Site will be going down for maintenance today

Everything posted by Zed Head

-

Half Shaft Flange/Yoke 1970 240Z

Looks like it wasn't seated properly and worked its way loose, or vice-versa. Flip it over and look at the mating surface. It might be beat up. I think TerrapinZ might have some yokes. @Terrapin Z

-

Half Shaft Flange/Yoke 1970 240Z

What area is worn out? The yokes have a centering ring, the bolts are just for clamping. Any halfshaft through the 1983 280ZX will work. Doesn't have to be a 240Z shaft. There are differences over the years but the fitment at the ends is the same.

-

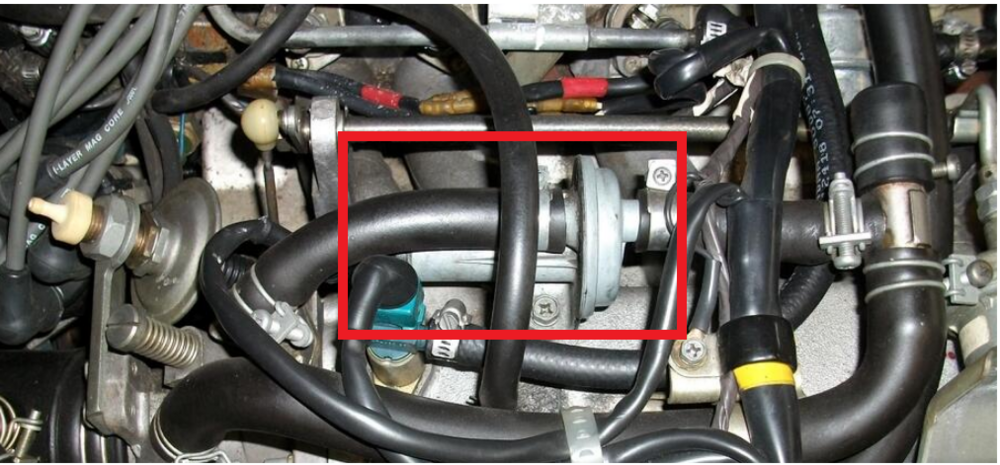

[2020] What Did You Do To/with Your Z Today?

Be careful unplugging it. I'd check for power first. It should have power when the engine is running. Like the fuel pump.

-

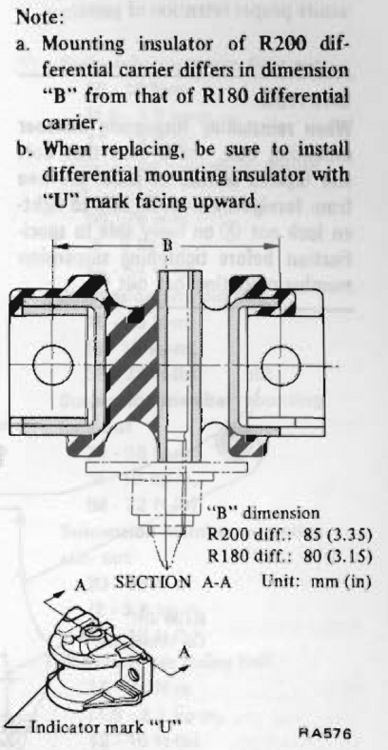

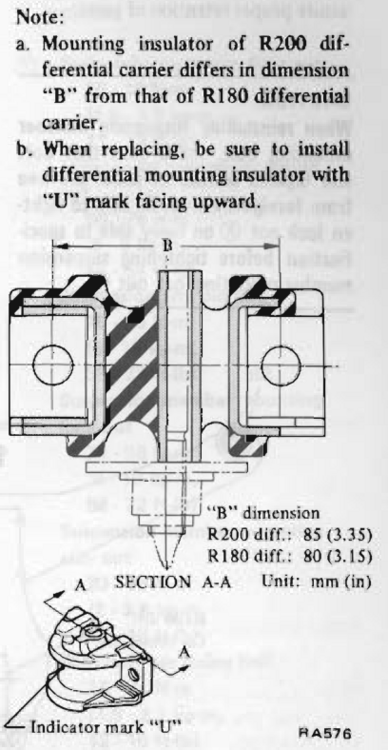

280zx rear diff mount direction

My mistake. Looks like there are actually two slightly different mounts for the R180 or R200. Weird. Even weirder that the part with an "up" side is symmetrical. And the unmarked part is asymmetrical. I'd set the new mount up so that the two stud holes are the same distance from the car body.

