Everything posted by motorman7

-

SN 00042 Restoration; The Older Twin

I am currently going through the various parts of the car and cleaning, re-furbing and painting (as needed) so that everything will be ready to install once the body returns. I figured I would post a few 'Unique to the early cars' parts here (or things that Rich has never seen before) on a 240Z. On the gas pedal there is a small bracket at the very top. I am not sure of the purpose of that feature. My guess is that it was intended to be used in tandem with the deleted throttle lever. The cover on the wiper motor is something I have never seen. Nice custom fit. The later bag covers were probably cheaper to produce. The steering column transition brackets have overmolded rubber in the locations where the shaft would be attached. I guess they decided that these were not needed. Interesting to see though.

-

1971 HLS30-14938 "Lily" build

I used this on my front air damage prior to paint. Can't remember who recommended it, but seems to work.

-

1971 HLS30-14938 "Lily" build

-

SN 00042 Restoration; The Older Twin

I don't think so. Les likes powdercoat. He always did the air cleaner housing in powdercoat also as they seem to always get scratched and exposed to fuel. It's a durable finish, but not technically correct.

-

SN 00042 Restoration; The Older Twin

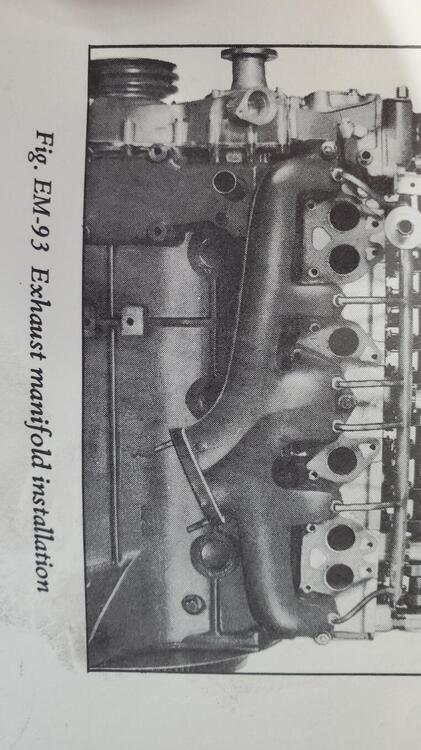

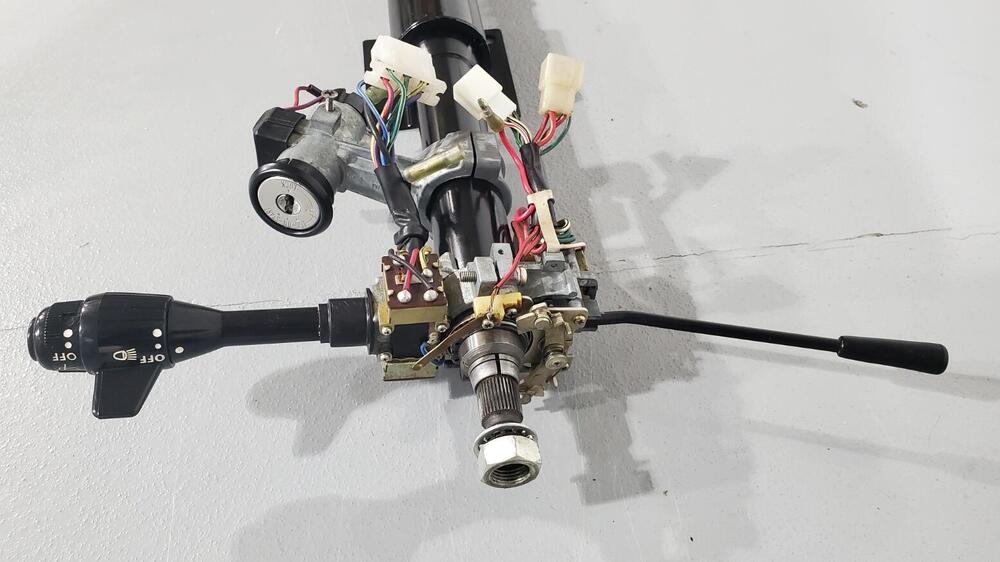

I should have a lot more updates and pics here as I have finished my summer home projects. Also, I am hoping the body and paint will be finished in the next month or two, so we should see some good progress. I appreciate all of the input here. I am always open to advice and the knowledge of those that have seen and worked on these cars in the past. Personally, I will listen to the panel of experts and then move forward with what seems to be the best direction. Also, as most of you know, I own a pretty much un-restored early 240Z that I grew up with since I was 9 years old (in the family for 55 years) , so I have a nice reference vehicle. That being said, I find it interesting that there seems to be a tendency to hold the ZCON judging in high regard. Personally, I do not have a very high regard for ZCON judges. In reality, many of them have never owned an original Z car or examined one closely. As a result, they make a number of mistakes in their judging, none of which can be contested because you do not receive the judging sheets until several months after the show. One of these days I will start a thread here titled "ZCON Judging Errors" and see who weighs in, in addition to the items I would list. A few examples are the deductions on my early Z for the weld lines on my oil pan. (FYI 0042 has the same weld lines so they will probably mark this off too). Another good example is the Franklin mint car losing points for having the 'Silver zinc' coil holder instead of 'Yellow zinc' holder. I have heard of judges insisting the original brake lines were stainless steel, the rear diff cover was bare aluminum and fuel hoses were not the 'cloth wrap' style. I am sure that I am just hitting a very small portion of the errors as I am only