Everything posted by Captain Obvious

-

[SOLD] NBRautoparts Nissan big letter ABS plastic valve cover RARE

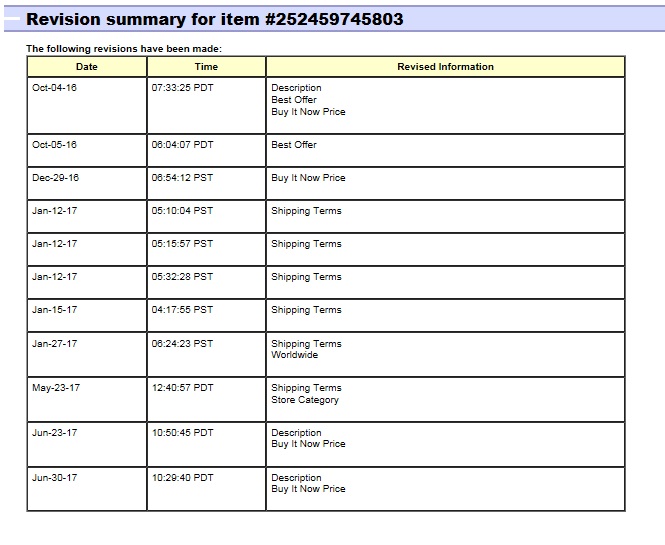

Wait... You're saying that the part for sale here is the same part that didn't sell on ebay for almost a year now? You're saying this is the exact same part??? And not only that, but it's being offered here for MORE than it was on ebay? Really??? Here's the revision history from the ebay auction. Seems it was up on ebay for almost a year with a number of price reductions along the way: And here's another shot of the one from the ebay auction. It looks nicer than the one being offered here. Like someone hosed it down with Armor-All right before the pics to make it look all shiny for the auction:

-

Photobucket Rant - They SUCK

I'm not sure how "short sighted" their management is. Looking at it from their point of view, I'm a waste of space. Sure I look at their ads, and I've even clicked on a couple of their vendors ad links to suppliers, but they surely can't get a lot of real money out of my existence. From their perspective, I'm sure they believe people like me are not bringing in money, but are taking up space. I suspect if they can weather the current shite-storm of bad press and hostile attitudes, they will be in a better financial position in a year or so. I can hope that doesn't happen and they change their mind and go back to how it was three weeks ago, but I doubt it.

-

Photobucket Rant - They SUCK

Well the big draw for me was a place to host my photos without a money outlay and make them available to youze guys. In other words, they would host my pics, and in return, I would look at all their ads as payment for the service.

-

[SOLD] NBRautoparts Nissan big letter ABS plastic valve cover RARE

There was some discussion about a plastic valve cover here on the forum a little while ago in this thread: http://www.classiczcars.com/topic/57530-sold-240z-2400-valve-cover/?page=2#comment-521058 There was also a recent ebay ad for a similar part. The asking price was $550 and ended - no sale at that price: http://www.ebay.com/itm/Datsun-nissan-240z-260z-280z-280zx-RARE-ABS-valve-cover-JDM-1970-1971-1972-1973-/252459745803?rmvSB=true&hash=item3ac7c6020b%3Ag%3AH94AAOSwp5JWZ6Qw&afsrc=1&vxp=mtr&nma=true&si=ukwOSXVYy0FSfXGrdddCOdYZ3%2BY%3D&orig_cvip=true&rt=nc&_trksid=p2047675.l2557 Here's a pic of the no-sale $550 one from ebay:

-

2000$ rear hatch glass

"Late to this thread but better late then never.... " Wow. I disagree. I think never would have been better than late. Your first post ever on this forum - "Nyeah Nyeah Nyeah! Pbbbbbbthhhh! My part sold for exactly what wanted, so for all you people who said anything I didn't like about my auction... you are smart a$$ with little minds or have personally problems." It might just be me, but I would rather see someone come to the forum and try to participate in some way other than simply trying to profit from it's members. Add something constructive to the community before you start trying to make money off them. I mean... I get it. I understand you're trying to sell parts for the highest price you can get. Who doesn't?? Just add something constructive to the community instead of coming here to wave your fantastic awesome success in the air and rub members noses in it, and call people names simply because they have opinions you disagree with? Never would have been better than late. @Mike

-

BBQ

I like that Alton explains the science behind much of the tasks. Understanding what's going on lets me port the concepts to other recipes. Like the difference between giving a man to fish, and teaching a man to fish. If you understand the "why" in addition to the "what", you can use the same knowledge in other applications.