-

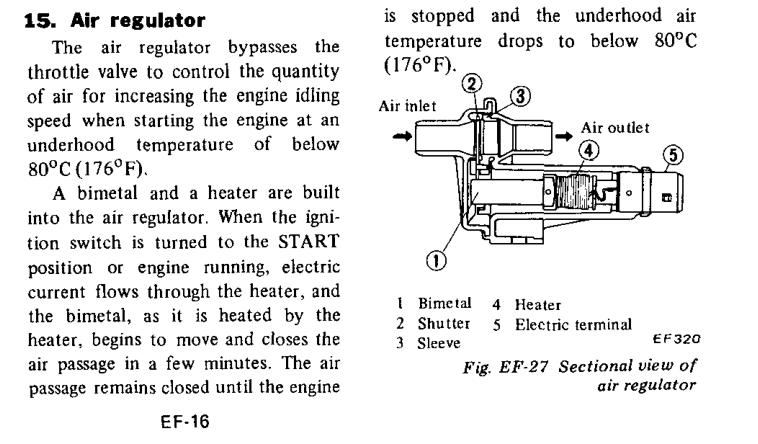

[2020] What Did You Do To/with Your Z Today?

Actually (sorry) the auxiliary air regulator (AAR) is what keeps idle speed up until the engine warms up a bit. Pretty common for them to be stuck open or closed and/or not have power to the heating element. There are several threads on the forum about them.

-

280zx rear diff mount direction

Depends on R180 or R200. The right way for one is the upside down way for the other. I think. Vague memory...

-

cooling help?

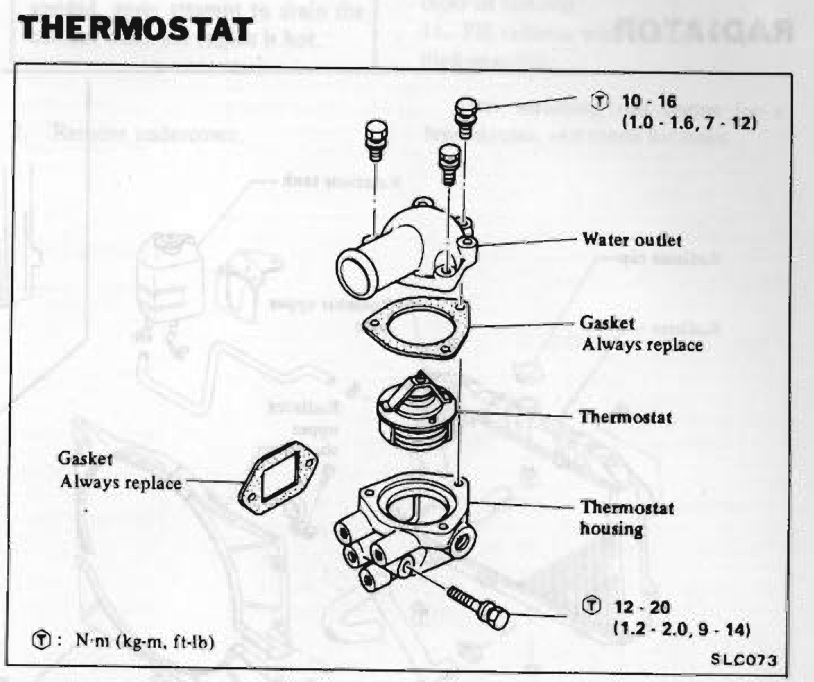

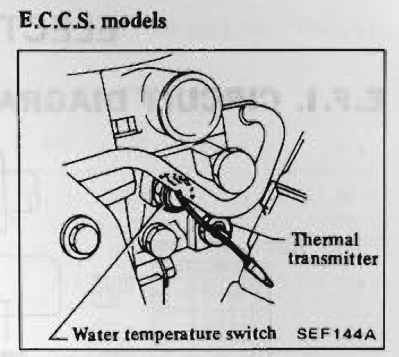

Pictures would be neat of the cover Sensor part numbers or links too. I can't find any sign that Nissan made a thermostat cover tapped for a switch or sensor. 1983

-

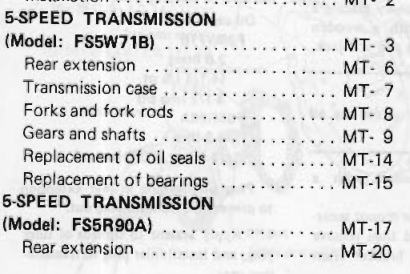

1977, 280z with FS5W71B transmission

Nissan went to aluminum front covers in later transmissions. That's not an aftermarket piece. Check the nose for wear. The throwout bearing rides on it and if it seizes it can wear a groove in the nose. The hole is a weep hole so that any leakage will exit before it travels down and out the end of the nose over the clutch disc. Like Dave WM said, make sure you find that shim. It's important.