familiar with the cars that I have been involved with and what I can remember off the top of my head. Anyway, just had to rant a bit about the judging issue. Don't even get me started on the non-Z show judging. Regarding the Exhaust manifold finish, that is an interesting discussion. For most of my restorations, I have always consulted Les Cannady at Classic Datsun Motorsports and never questioned his advice (He was just 10 miles down the road) . If I am not mistaken, I think only his shop and Pierre Z were the only shops approved to build the Restoration Z's. Because of that, I have always used the gray powdercoat that he recommended as the default finish. However, given the current discussion and comments, sounds like there are several other options out there that might be more true to form. After looking at a number of different options and comments regarding the color, I am happy with the graphite finish option. Two of the items that lead me in that direction are pics from the Nissan engine service manual and pics of my own motor disassembly that are pictured below. Both pics show a dark cast iron finish, not a light gray finish. So, I am sticking with the graphite and will probably go with that in the future as well. I installed the exhaust manifold and intake assembly to the engine. Pics below. (Also looking for a correct rear engine hoist bracket) I finished up the steering column, and replaced the connector on the turn signal assembly. The main shaft was sanded and re-painted and all the electronics cleaned up. I re-finished the steering wheel that now looks much better, but not sure I will stick with this. The wood finish should be more redish. Problem is that the wood veneer is very thin and I am not sure how much was removed in the restoration attempt from the previous owner. Previously, the nubs on the opposite side were sanded through unfortunately. I will let it be for now, but may revisit it. The center metal portion looks good though. I cleaned up the brake and cluth pedal box. Ready for install. I have no idea what is written on that silver can below.

-

1971 HLS30-14938 "Lily" build

I have had bad spark plugs before...brand new ones. Ended up cleaning an old one and sticking that back in.

-

1971 HLS30-14938 "Lily" build

Probably not your issue, but thought I would share. I had an issue with my white Z where it ran great driving to a show 20 miles away and then horribly on the return drive. Cylinders 2 and 3 were bad. I was convinced it was fuel and wasted a couple hours rebuilding and then replacing the front float bowl shut off valve. Eventually I took off the valve cover and saw that the #2 and #3 valve rocker arms had 'relocated'. The end that was supposed to depress the intake valves was no longer touching the valve. Long story short, took the head to the machine shop and was told the valve stems were all gummed up from running old/bad gas. Sadly, I do not drive the cars enough. Anyway, put it all back together and it runs great now. Machine shop cleaned all the valves and guides. Fortunately, no damage was caused to anything except for my wallet. You can see the two valve 'nicks' on cylinders 2 and 3 in the pic.

