Everything posted by Captain Obvious

-

Cool Exhaust Sound Options please

Sorry, but I'm lost. I don't understand all of the distinctions being made with the terms above. Duals Duals all the way to the back Twice pipes Split pipe I understand that all of these options eventually end up with two tips sticking out the rear of the car, but how many mufflers are used, and where does the separation between the two sides start?

-

Speed Odometer Reset

I consider that a more philosophically complicated question. You're essentially saying "Everything in the car is new with zero miles on it except the odometer. With that in mind, should the odometer read the old original mileage, or can that be changed to zero miles as well?" I think the answer is "No, it should not be changed and it should reflect original mileage".

-

Speed Odometer Reset

Well from what I heard, this guy's cousin is a pack-rat and has a file folder containing years of annual DOT registration records, annual state safety inspection records, and annual insurance documentation that all show the steady progression of mileage from when he purchased the vehicle until now. He can also answer the following questions completely honestly with his head held high: Q - Is that the original odometer in the vehicle? A - Yes. Q - Not considering any potential discrepancies which may have occurred without your knowledge and before your ownership, is the correct mileage of the vehicle what is shown on the odometer? A - Yes. Q - Are you sure? A - Yes. Q - Are you double dog sure? A - Yes. Q - Do you have documentation to prove it? A - Yes. Haha! I think he should be OK. Here's to hoping the DOT has better things to spend tax dollars on than pursuing that dead end!

-

1973 Rebuild

- Speed Odometer Reset

Thanks guys. I added some clarifying detail to my original post.- Speed Odometer Reset

I knew a guy, who knew a guy, who knew a guy, who knew a guy's cousin who temporarily installed a spare speedo in his car because the original was jumpy. The problem turned out to be the routing of the speedo cable and not the gauge itself, but before he put in the replacement, he took it apart and adjusted the odometer to reflect close to the correct mileage. He didn't bother with the 1's or 10's digits, but he changed the others so it was within 100 miles of my actual mileage. And then when he figured out that the speedo was never the problem in the first place, he took out the test unit and put his original back in. From what I heard, it's not too hard, but fiddly with small parts and the like. If you're good working on small delicate things, its not bad. If you're all thumbs and your best tool is a breaker bar or an impact gun, I'd send it to someone else.- Dash cracks

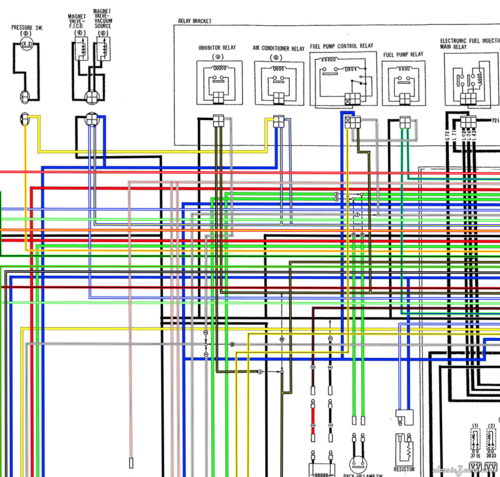

- Fuse link wire identification

No. The only one that goes directly to the fuse box is the same one that goes to the alternator. The one that goes to the multi-function stalk goes to the fusebox after the switch. The two that go to the ignition relay go to the fusebox after the relay. The one that goes to the ignition switch and powers some stuff after the switch does not go to the fusebox at all (which I consider a design flaw). For example, the starter solenoid has no fuse in the line at all. Neither does the ignition module or coil. Now that we have identified the wiring harness year (probably? hopefully?) you can download that year wiring diagram and take a look. Here's a mostly finished color wiring diagram for 78: http://www.classiczcars.com/applications/core/interface/file/attachment.php?id=41454- 1978 Color Wiring Diagram

- 555 downloads

- Version 1.0.0

Not completely done, but better than no color at all. I didn't make it. It was already uploaded to this site, but I just added it to the wiring diagram list.Free- Dash cracks

Can you point me towards any documentation that describes the process? Or youtube videos of parts made using the same process?- Dash cracks

Yikes. I can see why you bailed on the project. I sure do wish there was a cheap way to get a whole new skin on the dash.- Need help identify missing part

The only thing missing is one of your dash retaining bolts. There was never anything installed in that "empty spot", It's simply a recessed area for one of the mounting bolts that holds the dash in place. There is supposed to be a bolt in the threaded hole that helps hold the dash. Yours is missing. If I had to guess, they may have used that location on earlier years to attach the hood release and vent control. But then they put in the lower valence panel and I think they changed how the vent and hood release are attached. Anyway, the only thing you are missing is a bolt.- Dash cracks

How far into this process did you get? Were you thinking you would make the molds yourself, or were you looking for a company to make it for you?- Steering Rack Disassembly and Refurb