-

1977 Cylinder #1 Mystery

Coolant passages have been known to leak in to the intake system. Maybe you have a cracked head. Coolant in the combustion chamber makes things clean. Have you noticed any coolant usage? My engine never used a drop. It was boring. Speaking of boring, how about a bore scope? Take a look down the intake manifold passages and inside the cylinder. Can't remember if you ever did a smoke test or if you just decided that you had a better idea, in past conversation. A smoke test will show if you have any vacuum leaks, and if you remove the spark plugs and turn the engine by hand should show smoke flow through the intake ports, and, if you wait long enough, through the exhaust ports. And, on ports - maybe you have an EGR port opened in the intake manifold and a rotted EGR valve. Each cylinder has its own little EGR jet. The borescope should see that if you get a good one. They have side view now. Here's a video from a guy that seems to know a lot.

-

77 280z Restoration

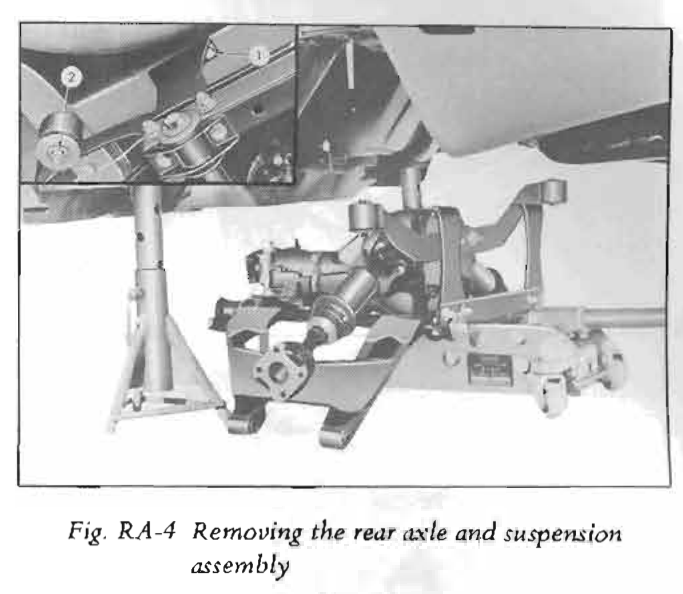

This used to be a hot topic and John Coffey actually measured a bunch of half shafts, compressed, and found that they were all the same length. He had the work on his Beta Motorsport site for a while and then on a separate Facebook page but I think it's all gone now. I think the original subject was about why half shafts bind in 240Z when you install an R200. The question never really got a good answer. But at least a bunch of half shafts got measured. One of the Z books, maybe the Humble Restoration book, has a TSB in it about Nissan removing one of the ball spacers in the half shaft so that it would extend further, so a longer shaft suggests a newer half shaft. But, compressed they're all the same. In short, there's not really a left or right shaft.

-

1977, 280z with FS5W71B transmission

You're down there in California Datsun territory. I think that he buys up all of the used Z parts he can find. You'll have to be really quick, I'd guess. Or travel.

