Everything posted by duffymahoney

-

'71 temp sensor thread size

I have an updated sensor I would sell cheap that I have left over for it. Shoot me a message.

-

Duffy's 1/71 Series 1 240z build

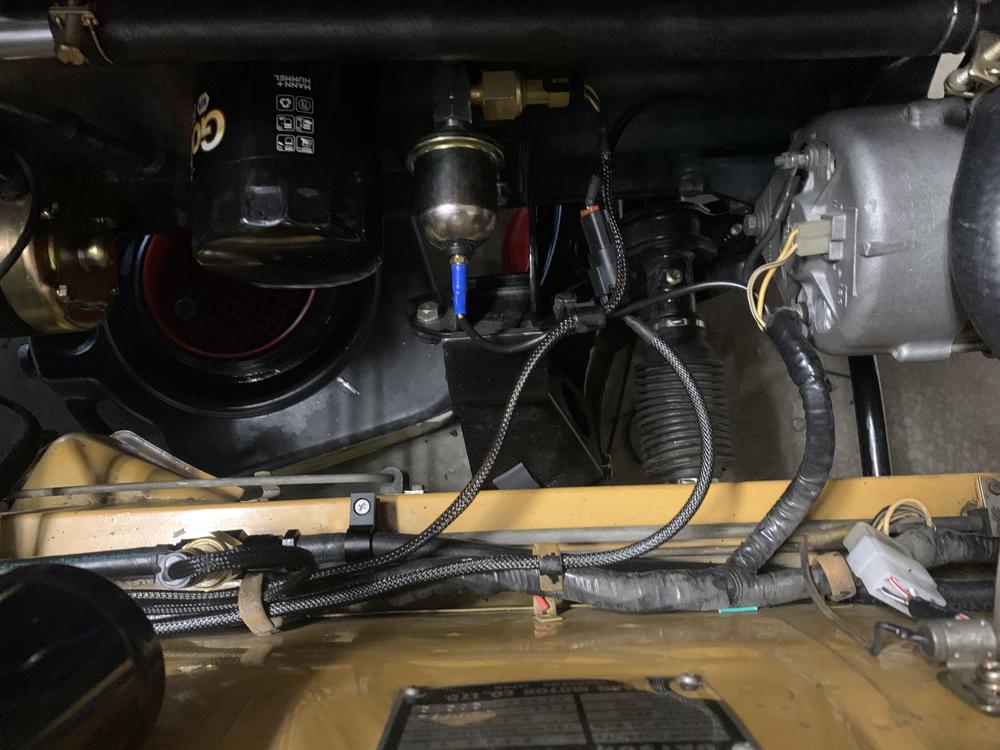

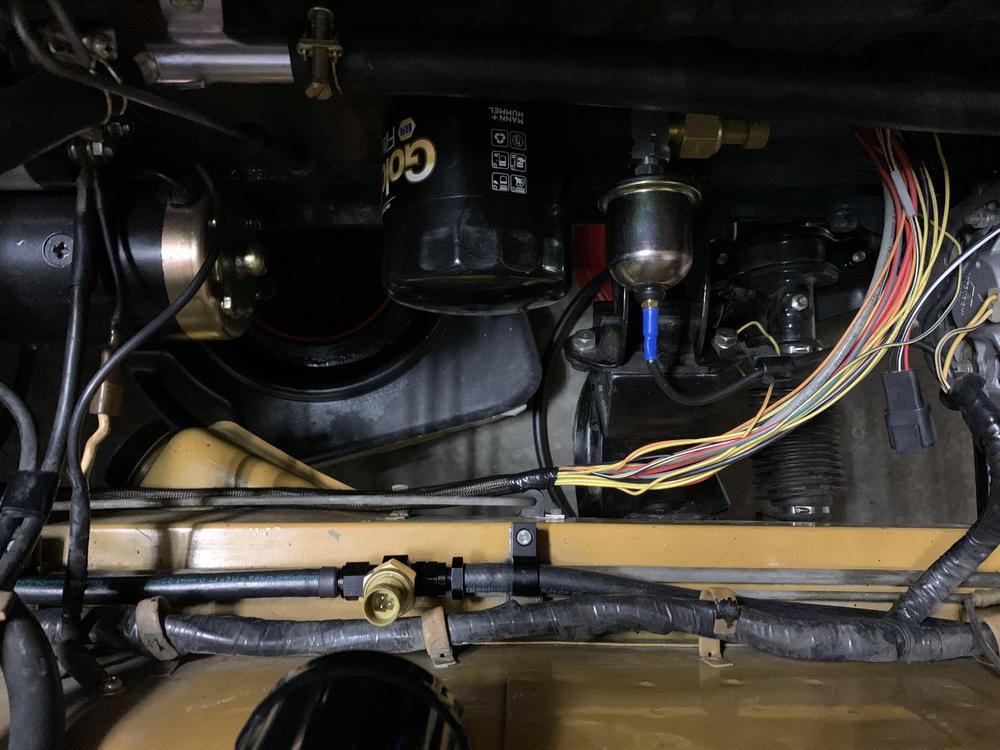

I am going to attempt to move my FPR to the drivers side and use it. That way I am hard lines under the car. I will T the return from 7mm to 5mm and return via the stock 5mm line and the 7mm vapor vent line. Then use the 5/16 to feed the ITBs. Hopefully it works! I bought some 7mm efi fuel hose from belmetric. So that should give me a good amount more flow. Hopefully my push lock fittings work with it. My FPR mount was waiting to fail, i cut a lot of the strength out. So I will need to fabricate another and put it in my stock coil spot. Should end up looking pretty clean and simple.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

