Everything posted by dutchzcarguy

-

New guy

For as far i can see a Original 280zx 2 seater, i'm restoring my 3rd 280zx 2+2... know a bit about 280's ? Only the extra floor mat, the bumpstrips on the car and a few extra tie-raps in the engine compartment… are not so standard.. but overall a beautiful car.. Today i'm busy with the front bumper indentations in the front fenders.. I can't see those in your pic's, are there indentations behind the end flaps of the front bumper (on the sides, the ends of the bumper) ?? see the right-under corner of the fender.. Maybe you can make a (close up) picture of your front left bumper side for me, it would be very nice!

-

Another new Z owner

Bumpers guards… not needed.. i throw them away , much more cleaner car.. It was a tipical USA part.. europe and Japan don't have those (stupid (sorry) things that only make the car ugly and heavier.. just my opinion!

-

Shift lever boot

It was as far i know Always a vinyl boot with boot lace at the top.. Leather in a Z ? no way!! that came with the 300zx or so..

-

280ZX Frame Rails - Any Volunteers?

First.. sorry for my off- topic answer.. I'm restoring a 280zx 2+2.. but the framerails are in good condition.. also.. i don't think i can help seen the distance i'm on.. Over here the 280zx is a very rare car.. there were few sold overhere..

-

2021 Nissan Z: What We Know So Far

Ah... another giant annoyance!!! over here (The Netherlands..) the 370z costs over 100.000 euro!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! Due to taxes taxes and taxes... that's nothing new here.. i drive a 300zxtt 1992 and i was told and i did the math and there are 50000 good old dutch guilders that dissapeared in the pockets of the government It costed 173300 guilders about 65000 dollars then?....

-

280ZX Frame Rails - Any Volunteers?

My question is to also mention the thickness in mm or inches.. Gauge is a strange thing the higher the number the lower the thickness??? what? are we still living the stone - age ?? It's like the english.. what's your weight? 10 stone ? WTF!!! (Around 130 kg..? !!!) I know… SI has failed (started oct 11 1960!!!!) but can we use some understandable units, that people over the world can understand, why make it complicated.. kg - pounds oké .. feet and meters, maybe a yard? but gauges and stones… i might as well take out my el Or thump? ? ? (EL= armlength and a thump is a "duim".. around 2,5 cm .. no not as big as an inch , to make things even worse..) What you say Temperature? It's Celcius… don't have a big problem with Fahrenheit.. lets all go to Kelvin!! to day it's 279K over here ? !! ( yeah 6 C.)

-

2021 Nissan Z: What We Know So Far

Over here.. we call that: eenheidsworst!! (translated: all look the same?) It looks to much like a KIA or other coupe... not for me.. thanks!

-

Parts Wanted: Wanted, for my resto.. datsun 280zx 2+2 1979, front window clips.

bump.. Or has anyone a solution/ replacement option for this problem? need your advice!!

-

adjustable roof rail on doors?

Hi, there is a diff between a 240 and 260 2 seater door and it would not surprise me if the 280z door if different again.. you could have a 260z door (2 seater) Pic's from the inside will tell.. Those glass surrounding stainless strips are adjustable but only a small amount.. I think you have the wrong door..

-

Fitting 240Z bumpers and Valences to a 280Z

I've got a few sets of Original 240 and 260z bumpers in good shape, need new chrome but overall very good. not sheap i gave a fair amount of money for them…

-

Parts Wanted: Wanted, for my resto.. datsun 280zx 2+2 1979, front window clips.

View Advert Wanted, for my resto.. datsun 280zx 2+2 1979, front window clips. Hello, I'm looking for the 2 strips of rubber needed (upper and lower.) to put in a new front window glass in a datsun 280zx 2+2. there is a firm in the States who sells one of them but i need both, these strips with (stainless?) clips are NLA for some time, who has a solution to this problem? I could just lay the stainless trimming into some rubber sealant.. but then you can forget it to take the trimming of in one piece when your window needs replacement. sought advice! Advertiser dutchzcarguy Date 01/17/2020 Price Category Parts Wanted Year 1979 Model 280zx 2+2