-

77 280z Restoration

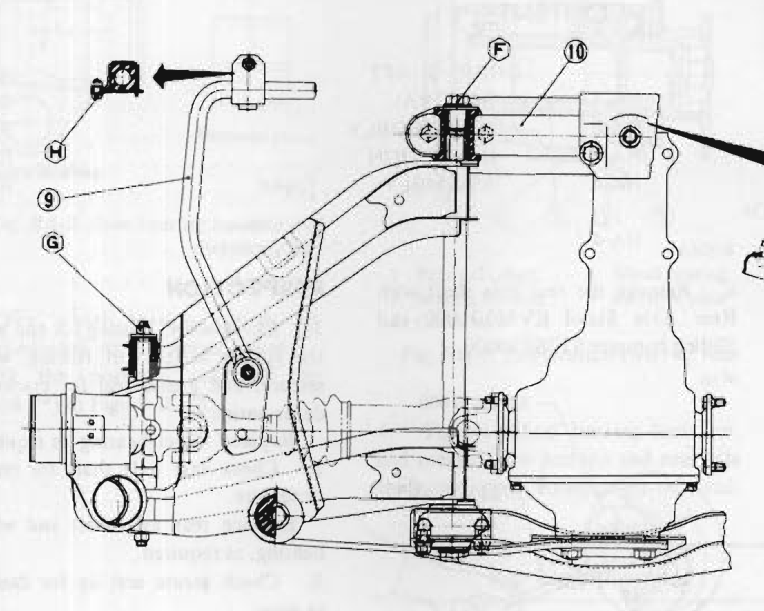

I was on sway bar also. The mustache bar (aka transverse link) is installed oppositely for the R180 and R200. The FSM only shows the R200 for the 280Z. For some odd reason they ignore the R180 in the RA drawings for the 280Z, even though they include it in the Prop and Diff chapter. This is R200 from the 1978 280Z FSM. This is R180 from the 1973 FSM.

-

77 280z Restoration

Picture 123 here might show what you want. Seems to have all of the stock parts, including the damper weight. Browse the other 280Z listings to be sure. https://bringatrailer.com/listing/1977-datsun-280z-71/

-

Crank Pulley washers l28

Never mind. Good luck.

-

1977 Cylinder #1 Mystery

Didn't realize that the car had been at Sakura Garage already. Thought it was in the future. Still wondering how the tuning for the cam will work out using the stock EFI parts. Good luck.

-

Parasite drag on battery

Any chance it's the alternator? It's the other "new" part. Not sure what the path would be. Unplug the T plug and see what happens.

-

cooling help?

The sensor is going to pick up surrounding heat through the threads connected to the metal. It could be in a hot pocket or stagnant flow area also under the thermostat. Which hole is it in?

-

Z's on BAT and other places collection

That guy has turned in to some kind of diamond finder. He has a whole list of nice cars sold on BAT. https://bringatrailer.com/member/adamike/

-

cooling help?

Where is the sensor located?

-

280Z Starter draining battery

"It has to be something else" is the transition point? Might help to re-describe the problem. "recently the battery was draining for an unknown reason" seems to be all that's left of the original description. Age of battery, type of charger, level of charge, condition of battery terminals, details like that might help. It looks like a car that sat in a cold, probably freezing, garage all winter and now has a battery problem. Kind of common. Batteries don't like to be cold and discharged. Another cause might be mice. Urine is a good conductor.

-

1977, 280z with FS5W71B transmission

Do you know what vehicle it came from? There are truck transmissions with similar features. It definitely looks from the 280ZX time frame. The only words you've supplied are "82 71C" though. What is the full description?

-

1977, 280z with FS5W71B transmission

I'd watch the wrecking yards and/or look for a damaged 5 speed 71B. Like EuroDat said, the failure modes are fairly common. You could probably get an undamaged main shaft and that coupler from any "blown up" 280Z or 280ZX 71B 5 speed. Or, buy a whole junk car with transmission. People often just sell compete cars for not much more than a transmission costs. I got a complete engine and many extra parts when I did that, plus made some cash back when I junked the remains to the salvage yard.

-

1977, 280z with FS5W71B transmission

I screwed up. Seems like the 4 and 5 speed should be the same, they have the same first 4 gear ratios, but, apparently, they are not. Make sure that that 1982 5 speed is not a Borg Warner 5 speed. The turbo 5 speed. It is very different and requires a different mounting, propeller shaft, and shift lever. Plus the ratios might not be what you want. If the guy doesn't know it's a "B" he might be confusing it with the BW. Did he supply a picture? They look very different.,

-

1977, 280z with FS5W71B transmission

It's a collection of parts. The fact that you had a very odd failure actually works in your favor.

-

1977 Cylinder #1 Mystery

Not really clear what cgsheen1 meant. The cam towers have to have the ports for the spray bar. If you run spray bar cam towers and a spray bar then oil will flow to the spray bar. The cam towers have the passages. As I understand things, but I haven't actually seen it, only read about it, the cam will accept oil from the cam towers if it is drilled for it. So if you put a drilled camshaft in a spray bar head you'll get oil traveling both ways. Can't find anything on carpartsmanual because Nissan considers the cam towers as part of the head. You can't buy them separately.