First major setback. The return stock hardline is too small and is causing pressure to build up. Lowest I can get is 75psi. My plan is reuse the 8mm fill line as my new return then run 3/8 new flexible hose from the pump to the fuel rail. Then 5/16 line from the FPR to the 8mm stock line back to the tank. Then Y the 8mm (5/16) hardline to stock 5mm return and the 10mm tank vent.

-

Triple Mikuni Tuning Manual?

Here is the original.Pm I can send you one, that I would rather not share. http://www.tuning4performance.com/documents/Mikuni -44-PHH-SM.pdf

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

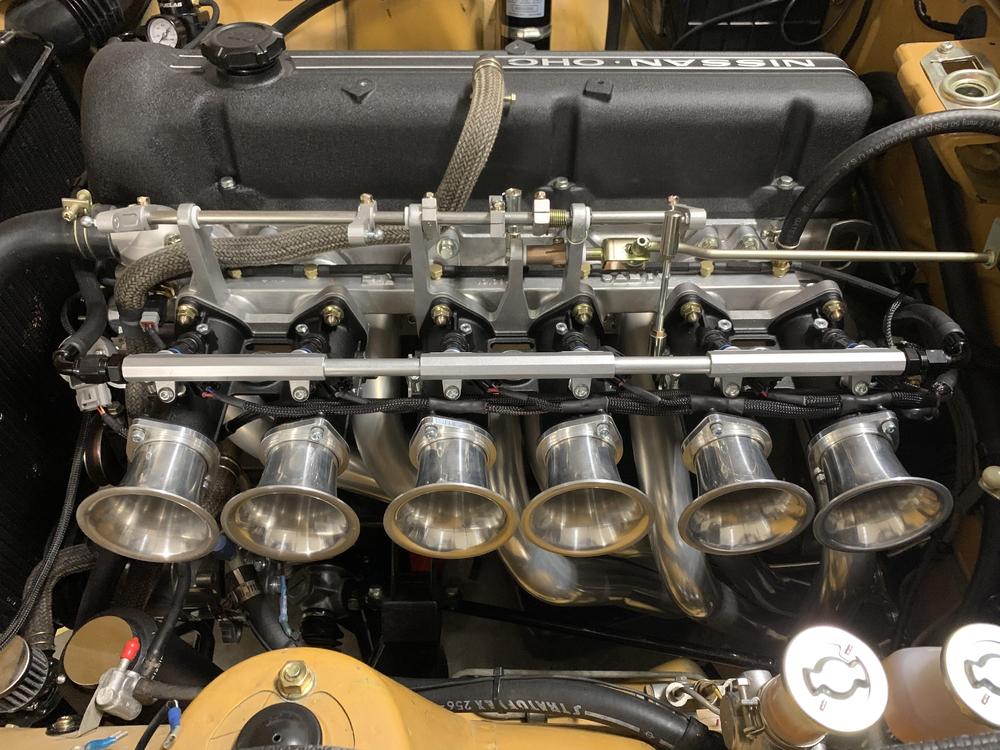

I sold my tirple Mikunis for a lot a lot of money, I won't come out even, but it will be pretty close. As far as the wife knows, it will be even:) From the videos the noise they ITB is similar, I think the main difference will be the noise that the accelerator pump gives the car. That growl. I would guess that will be gone.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

