Everything posted by Namerow

-

Traveling to Japan — any friends, dealers, part recommendations?

Things in Japan are not as 'obvious' to an outsider as they might be in NA and Europe. I agree with CO, in that Kays may prove invaluable. However, you need to be specific about what it is that you're looking for.

-

Repaint Refresh of HLS-02446 3/70

Please provide some discussion for the final photo. That looks like an old-tech commercial frame alignment rig... but is that a commercial shop or someone's private garage?

-

HLS 30 hub caps

I wonder if "60 or 80 grit" was really meant as "360 or 280 grit"? Those would be credible recommendations for paint prep.

-

Floor panels canadian reseller

I suggest that you give Charlie a call, rather then relying on Facebook or email. 613) 389-1397

-

Finally getting around to it - '71 series I

The 'B' transmission's design places the base of the shift lever further forward relative to the front face of the bellhousing, resulting in a number of complications when a B unit is installed in a car that was designed for the A unit... - Base of shift lever hits the front edge of the cutout in the transmission tunnel when 1st or 3rd is selected. - Shifter knob comes too close to the HVAC fascia when 1st or 3rd is selected. I'm curious to know how this issue was handled by the dealer who did the B-for-A transmission swap in your car. p.s. I like the wood cradle that you built to support the car. I know of another Z owner who built a rotisserie from wood.

-

240z Front turn Signal weak points

Mounting studs and hardware should be stainless steel. Too bad the same can't be done for the screws that fasten the lens to the housing.

-

Restoration of BringaTrailer 240z - HLS30-35883

A dry cleaner's bag works well for this purpose. Also: The seatback upholstery is easier to install if you do the job outside in direct, afternoon sunlight (solar heating helps to soften the vinyl).

-

Z's on BAT and other places collection

I agree... although baby-boom demographics will probably keep the torch burning for at least another 5 years.

-

New Source For S30 Door Seals

Thanks for taking the time to create and post these photos. Maybe I'm just getting old*, but Photo #2 is confusing. Did the rubber really sit under the weatherstrip before both were pushed down over the inch strip? Looking at the photo, it seems hard to believe that the weatherstrip would be capable of generating enough clamping force. (* I plead guilty, as I'm sure many others will, of just pulling the rotted old stuff off without giving much thought to how it actually worked.)

-

Installing hatch glass- not working

It would be fascinating to see a video showing how the rear glass was installed at the factory back in the day.

-

One-Family 1972 240Z Restoration (HLS30-93069)

If only the SU's designer had included an external adjustment screw for setting the float level.

-

Mystery Part

It's a Velcro strip that helps hold the spare wheel cover (pressboard) in place.

-

Video recommendation: "My Mechanics" restores a 240Z

I wonder if it's similar to this dental sandblasting unit?... https://www.vaniman.com/product/sandstorm-mobile-io-80141/ US$540 - ships from manufacturer in California

-

Still struggling with car at idle after 8 years

Let's be careful here. Jalex posted a photo of the choke cable for one carb, illustrating two cable screws: the #1 screw (upper screw in the photo) is the one that clamps the choke cable's outer casing to the carb; the #2 screw (bottom screw in the photo) is the one that clamps the choke cable wire to the choke cable linkage. The way I read it, he was asking whether he should loosen both the #1 and #2 screws on both carbs (which, of course, would lead to brand new problems). So, JAlex: If you're reading this, when Mark Maras tells you to loosen 'both screws', he means that you should loosen the #2 screw on both the front and rear carbs. Do not loosen the #1 screw.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Great write-up and photo coverage. As someone who also lives in the north-east, it's great to see a project like this that looks 'real' in relation to my own experience (rotted wood, old timber, uneven concrete, dirt, and leaves). Hope you enjoy your upgraded workspace. Epoxied floors?

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

There are two hammers visible in photo #4. The one on the left would normally qualify as a 'BFH', but it looks puny when compared to the one on the right. That one appears to be a shaped piece of concrete with a handle. Did you make it yourself?

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Nice to be able to check off three items on three different cars, all in one day!

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

That same storm dropped over 4" of rain in Toronto.

-

Question about sealants

Can anyone recommend a product that would be a reliable, long-term solution for sealing a cracked gas filler neck? The vehicle in question is my friend's 10-year-old Hyundai Elantra.

-

1971 HLS30-14938 "Lily" build

Fabricating coil springs is pretty easy. Find a drill bit of the appropriate diameter and use that as your former. Chuck it in your bench vise -- horizontally or vertically, whichever makes the wire-winding process easiest. You can use ordinary, hardware-store wire for the job (stainless steel preferably). Wrap the required number of coils around your former. Make sure you leave enough extra at the starting end to be able to form the bent-over tang afterwards. There's a bit of trial and error involved in finding the right drill bit diameter so that you end up with the desired coil diameter after you complete the wrap. It may help to temper the wire after you've got it fully formed -- but I suspect that it won't be necessary for the lock springs. As an example, the spring that I fabbed for the lid of my 70 Z's ashtray didn't need tempering.

-

1971 HLS30-14938 "Lily" build

I wonder, perhaps, whether you could fabricate a metal stiffener (tubing? U-channel?) and glue it to the underside of the lip. You'd probably need to use countersunk sheet metal screws (or flush-fitting pop rivets?) to pull the urethane lip down onto the stiffener. They might need to be permanent. I don't think the glue bond would hold up over the long term without some mechanical assistance.

-

1970 Wiring Diagram

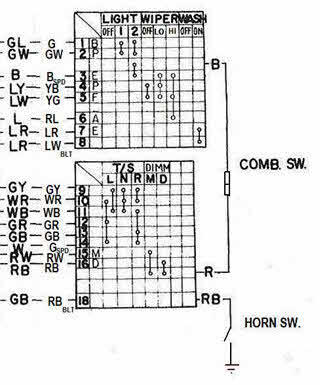

While I'm at it, here's my edit of the mini-schematic for the Combination Switch, corrected to reflect what I found in the actual layout of the wiring and contacts in the Combination Switch installed in my 4/70 car. I started with the mini-schematic that was part of large wiring diagram included with my car's Owners Manual ("20-Mar-1970 - 030300 - OM0E-0S30U2") and then made corrections... Note on the left side of the diagram that I have two columns of wiring colours: The left column indicates the colour of the wiring on the vehicle side of the Combo Switch connector. The right column indicates the colour of the wiring on the Switch side of the connector. 'SPD' = spade-type wiring connector 'BLT' = bullet-style wiring connector

-

1970 Wiring Diagram

Several years ago, I worked with your #2 schematic ("Datsun Factory Parts are fully warranted to give utmost satisfaction") and then added editing comments, using the wiring, connections, and devices in my car (unmolested 4/70 240Z) as my primary guide. See attachment #1. Back in 2015, CZCC member @EuroDat (Chas) did a beautiful job of creating a full-colour wiring schematic based on the specs for MY-1970 USA-Cda cars (see attachment #2). It addresses most of the issues that I identified in my own review. S30 Wiring Schematic - 70 240Z - B&W - 70 Owners Manual - Comments added for errors 7.pdf S30 Wiring Schematic - 70 240Z - Colour - Eurodat.pdf

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Second that. Not an easy job: 1/3 educator, 1/3 keeper-of-order, 1/3 entertainer. Made all the more challenging in this modern era of cell phone and texting distractions.

-

1971 HLS30-14938 "Lily" build

That's going to be a great looking car when you get it done and out on the street. Keep up the good work.