Everything posted by Captain Obvious

-

F54/P79 Swap Project

Yup. One of the things they say is to always insert and remove the hone while it's spinning. That's why I was "bumping" the drill while I put the hone into the cylinder. Taking it out is easier (and smoother). And yes, you are shooting for a 45 degree angle, but it's not 45 WRT horizontal or vertical. You're actually looking for 45 degrees between the crosshatches. So each opposite direction crosshatch would be 22.5 degrees from horizontal so that when added together, they form a 45 degree angle between them. Does that make sense?

-

F54/P79 Swap Project

I (think I) managed to get a video uploaded... https://www.youtube.com/watch?v=WaEgaQ92rj4&feature=youtu.be

-

F54/P79 Swap Project

That's pretty much it, but I had one other advantage in that I had a trashed "nobody cares what happens to it" spare block here to practice on. So I had six cylinders to get the rhythm down on before I moved to the two other blocks that I DO care about. Hopefully by the time I moved to the two good blocks, things were consistent and my angles turned out right. And having my coxswain there helped. I just like saying that.

-

F54/P79 Swap Project

And BTW, I'm not looking to remove any defects with this honing. I'm just looking for new oil holding scratches to seat my new rings. So I may not have gotten 100% coverage on every square millimeter of cylinder wall, but I don't think I really needed that. I guess I'll find out in a couple thousand miles!

-

F54/P79 Swap Project

Of course, the stroke speed is related to the drill speed and with MY drill running about half-full, it turned out to be about one stroke per second.

-

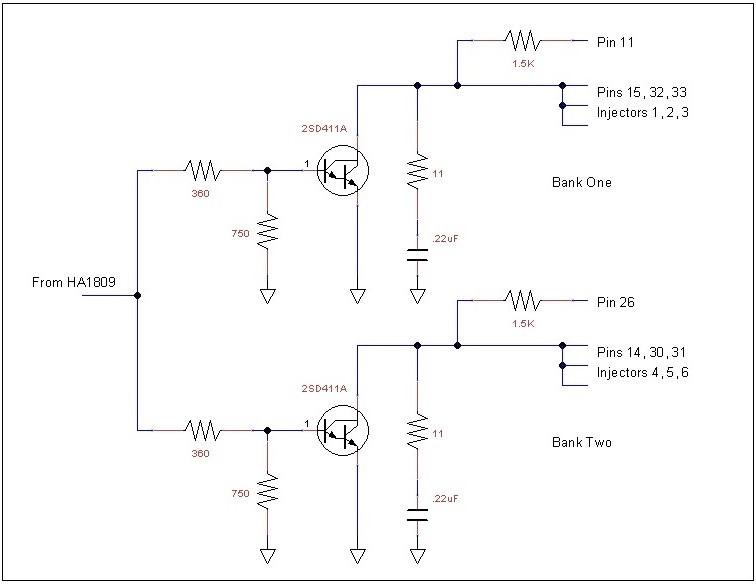

What are the facts about 280z ECU compatibility and differences

@Dave WM, I was looking through some files and turned up my schematic for the output stage: I know it's a tiny portion of the whole but that's all I got.

-

F54/P79 Swap Project

Now that the main caps are off and the crank is out, I honed the cylinders. Bought a three and-a-half inch 240 grit silicon carbide ball hone dingleberry: I ran the drill while my build buddy @GGRIII manned the WD-40 spray and kept me in-time on my stroke frequency. I think that makes him my coxswain (snicker). In this pic, there's an un-honed cylinder in the foreground and one that I honed in the background. I was attempting to get the hone marks of both cylinders in the same shot so I could compare them, but after all the miles the stock honing is hard to see: Here's a closeup of what I did. About 20 seconds of honing per cylinder and I ended up with this: I've got a two second video clip example that I will upload as soon as I figure out (again) how to run youtube.

-

Parts Refurb

Has anyone tried just roughing up the metal toggle handle and painting it flat white? And if someone really really needs a plastic one and has a dead example for autopsy, I bet I could come up with a plastic replacement. Might take 100 hours and cost thousands, but I'd be willing to at least take a look at it.

