Everything posted by Captain Obvious

-

Restoration of HLS30-12070

That's not it. Docs says same slinger number used for all cars 240 through 280: THROWER-OIL CRANK - 12302-A3500 And I know the ZX motors I've been into lately all have it too, so it went beyond the Z and into the ZX.

-

Restoration of HLS30-12070

And I apologize for the distraction, but does anyone know what they changed with the crank sprocket that warranted a new part number? The 240 used P/N 13021-21000 260 and 280 used P/N 13021-U0100 And when they made the change, the 240 P/N was superseded to the later number. So Datsun believed the newer 260/280 crank gear could be used on an earlier 240 if necessary, but not the converse. Anyone have any idea what the difference is?

-

Restoration of HLS30-12070

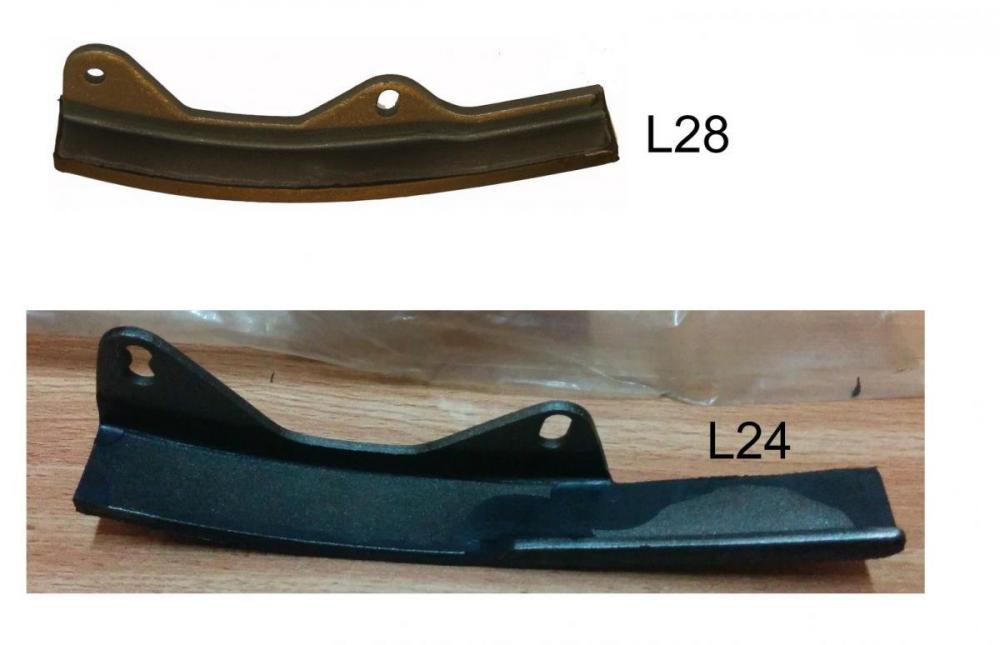

Thanks for checking. But now I'm really wondering. According to the parts fische, four of the parts (cam sprocket, chain, tensioner, and the tight side (straight) guide) were used unchanged on all the cars 240 through 280. According to the docs, the only two parts that ever changed were the crank sprocket and the slack side (curved side) guide. I have no idea what they changed with the crank gear and they all look the same to me, but the slack side guide is visibly different. Here's a pic showing the differences. (I don't remember where I hoovered this from so I unfortunately cannot credit the creator). They used the top one on the 280 and the lower version on the 240 and 260. Notice that the shape of the lower hole is different and so is the shape of the metal support bracing at the upper end: Again, it's tough to tell from your pic, but your curved guide looks like it has the single hole at the bottom and the metal bracing at the top. Meaning it's the 280 style and not the one for the 240. At this point, I bet you're wondering why I'm wondering... I need a timing set (for an L28) and the ITM sets are relatively cheap and plentiful. The pictures on ebay for their 280 set (053-90400) show the guide for the 240, and the timing set they offer for the 240 has a PICTURE showing the 280 style slack guide. Up until I saw your timing set, I thought it was just a picture problem. Now I'm really not sure. I want to make sure I get a 280 style guide and now I don't know if I should intentionally order the "wrong" ITM set. Now everything is muddy.

-

Just Another Damned Z Car Project Thread

Well good luck and in the event that it doesn't work out with SpaceX, let me know. I'm betting that with enough time and money I could eventually carve something that would work. Also, if you want, send me a PM to connect me with your son and I can do some design review for him. Might be able to add some value there. I'm no CAD jockey, but I'm sure there's a file format the two of us could use to communicate on some basic level.

-

Future of driving a "classic" car

LOL. It's true. And I stand by my decision. Haha!

-

Just Another Damned Z Car Project Thread

Hope your SpaceX guy can take care of you. I had thought about closing up the original holes and redrilling for a different pattern. I also thought there was no way you were going to try that.

-

Z's on BAT and other places collection

Haha! Agreed about it sounding like salesman. Best year for the EFI? What is about 78 that makes it so much more refined? My 77's feelings are hurt. And the dash... So he installed a new repro from the guys that are making them. HIS supplier. I mean, it's well written sales literature. It's just a little over the top for me.

-

Restoration of HLS30-12070

Sorry, I wasn't specific enough with my question. Based on the tensioner and the way the cam gear looks, I figured it was an ITM kit. The question(s) is What ITM kit is it? What's the ITM part number? The reason I ask is that the ITM kit listed for the 240 and 260 is 053-90300, while the kit for the 280 and 280ZX is 053-90400. From the pic, your slack side guide looks like the one that comes with the 280 kit, not the 240 kit. Hard to tell with it mounted up, but that's what it looks like to me.

