Everything posted by Patcon

-

Idle dying when warm

Possibly, but maybe not. My first suspect would be fueling, so starting with the carbs is where I would start. Next would be ignition

-

Not a Z but so charming

Similar, I suspect the red one is the same model but older

-

Not a Z but so charming

- The last word in 240Z Restomods

There was a post a while back about this shop. Pretty cars, but quite pricey!!- RIP Spiderman

Married for 70 years to the same woman!!!- Who makes the best repair panels

I suspect that pretty much all of these parts are made by one vendor and retailed through multiple sources. The market demand isn't that large IE: all of the rear valances are stamped on the same line, all of the hoods are made on the same line, etc.- Time to cut and buff my new paint! Product suggestions?

I love Meguiars products but I find the assortment of options confusing and their website doesn't help to determine which product is best for what or why. I found what I used Smart by Puris 2 stage product. It was really easy to do. I found the wet sanding to be the more difficult part. http://www.finishmaster.com/products/smart-by-puris-a1-pure-compound-1-gallon When you buff, buff away from edges, never into them. If there is a body detail that might burn or cut, you can run a tape line down it when you use the cut compound and only use buff compound on it. Don't overheat your buffer pad or add a lot of down pressure on the buffer. The machine should be heavy enough to do the work. It slings everywhere so tape up rubber and windows if necessary.- Where to go with this rusthole

Good score on the parts! What ever you lay on bare metal, will not be your final primer (etch primer or epoxy primer). There should be a filler primer laid down after sealing then blocked out. If you paint in sections, your high build aught to take care of any overlapping epoxy paint. Epoxy is not know for it great sanding qualities. It's hard! and hard to sand, that is the way it is supposed to be.- Another Clutch Pedal Question

- Roof joints

- Where to go with this rusthole

Sounds like a good father in law.- Where to go with this rusthole

I think I would go the drill welds and replace route. I might change my mind if I could see it. More pics might help. Grannyknot likes pictures...- Time to cut and buff my new paint! Product suggestions?

I used 1500 then 2000 wet. Soak in a bucket of warm water with a little bit of dish soap in it. I used a hard foam block designed for sanding (it's blue on one side black on the other) and just wrapped the paper around it. I have a Makita digital VS buffer that I used for cut and buff. Pads are sold specifically for cut and buff. They are color coded for which ever activity. IIRC the black pads are cut and the white pads are buff. I used 2 liquid products I got from my local Finish master. I believe it is their in house product. Didn't have any real issues but it's a little nerve racking to take sand paper to fresh paint.- Cody's Goon

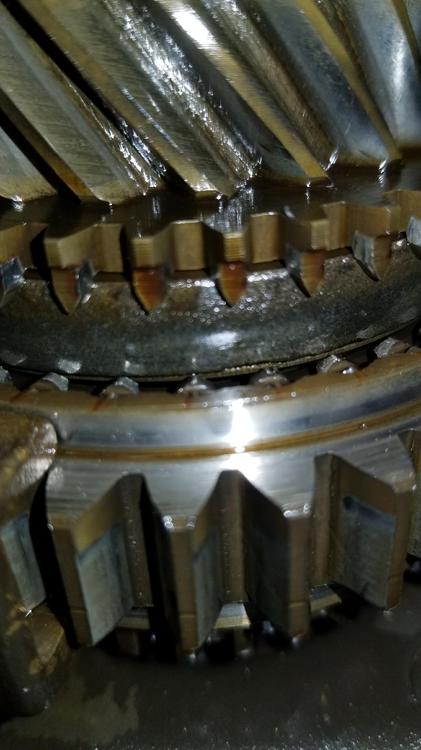

Ok, I haven't done an amperage test on the tacho yet because it was cold today and I didn't feel like messing with it. I did adjust the timing a little. We had about 6d at idle and about 33d all in at 3000 rpm's. I moved it to 9d at idle. It seemed to clear it up some. How much total advance can I run? I think some more initial advance would be good but I don't want too much OA. I have a matchbox dizzy. I could unhook the VA and run more initial advance. Thoughts? We have a speedo problem. Coming home from Zcon he didn't want to run 85mph. I told him we were running about 70. By the time we got home, his speedo would read almost to 100 mph. We took it apart and checked it. Seemed like to grit in the speedo case but it rotated freely. Can I spray some lubricant into the speedo without damaging it? Any other ideas? We took the ends off the 5 spd tranny. Looked pretty good to me. But I didn't see the infamous oil gutter Anybody see any issues? @Captain Obvious, @zKars @Dave WM We started with this for an input shaft I sanded the snout and it looks ok. The pitting is very light and hard to feel except with a finger nail. I could probably remove almost all of it, but I don't want to overly reduce the ID. I had to file and sand each spline after wire wheeling to get it clean enough for this There is this long gutter in the rear case Is there supposed to be a short gutter in the main mounting plate? This is a 280ZX transmission. I don't know the exact year. Is there supposed to be a gasket at either of the mating surfaces. There was only sealant at both transmission halves. Let me know if I need to make any other pics Thanks Guys- Found old Z pictures. I’ll start!

I like the shape of the door and the side glass, I like the way the rear behind the wheel rises quicker than the stock Z. The A pillars are non existent and wouldn't work. It would look really sharp with a good air dam up front.- Where to go with this rusthole

The little pitting at the quarter window, I wouldn't worry about. Treat it and just skim coat it. As far as leaving previously painted areas, I agree with Grannyknot, what ever your comfortable with. It makes me nervous to leave it. So I strip it. If it's bonded good and no cracking or bubbling it should be good. That A pillar is a mess. I would send your one but the postage is awful, Zkars might have a donor. A donor makes that repair much easier- Bringing a 1977 Z back life

As they all should!- My Throttle Cable Conversion

Branson!!!- Bringing a 1977 Z back life

I have a very similar app and a bluetooth obd reader. I can watch all my 7.3 values in real time. Very cool and very help for diagnosis- Duffy's 1/71 Series 1 240z build

- Cody's Goon

I will see if I can set up an ammeter measurement with what I have. I watched the needle, it never moved in any of the 4 configurations I will post this in here too. Retro fit repair for a 510 tach using newer parts. This would probably work for a Z tach too, if needed http://dimequarterly.blogspot.com/2011/08/tech-how-to-510-factory-tachometer.html- New (To Me lol) 240z and Advice Needed

@Jem2749- Cody's Goon

So that sounds like my loop measurements are correct. The crimps on the gauge make me wonder if they're good Here is the link http://elfecc.no-ip.info/510/Tachometer/Simplified_Tach_Hookup.htm- New boxes

Yes, I got them from the auction. They had some 17 drawers cabinets that were about 60" high that I liked but they got close to $1000 each. When I went to load up, there was a guy there that bought like 5 of them and the bridgeport among other things. I think he was flipping merchandise.- Duffy's 1/71 Series 1 240z build

- The last word in 240Z Restomods

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Subscriber

Subscriber