Everything posted by 882993md

-

CamTower 12mm bolt torque question

Thank you Howard

-

CamTower 12mm bolt torque question

Hi: I found my cam tower bolts on the passenger (higher) side loose. I torqued them to 13 ft lbs. My question is what about the driver side cam tower bolts that share the same space as the head stud bolts? I checked and they are tightened very tight. Are the driver side anchoring in the engine block or the head? Should I loosen them and retorque to 11-13 ft lb? Thanks. Howard ’74 260z

- Adjusted valves for the 1st time; questions regarding engine temp. and lock nut torque

- Seat belt release attachment point-correct belts for 260z?

-

Seat belt release attachment point-correct belts for 260z?

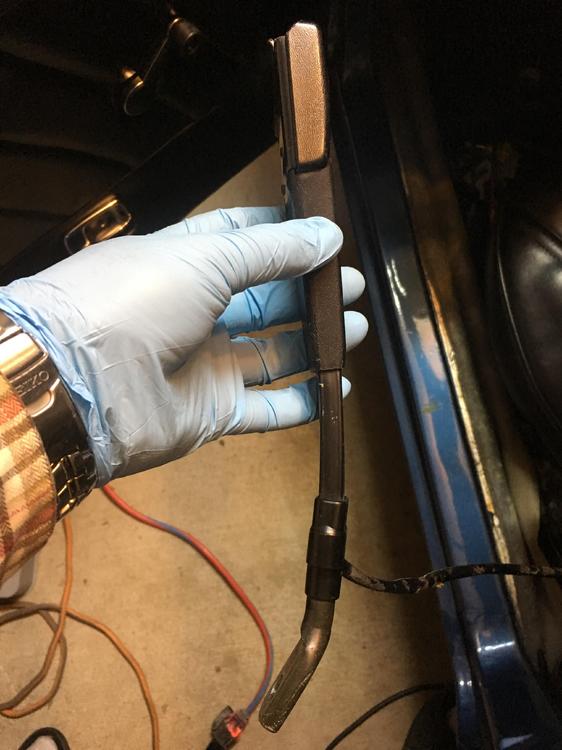

I scoured the internet for 240z/260z seat belt location/attachment pictures and was able to find the following pictures. It seems my latch side doesn't have enough of the L bend in the bolt hole part. I'm thinking possibly about using a MAPP gas torch to heat it and try bending it in a vice with help from a hammer. if the results aren't good I will just have to spend money on the Wesco roadster belts. Howard

- Seat belt release attachment point-correct belts for 260z?

-

Seat belt release attachment point-correct belts for 260z?

Hi everyone: I’m installing my seatbelts and the shoulder belt portion is fine. However the side with the release latch I can’t figure out how to attach this. I thought initially the bolt hole would be on the transmission tunnel but then I see this attachment point. If I try to attach it so that the receptacle is pointing forward (between the tunnel and the car seat) it’s impossible to get a secure connection. There is a curve in the body that doesn’t allow the seatbelt attachment point to lay flat. If I orient the belt so that the attachment point lines up perfect, then the belt is basically pointing towards the back of the car versus forward. I was also thinking do I have the wrong belts for my 260z? Howard

-

Adjusted valves for the 1st time; questions regarding engine temp. and lock nut torque

Hi everyone: I just adjusted the valves on my 260z (first time ever performing valve adjustment on any car). I did get the engine hot and had all my tools ready and I had antiseize on the sparks plugs. It took me a while and by the time I was done with the last set the engine was barely warm. I’m thinking I should try it again with the engine still hot when I’m done? I also had to redo several of them as I was tightening the lash was thrown off and when I double checked it was too tight and I had to redo it. Any tips for holding the setting while tightening the 17mm locknut? Lastly is it ok to get the 17mm locknut really tight with a wrench, then come back later to torque it to specs, or would I need to torque it from the outset? Howard 1974 260z

-

Can't get timing to less than 25 degrees?

Great news everyone: I reinstalled the distributor, crossed my fingers, and checked the timing: it was 15. So I twisted the distributor and lo and behold I had good range up and down the timing scale. I set it at 10. I think what also helped was the 8mm adjustment screw was loose from the disassembly. I notice I have more range of movement now for retard/advance. Howard

-

Can't get timing to less than 25 degrees?

- Can't get timing to less than 25 degrees?

