Everything posted by cgsheen1

-

E brake light dim on speedometer

Yes (it's a "bullet" connector and just pushes on, doesn't screw on). And clean the inside of the connector that attaches to it also. Once you get the connection all cleaned up and reattached, that light will probably get brighter. If it does, you have a problem with a brake circuit or a faulty pressure differential switch that will need to be replaced. The switch inside completes a ground circuit for the warning light. It can only do so if the shuttle inside is pushed out of it's neutral position by a brake circuit imbalance.

-

Removing Clock Arms

That's too bad... I've taken apart several clocks and I've always been able to get the mechanism loose and away from the case. I've painted all my gauge cases white inside and it's amazing what it does for gauge illumination! I've never need higher wattage bulbs in my 260Z...

-

Removing Clock Arms

OMG... I didn't know such a thing existed - but of course, you can buy them on Amazon! https://www.amazon.com/MagiDeal-Pressure-Pointer-Caliper-Lifting/dp/B07GLB3MNL/ref=sr_1_1?ie=UTF8&qid=1538673176&sr=8-1&keywords=gauge+needle+puller

-

Removing Clock Arms

They press on - so the key is just care and patience. The metal is thin and easily bent.

-

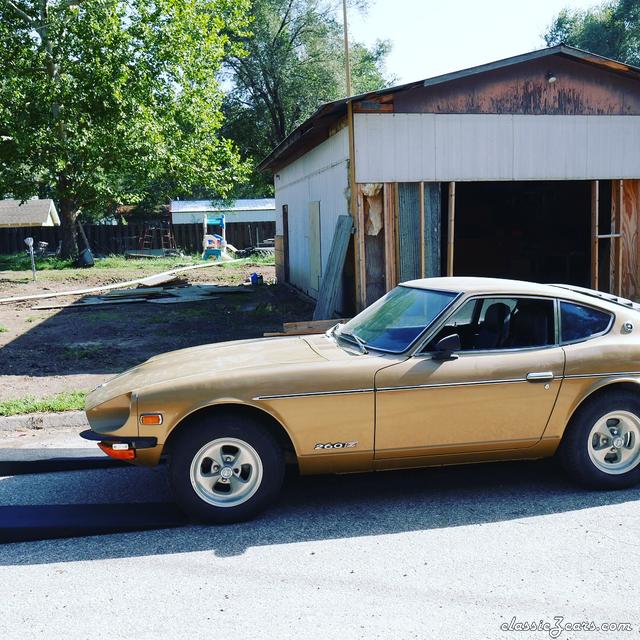

13CB17DE-A17F-4047-A874-30DB05ECCFBC.jpeg

-

Installation of Dynamat or similar material

I'm currently doing the same and have the a similar conundrum... I don't really want to cover the top of the doors. If I don't, I feel I'll need to line both boxes completely and possibly the underside of the doors. Maybe just line both boxes?? I know from building my Home Theater that an open seam equals a sound leak. I have a fair amount of the rear covered and it seems like most of my noise is now in the tail (light panels) and from the quarter panel area. IDK how I'm going to deal with those sections either...

-

240z 1972 Owners Manual

The 240Z we had here was fitted with Euro gauges - KPH, Liters, and etc... New owner thought they were cool and left them in the car. The car also had to have a rear license plate light that was under the plate. It had a lamp mounted on top of the rear bumper. It had to come from the factory like that as the holes and the wiring weren't done after the fact. It didn't have the usual plastic light holder under the hatch. It was kind of an interesting story of a US serviceman who bought the Z over there and brought it back to the US back in the day.

-

240z 1972 Owners Manual

Do the Swiss still have the law that the turn signals have to be above the bumper? We had a Swiss 240Z in the shop that had blank valance pieces right and left (no holes for what we consider stock front turn/park light lenses) and had turn/park lights mounted on top of the chrome bumper. Looked kinda like fog lamps but smaller...