-

Z's on BAT and other places collection

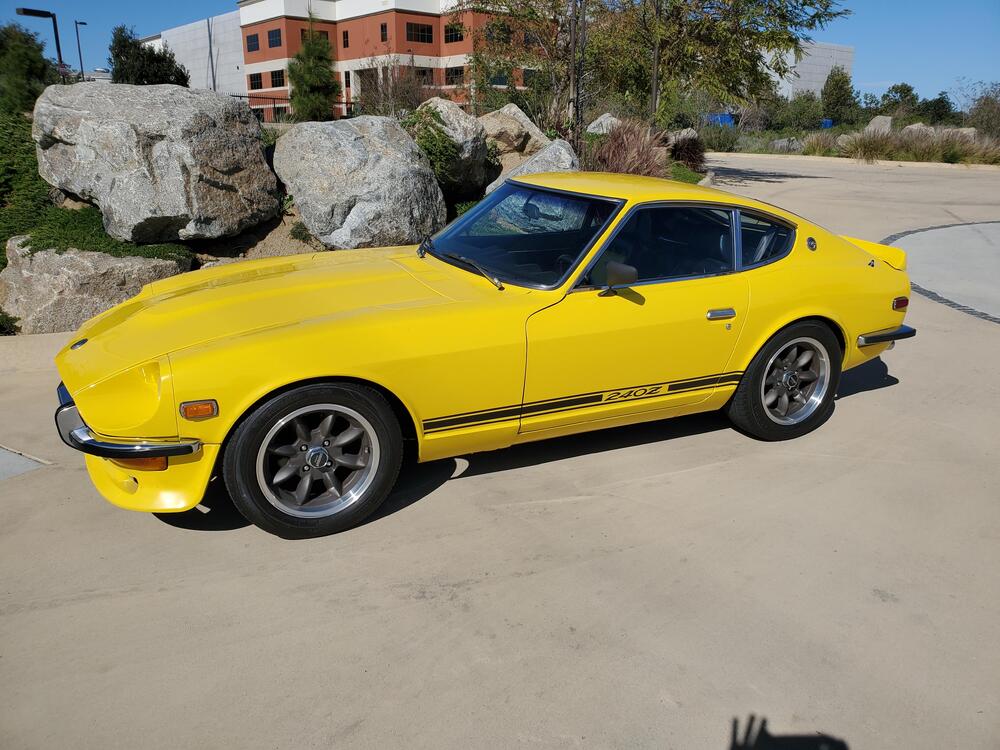

That one is tempting....my favorite color.

