Everything posted by Captain Obvious

-

Best Captain Obvious so far

Hahaha!!! I saw that commercial a little while ago. Loved it.

-

L28 full rebuild assembly

Consider it done. I'll put a set aside for you.

-

What are the facts about 280z ECU compatibility and differences

And about that HybridZ page... "If I remember correctly... The pics are wrong. The resistor designations are non-existent. And there's talk of a lamda sensor. All that spells different ECU."

-

Crankcase to PCV Valve Hose

Electrically conductive coatings can be measured, but depending on the style of coating, it might not be as simple as sticking your generic VOM leads into it. If it's intended to be "static dissipative", it might be a high resistance. In the MegOhm range. And in that range, the resistance through your body might be enough to get a reading on the meter, so if you're touching the leads (or what you're measuring) with your fingers, you won't know if it's the coating, or you.

-

What are the facts about 280z ECU compatibility and differences

I've never seen a schematic for the entire ECU. I've reverse engineered a little bit of it (very little). One of the sections I DID do however, is the output transistor section. Pretty self explanatory. I'll see if I can dig that up.

-

L28 full rebuild assembly

I've got a spare set if you need one. I had zero, so I put out a request a little while ago that was generously answered by @240260280. Then shortly after his gift set arrived, I lucked into a second set in a box of misc Z parts off craigslist. So now I have two sets and would happily send a set your way with the next shipment headed your way. But if I know you, the new set is already on it's way to you.

-

Crankcase to PCV Valve Hose

Sorry... I've hear that the silver coating is ELECTRICALLY conductive. I believe the belief was static dissipative or spark prevention? Apologize for the confusion.

-

Restoration of BringaTrailer 240z - HLS30-35883

LOL!

-

What are the facts about 280z ECU compatibility and differences

It sounds like your A11-600.... unit has a problem. My first WAG would be a blown output transistor and you're running on three cylinders. You should be able to check those big TO-3 buggers in-situ. They're Darlingtons, but you should be able to check them with the ol' Simpson.

-

Crankcase to PCV Valve Hose

I've heard the belief that silver paint is special because it's conductive. Haven't done a lot of research though, but "I read it on the internet".

-

L28 full rebuild assembly

Cool. So you just verified that the ZX pick-up tube fits with the Z oil pan, right?

-

F54/P79 Swap Project

Thanks guys. I'll hit them with a little heat and try an impact driver. I haven't really put a lot of grunt into them yet because I was worried about fighting thread lock. Keep you posted! And in the meantime... Here's some catch-up pics. This was my experience popping that troublesome front expansion plug. I made this little adapter contraption for my slide hammer: Carefully drilled (making sure I did not drill too deep) and tapped a hole into the expansion plug to accept the adapter: Thread on the slide hammer and with a couple taps, out pops the plug: Don't know if it would work on all attempts, but so far, I'm batting 1000 at two for two.

-

F54/P79 Swap Project

So I've been slowly working on the two F54 blocks here and I've got a question, The two Phillips screws that hold the PCV vent baffle screen into the block... Mine aren't coming out easy and I'm wondering if they used thread lock on them. Anyone who has taken those out have trouble with them? Last thing I want to do is snap one of those off in a newly painted block @GGRIII 's in front and mine in the back: We used different paints on our blocks. I like mine better.

-

L28 full rebuild assembly

Well I know from holding the two of them in my hands that the stock ones for the ZX are different than the ones from the Z. The one for the ZX is a little longer and comes off at more of an angle towards the back of the engine (which makes sense since the sump is in the rear). There are pics on ebay of both styles, but without them side by side, it's really hard to see the differences. Looking at the oil pans though, the holes down into the sump look like they're pretty much in the same spots, so I don't know if you can actually get one style to fit into the pan that it wasn't designed for. That link to zcardepot seems to indicate that it's (at least possible) to share the same pickup tube on all years 70-83, but that may be an aftermarket difference from stock? In any event, if you've got the ZX pickup there, should be easy enough to bolt it on and see if the oil pan will fit into place.

