Everything posted by Patcon

-

L24 vs L28ET

I think I am 7 years in right now. the car is jambed out and ready to start putting some suspension back in and lines and such. If I got really serious I could be done in a year and a half but I have a large family and am self employed so these projects take a long time. If I live long enough that's good. If I don't then it's "all gain"...

-

#0064

I agree, if he just bought it for $25k and had bids to almost $59k that's a home run. Sell it!

-

cranking untouched 2 years Sentra

I agree, feed it off an alternative fuel source to get it home

-

Carlisle Import & Performance Nationals needs show cars and race cars

3 1/2 hours from me...Tell them to look me up if they're in the area...

-

#0064

5k will buy you a decent project these days. Really clean daily drivers are in the low to high teens. Just goes up there from there...

-

Ken's 280z Resto Thread

I run more pressure at my gun. They make what is called an air cap pressure tester. You don't need one but it was very informative to use one. Many P sheets have pressure at the cap not at the gun. I checked my gun one time with air cap tester and I am probably running 30-35 psi at the gun. I had to actually turn it up to get to where they wanted it. Some of the pressure recommendation is environmental to limit the airborne VOC's. The problem with too much pressure is you have more overspray and less paint on the car. Which means you need more paint. Yellow is not a very opaque paint and can be difficult to cover darker primers that is why I decided to run white basecoat under my yellow. If you are running lighter coats you won't get the build the manufacturer is looking for and it can also cause orange peel if you don't have enough material to level out. There is a fine line between too little and too much causing runs and drips. Your fan should probably be broader too like 8" or so. There is a test I use to use where you shoot the gun against a piece of cardboard and test the fan. You were supposed to hold it there for some count which I don't remember. It should paint a nice sort of oval fan and not run. That helps you adjust the material. I just adjust all these things by eye now and my pressure gauge at my gun is illegible. Also I don't keep my fan constant. I narrow it for tight areas and broaden it for bigger areas but you have to adjust the paint volume too when you narrow your fan or you'll have runs HTH

-

Carlisle Import & Performance Nationals needs show cars and race cars

Where in SC?

-

Stainless steel headers, exhausts and JDM twin-pipe mufflers.

That's the quite the operation...This is on my wish list...

-

Caswell Plating

Namerow I have seen moss boss and had thought about doing that. I also really need to go to a 3 gallon kit instead of 1 1/2 kit. I was really just trying to make a first stab at it and then figure it out. I will try the power supply again but it will probably be Saturday... I understand but I do the hard work everyday... I also don't give up easily, but your experience is invaluable. Especially after seeing all the beautiful plating. Also where are you on your car? Have you set the motor yet?

-

Caswell Plating

Thanks Steve

-

Caswell Plating

Here is an area calculator from Caswells site http://www.caswellplating.com/surface.html They list the tube and ask whether you are plating the inside or not. I assume if you're not plating the inside that is a line of sight thing? Not actually plugging the ends...

-

Caswell Plating

Not really any platers in my area and they don't like to mess with little stuff. Also I have had issues getting everything back from the plater, small parts are easily lots in the larger tanks. Easier to just plate in little batches as I get to it and cheaper for me in the long run because I have other cars to work on, obviously...

-

Caswell Plating

Yeah I have a few too many projects lying around but I am working on that. The thunderbirds were gonna be a restoration project and the Lexus and BMW were being parted out when work got really slow. Too many projects, too little time I have a 5" piece of 1/2" copper tube. Caswell recommends this as a test piece. As for calculating area I was unsure whether you calculate just the exterior or the interior of the pipe too. After plating for 40 minutes and still really not being fully plated, I am assuming that you should double the area So: 7.865 Squ In @ .15 = 1.179 amps if it's necessary to double it then 2.358 amps I could only get to about 0.7 so pretty far short of just the straight amperage needed. I am not sure the area of the zinc plays any part in the area and current calculations... Also in this part of the world stills are legal for personal use, but it really feels more like Dr. Frankenstein's home lab kit

-

Caswell Plating

Thanks

-

Import & Kit Car Nationals - Carlisle, PA - 16 May 15

$30 is home run if they're from a Z...