-

SN 00042 Restoration; The Older Twin

-

SN 00042 Restoration; The Older Twin

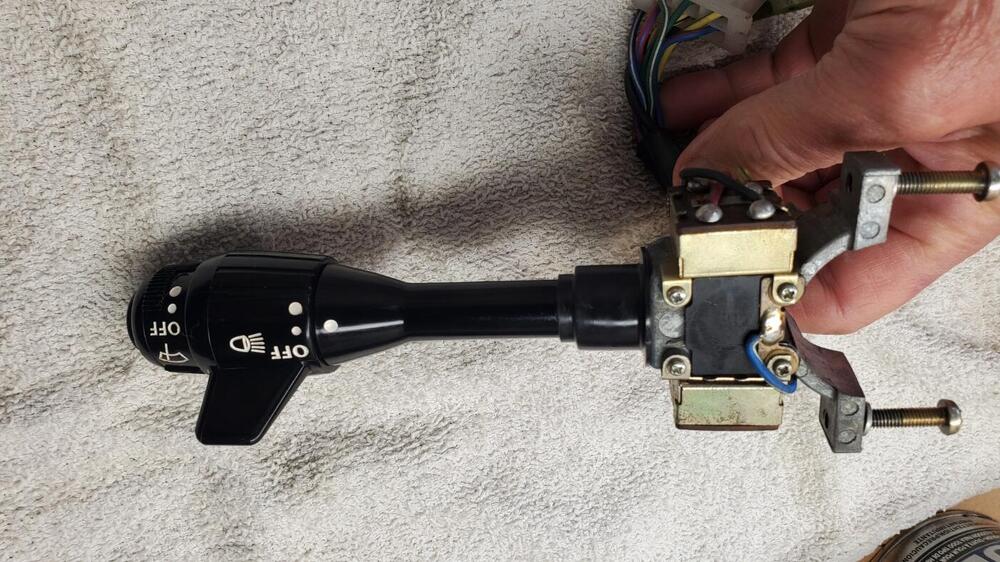

The body shop work continues and looks like things are moving along nicely. I am happy to see that they are being very thorough and even cleaning up areas that no one will ever see. I did check the seat mount locations. The rear inboard bracket on both the drivers and passengers side is off by about 2 inches (both are too far outboard). Carlos has a welder and will do the re-mounting of the bracket. I did contact Larry, the original metal work guy, to point out the error. Looks like we will get that re-mounted for no additional cost. I also sent pics of the dimesnions from the seat rails. The dimensions that I measure are 13.0" wide (330mm) and 12.75" deep (324mm). I removed the air galley from the exhaust manifold, but was not able to salvage it. After repeated heating, cooling and lube applications, I was only able to get 2 of the fittings out. By this time, the hex portion of the remaining fittings were starting to get pretty trashed, so I ended up cutting the tubes on the remaining 4. Fortunately, I did not have to do any re-tapping of the four difficult fittings. I was able to drill away most of the metal in the center of the fittings and sort of peel the threads off of the manifold. This made is easy to save the extension tubes that are secured by the fittings. On all of the previous cars that I have restored, I have always used a gray powder coat finish on the exhaust manifold that Les Cannady at Classic Datsun Motorsports always uses. Since we want to be very exact on the reproduction, I was considering a high temp cast iron paint which would be closer to the original color. However, it was noted that those typically peel even with the best prep and application. POR 15 was recommended, but again, this ends up being a colored paint and softens the texture of the original cast iron and doesn't really replicate the original color. I eventually phoned Rod Schmitt of Rod's Garage (Restorer of the 2025 JCCS Best of Show Red 240Z and John Morton's 1st place Green 240Z in the 240Z category) to find out what he uses for the final finish on the exhaust manifold. Rod says he cleans the manifold well with wire wheel and then uses a couple light coats of graphite spray for the final finish. He says this comes the closest to the original color and finish. It also handles the high temps well. So, this is the current plan for the exhaust manifold finish. I have started cleaning up some of the steering column parts. Some before and after pics are attached. It looks like these components have been accessed previously as the turn signal mechanism had a wire that was just twisted together with an extension on the horn circuit, so I removed the extension and soldered the wire in place. It has a broken connector which I thought I could replace with another signal mechanism that I have but that replacement was just as brittle as the broken coneector, so I just ordered a new one. Also, the headlight mechanism looks surprisingly good, so I am thinking that may have been replaced as it looks virtually brand new. Typically, these are pretty gummed up and the white parts are yellowed and/or dirty. This one looks untouched. I will re-restore the steering wheel as the previous restoration is poor. The black paint is thick and uneven and should be a satin finish, not gloss. The 'wood grain' portion has a heavy gloss finish, should be light satin or semi-gloss, and the back side with the 'nubs' was over sanded so the wood grain appearance is missing on the nubs.

-

SN 00042 Restoration; The Older Twin

Thanks for the heads up. I will double check the seat mount location next time I am out there. I was thinking it might be the picture angle but won't hurt to check. Thanks!

-

SN 00042 Restoration; The Older Twin

Oh, and regarding the dash, it is the original and has one small crack right in the center. There is a local dash repair shop that I will have look at it to see if it can be reparied.