-

280zx 1979 2+2 slick roof restauration

Just another week at the bodyshop.. Some pic's of the right hand floor.. Welded spot and also on this pic the two bolts that in a lot zx's are a problem but not in this car! (the red is not rust it's a Original layer of the old glue that sat under the greenish tape.) Bought a old r-hand door for some internal parts, like the little clips../ window mechanism/ opener...etc. Here one can see what a "normal 280zx door looks like after 40 years.. So far so good, this is what the car looks like, putting it together for some fitment checks. Maybe next week or so.. the bodyman of the shop is taking over to get it perfect. I wanted to do that also but as the germans say: ICH HABE DIE NASE VOLL!! (STAUB) (translated.. I'm fedd up with it.. or.. I'm sick of it?) no seriously.. i've done this before but i can let them do this in less than half the time i would need. (And if i'm honest.. i really.. really!!! don't like prep and sanding!) Later on assembling the car looks like a nice job to do, especially now most parts are ready to fit to the car. Getting the front window in seems to be one of the last hurdles to take.. Does anyone know where i can get those clipstrips (rubber band with several stainless clips on them) needed to put the stainless trimming on? There was a shop is the States but they only had the lower or the upper strip for sale, (i'm not sure ) if i order there i need them both..

-

280zx 1979 2+2 slick roof restauration

Today i painted the hood and the 2 front fenders... after a week of... yep... mostly sanding.. The fenders are going to need some bondo were the new parts were welded in. Here some pic's of the work done.. Ready for epoxy.. To weld these fenders you have to have the 3 courses Newspaper welding, otherwise you will not be able to weld them! Definitely in the wheel arch! Here you can see the copper welding i've done in the arch.. Result.. The last weld-job (?) is a spot .. a typical DATSUN 280ZX rusty spot halfway in the floor, the left side was done last year and now i discovered that the other side (right) is also in need of an 2x2 inch peace of 1mm steel.. Also, the spot where the rear axle is connected to the chassis is a typical spot but in my case no problem at all!

-

Considering a 1980zx

I have never seen one without! Even the very good one i'm restoring has some damage.. one day i'll take those little bumps out.. Things to check/worry about.. I've got one concern for you.. a V8 in an already not so very strong chassis can be a problem.. even more when it's a T-bar chassis. The longer length of a s130 makes it not strong enough for a V8. Look for rust direct under the floor where the front safety belts are hanging.. between the point were the rear axel is attached and the side of the car. There is a piece of floor that is double layered steel.. and Always a problem.. (I'll put a pic in my thread.. restoring a 1979 slickroof 2+2 280zx this afternoon.. after that i (now!) go into the paintboot for some more painting parts! )

-

123 Ignition plasma ball

Yup! That reminded me about Hugh Laurie and Stephen Fry! ( should there be someone who do not know them.. google them!)

-

123 Ignition plasma ball

Use a standard .. what is it.. 20-25 Kv coil.. all that 123 ignition nonsense with 40+ Kv… gives you only one thing… trouble!!!… just my 2 cents...

-

Parts for Sale: 240Z quarter panel right NEW NOS

Sorry but what is a GT junior? Italian? Those brown spots (round wheel arch and where the bumper go's are not rust? pics after a good cleaning??

-

Modern power antenna on original up down antenna switch

Problem is those antenna's are not worth looking at.. leave alone the hassle to install them.. they work a few weeks or month and break down.. those relais probably cost more than the antenna, buy a good antenna or don't do it at all.. just my 2 cents..