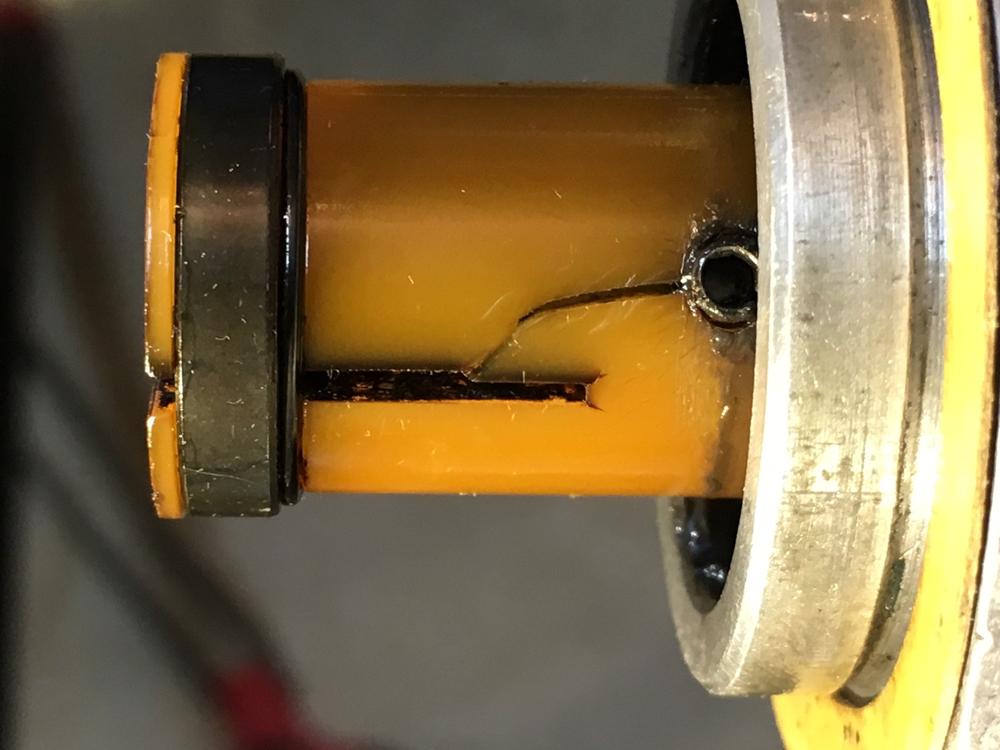

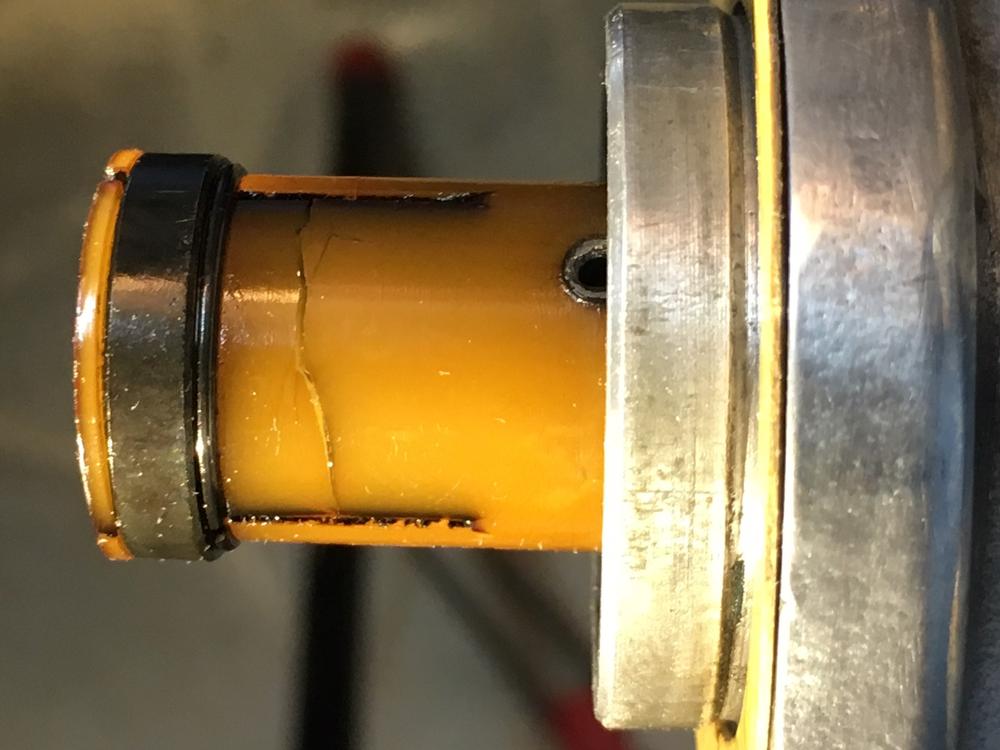

Hi everyone here is an update: I put the vacuum tube back on the revved the throttle and the timing did advance. I used the advance knob on my timing light to zero the timing and it showed 29 on the knob when revving. So I pulled the dizzy and verified the oil pump is at 11:25 at TDC. I did find this piece of metal (looks like a staple) on the stator. I don't know if may have caused a jamb in the breaker plate? Stator appears in good condition. I totally forgot to verify the zx mount so I have to check when I get home from work today. I don't have a vacuum pump and I tried to suck on the tube on the diaphragm and the breaker plate moved a little, but I need to properly check it with pump. It seems the unit is in overall good condition except for the plastic collar at the bottom. Anyone know if this is sold separately, or if there is a generic replacement? Or do I have to replace the whole distributor? Should I continue with disassembly or reinstall and see if that loose metal was the culprit interfering with the timing? Howard- Can't get timing to less than 25 degrees?

Thanks everyone I have my to do: 1. Reconnect everything and apply vacuum and see if timing advances or is stuck. 2. If stuck check breaker plate. 3. Check for ZX distributor mount. As far as I know it’s its just a standard oil pump. Howard- Can't get timing to less than 25 degrees?

When setting the timing I unplugged the hose from the vacuum advance and plugged it. I also capped the the port on the carb that the hose attached to. Should I not plug the vacuum advance hose, or does it not matter? Howard- Can't get timing to less than 25 degrees?