-

SN 00042 Restoration; The Older Twin

Thanks for the prompt. I have been meaning to update the thread here but seem to have gotten side-tracked. The metal work has been completed on the body and it is now at the body shop. It has been there for about 3 weeks now and work on the underside has already been started. Carlos said the underside should be finished by the end of this week. He estimates that the body work and paint will be complete sometime in December. Would be nice to get this back before Christmas. There was quite a bit of metal work to do as you can see from the pictures below. The battery area was pretty bad as usual, as well as the floors. There were a number of smaller areas that were rusted through, and Larry did a good job filling and/or patching those. I wanted to make sure everything was very structurally sound and that all hidden rust areas were addressed. That being said, I am glad that part of the job has been completed. It is nice to see the body work started. The underside is looking better already. Carlos (the bodyshop/paint guy) stopped by my place and took a number of pictures of 2614 to see how the frame rails and other welded on parts were finished i.e no seam sealer. He also brought a paint camera and took pictures of the car color inside the door jam for color reference. I told him the color was the 920 Safari Gold per Nissan. I asked him to let me know how the colors line up. With 55 years of age, I am curious if the color on 2614 has darkened or developed a patina over time. Carlos has his own mixing set-up so he said that he will set me up with color samples prior to paint. In the mean time, I have been accumulating parts but not much else other than inspecting the body progress on a bi-weekly basis. However, now that my summer projects are nearly complete, I will get back to work on 0042.

-

1971 HLS30-14938 "Lily" build

I have no clue what those are. Also, looks like you have 5 of them, which is an odd number.

-

1971 HLS30-14938 "Lily" build

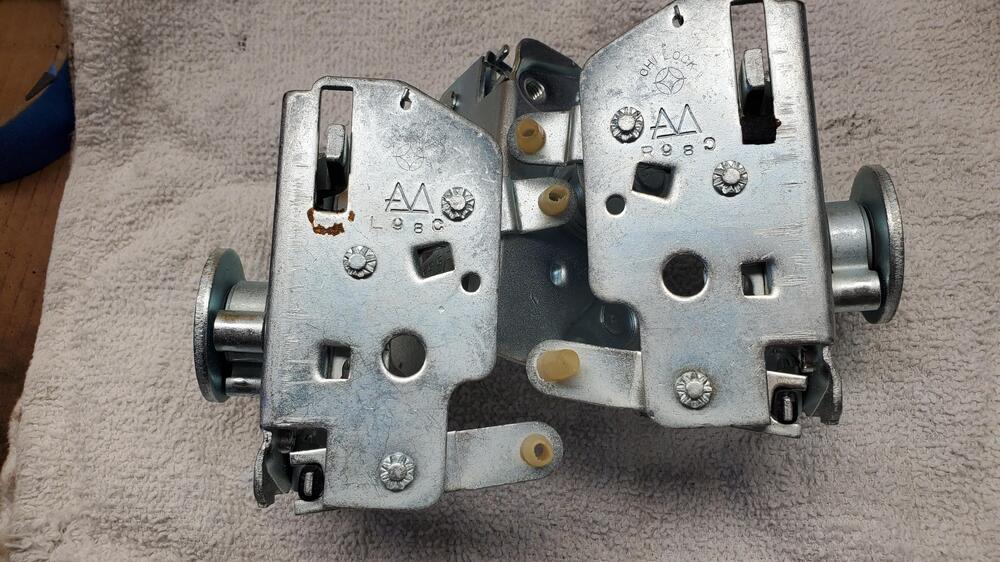

This is all great info regarding date codes. I had to check my parts on this as the drivers door on 00042 was obviously replaced, passenger door is original. Drivers door has a 5-5 date code, while passenger door is 9-8. Amazingly, I checked my stash and I actually have a 9-8 driver's latch. Guess I will swap those out so they both say 9-8 Last pic shows the two spring types

-

SN 00042 Restoration; The Older Twin

-

1971 HLS30-14938 "Lily" build

When installing the door latches, make sure you use the correct length flathead. The lowest screw that attaches the latch is shorter than the others. If you put in the longer one in that position, the latch will hang up. Again, ask me how I know 🤣😝

