Everything posted by Zed Head

-

Tranny Bolts

I think that the later 4 speed, and 5 speed bolts might be the same. carpartsmanual shows the same part numbers, just different quantities. Weird. I just used my 4 speed bolts on all of my 5 speeds. Seemed to have plenty of thread engagement. Looks like the very early 4 speed had one bolt different from the later 4 and 5 speeds. Also, I think that the bolts are still available from the dealer. $1.12 each at courtesy. A good parts guy could find them on the microfiche. Of course, if you're not looking for the parts, just the specs. this may not help. http://www.carpartsmanual.com/datsuns30/DatsunFairladyZIndex/PowerTrain/TransmissionCase/5Speed/tabid/1702/Default.aspx http://www.carpartsmanual.com/datsuns30/DatsunZIndex/PowerTrain/TransmissionCase/4Speed/FromSep-71/tabid/1701/Default.aspx

-

Tranny Bolts

Pretty sure that EuroDat knows. I think that he made a list. You might find it with a search. Or a PM.

-

Hot-start issue with EFI - who has it, who doesn't

This guy seems to be the most popular for finished complete rails for the L6 engine. He offers a variety of fittings from 11mm to barbed, along with a gauge fitting if wanted. Check the last few posts to see how to order. http://forums.hybridz.org/topic/99098-pallnet-fuel-rails/ And a few of us have made our own. You can get stock from Ross Machine Racing on eBay. If you're not worried about finish sometimes he sells dinged stock for a discount. http://stores.ebay.com/Ross-Machine-Racing

-

Hot-start issue with EFI - who has it, who doesn't

It definitely helped. I had it on a 20 minute timer and if I turned it on I had no problems when I came back, if I forgot and came back in the critical window, it always had the problem. But I had a hose with holes directly over the injectors to direct the air right at them. Then I added an aluminum fuel rail with different injectors and solved the problem completely (I thought) so I removed the fan. Adding others' experiences in to the mix suggests that the larger fuel volume and the better heat transfer of the aluminum rail keeps the injectors cool. Fastwoman suggested heat-pipe technology as a reference, like distillation but for the purpose of removing heat. Things were fine unit just this winter when the problem came back, probably due to fuel changes. So I added insulators to the injectors and it dropped it to about a 2% level. Occasionally, after a long drive and a stop I'll get a second of roughness. But it goes right away. Everything points to hot injectors.

-

A Project Is Brewing...

I think that the CHTS hole is dry. On the ZX distributor - some, the later ones, came with an E12-92 or -93 module that has an electrical timing advance connection. It can cause problems sometimes, apparently. The E12-80 only has one external connector, with two pins, and the reluctor connections on the inside. You can swap the modules, or there's a method to lock the advance connection into one state by applying power to it.

-

Hot-start issue with EFI - who has it, who doesn't

I looked for it in the FSM but didn't see it referenced anywhere. From what I've read, most people that have the fan have never actually heard it run. The switch is set for 210 degrees or somewhere close to that, apparently, and it's mounted in the thermostat housing. I mounted a ZX fan on my car, with a manual switch, and they're pretty noisy so you'd know if it was on.

-

Fuel Vapor Check Valve Substitute

Where is the check valve located? I see that it's in the vent line, but haven't seen its actual place on the car. I've never had my side panels off to look at the reservoir and lines above the tank. Afraid I'll crack the panels getting them out.

-

Hot-start issue with EFI - who has it, who doesn't

I have a book that compiles all of the Road & Track tests of the Z cars over the years. Found an interesting comment in a test of the 1979 280ZX from April 1979, compared to three other sports cars. "And we found that after a brisk workout, it would sputter and spit back through the injection on restart." Think they meant intake, not injection. So it looks like the hot-start problem has always been there, even with ethanol-free fuel. Just a consequence of placing the injectors next to the hot exhaust manifold. The R&T guys probably got things pretty hot so there would be a lot of excess heat in the block and manifolds.

-

Need some help with NOS parts values.

Are these big bumpers or small bumpers?

-

Questions about 70.5 or 71 240z value

"Ripped off" is in the mind of the buyer. I'll guess $3000. Never mind, Nada and Kelly apparently don't even do old cars any more. Try Hemming - http://www.hemmings.com/priceguide/ Notice the difference between 70 and 71. 70 is a collector car, 71 is just a 240Z. No offense to any post-70 owners.

-

Problems with chugging and stalling 1976 280 Z

There are two engine pictures there now. I see one potential problem right off the bat. The wires to the battery. Probably not the cause of the engine problem but they look bad. I assume it's the negative terminal although I can't be sure. That exposed junction probably would have shorted by now if it's the positive. But usually it's the positive that corrodes like that. The PCV hose from crankcase look unusual also but maybe that's the rerouting that Nissan retrofitted in 1977. It looks like the original hose connection is plugged. The battery connection alone suggests that the engine has not been maintained at the highest level. So there's hope that the cause of the problem is a simple one. Isn't it tic-tac-doh!..?