- 240z - fabbing new front rails

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Have I mentioned that one of the transmissions I've been into, I was into so many times that I could do a whole disassembly and reassembly blindfolded. I did it once just to prove I could. Simple three speed box, and I was into it way more times than I should have been. And it was all my fault.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Yeah, even if the jaws DO meet together flat and close down completely, the three jaw just isn't the most accurate tool in the drawer. Works fine if you're starting with a piece of stock larger than you need and turn all of the important features without taking the part out of the chuck. That way, even if the chuck isn't accurate, it'll come out in the wash because all the surfaces you turn will be concentric with eachother. Don't worry about the jaws of the 3-jaw unless they're really really bad. Just understand the limitations and use it accordingly. Use appropriately, it'll produce accurate work. So you're thinking to yourself... No prob. I can chuck that shaft up in my 4-jaw and indicate it in, right? Answer - No. Even if you indicate it to zero at one position out from the chuck, you haven't guaranteed that it's parallel to the ways. You can put something into the 4-jaw crooked and STILL make it run true in one location.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

I was going to suggest that to you. My assumption is that the error is in the measurement method, not the shaft. And it's probably not the lathe spindle itself. The spindle is probably pretty good, I bet most of the error is coming from the chuck and the unrepeatability of the mounting of the part. If you're just tossing the shaft into your three-jaw and tightening it down, it's not going to be centered unless you've got a fantastic three-jaw AND you get lucky (that time) when you put the part in. If you really want to check something like that you'll have to do it between centers.

-

240z - fabbing new front rails

Haha!! I was thinking the exact same thing! And it probably involved lasers. And possibly even sharks. Where I come from, "HSS" is "High Speed Steel", and is hardened. I'm assuming that's not the same thing you're using it for, because if so, there's no way you're going to use it for a rotisserie.

-

New Source for Wiper Linkage. Speed up those wipers!

Interesting! And cheap! The "used on" info on rock auto shows as: SUZUKI SWIFT 1995-2001 How did Harold figure out they fit the Datsun?

-

F54/P79 Swap Project

Well you know me... I'm all about the fancy. I was going to be doing two or three motors in rapid succession, so I figured it was worth a little bit of time to put together a couple tools that would make the job a little less cumbersome. And I gotta tell you... Those handles for pulling the smaller caps are really nice. I've done it in the past using just the main bolts for makeshift handles, and in comparison, the "handles" I made are a thousand times better! When I'm done with the build, if either of you guys want to try any of my "special tools", just let me know!

-

240Z D hubcaps ... reproduction?

My BS detector goes off loud when I see those too although I don't have any specific tell to point to that is a clear indication they are repros. I do worry that it seems the people who are making these are simply getting better at fixing their mistakes and making the repros harder to distinguish from the original versions. I suspect the chatter here pointing out the differences is allowing them to monitor this thread (and maybe others like it) and use the info within to improve the parts. Double edge sword... Better repros that are virtually indistinguishable from the originals are a good thing. But if they are sold claiming to be NOS parts made by the original manufacturer, it's a lie and should not be allowed.

-

F54/P79 Swap Project

And just in case everyone isn't already tired of talk about pulling main bearing caps, here's what I did for the remaining (2, 3, 5, 6) caps. I grabbed some steel rod just slightly larger OD than the bolt holes through the caps. Turned them down a small amount so they just barely slipped into the bolt holes. Here's the pair of them, You can see the machined ends at the bottom: Slip the pair of them into the holes like so: And when you squeeze them together, they pretty much lock into the holes giving you a handle to wiggle a little bit and easily pull the caps up off the block: Sure, I could have just tapped them with a hammer and used the original cap bolts to wiggle the caps off, but for ten minutes of invested time, now I've got handles.

-

F54/P79 Swap Project

This was my experience pulling that troublesome center main bearing cap (#4 with the thrust bearing surfaces). The chunk of scrap I used to make the puller for the rear main #7 (above) wasn't long enough to span across the width of the block, so I couldn't use it to pull the center main. If I had something longer laying around that was thick enough, I could have made one puller that would work for both mains #7 and #4. But I didn't. However, since cap #4 is so much thinner and easier to pull than #7, I can get away with something thinner. So for cap #4, I used a simple length of angle iron with a hole in it for a jack bolt. Use a couple pieces of scrap wood to straddle it off the oil pan mounting surface and it looks like this: Straddle the bearing cap, screw in the jack bolt, and then use a ratchet to crank the nut down against the "fixture" to pull the cap off the block: Couple turns with the ratchet and #4 cap pops off easy-peasy:

-

280z sitting voltage?