-

SN 00042 Restoration; The Older Twin

-

SN 00042 Restoration; The Older Twin

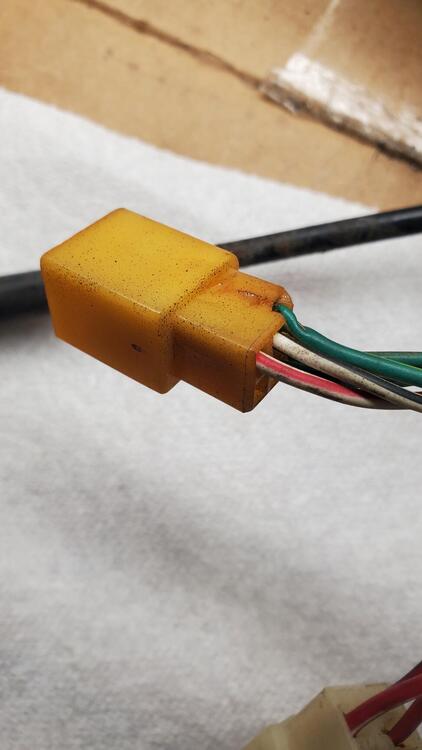

Regarding the spade connector on the black wire, I replaced the original with a new terminal. There is an earlier picture of this section that shows the original, although the cover is so dark that the terminal type is not clearly visible. Typically, I replace all terminals and their respective covers and most connector bodies on all of the harnesses.

-

SN 00042 Restoration; The Older Twin

Thanks for the picture on the spring installation. I will make sure to correct that.

-

SN 00042 Restoration; The Older Twin

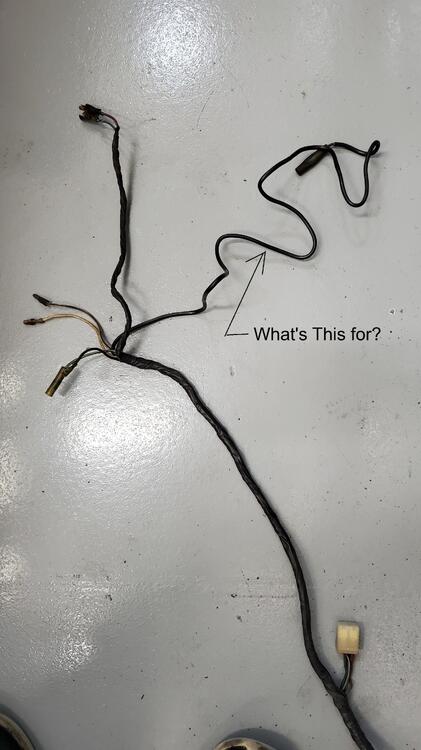

Just for clarification, the transmission info on page 7 has no relevance to this thread. We will use the original stock transmission for this build. Thanks for the info on the antenna. I added a couple pics for reference. I do not think it is an antenna ground wire as it is very long. It extends approximately 20" beyond the antenna power wires. Also, it breaks out at the junction of the speaker wires and left signal lamp. I can confirm that the wire is black, so most likely a ground. It also has a heavy black shielding over it, so maybe it was intended to pass through the body to something near the fuel tank. Interesting. Also added a pic showing the 10/69 date of the harness. Added a pic of the rear break springs installed just for the Captain 😊 I rebuilt the front brake calipers with new seal rubber, retainers and pads. I cleaned them up first and then hit them with a clear coat to prevent future rust. (Notice the ones on the current 1970 BAT car). I then installed them on the front stuts so they will be ready to install once the body shows up. The body shop work is progressing, always the long pole. The passenger side rear quarter panel has been welded in place. Right front section behind fender has also been replaced, battery tray removed and holes plugged on right fender that once supported the aftermarket AC. The rear hatch has been installed and the flanges that attach to the hinges have been welded up. Next to be installed will be the lower rear panel. And, once the rotisserie is free, the new floor panels will be installed.

-

SN 00042 Restoration; The Older Twin

What is the link to your site?