-

Problems with chugging and stalling 1976 280 Z

This will make things difficult but not impossible. We all, out here, tend to forget where we started. I worked on cars all through high school and many years after before taking a break and buying a new car. When I came back to it, even I took some time to get back up to speed. Here is a simple thing to look for that might help determine if you have a fuel problem (clogged lines or bad fuel pump or bad fuel pump power circuit), versus a bad ignition system. As you're driving down the road, if the engine dies, leave the car in gear and watch the tachometer needle. If the needle drops directly to zero even though the engine is turning over, that's a sign of an ignition problem. If the tachometer needle still shows RPM but the engine is obviously not running, that's a sign of good ignition but no fuel. I don't know if the engine turns fast enough to make the needle move during starting but it might, So if you end up dead on the road, watch the needle while trying to restart. If it moves with the engine turning over, you probably have spark. Of course you'll still need someone to work on it, but at least you'll have a better idea of what it needs. You might also consider letting the engine run in the driveway and seeing if it dies eventually. If it does, you can do some detective work within walking distance of your home. It will cost you some fuel but won't hurt anything.

-

Problems with chugging and stalling 1976 280 Z

That is not correct. It's one of those things an "almost there" mechanic might screw up for you. There are two temperature units, one for the ECU and one for the gauge. The engine can run fine without a gauge and can indicate temperature just fine but have a problem with the fuel mixture due to a bad sensor. Two totally separate issues. One thing that any decent mechanic could do for you is to put a fuel pressure gauge on your fuel rail, between the filter and the injectors. If they could mount it where you can see it while driving you'd be able to see if you're losing fuel pressure. You'll have to drive with the hood partially open so the gauge can hang out but you'll know something very important. Since the problem is happening frequently now, it should only take a short while to see if it's fuel or ignition.

-

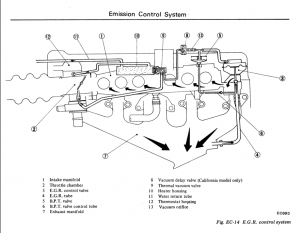

Coolant lines question

Those lines run to your Auxiliary Air Regulator (AAR) mounting block, and,probably, the EGR system. You could get a T fitting to put in to the hose for the return line. I think the hose size is 5/8". I posted a picture but the size is wrong so don't buy that one. An auto parts store will usually have a selection of sizes.

-

Redwing. Nice young woman needs our help.

The liquid could just be spray from a bad hose fitting. Might just take that hose off and smooth the hose nipple. They tend to get cruddy and corroded. Pictures before cleaning are best.

-

Hot-start issue with EFI - who has it, who doesn't

Like a NOS setup except the pssst, psssst is for cooling, not clearing the NOS lines? All the kids would think you want to race. The scary thing about rapid cooling of hot parts is that they tend to distort and sometimes break. I had a cooling air setup on my injectors for a while, with a hose with holes in it to direct air on to each injector. It worked great but I had to twist a timer dial every time I stopped the engine. Keeping them cool, instead of cooling them after they got hot. A turbo timer would probably work. It was a lot of complexity though. The aluminum fuel rail and the insulation of the injectors seems simpler. A timer on the fuel pump do the trick. Keep the cool fuel running through the rail. I had pondered that but never tried it. Leaving the fuel pump running with the car unattended bothered me, plus heating the fuel in the tank. I also thought about running a line from the coolant system over the injectors with an electric water pump, but air was easier. The situation is just aggravating, overall.

-

Problems with chugging and stalling 1976 280 Z

Probably a ground wire and the condenser body. Don't let any well-meaning person start tweaking and adjusting things to try and get it to start. If it ran well before, and now you just have a no-start problem, the solution is probably a simple one, like an ignition module, or bad battery. A picture of the wires and your engine bay would help a lot. And keeping everything in one thread. This thread, for example, doesn't have the description of the car dying and not starting. But the other thread does.

-

Last Chance To Stop Me: Going Coilovers?

Ideally, your struts have been cut to give the desired ratio of compression travel, to extension travel. That's the main goal of the strut sectioning. John Coffey posted some numbers a little while ago, somewhere. Can't remember it but I'd guess it's like a 2:1 ratio. So if you have 6" total, you'd look for 4" compression, 2" extension. On the springs, I've looked at spring extenders myself. They're basically spring perch elevators. Molded plastic pieces designed to fit the spring shape and sit in the perch to lift the spring. I found some but they were more than I wanted to spend. I'll probably fabricate some, eventually, just to get another 1/2 inch. They are out there though.

-

Redwing. Nice young woman needs our help.

