Everything posted by DaveR

-

Float level advice, please.

This is the first I had heard about the different heights of the float level (front to back Carb). Is that really a thing? The only thing that could have been different about the housings would have been the "ears" on the float housing cover possibly having some higher or lower through holes for the pivot pin. I honestly didn't check which one is in which location. Also, i opened up the grose jets and attempted to stretch to the spring out a bit. Didn't have much luck and I think I would have deformed the spring way too much if i pulled it any further. The first bit of the pins travel really has no strength to it. Sinks down with almost no effort so its no surprise that the float (however light it may be) pushes it down. This is the case with both sides (both jets) Should the float be resting on the retaining clip? Seems to be contrary to what I've read, but what do i know.

-

Vogtland springs

No worries, I read all the threads beforehand. My part numbers seem good, and my rear strut fits perfectly, as does the gland nut. I don't think I will need a spacer. The rear spring is short enough that I don't need spring compressors to get the hat on. I can put a little weight on them and get the nut started. Not sure about the front though as it's not off the car yet. I hope the ride is good though and not too rough, but I didn't want any issues that might occur with progressives. (Although most of those were probably mixed up back to front eibachs) FYI the following is definitely the case for 240's as well. I plan to email JDMWerks since I have some time before I will get to install them and see what they say. Really the answer doesn't matter since they don't sit better one way or the other (both ways sit pretty nicely) but I just wonder what their response will be

-

Vogtland springs

Received my 240 versions the other day, was expecting them to be the same top to bottom if not front to back. They are neither. Front versions appear to have 2-3 tight coils at one end. Rear ones appear more uniform. It is making me consider which way I should put them in the car (which end is up that is). Do linear springs often have tight coils at one end? Left: front Right: rear Left: rear Right: front

-

Vogtland springs

What did you use for the coil sleeves, and is it holding up? May go that route while I have the opportunity, but unsure of what material I should use that is thin enough but hopefully will do the job.

-

Vogtland springs

Cool thanks, whats the reason to install the sleeves? just to protect the surfaces from any rubbing off of coatings?

-

Vogtland springs

Does up and down orientation of these springs matter? Clearly the coils are not wound with a smaller diameter at the top or bottom, and because they are linear, that shouldn't matter. I am thinking it doesn't, but I just want to see what you guys think.

-

Float level advice, please.

Haha, Actually i'm not a huge fan of the Pilsner. I much prefer their IPA and Double IPA.