-

SN 00042 Restoration; The Older Twin

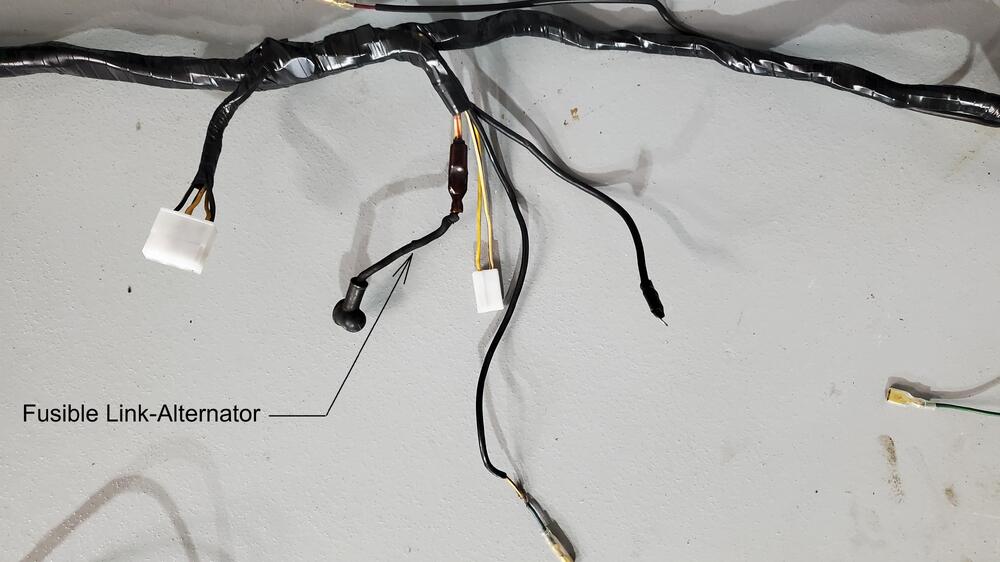

@Captain Obvious thanks for the info on the alternator. I will check that out when I get to that point. Also, new fusible links and harness firewall grommet just arrived today from jdm-car-parts.com. I will attach them in the next week or two here.