Hi everyone, My car is using a 280zx distributor, I checked my timing last week in anticipation of fine tuning my carbs. It was set at 15 degrees and I wanted to check on this forum to see what was best for my set up. The consensus after searching was 10 degrees. So I go to use my timing light and holy *** my timing is way off at 25 degrees. When I turn the distributor it will come down to 20 degrees before stopping it's range of movement. I thought maybe my harmonic balance slipped and messed up my TDC mark. So I put the engine to TDC with the pulley detent at the zero mark, #1 piston on compression stroke, intake and exhaust valves lobes pointed up and away, notch in cam sprocket aligns with groove. So harmonic balancer is ok. However I noticed that my distributor rotor is at the 8 o'clock position and not 9 o'clock to line up with the #1 spark plug contact. Should I put it back at TDC and pull the distributor to see if the oil pump is clocked at 11:25? It totally puzzles me how it can go from normal range to such a high timing? Howard 1974 260z- Plugging open port on underside of exhaust manifold

Hi Jason, Yes you did. I decided not use to use it for now due to heat. Howard- Plugging open port on underside of exhaust manifold

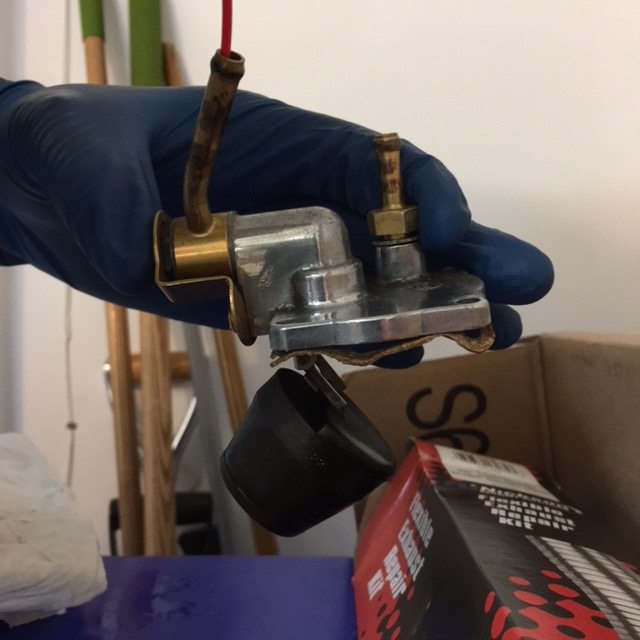

I installed this 3/8” BSP plug I ordered from Amazon. I also used Permatex muffler repair goop to help it seal. Hopefully the brass will hold up to the heat. My car is now quiet and I get on with adjusting the carbs without fear of my neighbors complaining. Howard 1974 260z- Plugging open port on underside of exhaust manifold

Hi everyone, I was dreading the exhaust sound which I thought was a cracked header. I stuck my phone down there and took a picture. Apparently there is a port (assuming emissions related) that is venting exhaust. Would anyone know what size thread I would need cap this hole? Thank you. Howard 1974 260z- Gasoline dripping out of air intake ports

