Andy

-

New mustache bushing updates?

Follow-up to Zed Head's suggestions yesterday. I scored, pounded over and finally removed much of the rolled in part of the remaining bushing sleeve hoping to create that "gap" and allow the poly bushing to seat. As it turns out the spacer is still shorter than the overall bushing height (3rd photo) so will require considerable compression to get the washers against that spacer. All the big flat washers that came with poly bushings have same hole I.D. Is one able to reuse the stock washers shown above on the poly bushings?

-

New mustache bushing updates?

Thanks, that's great!! When I said "fit" I meant they will press in to the old sleeve from the one direction. I'll start by peening that edge out as now it curves in and is way too small and sharp for the bushing to pass. I've heard of some folks drilling 1/8 inch holes in the poly bushings every 90 degrees to soften them up a bit and can be packed with pu lube. Any opinion on that and is there any availability of rubber bushings here?

-

New mustache bushing updates?

The poly bushing fits everywhere except the edge where I notched it with my jigsaw. Could I not carefully remove that inward curling flange? . . . and if not, I haven't seen the stock rubber bushings available. I would prefer those anyway.

-

New mustache bushing updates?

Thanks for the reply. . . Bottom of the sleeve lays over and top of sleeve curls in. I helped the removal along with a jigsaw not realizing I might need to keep the sleeve. Does this sleeve need to come out too? Bushing seems to fit snugly an bottom as-is.

-

New mustache bushing updates?

I just burned out my old decrepit mustache bushings and wondering if there is any new availability on a rubber product? I searched and the conversations I found were from 2017. Hoping to not use the urethane ones I bought in the beginning. . . . and if I use the poly ones do I need to grind off the lip that turns inward in the existing outer shell of the original? Thanks. . .

-

Outer Tie Rod Ends

I did hear somewhere not to pre-grease the lower ball joints before getting the castle nut on because too much grease will keep it from closing up.

-

Outer Tie Rod Ends

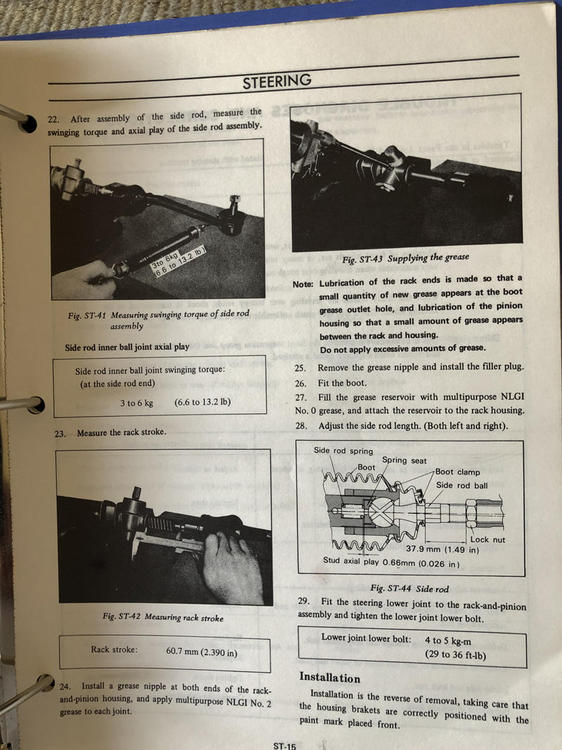

Hey Bill, I've included a page from factory manual that gives rack lube instructions. (another set to consider). It seems to state that No. 2 gets used on the rack and pinion gears and the only place they specify No. 0 is in the little gravity feed reservoir screwed to the top of the housing. Zerk fitting is temporarily borrowed from pinion housing to grease tie rod inners thru the hole on the rack shaft and then reinstalled on housing. I have always wondered why the diffo grease here and I was guessing it might flow easier down into the housing when needed?? After researching I'm using same grease that was used on my wheel bearings as shown. 50 years ago the manual asked for a lithium based No2 Grease and this red stuff is lithium based. If anybody wants to chime in and give me a thumbs up or down I welcome the input. Good Luck!!

-

Staked Nut and Steering Gear

Hey Captain. . . Thanks for that. . . I have read several iterations of the nut removal and tried to imagine the force it would take to push that staked portion away with just brute force. Nice to have a better way based on real world execution. Dug out my 1 hp dremel today. Thanks again. . .

-

Staked Nut and Steering Gear

To Zed. . . I was just surprised to see it. The savings in manufacturing hundreds of thousands of one part vs two held against the aesthetic of looking at the underside of the car and seeing one "upside down". Is it the same thru the entire S30 line? That might have been an interesting decision to witness. Does it show up anywhere else on the car? Just curious.

-

Staked Nut and Steering Gear

Anybody know how is it possible that these two parts aren't mirror images of each other?? I thought someone made a mistake and then I looked at photos and the FSM.

-

Staked Nut and Steering Gear

One final question. . . (for now). What does it mean "do not release caulking" when breaking the nut loose?

-

Staked Nut and Steering Gear

Thanks a million to all!! That reference to Mr Hoover's photo step by step is awesome. I need to pick up a few things but now I'm dying to get these stub axles apart. If I'm unable to find a suitable rack and pinion replacement I'll contact zKARS too. As I have the entire housing bead blasted and meticulously painted I'm hoping I can just swap out the better gears when I find 'em. Jan 71 # 19500. Also need to check if my torque wrench goes to 240? Thanks again!! Great to have you guys as a resource!!

-

Staked Nut and Steering Gear

Hello to all, I have two issues that I'm putting out there in hopes of some guidance (maybe from the old school?). I have entire rear end and diff out of my series 1 car and I'm trying to remove the staked nut from the stub axle. I've cut away a good deal of the staked part of the nut and now hearing I need to put most of it back in the car to remove the 240 ft lb nut. Is there another trick to breaking this nut loose? The nut is also on the inside of the hub and I'm wondering how one gets a good position to crank on that nut? It seams to be regular threaded but a confirmation of that would be appreciated too. I'm also having trouble locating a used rack and pinion gearset that doesn't catch in the middle as badly as the set that came in the car. Already sent one back from ebay. I have the bearing and seal ready to go but my gears are worn in the straight ahead position. Anybody have a source of these parts used? Thanks to all . . . Andy

-

Locating rack/pinion parts car19500

Thanks Patcon. . . I was able to find the pinion bearing and seal today and I'll have it soon. If new bearing doesn't at least improve the catch I'll be shopping around. Somebodies rebuilding and selling them so there might be a pinion gear out there somewhere. Maybe not.