-

SN 00042 Restoration; The Older Twin

Yes, they are on order.😄

-

SN 00042 Restoration; The Older Twin

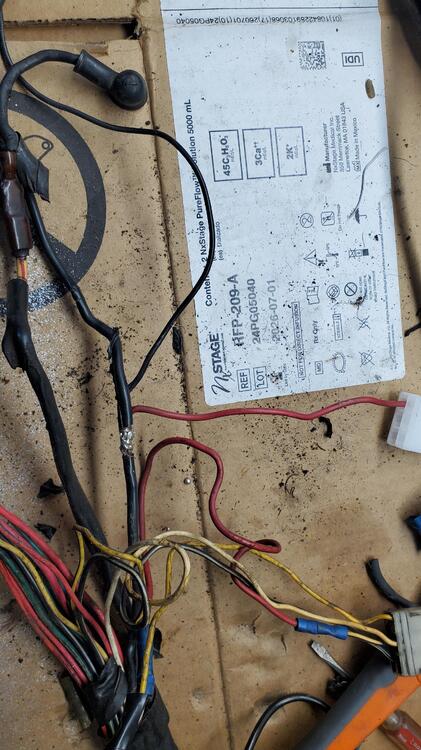

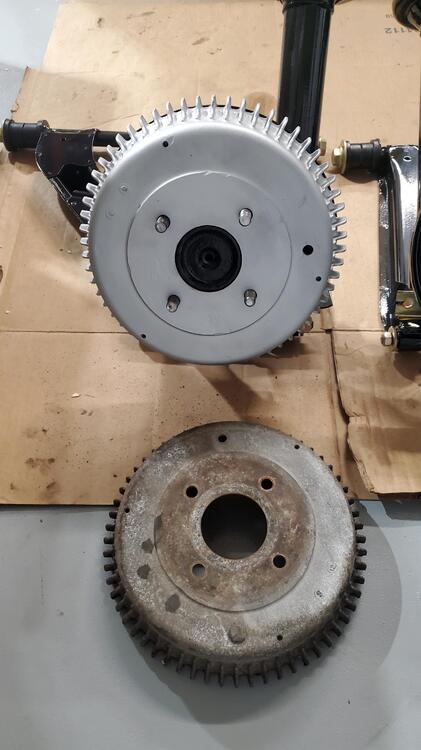

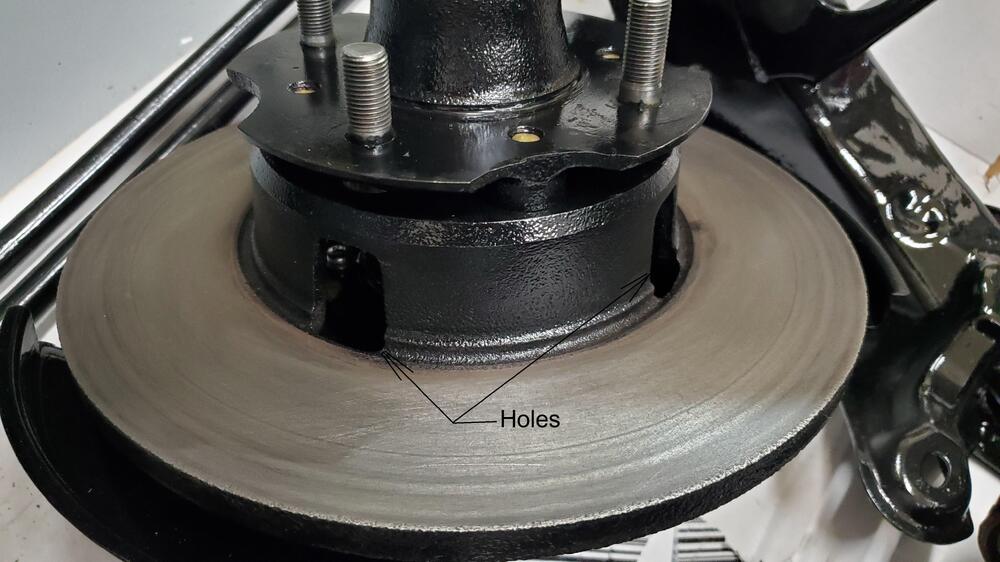

Finally, another update. We last left off with my attempt to remove the Air Galley from the Exhaust Manifold. This is still very much a challenge and I am continuing to work on this. I did get one fitting out, but the others are very stubborn. I continue to soak them in PB Blaster almost everyday, but have not used the Electromagnetic heater for the last couple weeks. The fumes are pretty bad from the heating process so I have backed off on that, even while doing that outdoors. Will probably go back to the heating process in a week or so and see if I can make some progress. There really is no rush on this, so I will hit it at a more convenient time. The body work is moving along, slowly as always. Pictures below show the latest updates from the body shop. I am almost finished with the engine electrical harness and have finished the rear harness. The engine electrical harness had a couple of interesting items. First is a Fusible link that goes to the Alternator. I have not seen that before, but apparently it is a thing on the very early cars. Also, on the alternator charge/regulator cable, it look like there was some outside work done. There was a red wire connected to the main black ground wire. That's a little scary. I checked my Z charge cable wiring and noticed my wire was black, so I am guessing that whoever did the work didn't have the correct gauge black wire, so they used red instead. Anyway, I replaced the red wire with the correct color black wire just to get everything back to normal. Pics are below. On the rear harness there is a wire at the end of the harness near where the speaker and antenna control wires are. Haven't seen that before. Not sure what it would operate. See pic below. I got the shocks and springs installed on the struts. Also cleaned and lubed the front strut bearings prior to re-assembly. I re-furbed the rear brake cylinders and assembled those onto their respective backing plates. Also noticed the both emergency brake arms had an 'R' on them, odd. Cleaned up the drums also. I cleaned and installed the front discs and noticed slots/holes in the rim of the disc. First time I have seen that. Again, probably unique to the early cars. 20250404_153515.mp4

Subscriber

Subscriber