-

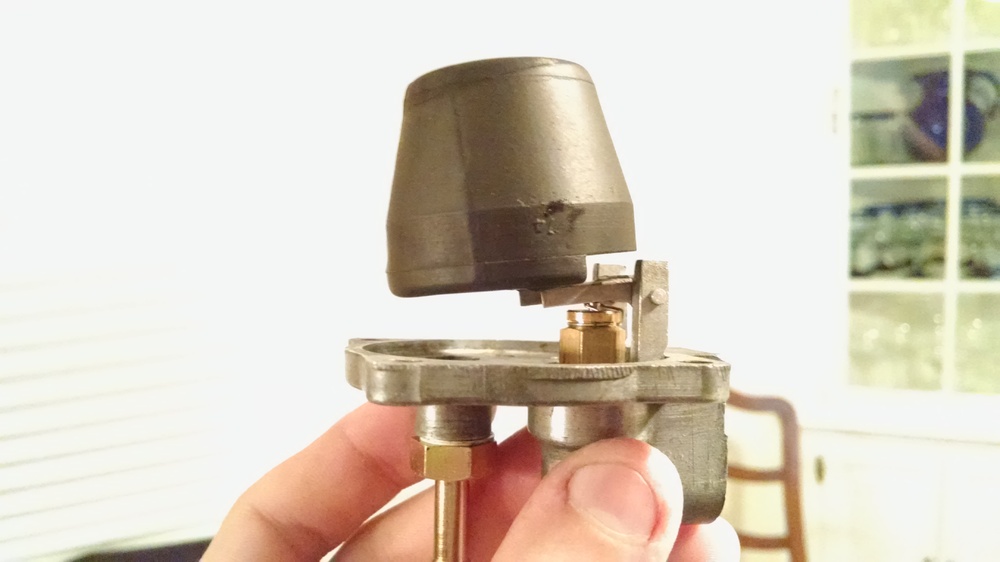

Rear Pass wheel (when jacked up) hanging very low/not spinning

Trying to determine if I should replace my strut isolators, so here is a look at one. The rubber on the bottom is still flexible and compliant. The top surface where it bolts to the car is basically stiff without any rubberish feel there. Not sure if it ever had any. No surface that currently has rubber seems to be in bad shape. Guy at work who is a very experienced mechanic and spent many years with Z's when he was younger said absolutely no need to replace them. They are totally fine. I tend to default to his judgement as he is truly a sharp guy, but in case there was supposed to be a bit of damping on the top surface I figured I would see what you guys thought. Would be nice to save that $50 a corner or so they cost from Courtesy Nissan. Looking at the pictures online, there doesn't appear to be any damping on the top surface, just the bottom. I think I am good to stick with what I have.

-

Float level advice, please.

Errr, floats are REALLY light, so yes I am pretty sure there is no fuel in there. They are clean and not puffy. I may need to take the spring out of the jet though, because right now there is a bit of travel on the plunger before actuation occurs. So with the pin up I can blow through, with the pin in slightly I can blow through, with the pin in deeper I cannot blow through. My pin's first 1/16" - 1/8" or so of travel does not effect its ability to shut off. Another interesting fact, I have to hold it downward to do my test properly... leading me to believe my spring isn't properly returning the float to an open state even with just the miniscule weight of the pin on it. Honestly, it's not impossible that there isn't a spring in there at all. I didn't check it out. I'll investigate the spring issue tonight, something definitely seems off in the jets.

-

Float level advice, please.

Quick bump for a quick question. I am setting the carbs up (off the car for now) with a Ztherapy tune up kit. The grose jets included must be different from the ones used back when they shot the video. In the video, they describe a good starting setting to be 9/16" from the top of the float to the housing cover. Unfortunately, the spring in my grose jet is not strong enough to support the tiny weight of the float resting on it. Because of this, I can't really set the float level based on this method. I had assumed that the intention of that 9/16" setting was that it should be a 9/16" gap between the float and the housing at the point where the grose jet toggles from OPEN to CLOSED. So I blew threw the grose jet, and moved it up and down until it shut off. I then set that shutoff points height to equal a 9/16" gap. So my grose jets initial setting prior to any experimentation is that 9/16" gap which straddles the actuation point. Hope this gives me a decent start to fire up the car for the first time. This would make my fuel level 9/16" + height of the float, down from the top of the float housing cover.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

Well I took a stab at it tonight, and by taking off the single corner at the pivot/bushing point I have it off the car. I had to remove it because it couldn't pivot down far enough to release the overextended strut. When I got the thing out, the strut was so extended that there was no compression on the spring whatsoever. I still have to get a wrench and take a stab at the gland nut, but barring that I think I will be okay. I will do the same thing on the other side, but hopefully I can get the strut pivoted out without removing the entire corner. A non-failed strut should let me do that I hope. I will end up doing all the struts now. It looks as if I will pursue the stagg strut and Vogtland spring combination. Its unfortunate that they are linear and thus probably not help the ride quality, but I'm thinking I may prefer that reality over the somewhat mixed bag of opinions for the progressive Eibachs.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