-

Don't buy this from Z Car Depot

Or you could just use the one in the kitchen when Ms. J isn't looking. Ms. Obvious was distracted by something else while I took the toaster oven outside and did bad things to it.

-

Cars Wanted: Wanted: '76 280Z in 305 blue over black int

I bet you'd let yours go for $49K if pressed.

-

Just Another Damned Z Car Project Thread

When they are stating the size of a throttle body, they use the diameter of the butterfly. And usually, the outlet size is the same size as the butterfly, so that would make that a 70mm throttle body regardless of the larger diameter inlet side. Now, I have no idea if that throttle body you have there is the same as the factory supplied throttle bodies for the 350Z, but that one you have there would be called a 70mm. As for the mounting... Did your son make up drawings for an adapter?

-

Restoration of HLS30-12070

Very pretty work. So what timing kit did you buy? I can see the ITM on the tensioner, but the curved (slack side) guide looks like the one for the 280, not the 240. I have also heard (somebody's post-purchase feedback) somewhere that there were some minor fitment issues with the front cover hitting one of the guides. Too much material on some spot and it hit the timing cover. I think it was ITM, but I don't remember for sure.

-

Don't buy this from Z Car Depot

I did that a number of years ago. Back before I started taking pictures of stuff like that. My "jig" was a piece of coat hanger wire that was bent into the desired shape (over-bent actually to account for spring-back), and my "heat" was a toaster oven. Worked pretty well. I did some parts out of Viton and some others out of neoprene. PSA - Don't burn the Viton or anything else with fluorine in it. Some more detail just to fill out the story... I ran a pair of those tubes on a some round tops for a while and then pulled the round tops off to go back to flat tops. They worked great while on the car. No binding or other issues. However... Just a few days ago (quite coincidently) I was inspecting those round tops and noticed that the rubber tubes were failing. Cracking around where they were expanded onto the nipples at the ends. I don't know why they were failing. It was Viton from McMaster, so it should have been quality material. Maybe I did some damage with the heat.

-

Air / Fuel Meter Recommendations

Here's what Innovate says in the user's manual for the gauge: "Using a clock as reference, mount the bung between the 9:00 o’clock and 3:00 o’clock position. Welding the bung in the lower section of the exhaust pipe can result in sensor damage caused by condensation making contact with the sensor’s internal heating element." My interpretation of that is "anywhere along the top half of the tube is OK." That said, I think I would rather have it a little off 12:00 for the surface tension reasons Dutch mentioned.

-

Don't buy this from Z Car Depot

That's not to code.

-

Restoration Unveiled Today 08.17.2019

Haha! The stupid stuff we hopefully and thankfully lived through in our younger years.

-

Air / Fuel Meter Recommendations

LOL! So I saw a note (probably on Innovate's website) about sensor mounting. They said that if the sensor gets wet it can cool too quickly and crack some ceramic portion. For that reason, I think they recommended 3:00 or 9:00 with 6:00 being the worst not only from the standpoint of ripping the sensor off on a speedbump, but also for potential water damage.

-

Air / Fuel Meter Recommendations

I thought it was more complicated than that. I haven't really looked into it, but I guess I should dig around a little and get some learning.

-

Air / Fuel Meter Recommendations

LOL. Well that took a turn quick! I'm sure I wont. Only thing that has me a tiny bit worried is I bought it off ebay from the cheapest guy I could find. He's head and shoulders cheaper than the next guy and because he's so much cheaper than everyone else (and the MSRP of the device) that it sets off my scam danger alarm a tiny bit. Hoping it's all legit and I'll have it soon.

-

Air / Fuel Meter Recommendations

Easy for me to say, but the monitoring and logging of the sensor output sounds like a relatively easy ordeal. What I don't know anything at all about is how to deal with the heating element.

-

Air / Fuel Meter Recommendations

I just pulled the trigger on an MTX-AL. I'm assuming I'll eventually be in the market for something with more features (and a bigger price tag). But for now, baby steps. Thanks for the generous offer, but I'll install my simple gauge first and see what happens. If it were safe to have company right now, I'd be on my way up to spend some time with you. Hopefully soon my friend!

-

Air / Fuel Meter Recommendations

Sure I remember! Lets to that again! Having you as my co-pilot again would be a much better solution as far as I'm concerned! So I knew you had the analysis equipment, but I didn't know it was an LM-1. I guess at the time, I just knew it worked.

-

Air / Fuel Meter Recommendations

jonbill, thanks for that link. Good read, and simple enough for my little mind to work through. So it seems that the real value would come with a multi-variable logging system and you can put them together with multiple pieces, or buy one already packaged together (like the Innovate LM-2). I was hoping to get away cheaper than that. AK260, So you have the analog MTX? And I agree with your assessment as well*. There's a lot of value there too, but not as much as a multi-variable logging system. So do you get any meaningful info while just cruising normally and not at WOT? Or is the needle all over the place all the time? * Except for the Bond-esque part about flipping a switch and having your clock become an A/F meter.

-

Air / Fuel Meter Recommendations

Thanks Jon. Hmmm... I see your point. For my logs, I guess I was looking for mixture vs RPM. As far as engine load goes, I was going to have to do that by memory, as in "This was a full throttle third gear pull." and then interpret the results knowing those conditions. So I guess the question is do the stand-alone gauges (like the Innovate MTX series) even know what the RPM is and output the RPM data on their log stream? Does the MTX even have an RPM input pin? Or do I need something like the LM-2 to do that like blodi:

- 1976 280Z Restoration Project