Everything posted by Carl Beck

-

Z's on BAT and other places collection

Well... it started life at Pierre's Z... saw it in 2001 at the Motorsports Auto Show. The best looking Z Convt. conversion I had seen. The body lines were beautiful..

-

Z's on BAT and other places collection

Sold for $101K on BAT in 2019... Adjusted for inflation, to break even it needed to sell for $129K in todays money. Nonetheless in todays market - $90K was a pretty strong offer.

-

Z's on BAT and other places collection

In Brief: Paul Taylor is the person that bought HLS30 02545 from Bill Reagan, the person that restored HLS30 02545. Paul then took his Datsun 240Z to a Z Car Club Association (ZCCA) annual convention. There I believe it caught the attention of a company that produced/sold fairly high end Die Cast Models: The Franklin Mint. They talked Paul into allowing them to use his 240Z as the model - for their Die Cast model. Thus it became the Franklin Mint Model. At issue AIR they sold a limited edition for ??? $125.00… Paul’s Z was also invited to the Automobile Hall of Fame’s Ceremony of Mr. Kayatama being inducted to the US Automobile Hall of Fame. Because of #02545 documented history, full restoration and association with Mr. K and the Franklin Mint’s model - It has become a very desirable Collector item.

-

Z's on BAT and other places collection

Looks like a pretty nice 240Z. Bidding at $17K with an hour to go. https://www.hagerty.com/marketplace/auction/1971-datsun-240z/0992a21b-6574-49c6-91f2-56f7b6250d67

-

Z's on BAT and other places collection

The Black underside didn’t hide the poor metal work done when the new floorboards and frame rails replaced the originals. You could clearly see the lines where everything was cut out and the replacements welded in. The OEM reinforcement patches at the rear of the floorboards were cut and left off the floorboards as well. Perfectly OK for a daily driver refresh, but not the professional metal work you expect to see on higher dollar restoration. Picture #127 and #228 of 325

-

Z's on BAT and other places collection

It was "bid too" $35K with 20 bids. It was NOT Sold For $35K as the reserve was not met.

-

Z Restoration Progam

No absolute answer... but interesting non the less. ASK gork: "What can you tell me about Nissan Motor Company using Cadmium plating on automotive fasteners in the 60’s and 70’s?” response below. Information specific to Nissan Motor Company’s use of cadmium plating on automotive fasteners during the 1960s and 1970s is sparse, as historical records and available sources do not provide detailed documentation on Nissan’s fastener coating practices during this period. However, based on general industry trends and the limited information available, here’s an informed overview:Cadmium Plating in the Automotive Industry (1960s-1970s): Cadmium plating was a standard practice across the automotive industry during the 1960s and 1970s due to its excellent corrosion resistance, lubricity, and predictable torque-tension characteristics. It was particularly valued for protecting steel fasteners (bolts, screws, nuts, etc.) in harsh environments, such as exposure to road salt or marine conditions, and for its compatibility with aluminum components, which was critical in automotive applications to prevent galvanic corrosion. The plating’s gold or yellow iridescent finish was common on fasteners in vehicles from this era, including those produced by Japanese manufacturers like Nissan.Nissan’s Context in the 1960s and 1970s: Nissan, operating under the Datsun brand for many markets during this period, was expanding globally, particularly in the U.S. with models like the Datsun 510, B210, and 240Z. These vehicles were designed for affordability, reliability, and fuel efficiency, especially during the 1970s oil crisis. While there’s no direct evidence in the provided sources confirming Nissan’s use of cadmium plating, it’s highly likely that Nissan followed industry standards and used cadmium-plated fasteners, as this was the dominant coating for automotive fasteners at the time. Cadmium’s properties, such as its ability to resist corrosion in marine and alkaline environments and its low-friction characteristics, made it ideal for critical components like bolts and brackets in Nissan’s vehicles. Environmental and Regulatory Shifts: By the late 1970s, concerns about cadmium’s toxicity and environmental impact began to emerge. Cadmium is a heavy metal and carcinogen, and its use in manufacturing posed health risks to workers and environmental challenges due to waste disposal. While European regulations like the 2000 End of Life Vehicle Directive (ELV) and the 2006 Restriction of Hazardous Substances (RoHS) directive later restricted cadmium use, these concerns were already prompting automakers, including Nissan, to explore alternatives like zinc plating or zinc alloys in the 1970s. Nissan’s commitment to reducing environmental-impact substances, formalized in 2007, suggests that by the late 1970s, the company was likely transitioning to less toxic coatings like zinc-nickel or zinc phosphate, especially as it expanded manufacturing in regions with stricter regulations. Nissan’s Manufacturing Practices: Nissan’s manufacturing facilities, such as its Cuernavaca plant in Mexico (established in 1966) and later the Smyrna plant in the U.S. (1980), focused on producing vehicles like the Datsun 510 and B210. While specific fastener plating details are unavailable, the industry’s reliance on cadmium plating during this era implies its use in Nissan’s assembly processes, particularly for components exposed to corrosive conditions, such as underbody fasteners or engine bay hardware. The lack of specific documentation may reflect the standardized nature of fastener coatings, which were often sourced from suppliers adhering to industry norms rather than being a proprietary Nissan process. Comparison to Ford: Like Ford, Nissan likely used cadmium plating for its corrosion resistance and mechanical properties but faced similar pressures to adopt alternatives as environmental regulations tightened. Ford’s struggles with rust prevention and slower adoption of advanced coatings like E-Coat suggest that Nissan, with its focus on economical vehicles, may have prioritized cost-effective coatings like cadmium initially before transitioning to zinc-based alternatives. Conclusion: While direct evidence of Nissan Motor Company’s use of cadmium plating on fasteners in the 1960s and 1970s is not explicitly documented in available sources, it is reasonable to infer that Nissan, like other automakers, used cadmium plating for its fasteners due to its widespread adoption in the industry for corrosion resistance and lubricity. By the late 1970s, Nissan likely began shifting to alternatives like zinc or zinc-nickel plating as environmental concerns grew. For more precise details, contacting Nissan’s heritage division or automotive restoration communities specializing in Datsun vehicles from this era might provide additional insights. - - - - - - End Quote - - - - - - - - -