-

L28 full rebuild assembly

I've done a little digging on the subject (because I'm in a similar situation), and my understanding is that any pan will bolt up to any block just fine. There are some issues however... First issue is fitment into the car. Either the original (middle sump) Z pan OR the rear sump ZX pan will work in the Z. But the converse is not true... The middle sump pan will not work in the ZX. But since you're putting the motor in a Z (and not a ZX), either pan would fit fine. Other issue is that I (believe) you need to use the correct sump pickup tube for the pan. In other words, if you're using a middle sump Z pan, you need the middle sump pickup. (And conversely, if you're using a rear sump ZX pan, you need to use the ZX pickup.

-

Excess fuel pressure: tank vent or pump

Yeah, if the pressure in that tank vent line gets about 2psi above the crankcase connection, it's supposed to burp the excess pressure off. If it has stuck in the past, I give strong money that it's stuck again. I've never opened one up, but from the pics and the description, it's just a couple springs and sealing balls inside.

-

HTP Quick Spot II spot welder - quick review

You already bought the $649 machine, right? You're just looking to see if you can commend yourself on a worthwhile purchase, or need to kick yourself in the butt for buying an the expensive one when you could have bought one for a quarter the price that does the same thing? Well for making that decision, here's some fodder... The only thing fuzzy about that HF welder is the quality, and there's no invertor technology employed there. That HF welder is the big asss heavy lump of copper transformer that we talked about above. Works OK, but doesn't come with any of the adjustability that yours does. In fact, the only thing adjustable about that HF welder is weld pressure and the amount of time the power is applied (because you can let off the handle any time you want to). So it kinda all depends on what you're looking for... That HF welder is old bulletproof technology, but the results will be only as good as the guy using it. Your machine is programmable so you can get dependable consistent results from one weld to another even if you have no idea what you're doing. From what I've seen, in the small amount of poking around I've done for this thread, Telwin has a good reputation, and that spot welder seems to be well a respected portable unit. Not sure the same sentiment exists for the HF offering.