-

Duffy's 1/71 Series 1 240z build

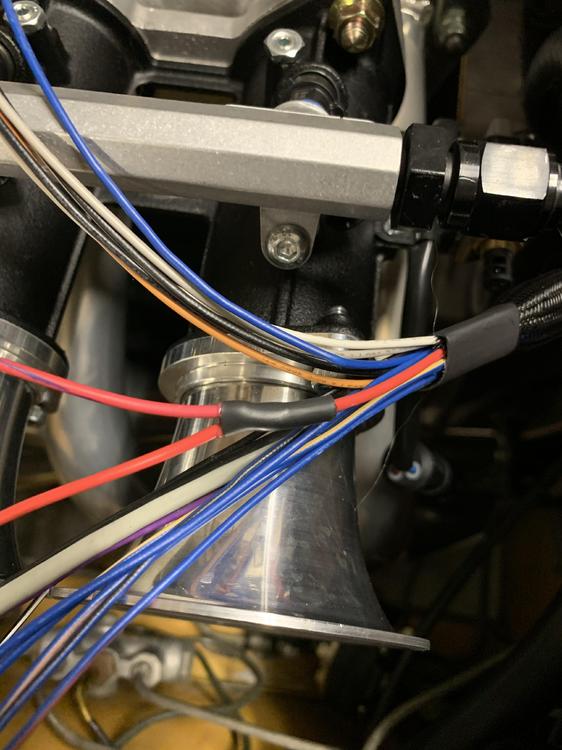

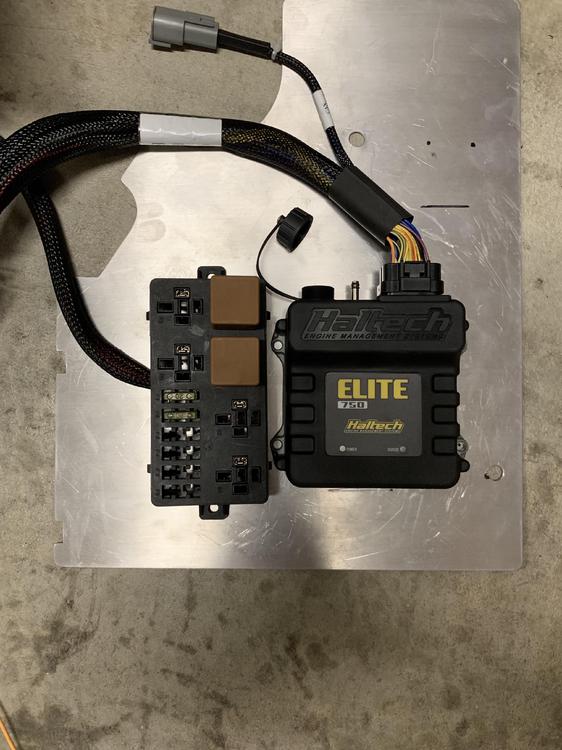

I got way further on my ITB install. My kick panel mount worked perfectly and I have about 2 spare inches on the wiring harness. I successfully installed it all with zero cutting of my stock harness and zero new holes which I’m pretty happy with. Now the hard part. Making all the shrink wrap and loom look clean.

-

Duffy's 1/71 Series 1 240z build

Well I found a 2nd hole I didn’t know I had. I tested it and I should be able to fit all wiring with zero new holes in the car. So that’s a full efi install with zero holes or Permanent mods! Stoked. 02 sensors go through the shifter hole. Tps, air temp, coolant temp, home signal and injectors through the choke hole. R35 coils, crank trigger, oil pressure, fuel pressure, dual positives and ground will go through the hole below the stereo.

-

Duffy's 1/71 Series 1 240z build

Dampener doctors rebuild my stock Dual v crank pulley (keeping AC) . Then this is a 60-2 trigger from Hoke. I had to lathe off the back slightly. The trigger ring was not made for my pulley. Works awesome. It’s a great kit. I will have it professionally epoxy painted black. They must of rattle canned it.

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build

- Duffy's 1/71 Series 1 240z build