So for dropping the rear end... what is involved? I assume I have to lower the rear diff, I would prefer to string up the drive shaft simply because I JUST refilled the trans with fresh fluid and changed the tailshaft seal. I also just put the exhaust back on, but I could take that off as well. I imagine I would have to. - Disconnect brake lines - Disconnect e-brake cable - Remove exhaust - Unbolt driveshaft from rear diff and in my case secure it somehow - Unbolt brace under differential/mustache bar/link mounting base from frame, and lower the whole thing? Can I lower it all from a single point under the differential? or I imagine the links and stuff will start to flop over as it comes down. I say all this because my 4 jack stands are currently tied up supporting the car. I will have to relocate the rear 2 as they are currently under the brace below the differential. Or conversely.... I disconnect e-brake/ brake line/half shaft. Unbolt the link bracket in the rear, slide the bar out from the bushing in the front and lower just that corner. Given my available tools and hands this might be easier.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

The plate seemed to be so there was something for the strut tower cap to snap to. I was going to go with the Tokico's, but was getting a bit of sticker shock. Based on your comment I looked at the Staggs and will probably go that route since I can realistically do springs at the same time without too much more of a $ hit. This car won't be a daily driver, more of a weekend project and cruiser. Based on that I think the Stagg seems like a good choice.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

I appreciate this, but unless you are coming right by me its probably not worth it. Milford isn't very close to Danbury ~45min southeast. (although New Milford is, which may be what you are thinking of) I think I have my plan going forward, just requires replacing some struts!

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

I can certainly not lift the wheel into position. Only with significant rotational effort on the tire will it move upward at all, and I think I am gaining mechanical advantage with my motion. The strut/spring is definitely resisting my efforts to raise it. Even when jacking the corner, it is definitely overcoming the resistance of the strut/spring. As far as I can tell the top of the strut appears to be seated correctly. The nut up there is the same height as the drivers side (from the inside of the car) and there doesn't seem to be anything mismatching between the two sides with the exception of the extension of the strut internals. From what I can see of course.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

So I'm trying to wrap my head around the strut replacement options. Obviously the struts control the maximum travel, and the springs set the height... so is it safe to assume that any of the major strut options will work with stock springs? I know some struts specifically say not to be used with lowering springs, but I have never seen a strut say that it REQUIRED different than stock springs. And while I realize its a good time to also do a spring swap... this strut failure was unexpected so I would prefer to not go down the spring path right now if I can help it.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

Seems like its the last thing I want to do... to tackle that spindle nut or those control bushings... So I suppose now I look at how to replace the strut while its flopped over on the car.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

Car will always be on jacks for these photos. That last picture is with the wheel removed (i believe I am remembering correctly), so there is no additional hanging weight from the wheel, but i assume the spring is what is pushing it apart. Seems likely that the strut is simply hyper extended. It doesn't look like the rubber bits are ripped up. Guess I'll be looking into new struts.... Since I don't have air tools I may attempt to get the spindle nut out of there so I can bring the entire assembly somewhere. Or disconnect the entire control arm and replace the bushings while I am at it. and yes, unfortunately I think that cable has been loaded like that for quite some time in my garage.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

Some more info for you guys. It definitely seems to be the strut or something related to it. Attached are some photos that may shed some light. I wasn't super excited to find the little custom plates on top of the struts, not really sure why they are there and what was removed/done prior to them. Seems like some metal was knocked off in that area, although i couldn't tell you why. Maybe to get more access to the nut at the top of the strut? If i had some spring compressors I would have taken the strut out and taken a look up top, but that will have to wait. I really want to get this car on the road and driving, if only to test stuff. I assume it would be no go for me to ride on this strut temporarily? Thanks all Also looking into how I can service this thing. Trying to take apart as little as possible to get access.