-

HTP Quick Spot II spot welder - quick review

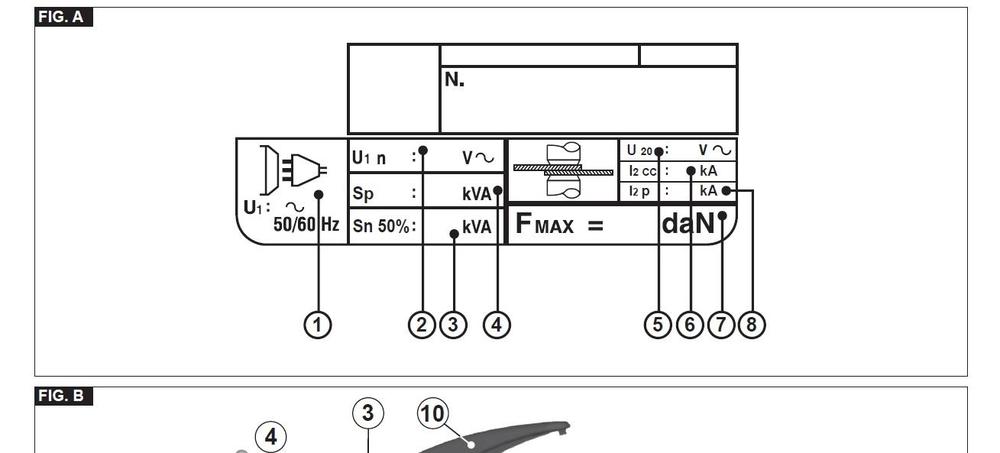

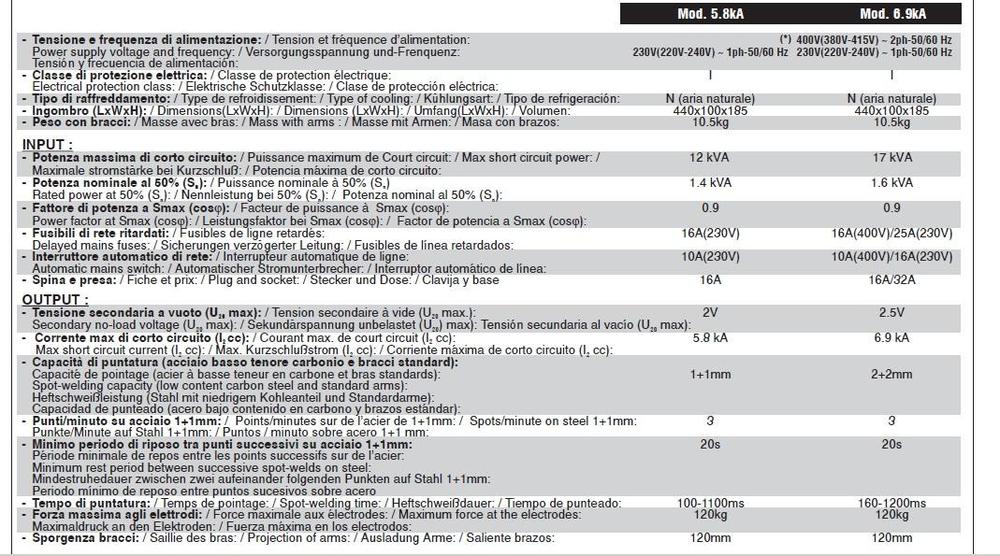

According to the label, that spot welder is made by Telwin. They are Italian (we already knew that). Web page here showing their products (prodotti) >> https://www.telwin.com/en/prodotti That welder is their Modular 230 (or an earlier version of the same), and if you dig down into that model, you can get to a datasheet. Here's some info from the datasheet that may help with the above academic discussion: Enjoy.

-

HTP Quick Spot II spot welder - quick review

I don't think it's a typo. I think there's a way to interpret that spec that makes it "correct". The 2.5 Volt welding voltage is probably the open circuit voltage at the electrodes. Problem with converting that to a simple KVA rating, however, is that as soon as the electrodes are closed, you don't have 2.5 Volts anymore. You'll have something less. The 6000 Amp max welding current is probably a very short burst of current that occurs for a tiny instant of time when the electrodes are first connected. The "realistic" welding current is probably something much lower than that. The "rated power" is probably an averaged rating of how much power it draws under "normal circumstances". At 180 spots per hour, you're doing 3 per minute. If it takes ten seconds to position and ten seconds to weld, you've got a 50% duty cycle. My guess is you're drawing an ave of 2.3KW under those conditions. And something else thing to remember... The electronics inside the device consume power too. It's not all presented at the electrode tips. Some of the power consumed from the line cord goes into powering the device itself. It'll get hot inside and that power came from the same cord. So it may draw 500W quiescent power when just idling between welds. No idea.

-

HTP Quick Spot II spot welder - quick review

Since you're not planning to use this in a professional every day heavy use application, my recommendation would be to use reviews instead of specs to compare. I suspect the big difference between welders is the duty cycle. And you probably won't be taxing the limits.

-

Excess fuel pressure: tank vent or pump

There is a device called the "flow guide valve" that lives up in your engine compartment who's job is to prevent exactly what is happening to you. I'm assuming that's what you referred to as the "vapor valve"? The flow guide valve has three connections to it. One to the vent line that leads to the gas tank, one to the crankcase, and one to the air cleaner. If the pressure in the tank goes above four inches of mercury (about 2psi), the flow guide valve is supposed to crack open and allow the excess pressure to bleed off into the engine crankcase. I suspect there's something wrong with your flow guide valve (like it's sticky gummed shut). There's a good description of the system in the EC (Emissions Control) section of the FSM. There's also some info on how to test it.

-

HTP Quick Spot II spot welder - quick review

The "inverter technology" means that it's more complicated than a AC output with heavy duty variable tap transformer and contactor with a timer. The variable tap transformer stuff is heavy and contains a lot of copper. The inverter stuff is light and contains a lot of electronics. I don't know what "Sn" means, nor do I know how to interpret the goofy numbers on the spec sheets. From what I've heard (from people who supposedly know such things(, welders are one of the prime candidates for "specsmanship". The specs are often convoluted, misleading, and highly dependent on lots of variables and how the unit is used. Fine print and all that.

-

Mint '71 240Z - More Fun Coming to BaT

I bet it was the flat top carbs. @Zup

-

Tim's 1978 280z

Welcome aboard! I suspect if you're a friend of Chris', you're already a special character. This is your place, right?

-

L28 full rebuild assembly

Yeah, I'm not sure now. I took a quick look at some old pics when I took my 83 apart and the TVV is up in the thermostat housing, so my pic with the notes on it is wrong (in at least one area). I'll take a deeper look into my old pics when I get a chance. I do think the long snout sensor is for the EFI though. It fits into the dry thermowell near the back of the head. The beveled nose is supposed to bottom out in the hole for good thermal contact.