-

Caswell Plating

I did try that, multiple ways. With the voltage all the way up, which should make the current adjustable and constant I could only get 0.7 amps. Motorman7 What power supply are you using?

-

Import & Kit Car Nationals - Carlisle, PA - 16 May 15

Are you sure the SU's you purchased are for a Datsun? Also what size are the bores? There are multiple Datsuns that ran SU's in different sizes and other cars that ran the SU design also...

-

Caswell Plating

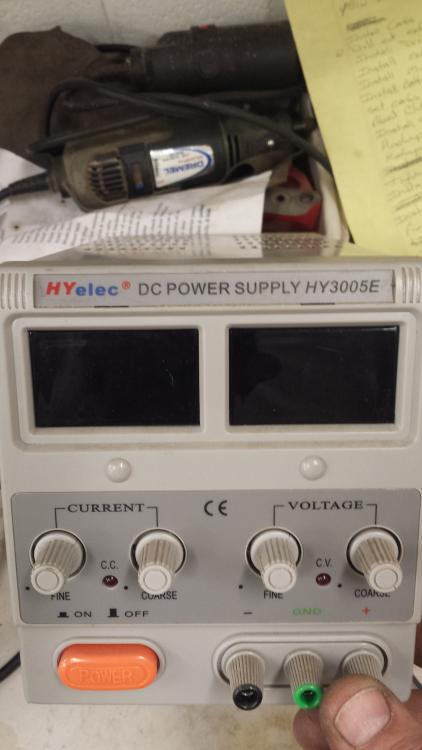

Ok, it's been a year and it's time to hit this again. I worked on my plating setup today and tried to do some plating...I was unsuccessful I am using this power supply that I purchased from another forum member with some Caswell heaters. I haven't run a full test but the power supply seems to working properly but I can't get my current up high enough... Sorry about the rotation, they show horizontal on my laptop until I add them here. The wire I'm using and the aquarium pump from Harbor Freight. The wire came from Michaels I believe. I thought the brass wire might have been painted but I have the same issue with the copper wire. Here is the current layout. Crock pot with SP degreaser in it on high. An acid tank in the next bucket after the power supply. The plating tank is this white bucket. Then I have an extra spot if I need it, then the yellow chromate tank in the 1 gallon bucket.. In the plating bucket I have the aquarium pump, the temperature sensor, the heaters and opposing zinc plates. I have done some reading and evidently the plating tank has very low resistance across it so the power supply doesn't want to raise the current. I added a 12v automotive bulb but still couldn't run the current up any higher than 0.7 Amps. Not nearly enough for my 5" copper pipe test piece. If I turn the voltage up any more I smoke the lamp. I also tried adding a regular 120v 60w bulb in series but again could raise the current up... Have any of you other guys had this issue with your power supply? I ordered a 1 Ohm 100 watt resister off Amazon. I hope that will get me going... @grannyknot @motorman7

-

My two swiss S30Z Fairlady Restoration build thread

I don't comment in this thread much but I want you to know I enjoy reading it and the pictures are fabulous. I will use them as information for my own build...

-

Need original power antenna for 72 240z

http://www.classiczcars.com/topic/55266-carlisle-import-performance-nationals-needs-show-cars-and-race-cars/ This is his thread

-

New owner of '77 280z from Upstate SC

That all sounds good

-

Need original power antenna for 72 240z

PM cbukzesk He has a lot of parts spread out at Carlisle right now...

-

Carlisle Import & Performance Nationals needs show cars and race cars

I like that drivers quarter, lots of badges and interesting stuff

-

closing sunroof

nix240z has done this on his own Z, and he knows what it takes. You could try to patch the hole but it is hard to do with out warping the roof. The best method is re-skinning the whole roof about 150 spot welds...

-

Carlisle Import & Performance Nationals needs show cars and race cars

That's the kind of advance I need...

Subscriber

Subscriber