-

Rear Pass wheel (when jacked up) hanging very low/not spinning

Back story: 1971 240z. Believed to be very stock and has sat in storage since early 80's. Being put back together by me. Has sat on jacks since Oct of 2015. Was driven/rolled into the garage by me at that time. Did light driving and seemed okay, but nothing at speed where the suspension would go through a large travel range. Since then the relevant work I have done to this area is changing the rear differential fluid (Red Line 75W90NS) and serviced the rear brakes: new cylinders, new hardware, new hard and soft lines at the corners. rebleed. Reused existing shoes and drums. Checked function of parking brake. ----------------------- So, I put the wheels back on last night, and went to roll the rear passenger tire. For one it was hanging very low in the corner. 2, it did not want to roll forward easily. If I put enough rotational force on the tire, the corner would actually lift up and then roll over maybe 90 degrees and would then fall back down. If I keep doing this it will keep spinning and lifting, as if going over a hump. If I jack the corner up enough (to roughly where the rear drivers side corner sits when in the air) it will roll freely. Interesting note, when the corner is dropped down to its currently (lowest) resting position, when I roll the rear passenger tire the rear drivers side spins. If i jack the tire up to a more reasonable resting position and roll it (which can now be done more easily) the drivers side tire does NOT spin. Can anyone explain what is happening if something is not working as intended? Very confusing. The half shafts are hooked up and bolted properly, and the strut appears to be connected at the corner and to the frame.

-

rear transmission seal replacement

Mega bump because while I was struggling with this, this is the thread I kept finding. I had issues getting my rear seal out, and partially destroyed the previous seal. Scared that I might do something like this thread, I stopped... and purchased the Lisle 58430 Shaft type seal puller. I had to find a way to prop it against the housing, but i used a block of wood and rigged it up and pulled out the seal successfully. When I got it out, I inspected the previously installed seal and it appears to have a metal ring built into the back side of it that my new OEM one does not. I crushed this when removing, but figured if it was necessary my OEM seal would have had it. Is this just a particular feature of the original or possibly aftermarket seal that was installed previously? or something I need to source and use for my replacement? Images of the original 32136-U0100 lead me to believe it might have been built into the original and possibly not required to replace with my new 32136-U010A version.

-

Speedometer cable grommet (@ trans)

Seems like by putting teflon tape there he just redirected whatever oil was leaking to stay in the speedo cable itself. I picked up some rubber washers today at HomeDepot. (in the plumbing/sink repair section) Believe the one i used was labeled a 1/2" washer, with a 3/4" OD and 3/16" ID. The smaller ID fit very snug, and I believe I have it seated differently than the original grommet. Here is where my washer sits. I think there is still enough engagement with the spinning gear that it shouldn't be a problem... but we will see. It fit so well at that point, i didn't want to try to force it over the next "hump" There seemed like the spring shaft was compressed enough that the keyway shouldn't pop out... but i suppose if i had popped the washer over that hump it would have helped to hold that in as well.

-

Speedometer cable grommet (@ trans)

Excellent information everyone. I appreciate the alternative grommet option, i figured there was another way and i'm glad to see that there is. I'll go poke around for a grommet. Also, i'm assuming that i need to grease up all these components when I install them, is that what you have seemed to find out site?

-

Speedometer cable grommet (@ trans)

A little more digging leads me to believe it is in fact: 24250-89943 Seems like a lot of retailers don't stock it, and there is some confusion about which part they say replaces it. Seems the replacement part is supposed to be: 24253-E4100 but internet seems to think this is the grommet for the firewall, and not the one at the transmission connection point. Unfortunately the site you linked points to the replacement part as well, so I am a bit curious as to what i will get. They also have a silly minimum shipping charge ($10) and i don't need much else at this time to justify throwing this part in there with the order to try it out.

-

Speedometer cable grommet (@ trans)

So i'm troubleshooting a leak and will be replacing the o-rings on the speed gear and housing although at this point they are probably fine. But I've discovered the grommet on my cable is toast where it mates to the part at the trans. Anyone know how to go about replacing this? I can't seem to find it for sale anywhere. I'd prefer not to buy a new cable assembly if I can help it. I believe the parts diagram is here: http://www.carpartsmanual.com/datsun/Z-1969-1978/electrical/meters and possibly the part is 24250-89943 or 25051-N4500 not sure. Either way, it appears hard to find now... but I'm not sure what kind of place might have one I can buy to replace it. (the top hat looking piece) Thanks all