-

High quality and snug fit driver's door weatherstrip

Correct. The weatherstrip is held in place by the "pinch welt". That "U" shaped part that fits over the flange. It has metal inside and you can actually remove it, squeeze it tighter in spots, and reinstall it if it's not holding well. That doesn't solve your "slamming to close door" or "weatherstrip pinching, cutting, or tearing in some areas" and/or "not completely sealing in other areas" though... The Kia Weatherstrip workaround is a viable alternative to the CRAP door weatherstrip that Precision sells. (We had a 1975 280Z Museum car in the shop and compared the stock Nissan door weatherstrip to the Precision weatherstrip and Precision got it very wrong. The stock weatherstrip is amazing in comparison.) The Kia door weatherstrip is essentially a "side bulb" type (similar pinch welt strip with a hollow circle of rubber attached to the side of the welt) that has a sharpish 90 degree corner molded in. It comes out of an SUV so it's longer than you need for a Z (can be cut and a have the seam under the sill plate), but the molded 90 degree corner fits fairly well in the upper rear corner of the S30 door opening. You can also buy generic side bulb welt that works as well as the Kia weatherstrip. It won't have the molded 90 degree bend needed at the top rear of the opening. I just put the seam there - I cut the ends at a 45 degree angle and mate them in that upper corner. The welt fits nicely around all the other bends in the door opening and I install the pinch without any sealant. BTW, you can also use a generic "top bulb welt: on the rear hatch. It's much the same as the side bulb I described, but the bulb is attached to the top of the welt. When you install it on the lower flange in the hatch area, the bulb will be on top and the hatch will close down on top of the bulb. These bulb type seals are very flexible and will seal a surface with a varying gap. Just another alternative... This is just to show an example of what I'm talking about: https://www.amazon.com/rubber-horizontal-Seal-weather-stripping/dp/B00NELWLPE/ref=sr_1_18?ie=UTF8&qid=1536258411&sr=8-18&keywords=auto+weatherstripping

-

Is my coilover spring rate too high?

You're correct in that the damper rod coming out the top of the strut cartridge is always fully extended when the strut is unloaded. You really can't do anything to "shorten it up" when you're removing the strut cartridge. The spring can come off either way, but I prefer to remove it from the top. The thread pitch on the cartridge makes unscrewing the lock nuts and lower spring perch annoying and time consuming...

-

Is my coilover spring rate too high?

Yes, you may need to disconnect the sway bar end links. NONE of the rest of this is true for Stance-USA strut cartridge! Please strike out the lower two comments. edit: In regard to ride height: The softer springs will compress slightly more when loaded than the springs he's using now - not an inch I don't think - but you're right that the strut cartridge will need adjustment in the threaded adapter to get his desired ride height after the spring replacement.

-

Is my coilover spring rate too high?

1. You DON'T need a spring compressor! a. There isn't a strut cartridge insert - you don't need to worry about anything shooting out or springing apart. The spring is NOT compressed between it's two perches! 2. Take the strut cartridge out however you can and/or want to. Personally, I'd just pull the whole thing out and work with it off the car. a. So, yes - loosen the nut at the top of the threaded adapter and unscrew the strut cartridge from the adapter. b. If you can work with it after it's loose at the bottom, unscrew all of the nuts under the spring and take the spring out. I'm going to refer to the two nuts locked together just under the spring as the LOWER PERCH (or lower spring perch) c. put the new spring up there and install the two nuts that make up the lower perch. When you're tightening the topmost nut, INSTALL IT SNUG TO THE SPRING so the spring doesn't move, BUT DON'T tighten it much beyond that. (If you tighten it more than snug, you're adding PRELOAD to the spring - the spring doesn't require ANY preload (unless you're corner balancing the car - then, your suspension expert will add preload if necessary to get the balance he wants...)) A. If you pull the whole strut cartridge off the car the same thing will be true. Personally, I'd remove the entire cartridge, remove the top nut which holds the pillow block, spacer, and upper spring perch, and remove the spring from the top. Then you'll lower the lower spring perch more than an inch or so, install the spring and replace everything you took off the top in the reverse order. You should have slack between the spring perches, so this is the point that you snug up the lower perch and it's lock nut. Re-install the strut cartridge. Before I remove a strut cartridge I usually measure the distance between the bottom lock nut of the lower spring perch and the locknut on top of the threaded adapter to make sure I've re-installed the strut to the same height. You can't do it this way because you're changing the height of the lower perch. I guess subtracting the additional spring length will get you close though. *** PLEASE GUYS!!! Don't make comments about a specific strut cartridge unless you know how it actually works! ***

-

What are the facts about 280z ECU compatibility and differences

Oh, I can! They probably finally figured out that it was more of a bother to eliminate the unused pins than to just install and not use them... I'm sure their connector manufacturer was complaining about having to leave out pins. Now every ECU has any number of unused pins - but they're still in the connectors.

-

front suspension and tire clearance problem

If you can't find one closer to home, PM me and I'll get you a FedEx shipping quote on the 1972 front strut assembly I have. It'll be coming from Arizona though...

-

front suspension and tire clearance problem

If you're committed to this path, make sure it's perpendicular in both (all) planes. Did your inboard/outboard repositioning affect the forward/aft position of the tube?

