Everything posted by Captain Obvious

-

Strut replacement?

Not that it matters now since you're going to get them off rockauto, but the answer to your original question is... The first link you posted above is the correct parts for your 78 while the second link is for the ZX starting in 79.

-

I'm a Boy Scout covered with patches, again.

Forget about the old saying. Just picture it with GRAND MASTER Z under your name!!! It would be glorious. And obnoxious!

-

I'm a Boy Scout covered with patches, again.

@Mike, so here's a possibly related question... So in the old days (like maybe two weeks ago before this last software update), you used to have the ability to enter a creative little quip "slogan thingie" that would appear between your user name and your avatar pic. Mine used to read "I'm a member of this forum" as I figured that was completely appropriate note for Captain Obvious. Well... I went to change my slogan to "GRAND MASTER Z" and that line does not appear anymore. So two questions... 1) What the heck?, and 2) What the heck?

-

I'm a Boy Scout covered with patches, again.

Haha! Last thing you thought was going to come out of this thread... Work for you!

-

I'm a Boy Scout covered with patches, again.

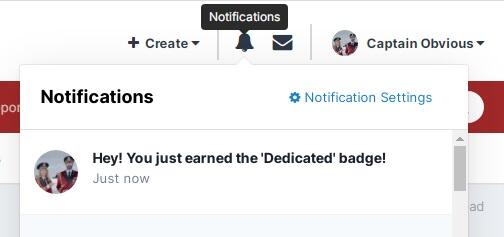

Woo Hoo!!! I just got my "dedicated" badge! Patcon still didn't get his "well followed" though. @Mike What's the deal???

-

Closing holes in trunk when removing crash bumpers

Great idea! Do you think it matters what kind of spoon to use, or is any ol' spoon just as good?

-

The Early 77 rear hatch differences

Yup. That's a 77-78 tank. And as for the mounting holes for the taillight trim panel, I don't have good enough pics to tell for sure. This is the best thing I have for the sloped rear deck and I can't tell if there are holes for the little screws or not. Should be easy for you to just check your car though.

-

The Early 77 rear hatch differences

One of those thread (the one about the spare tire) has all kinds of dead photobucket sucks links in it. If there's something you want to see, just let me know. So I think the biggest thing about the sloped rear deck vs. the flat version is how they handled the taillight trim panels. Do you have a plastic panel back there or does the sloped wood cover the taillights and associated wiring? Do you even have the mounting hole provisions if you wanted to put a plastic panel back there?

-

I'm a Boy Scout covered with patches, again.

Haha! Well I read those words! And enjoyed them!

-

I'm a Boy Scout covered with patches, again.

Jeff... I cry foul. You added waaaaaay too much real info to an otherwise throwaway* just for fun non-Z specific thread. What were you thinking man!!??? * Never meant to imply that a thread started by any GRAND MASTER was ever "throwaway".

-

I'm a Boy Scout covered with patches, again.

Exactly. I normally do the same thing. I lurk anonymously unless I've got something to say and then I log in. I've been letting badge points on the table! Haha!!

-

The Early 77 rear hatch differences

Ferg, from the pic you posted... Your 77 was designed with the shallow "space saver" spare. They started that design in 77 and ran like that for 77 and 78. The cargo compartment lids were used from 70 through 74 and they stopped in 75 when they started adding the false floor in the back. Here's some details of when I added the cargo compartment lids to my car: https://www.classiczcars.com/forums/topic/62698-spare-tire-well/#comment-582414 And here's a couple other threads with some good pics of the rear deck area: https://www.classiczcars.com/forums/topic/51367-project-boondoggle-or-so-i-went-and-bought-a-z/?page=9#comment-495703 And here's one that shows one of the things I did when I lowered my wooden false floor: https://www.classiczcars.com/forums/topic/64856-280z-double-floor-removal/

-

I'm a Boy Scout covered with patches, again.

That was my favorite too!!

-

I'm a Boy Scout covered with patches, again.

Go ahead GRAND MASTER Cliff. Blame it on the flip phone. That works for me!!

-

I'm a Boy Scout covered with patches, again.

And I thought it was "DANCES with wolves" and sleeping with cougars. Did I miss a memo?

-

The Early 77 rear hatch differences

Oh, and sorry to hear about the fuel tank. Hope you can find someone to fix that up.

-

The Early 77 rear hatch differences

The flat rear deck is no treat either. I have a bunch of pics of the rear hatch area that I'll dig up when I get a chance. I made a bunch of changes to mine to gain more space. I also added cargo hatch doors. I think I posted details of that stuff on here some time ago and I'll see if I can dig that up too. So do you have a full sized spare, or the space-saver and the bottle? I can't remember.

-

Jenny! Your car is for sale in the Netherlands! Now for €34900,-

For the price of a dime I can always turn to you. Great... Now you got that song stuck in my head!

-

I'm a Boy Scout covered with patches, again.

Oh boy... Here we go!

-

1971 HLS30-14938 "Lily" build

That's exactly what I'm saying!! Someone had to do it!

-

I'm a Boy Scout covered with patches, again.

Haha!! I just checked Patcon and he's still doesn't have "well followed". Maybe there needs to be ten followers added AFTER the forum update? The previous followers might not count towards the total? And for me... I don't remember when I started trying to log in every day, but I don't think it's even been a week yet. I'm not ready to call in tech support for me. In any event, this is just mindless entertainment.

-

I'm a Boy Scout covered with patches, again.

Ya think???

-

How to Block off Early Z Hatch Vents behind the Grill

I don't have any concrete suggestions on how to block off the vents, but I do believe that most Z's are leaky enough that blocking the vents off won't do much to mess with the ventilation system. Of course, that could just be mine...

-

I'm a Boy Scout covered with patches, again.

Mike, Very nice! I like the rest of the adjusted ranks as well. So now what about that "dedicated" badge for me? I should be almost there, right? Not sure how much longer I can keep this up! And doesn't @Patcon get his "well followed" badge now that he's got ten followers or more?

-

1971 HLS30-14938 "Lily" build

Done deal!! Looking forward to it! And if someone else brings it up, try this... "I'm simply PRACTICING on the areas that don't show, so that by the time I get to the ones that DO show, I'll have it down pat."