Everything posted by 240260280

-

Weber selection and initial jet tuning

lNo need to rush. Life is more important. I read the Tom Monroe Engine Rebuild book's section on engine noise and it mentions rod knock can occur on deceleration. If the noise is still there, it may be best to drop the pan and see what is going on. A first step would be to do an oil change and filter the oil to see if there are bearing fragments.

-

Complete Triple Weber 40 DCOE set.

Cliff, I have a friend who may be interested. I'll let him know. Philip

-

Weber selection and initial jet tuning

Just a thought: I think the characteristic shape we see with all E Tubes where the richness over-shoots on launch may be due to the squirt from the accelerator system. The area in the dashed box below is what I refer too. I think the liquid fuel squirt is too much and it over enriches the A/F ratio. I also think it continues for a while as the liquid will hit the manifold walls and will take time to evaporate and become consumed. (See the MP4 video below) Weber 40 DCOE acceleration jet.mp4 To test my hypothesis, once your valve train is sorted and you do some F2 runs. I would be grateful if your could do a run with the spill jet (item 12 in drawing below) blocked by metric bolts. This will turn off the accelerator circuit and hopefully remove the rich dip on start. Thanks!

-

Weber selection and initial jet tuning

I did a search and one possible cause could be timing chain tensioner not taking up slack and the noise would be chain slap. You may be able to replicate by revving a warmed engine by hand. For valve noise: You can pull plugs and use a remote starter to turn over engine. While it turns, a mechanics stethoscope can be used to hear valve noises. At high rpm deceleration, there is considerable vacuum pull in the cylinders but it should not rattle anything.

-

I.D. This Steering Wheel!!!!!!!

Looks like an aftermarket Nardi:

-

Bought # 4858

I cleaned my cam (above) with scotch brite pad. Some light oil helps too. Those spring retainers are titanium or aluminum.

-

Bought # 4858

-

Weber selection and initial jet tuning

You can pull each plug one-at-a-time while idling to see which cylinder is at issue.

-

Weber selection and initial jet tuning

Check your valve lash for the tapping. Usually that is the cause and an adjustment will cure it. Also make sure the rockers are getting oil form all holes in the lobes or oil bar.

-

Weber selection and initial jet tuning

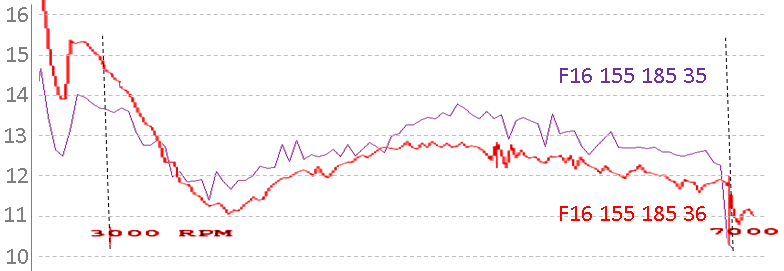

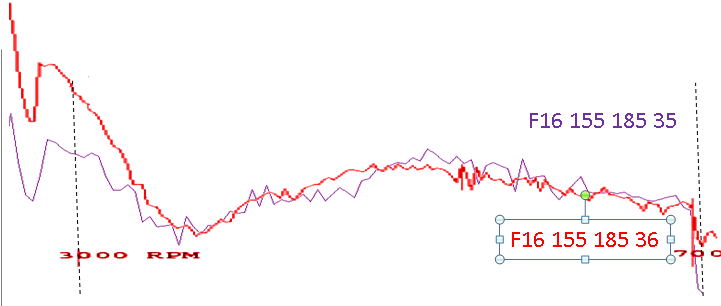

It is interesting comparing the 35mm to the 36mm choke. By Shifting the curves on top of one another and ignoring the a/f offset, the shape is the same except: - The 36mm is much leaner in the low end. - In the middle just before the peak the 36mm gets slightly leaner then it gets slightly richer at the peak. (Below)By aligning each plot to the AF Scale, 36mm seems to be richer in the mid to high; but this may be due to the variations that seem to be going on with the meter. One would expect the opposite: more dilution due to less venturi pressure drop (aka signal) to pull the fuel out of the well with the larger 36mm choke.

-

Weber selection and initial jet tuning

The curve is a lot flatter in the lower RPM's than the F16. This is very interesting. btw the Weber Tuning Manual recommends F2 emulsion tubes for cylinders whose range covers the L28 displacement. You should also consider 240 airs.

-

Weber selection and initial jet tuning

Be wary of Hybrid Z posts...especially the Weber stuff on that site. The scientific method is usually missing. They did not even recommend changing E Tubes in the thread nor could I see a mention of it? If you look at the range of their curves in the thread you references, it is > 3 A/F Ratio points, your best is less than 1.5 with the F2 and 2.3 with the F16. For your solution, the F2 will need smaller mains. Fuel height is another tuning parameter but it is labour intensive so we can call it quits for the testing and I can pick it up again when I get my SK's installed. They have external fuel adjustment. to make things easier.