-

Bolts, washers, lock washers

https://www.boltdepot.com/Metric_JIS_hex_bolts_Zinc_plated_class_8.8_steel.aspx boltdepot.com carries a smallish selection of JIS standard hex bolts. They have the "correct" head size for our S30's. Unfortunately, you won't find every bolt you'll need for a Z car there - many very useful sizes though... I hate having to pull out a 13mm wrench for a bolt that should have a 12mm head - but, that's just me.

-

front suspension and tire clearance problem

You've done it right and even if there is a little wiggle as it sits on that block, I think you can still see that the strut tube is no longer at a 90 degree angle to it's base. I have installation instruction photos on our website that show the relationship of the strut tube to the milled bottom surface of the hub where it bolts to the steering arm and ball joint - it's perpendicular in every case for the front strut assemblies. You can't do this same thing with the rear strut tube, but it's angle of inclination in relation to the mounting surface of the wheel is measurable and verifiable as well.

-

front suspension and tire clearance problem

Here's a test: Set the strut assembly on a flat surface - or a surface that you can verify it's "tilt" with a level. I'm talking about the surface showing in your last picture - The surface that bolts to the steering arm (and thus the ball joint). The bottom of the hub. We've found that the strut tube is at a 90 degree angle to this surface. Put a level on the top of the strut tube and see if it's actually in the same plane as the bottom surface. If the base is level (on a level surface) the top of the tube will be also - and all sides of the tube will be at a 90 degree angle to that surface. (That's how we determine position (lean) of a weld-on adapter tube when installing fully adjustable coilovers) If the strut tube is bent - and I believe it is, I would never try to repair that or suggest that to another. Personally, I stand by my initial suggestion that you replace the strut assembly.

-

front suspension and tire clearance problem

That's too bad...

-

Rear suspension arms bushings

If you think the Energy Suspension Poly bushings are too stiff, you'll need to replace all the suspension bushings and possibly the sway bar bushings... That would include all the lower control arm bushings (front and rear), the compression rod bushings, and probably the sway bar end links. If you think the mustache bar transmits too much noise into the hatch area, you should replace those too.

-

Rear suspension arms bushings

Yes. Nissan refers to those as "Rear Transverse Link Bushings". We mostly refer to that as the "Rear Lower Control Arm" and "Rear Lower Control Arm Bushings". But there are "inboard bushings" (64 on the diagram) and "outboard bushings" (57 on the diagram) (or- inner and outer). Most of us call the outboard bushings the "spindle pin bushings". If the shop installed poly bushings, they would have already removed the old bushings and the pesky outer casing of the stock bushing. Removing the poly bushings and installing stock should be pretty easy - depending on how the spindle pin removal; goes...

-

front suspension and tire clearance problem

Yup, carpartsmanual.com shows the same strut assembly part number through 07/73. The front strut assembly part number changes 08/73 - 08/74 - that's the early 260Z time frame. IDK when the cutoff was for the 1973's. The early 260Z has struts similar to the 240Z - or same length and tube diameter. The 260Z was heavier so the springs are different (a little longer, and thicker wire). The spring perch may be slightly different as the installed length of the early 260Z spring is 3/4" longer than the 240Z spring. I don't think the 260Z stance is 3/4 higher in front than the 240Z, so they may have lowered the perch slightly to use a little longer spring. I might measure that at some point...

-

front suspension and tire clearance problem

Just looking at the picture in post #38, I'd say the strut tube is bent. With the other issues the OP is having, I don't know why he isn't just sourcing a replacement strut assembly. I wouldn't put more time or energy into the current strut/hub - but then I have a spare in the shop so "that's easy for me to say"... I agree with Zed Head though about the top of the strut assembly. When I read the post about the wheel moving away from the lower perch when he loosened the top bolt and re-tightening it threw up all kinds of red-flags. If everything up at the top of the strut was OK, that never would have happened - it would have returned to the same position. I'm inclined to believe there might also be a problem with the isolater (top hat).

-

Is this a new find?

Oh my gosh that guy is good!!

-

Is my coilover spring rate too high?

Well, you can learn all kinds of things from the FSM - even damping force: I just found out the 1972 European models had more than twice the damping force than models sold in other countries... I was actually looking at the 240Z spring rates. They are constant 1970-1973: Front springs 70-73 - 1.48 kg/mm or 83 in/lb Rear springs 70-73 - 1.85 kg/mm or 103.6 in/lb The difference between front and rear is about 20% In the front, the two springs are nearly identical in specs except for length and load! The RH spring is 13mm (~1/2") longer (free length) than the LH spring. Installed they are the same height because the RH spring carries more weight apparently.