-

Z Restoration Progam

About 35 years ago, I was in the process of restoring a 240Z, as well as parting out another for spares. I took an assorted group of 10 or 15 nuts, bolts, washers and couple small parts off the Z's to our Materials Lab. "Our" being Honeywell Space and Strategic Systems Lab. A Materials Lab with men and equipment that supported putting men on the moon and probes on other planets. I ask the guys to tell me what was used for plating and corrosion protection, as I intended to have them re-plated. After testing them, they told me they were Cad. plated and given a yellow chromate conversion bath- and to be sure to wear a mask if I used a wire wheel ((bench grinder) to clean them up. Cadmium is very toxic and you don't want to breath any in. Given that the OEM fasteners on a now 50+ year old 240Z, treated with a little penetrating oil will break free and unscrew, without twisting off, is witness to me of Cadmiums use. That doesn’t happen with zinc plated fasteners in automotive use. In addition to Cad. plating having three to four times the durability of Zinc, Cadmium offers increased lubricity, so threaded fasteners release and unscrew. If you are not absolutely certain - best advice is to treat them as having Cadmium Platting..and be careful how you handle and clean them up.

-

Z Restoration Progam

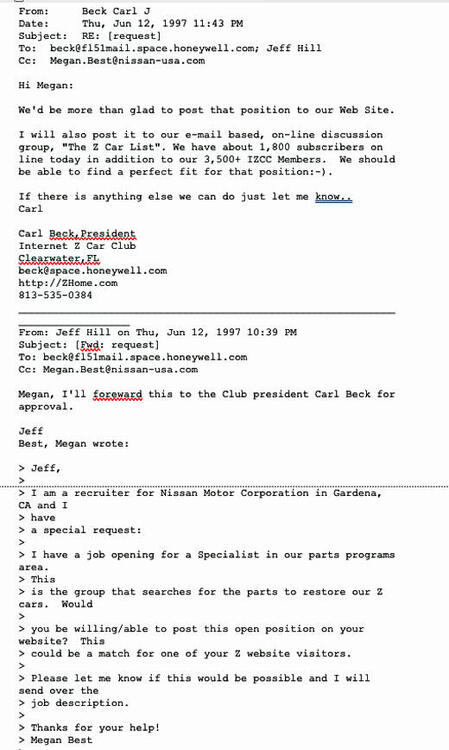

Speaking of parts - from the beginning getting all the needed parts was a real challenge. E-Mail from June 12, 1997

-

Z Restoration Progam

Good Point - - Yes, I have had that list for a long time. There are 59 Z's listed there and looks like 14 didn't have their original engines. Although at first glance, the original engine serial number are listed for a few, perhaps taken from the data tags? It will take a while to see if any of them are way out of line, with what would be expected... Also might account for the other 9 not getting their original engines.. I'll have to cross check Edit... I wanted to add, that list is of the Z's Pierre received, 2 Z's went to Les Canaday directly from Nissan. A couple others appear to have gone to Datsun Alley directly from Nissan as well. So two or three of the VZ's are not on that list.

-

Z Restoration Progam

Of the 11 I'm aware of, 2 got different engines by the choice of the owners. One now has a Rebello 3.0L and the engine for Mr. Crain's Z was custom built with performance enhancements (not an AER engine). Don’t know if the 1 with the Rebello had its original engine or not…it wasn’t recorded/reported by the owner. Pretty sure other than that 2 the other did get AER rebuilt engines. Need more data to be certain.. I spent a couple hours with Mr. Crain at the Amelia Island Concourse, where he was regularly one of the Judging Staff (along with Peter Brock etc). We spent some time talking about Mr. K, Nissan and Mr. Crain's Vintage Z. I hadn’t tried to track where the original engine out of his Z went… I’ll go back an look in my files/notes.. As far as I know - The original engine serial number were left on the engine bay tag. Owners that reported a different engine in the car - knew it did not match the original listed on the tag.