-

Photobucket Rant - They SUCK

wheee!, OK, you're allowed one strike, and since you're already ashamed about Nickelback, I guess the lesson has been learned. On quick search, I turned up lots of other artists from Alberta, but here's some that I recognized and don't turn off. Everybody's working for the weekend, right? Joni Mitchell K.D. Lang Tegan and Sara Loverboy Blind Melon Chitlin'

-

Photobucket Rant - They SUCK

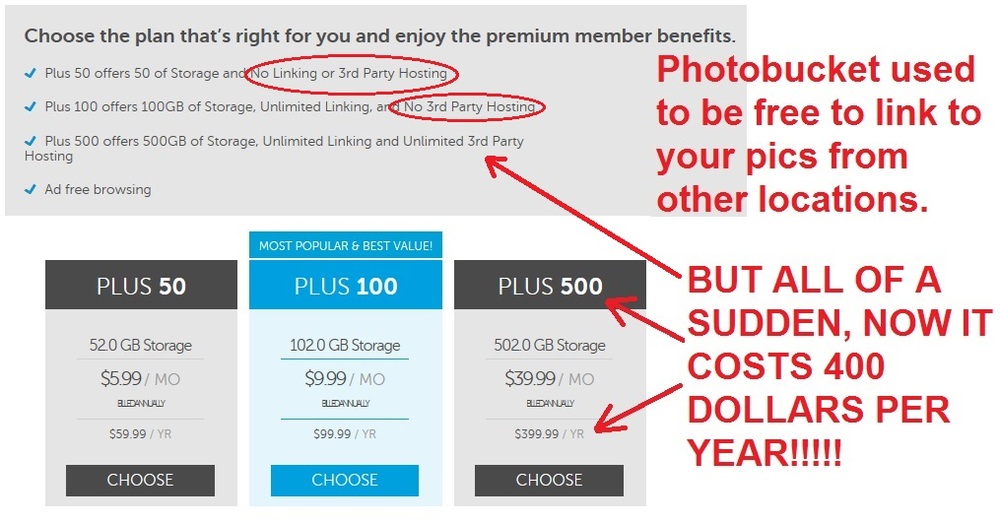

From looking around on the internet for other people having problems, I believe the answer is "yes". It will disappear as soon as they get around to enforcing their newly released surprise policy on you. Probably hasn't happened to you yet because you don't do enough of it to get their attention. They are probably waiting until you have done enough of it to make changing direction really really painful. Painful enough they think you will consider paying $400 per year to fix it. Make it free until you are hooked, and then make you to pay to fix it.

-

1971 HLS30-14938 "Lily" build

Were the hinge detent wheels worn on yours? I've got flat spots on mine from years of them not spinning properly and sliding instead of spinning. I've got a spare set of hinges here that I intend to rebuild before installing, but it's lower on the priority list.

-

BBQ

Alton Brown is my cooking hero. My son now even records old Good Eats episodes and shows me things he wants me to make for him. "You should make this for me" he says

-

Photobucket Rant - They SUCK

Haven't they been known to pick a song or two?

-

Photobucket Rant - They SUCK

Ewwww... Really? I'm so, so, sorry, but I have to hate you now. Crap. That's incredibly inconvenient.