The basic difference is the ability to really tell what's going on with the charging system. For example, consider the following... You're driving along, and all of a sudden, your alternator goes belly up. The voltmeter will still pretty much read the same thing because the battery is at full charge, but an ammeter would instantly start reading a negative charge condition (meaning that you're taking energy out of the battery instead of putting it in). Referring to the chart posted above in post number (nevermind, we don't have that feature anymore)... somewhere up above earlier in the thread, it shows that the battery voltage is only down to about 12.1 Volts by the time you have already taken half the total charge out of it. So with a voltmeter, it's possible that you wouldn't notice any problem until the battery has been drained down pretty far. But with an ammeter, it should never be on the "-" side of the gauge when the engine is running. If that ever happens, it's an indication of a potential problem. All that said.. .As SteveJ alluded to, it's just so much harder to install an ammeter in a system when compared to voltmeters. Voltmeters are hang on anywhere and are a snap to incorporate. And for that reason, the ammeter is almost extinct.

-

'71 temp sensor thread size

Perfect! Haha!! "Crank" that sucker in there!

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

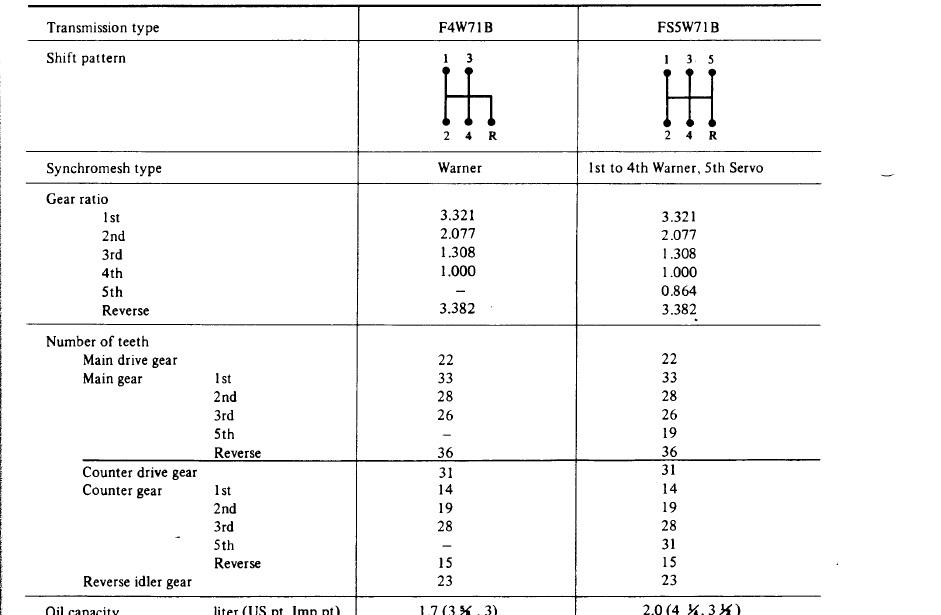

Sorry... I'm baaaaaaack. But this time it's actually with some useful input! I just snipped this from the 78 FSM (MT-18). Not sure if the other years contained this info (assuming not, or you would have simply found it and not asked in the first place), but this should answer most questions about the gear tooth counts: In 80 they they started messing around with the ratios, but this should hold for everything up to and including 79.

-

280z sitting voltage?

One thing to keep in mind is there is significant parallax error when viewing the gauge since it's over there on the side and you're not looking at it square. I find mine "accurate when viewed from the driving position", but if I look at it "straight on", my battery voltage appears to be low. I've decided that since I'm most often looking at it from the driving position, I'm going to keep it that way. Makes me wonder if maybe they calibrated them like that on purpose.

-

L28 full rebuild assembly

Oh well. So my first salvo was a complete miss. I'll have a beer or two and see if I can remember where I read about that...

-

"The Orange"

What did you use for harness wrap tape? I redid my engine room harness a couple years ago and the stuff worked great, but it's a little too shiny. Too glossy. Not a big deal since I'm not doing a real resto, but always wondered if someone else turned up a better option.

-

FS5W71B Rebuild Thread - Tips tricks and discoveries!

Oh, and by the way. Just want to let you know that I do totally get it. If you slide the synchronizer onto "the first gear" to lock it to the main shaft for 1st, and you slide the synchro onto "the second gear" for 2nd, and you slide the synchro onto "the third gear" for 3rd... Then what would you call the gear that gets locked to the main shaft by the synchro when you're in fourth? I'm gonna stop talking about it now.