-

Z Restoration Progam

Yes - quite possible, even likely as they ran out of NOS parts.

-

Z Restoration Progam

Hi Mike - You know what you are talking about, you made that clear. Your talking about your experience and knowledge. If someone at Nissan or at Pierre's told you there was no effort to retain original engines with their cars - that is what someone told you. You weren't there everyday, neither was I. I'm sure we both got a lot of information as well as misinformation and rumors out of that entire crowd 30 years ago.

-

Z Restoration Progam

In the 10 months between 19 March 1997 and 16 Jan 1998 Nissan sent 42 engines to AER for remanufacture; they were all received by Nissan as of 12 May 1998. When they were received by Pierre, they were assembled and hot tested, before installation. What did assembled - mean? To assemble a remanufactured Long Block, you have to add everything outside of the block & head. Oil pump, water pump, fan, alternator, intake/exhaust systems, electrical components etc etc. It would be good to keep in mind that Pierre constantly “hosted” Photo Shots for Nissan PR/Ad. as well as all the magazine and news articles in period. In many photos you’ll see hundreds of new OEM parts laid out on the floor or benches for the Photo Shoots. Video’s as well - these "props” were left sitting all over the place. I wouldn’t try to determine any process based on staged prop’s sitting around the shop. @zspert wrote - “…...there was NO effort, none, to keep engines and transmissions with the cars from which they came.” If that was the case, then we are seeing an amazing statistical aberration. If 42 engines were sent out, then received - and no effort was given to return the original engines to the cars. The odds of any 1 car receiving its original engine would be 1 in 42 ie 0.024 or 2 in 100. What we actually see is, of the 35 VZ’s accounted for, 24 of them got their original engines,11 did not. 68% got their original engines.

-

Z's on BAT and other places collection

AER Manufacturing in Carrolton, TX remanufactured the engines. Williams Technology in Summerville, S.C. rebuilt the transmissions. (Williams Tech was bought by Caterpillar circa 2004/5) Both were existing suppliers to Nissan. https://www.aermanufacturing.com/ https://www.ame.org/sites/default/files/target_articles/92Q6A4.pdf

-

Z's on BAT and other places collection

That was a great Deal for the Buyer.

-

Z's on BAT and other places collection

About this Vintage Z - As I recall - this one first showed up for sale about 20 miles North of me. New Port Richey or Holliday Florida. A friend of mine went to look it over, and reported that it was very poorly cared for. The next time we saw it, was its first sale on BAT. My fiend remarked that it had been very well detailed for that sale and looked 100% better than his personal inspection. Now we see it again, with an owner that put some significant funds and I’m sure elbow grease into it - to bring it up to better condition. Will the customer modifications hurt its market value? Not as much as the current market itself, the mod’s might hurt it a little as most collectors don’t want to mess with fixing anything.

-

Z's on BAT and other places collection

Always looking for more correct data/information. What is incorrect?

-

Z's on BAT and other places collection

Late 72 began the production of the 1973 Model Year. The Starting VIN series was HLS30 120001 09/72. Nissan didn't need the "late 72" data tags, because they did not use any 1973 Models for the Vintage Z Program. FWIW, Carl

-

Z's on BAT and other places collection

It was Yellow when advertised on Craigslist 2017. This is #55381 and #55380 is also Yellow. On a color change, you usually do not see the backside of the pinch welds on the rockers - painted with a new body color. I can see the areas that appear to be white on the undercarriage...where paint appears to have been wore of scuffed off. White Primer maybe?

-

Z's on BAT and other places collection

I seem to remember when an Aerovault was $11K... Bring a Trailer2024 Aerovault MkII LT TrailerBid for the chance to own a 2024 Aerovault MkII LT Trailer at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #194,177.

-

Z's on BAT and other places collection

It is a great Data Base - At some point in the very near future, someone will apply the right technical skills with the best AI tools - and we well all how important and useful that Data Base could be. I'd say leave the thread alone and keep building the data base. Also keep in mind that "the thread" should not be confused with "the people" that respond. The discussion thread is very useful even if some of the people that respond are not.

-

Z's on BAT and other places collection

It sold for a reasonable price - at least in todays market. $34, 350.00. Great buy for the person that loved almost everything about it.

-

Let's show vintage racing pictures. I'll start.

Too bad they didn't have Lee Midgley's Alfa beside the BRE 510. Lee was a friend of Peter Brock's, and co-driver of the Baja Z in the Baja 500 1973.

-

HLS 30 hub caps

Yes, that is a Nissan Vintage Z - HLS30 32089. A 1971 Datsun 240Z https://zhome.com/IZCC/ZRegisters/VintageZ.htm