Everything posted by Captain Obvious

-

280Z fusible links

Fuses and other protective devices are not a field of expertise I've been even grazed by in my travels as an EE. But I can tell you that even though the whole thing sounds so simple and mundane, I highly suspect the experts in the field would be quick to refute that. In other words... I bet the people who really know what they're talking about in this facet of engineering (which isn't me) would be able to debate the finer points of this for hours. That said... I took a quick look on the web and came to the following conclusions: 1.25 mm sq is approx. the same as 16 ga 0.3 mm sq is approx the same as 22 ga 32 ga And also with some web searching, it seems that the "general convention" seems to be that the fusible link gauge should be four sizes smaller than the wires they are intended to protect. So, for example, 12 ga. wire should be protected by a 16 ga. fusible link. And 18 ga. wire should be protected by a 22 ga. fusible link. All that really makes me wonder if that brown 0.3 mm sq link is really really correct. Maybe that red link really was the correct one all along?

- 280Z fusible links

-

1966 Roadster 1600, here we go!

Is that a seam in the middle? Like someone took something designed for a wider car, cut some material out of the center, and then bolted the two remaining pieces together in a narrower configuration?

- 280Z fusible links

- Silvermine Motors Electric Power Steering System

-

280Z fusible links

I had the camera handy, so I took some additional pics. Here's the correct position for the links on the 77-78. This time I took the pic from the angle that everyone likes. As it's shown in the FSM: And here's a pic that (although it's hard to tell), you can actually see that one of the White/Red wires is larger than the other three. That's the position that gets the largest (black) fusible link. The W/R wire gauge is larger to account for the higher current that circuit can potentially carry. Who knows... Since the blocks are just screwed to the fender well, maybe some of them have been switched around? So if you're looking for a way to definitively determine which location gets the largest fusible link, you can check the wire gauge sizes: And here's a pic of what remains of my fusible link labeling. Can't make out any of the color listings. Would be great if a 77 or 78 owner could post a pic of better condition labels, but this is all I got left. I can make out ??L (which I assume would be H-L) and "IGN", but that's it:

- Silvermine Motors Electric Power Steering System

-

Rear wheel bearing help 240z

That's the way it's supposed to be. The inboard and outboard bearings both have the same ID. (FYI, same OD too): https://www.vsm.skf.com/us/en/products/GRW116 https://www.vsm.skf.com/us/en/products/GRW117 Part Number: GRW116Type: Wheel Bearing Part Information: Outer Diameter: 2.7500 in Inner Diameter: 1.2500 in Width: 0.687 in Part Number: GRW117Type: Wheel Bearing Part Information: Outer Diameter: 2.7500 in Inner Diameter: 1.2500 in Width: 0.8646 in

-

280Z fusible links

I replaced all my fusible links a little while ago (still need to post up a public service warning thread about that whole thing, but...) and I believe I saved my old ones. I'll take a look at my old red ones (that are truly red) and see if there's any writing on them. I keep then in the center console as emergency backups, but I may donate one to the cause and open it up. I should be able to measure the wire inside. I can tell you anecdotally that the brand new 0.3 "sorta brown, sorta tan, sorta salmon" links I have installed run nice and cool. Implication being that they are large enough.

-

280Z fusible links

OK. At least we talked about it a little. I remember that at the time, the priority was addressing the headlights so you didn't get caught in the dark. We may have glossed over the fusible links with "here's something else to take care of when you get a few spare minutes" or something like that. I'm just glad we could get a handle on the intermittent headlight issue and get you home with a definitive answer to what was causing the problem. Yeah, I know @wal280z is all dreamy about the fuse replacements (note that I didn't say "upgrade" ) for the stock system. He's that kind of guy. Lives for the bling.