- Gasoline dripping out of air intake ports

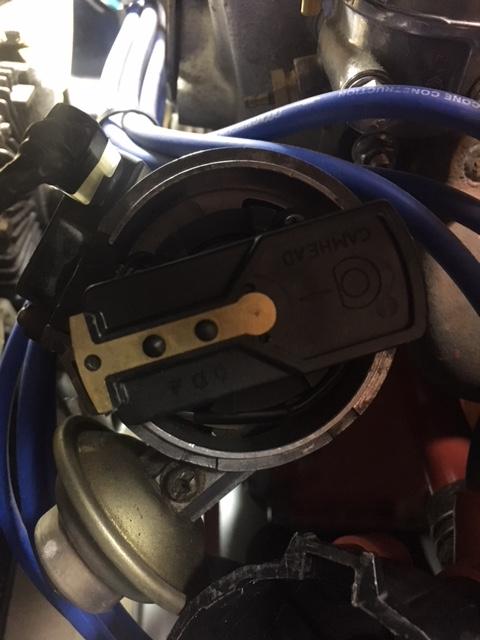

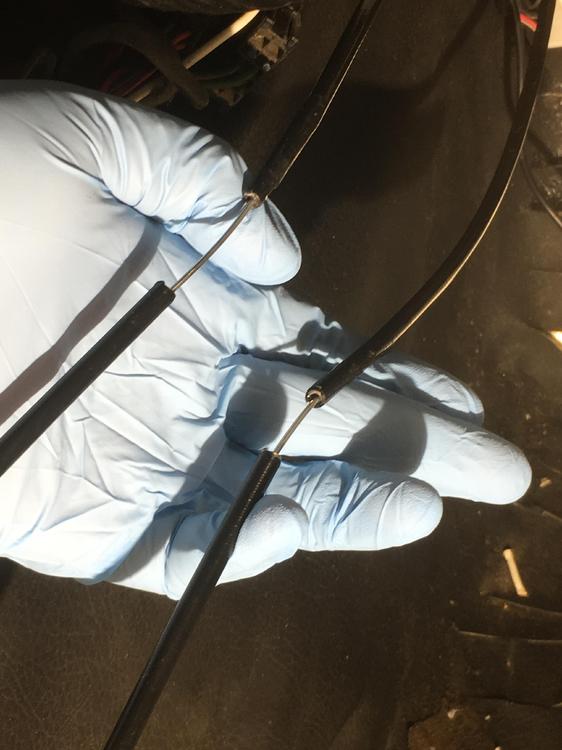

I removed the float bowl covers and drained and cleaned the bowls and flow control valves with B-12 Chemtool. I sprayed into the fuel feed tube and turned it over to drain. I did that several times and hopefully that removed any possible sediment in the control valves. I have to replace the cork gaskets as they are falling apart. I did notice that the pin that secures the float bowl slides without any sort of stop or tension. I don't know if the sides of the bowl prevent the pin from sliding, or if this is an incorrect pin. Both choke wire plastic casing are broken (under the dash). I will order some bicycle wire casings to replace from the levers to the carbs. These are three screw carbs. Is there a standard setting for the float levels, or do I have to locate a model number somewhere on the carb. body for specs? Howard- Gasoline dripping out of air intake ports

It started fine and ran well. I still have to set timing but it responded well to the throttle revs. I shut it down when I saw the leak as I was afraid of it catching fire. Howard- Gasoline dripping out of air intake ports

Hi everyone, I got the exhaust finally installed and started the car up for the first time in a year. I removed the air filter so it was easier to work and I noticed that both air intakes were dripping gasoline. Upon closer inspection the backside of the orange air filter housing also had gasoline being deposited on it. Where you see my finger touching is the location the gasoline was dripping down on both from both carbs. I’m guessing the gasoline could be penetrating the gasket on the intake to the orange housing? I checked all the connections and rubber hoses and there were no leaks, however when I wiggled the float bowls they had some movement (I don’t know if that’s normal). I have to tune the carburetors so if the settings are way off, and it’s running rich, would a rich setting account for the abundance of gasoline exiting the intakes? This is my first experience with carburetor so I really don’t have a knowledge baseline to draw. Any help is appreciated. Thank you. Howard 1974 260z- Size of bolts on the bottom of the fender?

- Size of bolts on the bottom of the fender?

- Exhaust gasket material for flange gaskets?

HI: It just stiff paper like a manila foder but a little stiffer. I will go with some metallic or semi-metallic gasket. Thank you. Howard- Exhaust gasket material for flange gaskets?

Hi everyone: I ordered a collector reducer to connect to my MSA downpipe (to stock manifold). The collector reducer comes with a paper gasket. Is this paper gasket sufficient? I see that there are other varieties of gaskets like copper, aluminum, and non-asbestos type fiber material, but I don't know if they are overkill for a street car? Thank you. Howard '74 260z - Can't get timing to less than 25 degrees?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.