- 1976 280Z Restoration Project

-

Photobucket Rant - They SUCK

Sweaty, I know it's not the end of the world, and I'm actually less connected to this kind of stuff than many (most?) people are these days. Just bugs me that they lured me into putting all my eggs in that basket and then after I was hooked, they started charging an unreasonable amount of money. I was out in the Z yesterday, and the old song "The Pusher" done by Steppenwolf came on the radio. Made me think of Photobucket! Mike, I know I could put all my photos here, but not all of them are Z related. I do put some here though, if they are specific to this forum. Doesn't seem right though to put pics here and then link to them from a different Z forum. I know it's OK, but it just feels like cheating.

-

Heater Core Alternative - Escort Core into 260/280

Could be, but I've not turned up a comprehensive catalog that has pics and reliable dimensions. I decided on the Escort core because it was the thinnest, smallest, most generic, cheap core that I could find with tubes that stuck straight out on the same side. No long funky bent tubes. No weird mounting flanges. Generic, small, thin, and cheap because it's from a ubiquitous cheap car that was produced in high volumes. There could very well be something even better out there, but finding it is the hard part!

-

GODZILLA!!!!!!!

History shows again and again how nature points out the folly of man. Great pics Zup and Happy 4th!

-

Happy Canada Day!

Haha!! Sometime, my friend, I'm going to make it to your neck of the woods and we can have Poutine and Beer. Guaranteed good times.

-

Happy Canada Day!

Happy Canada Day!! Is that an occasion for Royal Pudding? As is tradition?

-

Photobucket Rant - They SUCK

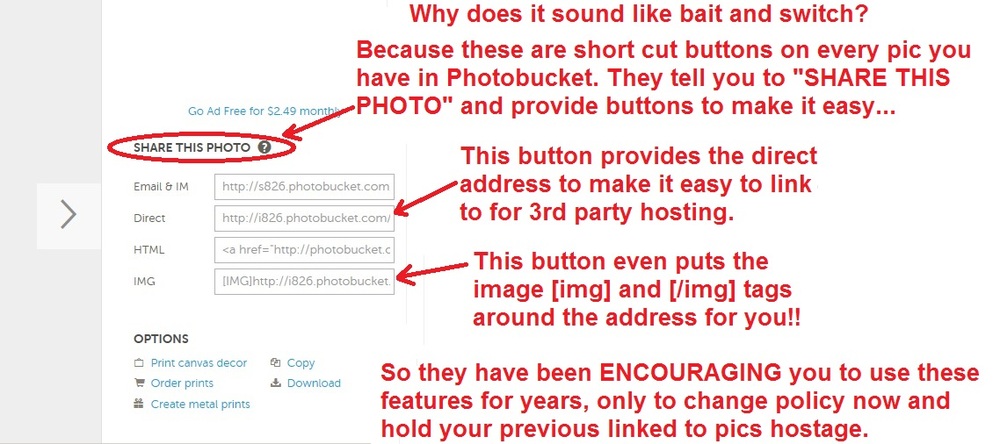

I'm not sure I was completely clear before as to why I question the business practices at play here. Here's a snippet from any photobucket pic that I have uploaded. On this pic you can see the easy to use short cut buttons they provide. You simply click on the type of address you want, and it's loaded onto your clipboard, ready to paste into the forum of blog of your choice. They tell you on that same page "SHARE THIS PHOTO", and provide you the means to easily do so. They have been ENCOURAGING THE SHARING OF THE PHOTOS FOR YEARS!!!!! And now, once you are mired in so deep that it would be a huge pain to change course, they change their policy and hold your links hostage to the tune of $400 per year!! I'm not happy.