Aside from engine mechanical issues, 1976 comes with EFI, unless somebody swapped carbs on to your engine. It really could be a project if you don't find someone who knows the system. It's fairly simple but has it quirks. A mechanic who isn't familiar can really make a mess of things. Once they're dialed in they're very dependable, on a daily basis. But when they have a problem they can be a nightmare.

-

Redwing. Nice young woman needs our help.

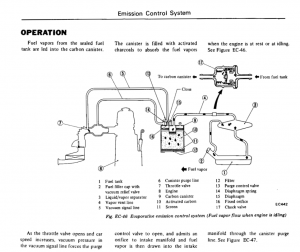

Good point on the spark plug well leak. I didn't think that one through. Another possibility case is a cracked head. Hopefully not. My gas cap doesn't whoosh, and the system seems to work fine. Could be that my check valve is weak though. Copied a picture just to show all of the parts of the system.

-

Redwing. Nice young woman needs our help.

I second SteveJ's recommendation. You need to find a mechanic that knows how to work on these old cars. There aren't many out there. Both siteunseen and madkaw know what they're doing and still feel uncomfortable with their mechanics. The trouble starting when hot could be the common "hot start" problem. The "whoosh" could be a modified tank venting system (some people don't understand that the charcoal canister in the engine bay is important no matter how ugly it looks). The leaking "main motor gasket", actually called a head-gasket, is not uncommon after many miles. My 76 engine had a leaking head-gasket. The head was also warped, but in the opposite direction of the leak. That's an example of a how a small job, gasket replacement, turns in to a big one - a head rebuild Unfortunately, many well-meaning mechanics will spend a lot of your money and time before admitting that they don't know how to work on the old L6 and its EFI system. Find that local club. Southeastern USA covers a lot of territory, more details could lead to more suggestions.

-

Thought i fixed it. l28 fuel injected

A spare engine I picked up had had water in the fuel and it rusted the inside of the fuel rail. The filters on the injectors are only meant as a last resort, thy can clog easily. On powering the injectors for cleaning or testing - I run six on a fuel rail with power from the battery in series. This gives about 15 ohms of resistance and keeps the current flow down. It's the current that would overheat them, they're made for 12 volts. For precise characterization though, a PWM would be the way to go. For comparing wide open flow rates to see if they're clogged, just turn on the power and fill six containers. I've seen up to 20% deficiency in flow rate this way, with old crummy injectors. You could either add resistance singly or rewire all six at once. Be careful with vaporized fuel and sparks though. Once you see an injector spraying well, out in the open, it makes you nervous. Edit - somehow I got a funky font, WTH. And I can't change it in the first sentence, it's locked in.

-

260z Ignition system electrical trouble

The first thing to do is know what you have, and get at least a basic idea of how it works. Your distributor could be used to trigger a $20 GM HEI module that would work just as well as the Crane module. But, it looks like your distributor itself may need work (Post #4) . It has the typical rust trails on the breaker plate and it looks like the plastic bearing cage might be misaligned which could mean it's broken and your vacuum advance is stuck. If that is the case it might be most effective, both cost-wise and for simplicity, to get a ZX distributor. Find the stock module first though.

-

Hot-start issue with EFI - who has it, who doesn't

I placed reflective Mylar bubble film in various places (standing up along the valve cover, for one) to reduce radiant heat (I measured temperature with an IR gun to see what was hot) and saw no effect. It did deform right where that hole above 3 and 4 is though, That was an affirmation of the hot air tunnel. I pondered better pintle caps for the conductive pathway but couldn't come up with anything. My injectors don't have the plastic pintle caps like the stock ones do so the metal-to-metal conductive path could be in play in my case, if an injector was misaligned. But the stock injectors have a plastic barrier, although it is thin. The insulators I made from plain old kitchen sponges had a significant effect. We're up in the high 80's and 90's here and I've been out (sweaty rides with no AC) a few times, restarting in the critical 20 minute window, and not seen any more hot start problems. The sponges are multi-color and look way out of place but compared to the problem, are worth keeping there. I have some thoughts for better covers, for when I next take the injectors off. It's not broke though, so no fixes planned. I wonder if the super-flammable North Dakota crude could be the part of the cause.

-

Hot-start issue with EFI - who has it, who doesn't

My 76 with the non-webbed intake has a pretty big hole in the heat shield above the 3 and 4 exhaust ports. Seems like it's a natural channel for a lot of heated air to pass up and by the 3 and 4 injectors. Nissan made the webbed intake for 1978 (maybe 77 too) and blocked that hole with a small heat shield (it has to be opened to reach the top-center manifold fastener). Must not have wanted any air at all coming up from below. Check out the link in #107 to see what Chrysler did for their hot injector problem. Might help to insulate 3 and 4, if not all of them.