- 1976 280Z Restoration Project

- SU carb/ running issues

-

280Z fusible links

Yes, I do believe the mis-placement did carry over from 77 into the 78 year. I think the location of the biggest (black) link never changed. I think they got it right on the diagram in 76 (right front), and then screwed it up in 77 which carried into 78. It would sure be nice if any other 77 or 78 owners could verify the position of the links just for additional data points. I know I've checked my 77 and positively determined the positions of the links. And I know that @240260280 did the same on his 77 some number of years ago. But I don't have any hard 78 data points. So for any of you 78 (or additional 77) owners out there who would like to participate? The easiest way to verify the link positions... Turn your headlights on. Remove the link that is closest to the fender and closest to the firewall (right rear) fusible link and the headlights should go out.

-

280Z fusible links

@gwri8, excellent! Glad we could solve a long standing issue. But I gotta ask... Did I pull the fusible link caps off your car in Atlanta and have a poke around? I know I messed around with the fuse block in the footwell and the multi-function switch on the steering column, but did I get up into the engine compartment? If so, I hope I would have noticed the links in the wrong positions. At least I hope I would have. I know it was a little drizzly at the time and we were rushed for time, but still.

-

1976 280Z Restoration Project

Wow. That's some pitting. Are you sure none of those pits go all the way through? Was there oil in the pan in recent past, or did you purchase it dry? Yeah, that was my reaction as well. @ksechler did specifically say the braided lines didn't clamp well. Maybe the non-braided original lines aren't a problem? Hopefully he'll chime back in with more info?

- 280Z fusible links

-

280Z fusible links

Zed Head, The pic you posted from MSA is one of the biggest contributors to the problems with the fusible link locations for 77. This diagram is wrong for the 77-78: I don't know where it started, but it probably started from the FSM wiring diagram for 1977. Nissan (seemingly) tried to lay the components out on the wiring diagrams kinds-sorta in the same positions they are located on the car. Problem is they screwed up the position of the black link. On the factory wiring diagram in the manual, it has the black link on the fender side back position near the firewall. But on the 77 car (I myself personally verified with a meter) that the black link should be on the fender side FRONT near the headlight. So Nissan never really said "This diagram correctly locates the link positions on the car", but it sure can be assumed that's the case. Problem is.... It's wrong. And others (like MSA) have been propagating that incorrect assumption ever since.

-

280Z fusible links

Chas, This pic, and the associated part numbers are the ones that apply to your 77: It says you need one black link (P/N 24161-A0100) and three "brown" links (P/N 24161-N4200 which has been superseded by 24161-Y0100): Just because the chart on page BE-6 lists the specs for three different colors, it doesn't mean that all three colors were actually used. They just copied that chart from the 1976 manual.

- 280Z fusible links

-

280Z fusible links

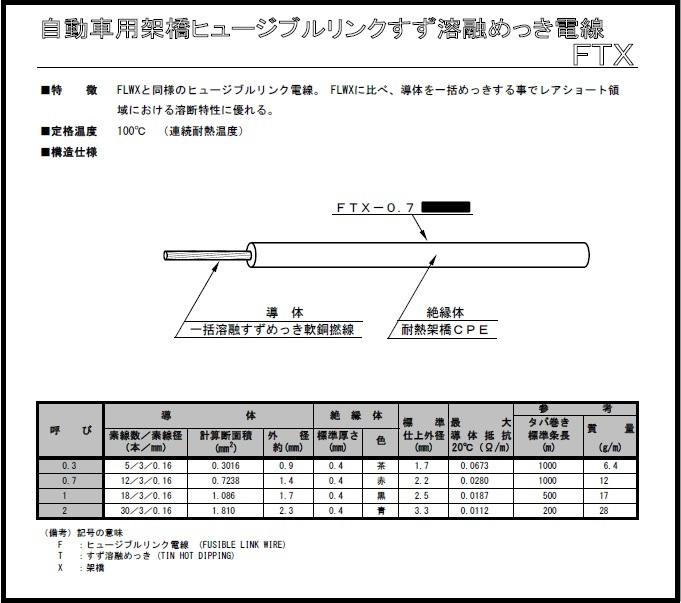

Some backup documentation for the above. Pic from a 76 that has excellent condition original labels. Note the link colors: Pic from my 77 with the links in the correct positions (regardless of the 77 FSM's misleading wiring diagram). I personally used a meter and verified these positions for 77 and 78: I dug into the specs for the links and determined they (like most of the rest of the Z's electrical infrastructure) was made by Yazaki. Here's a link where you can find specs on much of the Yazaki wires, etc, including the link material: http://connectors-catalog.sys.yzk.co.jp/yazaki-web/english/cables/pdf.html And since it's easier to discuss without downloading pdf files... Specs for the FLWX links. Would be cool if someone could translate into English for me: Specs for the FTX links:

-

280Z fusible links

I dug into the 280 fusible link stuff a little while ago and here's what I determined. First, what the FSM's say... The 75 FSM shows two fusible links and says they are black and green. The 76 FSM shows four fusible links and says they include three different sizes of links (black, brown, and green). The 77 and 78 FSMs shows four fusible links and says they include two different sizes of links (black and brown). Note that the above links are the ones bolted to the passenger fender in the little square boxes with the white plastic caps. There is another one (or two in the case of 78) fusible link that comes directly off the battery and is specific to the EFI system. That additional link (or two) is outside the scope of this discussion. I'm just talking the ones in the boxes on the inside fender wall. Also, I'm not sure what's up with the "brown" color link. Seems hard to find brown ones, or at least it used to be. I'm not sure if the brown was replaced by red or what, but I've seen more red links than I have brown although brown seems to be making a comeback. So about part numbers? When I last looked, the part numbers were as follows: FUSIBLE LINK-1.25 - 24161-A0100 - This is the black one FUSIBLE LINK-0.5 - 24161-28500 - This is the green one FUSIBLE LINK-0.3 - 24161-Y0100 - This is the brown (or red) one (supersedes old number 24161-N4200) EuroDat, for your 77, it seems you want one black and three brown (or red)

-

Spindle Pin Installation

Excellent. Keep coming to us with the easy issues. We like those. Don't forget to use copious amounts of anti-corrosion anti-seize on your new spindle pins when you slide them in for the final installation. And if you didn't already know.... The location of the notch for the lock pin is not in the center of the spindle pin. It's offset a little bit. (The pin is not symmetric). There is a correct front and back. Point is... If you haven't already done so, it's a lot easier to determine which is the correct installation direction when the parts are off the car and not all slathered with copious amounts of lube. Mark it with a sharpie or something now while everything is clean so you don't have to futz with it while it's all slippy.

-

Spindle Pin Installation

You should be able to insert the spindle pin all the way and spin it 360 degrees with just two fingers. If you can't do that, then I suspect there's a burr inside that's causing an interference fit. There should be no tools required to get that pin properly into place.

-

Odd Engine Bay ID Tag

Many moons ago (waving hand like "these are not the droids you're looking for"), I worked for a company who made equipment that featured a black on silver faceplate similar in concept to the VIN tags. They were some sort of black coating on a thin aluminum substrate and the black coating was some sort of photo-resist active material. You would lay a piece of film artwork (black and clear) over the substrate and then run the pair through a box which housed bright light of some sort. I don't know if it was UV or what, but fading memory says the light was greenish, not purplish. And then after the light exposure, you would wash the substrate in some chemical and parts of the black coating would come off. I don't remember if the parts exposed to the light came off or if the parts exposed to the light were "set", but clearly it was photo-sensitive in some sort. Anyway, when you were done, you had a black on silver rendition of the artwork you laid over the original all black substrate. I can't remember the trade name of the equipment, but I believe it was relatively common back then. It's probably outlawed at this point due to health risks from the chemicals and the light, but I used it a lot "back in the day". I wish I could remember the name of that system... Not that I want one, just that it bugs me that I can't remember the name!

-

Problem With Differential Installation

Yeah, I guess I've heard some people have a little trouble squeezing the PU bushings into place, but that's a cakewalk compared to removing an angry pair of spindle pins. Thanks for the info on the wave washers. I have a pair of moustache bar bushings I intend to install into my car some day, but there's really no point to doing so unless I come up with a plan for the washers.