Matt, I would be surprised if the bearings really needed to be replaced as it's not a high load application. Even so, I think pulling the whole thing apart is a good idea to clean out the gummed up crusty grease and make sure everything is working as intended. As for taking it apart, I'd be glad to give you a hand if you wanted to make the trip to my place. It's not as bad as it sounds.- Steering Rack Disassembly and Refurb

Yes, that is a lock nut. You thread the tie rod end onto the end of the rack and then tighten the locknut against it to lock the end in place. In that pic, the locknut had been backed off the tie rod end a turn or two. That's why there is a small gap between the tie rod end and the locknut. I think my style of tie rod end (round with the weld spots on it) is the original factory design. If yours had multiple flats on the sides and wasn't welded together, I think it was replaced at some point. No MINE is original OEM. Haha!!- Steering Rack Disassembly and Refurb

There are a couple other pics I have to find, but that should get you guys started. I don't remember where I put the boot pics, but I'll find them.- Steering Rack Disassembly and Refurb

Here's a pic of the whole rack exploded. Only thing you can't see is the lower pinion bearing. I pulled it out, cleaned it, and put it back in before I thought to take this shot. And I wasn't going to pull it again just for the camera: Left end parts: Right end parts:- Steering Rack Disassembly and Refurb

Here's some pics of the pinion gear bearings. There are two of them, and on the later racks like mine, they are identical. I've done a little digging and I believe the earlier racks used just one roller bearing at the top, and a sleeve bearing down inside the rack housing. But I've got two roller bearings. Here's the top bearing which is pressed onto the pinion gear shaft: The bearings they used are intended to be side loaded, and because of the design, you can take them apart. Carefully pry off the grease seal, pop off the retaining ring, and the bearing falls apart. You don't HAVE to take it apart to clean it out, but you can do a more thorough job if you do. Here's the retaining ring popped out of it's groove: Take the bearing apart, clean the old grease out, put it back together, and add new grease: The most intricate part of the rack work was probably getting the lower pinion bearing out and back in. I used a "blind bearing puller" from HF. This tool uses an expanding mandrel that pushes outwards against the inner race and a slide hammer to knock the bearing up and out of the rack housing. And I used my hydraulic press to put that lower bearing back into place after cleaning and greasing. Other than that lower bearing, everything can be handled with traditional hand tools. What if you don't want to go through that much effort? You can grease the two bronze bushings at the ends of the rack housing by slathering the rack gear with grease and running it back and forth a bunch of times. You can grease the rack gear teeth (and hence the pinion gear teeth) by slathering the exposed rack teeth that poke out of the end when the steering is turned all the way to one side. The sliding faces of the tension shoe will also get grease by slathering the exposed rack gear. But what you CAN'T do is get to the bearings on the pinion gear shaft without pulling the pinion out of the housing. So you can do a decent job of getting to maybe 75% of what needs grease without taking anything off the rack at all. In fact, that 75% can be done with the rack on the car without even disconnecting the tie rods. However, that last 25% requires pulling the pinion gear. This is the type of tool I used to pull my lower pinion bearing: Here's the lower pinion bearing popped out of the housing. Note that this was not the easiest part of the job: But after seeing the old grease in there, I'm glad I went through the effort:- Steering Rack Disassembly and Refurb

To get the rack gear out of the main tube, you have to take off the tension adjust shoe and the pinion gear. Most of this stuff has been handled before so I'm not going to include as many pics, but thought I would include some. To get the pinion gear out, remove the two bolts holding the retainer in place and pull the retainer off. Note that I put some masking tape over the shaft splines to protect the grease seal while it is being slid over the splines: Pull the pinion shaft, upper bearing, and gear up and out of the rack. I've heard some people have a hard time pulling this part out, but thankfully mine came out without a fight: Don't lose or bend any of the spacer shims that adjust the pinion shaft end play: After removing the pinion gear, here's what it looks like inside the housing. The rack and lower pinion bearing are still in place: To get the tension adjustment shoe out, first remove the lock ring and then unscrew the big slotted adjustment cap: After the cap is off, remove the washer and spring: Once you have the pinion gear removed and the tension shoe loose, you can silde the rack gear out the end of the housing. Obviously, if you only removed one inner tie rod end, then that's the direction you'll have to go, but if you took them both off like I did, then it will slide out either end. Once you have the rack gear out, you can reach inside the rack housing and push the tension shoe out of the housing from the inside. Sometimes the tension shoe will just fall out, but if not, it's likely that there are some small burrs on the shoe from years of use. Just push it out from the inside:- Steering Rack Disassembly and Refurb