-

Leaking Heater

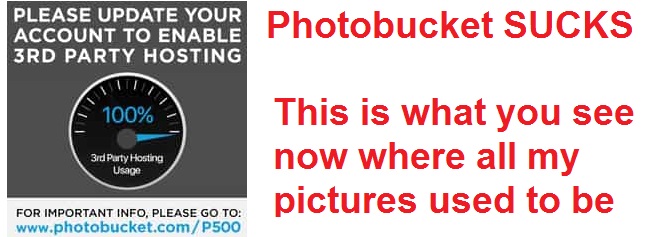

Yeah, that was me... Here's the thread, but it's mostly useless because Photobucket SUCKS: http://www.classiczcars.com/topic/56726-heater-core-alternative-escort-core-into-260280/ Used to be loaded with pics, not all you get is this:

-

Rear bushings

When I was messing around with my diff, I replaced the original mount hardware with socket head cap screws coming up from the bottom instead of the original hex head bolts. Here's the thread where I was talking about all of it. Thread is pretty much useless now because all pics are dead because Photobucket SUCKS, but here it is anyway: http://www.classiczcars.com/topic/55955-my-new-diff-mount-and-strap-project/ The bottom line is if you go through the effort to take the front diff mount off, I would use different hardware when you put it back on. Here's a couple pics showing the idea:

-

Photobucket Rant - They SUCK

Patcon, I know I could put the pics here on Mike's site, but many of what I have out there isn't specifically Z related. For example, the last pic I posted was my liquid level manometer that I was using for my motorcycle carbs. While it isn't Z car directly related, the topic came up, and you can even see a corner of my Z in the pic. I had that pic posted on a cycle forum and I would have to host it in multiple locations instead of just one and linking to it when appropriate. It's reasons like that which make it desirable to have an independent picture host that I can link to. Just not one that blindsides me with $400 per year!!!!

-

Photobucket Rant - They SUCK

Many people believe that Photobucket is hitting up people who are approaching their storage limit. Well I'm nowhere near my storage limit. I'm at about 10% of my allotted capacity. I'm nowhere NEAR the limit. So that rumor isn't true. The whole thing stinks like questionable business practices. After you have upload a picture, they present you with a number of link buttons to get the picture address in a couple different formats: One of these buttons called "Direct", gives you the URL address direct to the picture. This allowed you to use that link address to do what I did... Post it elsewhere. There's even another button called "Image", or something like that, which even puts the tags onto the address for forums that use that kind of nomenclature. You use that button if you don't want to put the IMG and /IMG tags onto the picture address yourself. So why is this noteworthy? BECAUSE THEY ACTUALLY PROVIDE EASY TO USE SHORT CUT BUTTONS TO ENCOURAGE YOU TO DIG YOURSELF INTO A HOLE THAT YOU NOW HAVE TO PAY FOR!!! In other words... They have been providing these free easy to use features forever. You use these features and get yourself mired into a place that is very hard to get out of, and then AFTER you have dug your impossible to get out of hole, they bait and switch you and tell you it'll cost $400 per year to save your butt. I've been looking at their ads for years. Photobucket gets paid by other companies for the right to have their ads pass through my eyeballs. And as incentive for me to look at their sponsors ads, they host my photos. That's the deal. I look at the ads, they host the pics. Then they decide they aren't getting enough from one end and hold my pics and years of built up threads as ransom? Almost as if they had this planned for a long time because they knew it would be impossible for people like me to recover from the change without paying. Unfair business practices?

-

Photobucket Rant - They SUCK

All my picture links are broken. All those threads with my pics in them are now pretty much useless because of Photobucket. They suck. I've been using a free Photobucket account for years. All these years, I've uploaded pics to their site and then linked to them from other places (like this forum). Well, guess what... They just made a changed their policy and removed the ability to link to pics from other locations. They call it "3rd party hosting", and you can no longer do it from a free account. In order to have that ability, you must upgrade to a higher level pay account. In fact, in order to have the ability to do "3rd party hosting", you have to upgrade to their "Plus 500" level account. Now get this.... The cost for the pay account that will allow this linking is....... $400 dollars per year!!! So, I'm really sorry, but my pics are gone. If anyone has a specific thread that they're looking at and want the pics, I'll see what I can do about hosting them somewhere else, but I have so many that there's no way I can wholesale move everything at once. Sorry...

-

Rear bushings

If you removed the spindle pin lock bolt and got the pin to turn that easy, then you're already more than halfway done with the job! The rest is gravy!