-

280zx 1979 2+2 slick roof restauration

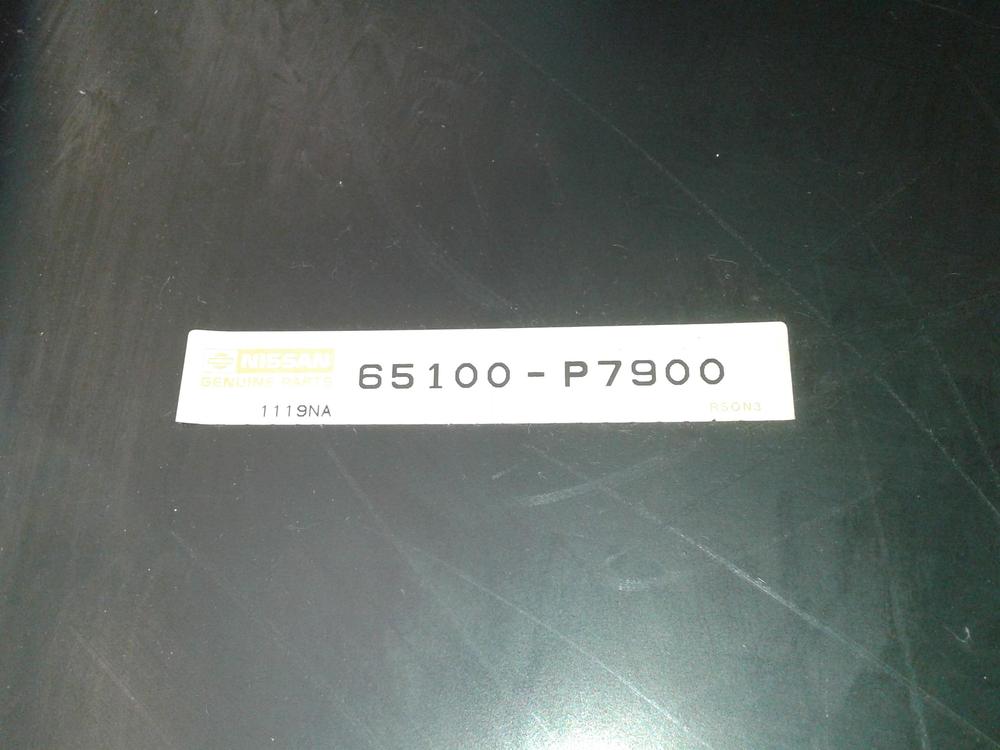

Yes Bart, it is going well, i try to work on it every working day and i get a lot of support of the guys who work at the bodyshop. Also from the owner of the shop. Because i count all the hours i work at it (or someone else, like the pro painter or bodywork guy) last week we went past the 500 hours ! working on the car and i think it's going to be another 250 to complete the restauration.. ? At least... These days i'm working on the fenders, left in particular and the hood (or bonnet!) whole lot of.. you guest it... sanding! ? Even a brand new bonnet needs work, a Original NISSAN hood… where do i find them haha...! Restoring the left fender.. left lower part of left front fender.. I had a problem with heat, despite the copper/silicium welding i now did.. but about 20 little blows with a special hammer made it strait.. learned again something! Then i discovered that i welded it to straight down, had to correct that.. now the lower front part deviates inward as it should! (see last pic in this part.) lower front left fender. Putting in a little piece in the wheelarch. If you want to do this… i told the owner of the shop you have to have a diploma to weld newspaper paper.. ? Sanding left and right fender.. (still busy..) Sanding (with some rattlecan paint to sort out the imperfections). Making the fenders and hood ready for epoxy coating. (later on the blue paint is sanded off completely before epoxy.) Front left corner, welded in part fender, deviates inward.

-

Inner fender liners

Nissan called them mud-guards if i remember correctly...

-

Newbie

You mean a rotisary? i think? ? Like to see some pic's of the bad spots on a USA type 280zx.. mine, (you can find it under: restoration of a 1979 2+2 slickroof 280zx) was almost without any rust, only the carglass guys had made a mess of the frontwindow edge at some time.. nice to see someone is going to restore another 280zx.

-

repairing a circuit board

Thats why i gave the advice to put the wire on the component side.. as pro's do.. (i've worked with studer revox machines, and ones opened up a TEAC... wow, there are a lot of those wires in there! A ReVox is well engineered.. they don't do/need that!)

-

repairing a circuit board

Clean the board well, then take of the damaged line(s) on the board and drill 2 small holes (1mm) at the ends of the line that has to be replaced and then put in a .8mm wire on the other side (componentside) of the board. It will look good and work well ? (Make shure the board is clean for soldering, use good resin core solder tin. )

-

Need to sell a 240z

Sad story, i would put in a lot of pictures, they say more than a Thousand words..

-

78 280z Thoughts

I'm with Charles, only if the rest of the loom is a firehazard i'll put in a new loom at this time..