After I got the bushings sorted out, I disassembled the rest of the rack. Remove the dust bellows and you're looking at this: My PO had screwed these plug bolts into the inner tie rod grease port. More on those bolts later, but the bottom line is they should have never been there in the first place. So take the bolts out: Hold the tie rod end in a vice and use a large wrench to loosen the lock nut a little bit: After the lock nut is loose, unscrew the inner tie rod from the end of the rack: After you get the tie rod off, inside you'll find the ball seat and it's associated spring. In this pic, the seat is out laying on the paper towel, and you can see the tip of the spring poking out of the hole in the end of the rack: Ball seat and spring cleaned up: Unscrew the lock nut and rubber coated bump stop washer off the end of the rack gear and you're left with this: If you pull the other inner tie rod end as well, just be sure you don't mix up the parts from the ends and make sure you put everything back on the same end it came from originally.- Steering Rack Disassembly and Refurb

OK. Trying to resurrect this thread with new pics. Here's the details again starting from the beginning. I've been doing a bunch of suspension work to my 77 this off-season and part of that work has been on my steering rack. I suspect this is old hat for lots of people, but it's my first time this deep into the rack and I've been trying to take pics of the interesting spots along the way. This whole project started with the rack mounting bushings. My previous owner installed polyurethane bushings on the rack mounts and they didn't look like right. The project snowballed from there, but let's start with the bushings. Passenger side steering rack bushing: Nissan changed the steering rack and bushing width on the later cars (for the 75 280 I believe. Maybe late big bumper 260s?). The driver's side bushing is the same for all years, but the later cars have a wider locating slot and hence use a wider passenger bushing. Because of this, you need to make sure you purchase the correct bushing set. If you try to put a later style passenger bushing on an early car, the bushing will be too wide and won't fit in the gap. Conversely, if you use an early bushing on a later car, the bushing will fit easily but will be too narrow and the rack can squirm around because of the gaps. Apparently my PO did not know any of this because on the pass side, the bushing was too narrow. Here's a pic of the bushing that came on my car. You can see the gap where the mounting slot is wider than the bushing: The solution appears to simply use the correct year bushing kit. Here's my new bushing installed and you can see how much better if fills the bushing slot. In fact, it was a tight fit and I even had to put a little silicone grease on the bushing and tap it into place with a plastic mallet. Much better fit: I've seen pics like this before from others, but for posterity, here's the older narrow style compared to the newer wider style: Driver's side steering rack bushing: On the driver's side, even though the bushing width was the correct (they're all the same), it still didn't fit in the slot properly. Because of this, my PO couldn't get the bushing to wrap fully around the rack properly and he just tightened things up anyway leaving a large gap where the bushing didn't wrap fully and was pinched by the mounting strap. Here's a pic of the driver's side bushing. You can see the gap and notice the deformation on the left side from not fitting into the mounting strap correctly: Problem was... When I first installed my replacement bushing, it was no better than the one that came off the car. I had the same problem and couldn't get the bushing to wrap around the rack far enough and I ended up with a huge gap where the ends were supposed to meet. After looking things over, I came to the conclusion that the replacement poly bushing wasn't designed properly. The rack has a smooth radius fillet on the inside corners at the bottom of the slots, while the bushings have squarer corners molded into them. As a result, the bushings don't fit comfortably into the slots. Here's a shot of the shot in the rack. Note the smooth rounded fillets in the corners: And here's a shot of the bushing that's supposed to fit in that slot. Note the inside corner is much sharper than the receiving slot in the rack. It's almost a square corner instead of the rounded fillet that is on the rack: Thankfully the poly was hard enough that I was able to cut it with a new very sharp fine tooth file. Using a file I was able to round the inside corners of the bushing to better fit the rack. Here's a shot after I rounded the corners with a file: Finished filing both sides of the bushing and tapped into place with a plastic mallet. Note how much smaller the gap is once the bushing fits snug in the slot and slides all the way to the bottom of the groove without hanging up on the corners: That's what started the project. I'll post more pics as the work progresses.- Steering Rack Disassembly and Refurb

I do have the original pics. I will upload them again tomorrow and hopefully breathe new life into this thread.- Wiper motor buzzes

Well that would explain why you didn't find the contact rattling around inside the shell. So I'm at a loss then to explain your test results. Motor made an unhappy humming noise until you bent the tab and then it went away. But now with the tab back where it started, the humming is still gone? Classic red herring! "He hates these cans!!!"- Windshield Washer Reservoir

You're soaking in it.- Fuse link wire identification

Gilles, Based on the description of the wiring, I believe your engine bay harness is from 1978. So, there are four fusible links. The first one you have already identified as splitting into two and one side going to the alternator, and the other side going inside the passenger compartment and connecting to the fuse block. It should also split inside the passenger compartment and go to the ignition relay. That first fusible link is the largest of the four. The other three fusible links are the same size and smaller than the one to the alternator. The remaining three all go through the firewall into the passenger compartment and go to: 2) The multi-function stalk to power the headlights. 3) The ignition switch to power things controlled by key rotation. 4) The ignition relay (there should be two large W/R wires feeding the two halves of the ignition relay). Is that the kind of information you are looking for? - Speed Odometer Reset

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.