-

"NOT OK" Stickers

http://www.reuters.com/article/us-nissan-safety-checks/nissan-to-recall-1-2-million-cars-in-japan-over-unauthorized-checks-idUSKCN1C716O?il=0

- WTB 260z Full Engine Gasket Kit

-

WTB 260z Full Engine Gasket Kit

WTB 260z Full Gasket Kit

-

My two swiss S30Z Fairlady Restoration build thread

-

Weber selection and initial jet tuning

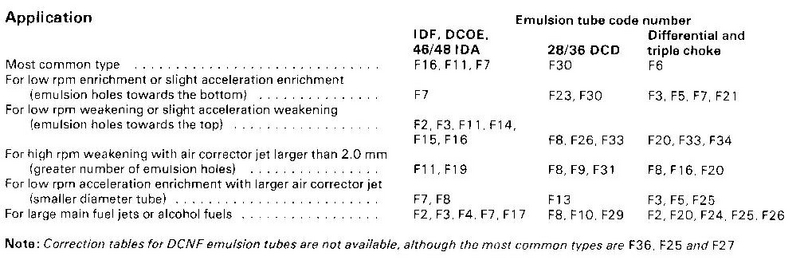

Hopefully when the main is reduced, the higher end of the F2 curve will lean more. Below are some general ratings and specs of E Tubes. The trend from F16 to F11 to F2 above has the tube diameter going from 8.2mm to 8.0mm to 7.5mm. This should enrich the mix as we observe. The drawing also shows F2 has the leanest low end of the 3 tubes tested. This agrees with the shape of the curves above. It is interesting to note in the hand drawing below that the F2, F11, and F3 have holes in the middle of the E tube. I think the F3 could flatten the shape even more by leaning the low rpm area. It seems this leaning also affects cruise (as you noted). If the cruise is too lean then the idle jet may need to go larger to compensate. So far from the E Tube swap experiments, the effects are subtle, and the defacto F11 and F16 tubes used in most Z's may not be optimal.

-

Weber selection and initial jet tuning

Not as big a difference in the shape as I had hoped. The biggest effect of changing E tube is like changing main jet... i.e. richness. All curves have the same hump in the middle so this can not be tuned out by e-tube. It may take fuel level or choke size. A smaller choke will cause high end richness and too high fuel level will cause low end richness. Your observations seem to match the curves: The F11 seems to be best near the start of the run (12 to 13) so you will see good power here. The F2 is the flattest. I agree with you. Please try smaller mains with F2. Hopefully the shape will change too.

-

Weber selection and initial jet tuning

F11 is slightly flatter but richer overall. F2 will be interesting. I am traveling and will post plots Friday evening. Great work to collect so fast. I am impressed.

-

Weber selection and initial jet tuning

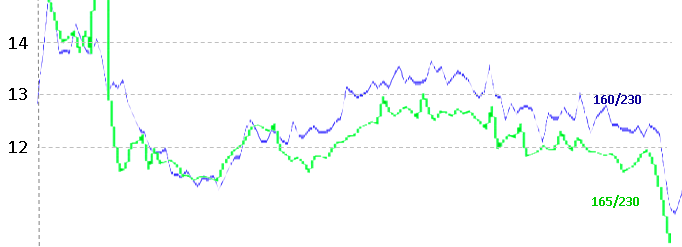

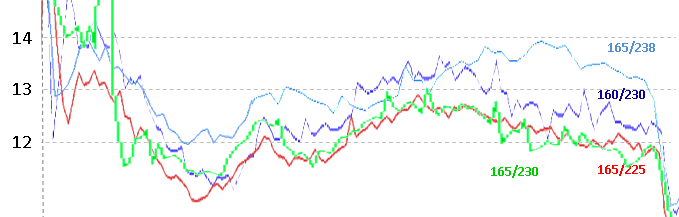

The data seems to scale correctly now but the air is not doing enough to raise the top end and flatten the curve. I think a manufactured 240 air with 165 fuel is needed. The 160/230 is the best combo so far. Please keep the 160/230 and give the new E-tubes a spin! (Let the fun begin! )

-

Winter Blend Fuel

This "fuel" is a big lie just like "speculation" of the price of gas. Govt should stop the energy cartel from these games. With global warming the winters here now start in Feb (compared to November) and they are shorter..... it should be called "spring blend gas" if they wanted to sync with the actual period where the temp is significantly lower. I wonder what they sell in Calgary where it can snow in August and you play golf in January.

-

WTB: 240Z Grill Parts

Jim, I'll check in the parts barn next week.

-

Thinking about installing an BMW M6 engine in my Z

WOW that is ingenious! Just like on modern cars but better implemented.

-

Weber selection and initial jet tuning

Could you please try the 160/230 again to rule out the anomalous data?

-

Weber selection and initial jet tuning

I did a comparison and the newest data (green) now looks normal across the rpm range. The160/230 (pink) run seems anomalous with the big hump in the middle and may not be valid. The data also shows that the 225 and 230 air correctors are too close to make a difference. I am now thinking the drilled 238 may be flowing more than a "manufactured 238". So a 235 or 240 air corrector may flatten the curve. Removing the pink data gives: