Everything posted by Nissanman

-

Gas tank tubes

You could try inserting some small diameter stiff wire through the pipe. That should dislodge anything trapped inside the tube. A dose of carburetor cleaner and a squirt of compressed air would help too. Trouble is, the blockage, may very well end up inside the tank, ready for a re-run. As for the loose pipes, sounds like they need to be re-soldered. Use an electric soldering iron which will have no naked flame. Build the solder up in a mound where the pipe exits the tank to improve the mechanical strength. I personally don't like the idea of using JB Weld for that, just my opinion. After you have finished the repairs, give the tank a good rock and roll with a small amount of solvent or de-greaser to wash out any sludge.

-

But Mom...it followed me home... honest!!!

Great little car:classic: I hope you enjoy driving the DNA source of the 240Z. ...and keep it that way:finger: Unless you are VERY careful, the factory jack will put an after market dent in the door of the car when you use it:tapemouth:tapemouth.

-

hesitation/ oil pressure?

If it heats up and stays that way then it does sound like the cooling system is marginal, it simply doesn't have the capacity to recover from a thermal shock. It might come good with a simple flush and clean but unless you know how old the radiator is, it may need to be reconditioned. You say you have an electric fan. How is it controlled? Does it have a thermostat to turn it on? If so what temperature does it cut in? Maybe it needs to be reset to a lower temperature. If everything else in the cooling system is in good condition, the electric fan normally will only be required after some minutes of low speed driving or idling in traffic. Another problem is using the electric gauge and trusting it as "gospel". These things are notorious for being vague at best and downright misleading at worst, especially if the Voltage Regulator that powers this gauge is on the fritz. Try and get another opinion in regards to what the engine temperature is really doing. You can use an Automotive multi-checker with a temperature probe or a mechanical temperature gauge as a temporary check. You just need to fix the sender of either device to the outside surface of thermostat housing so it can read the temperature of the coolant leaving the head. Borrow if you can:ermm:

-

Sticky SU linkage

Hi David and welcome to the Forum:) I would try the linkage with the throttle shaft disconnected if you haven't already. Then you can manually turn the shafts etc. and see where the binding is happening. Apart from the rotating butterfly shafts on each carb, there are some ball and socket joints that may be stiff. Try a dose of de-greaser on all the moving parts followed by a re-lube with WD-40 and see if that frees them up. That 90deg crank arrangement on the firewall can get cranky and cause problems if the shaft pivot bearing is worn out. There may be a bent shaft which is binding in the alloy bearings on the inlet manifold. Also, make sure that you have the carb. return springs fitted or the linkage will be very tardy to return to idle even when everything is lubed up and free to rotate. Probably nothing wrong that a good clean and re-lube won't fix:devious:

-

RB30 Turbo Mainfold fit on L28e??

Well the L28 is non-cross flow and the RB30 is cross-flow so they are quite different. The L28 is your typical 1,1,2,1,1 exhaust port arrangement whereas the RB30 is six equally spaced ports. Bottom line, she no fit:cry:

-

Starting issue

If the car starts when the key is in the START position but dies when you move it to the ON position then it usually means that the ballast resistor, or the connections to it, are faulty. The ballast is bypassed by ignition switch contacts when you START and switched in to circuit when you are ON.

-

Please HELP 280z fuel pump troubles

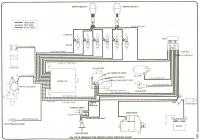

Here is a diagram of the EFI electrical for a 1975 280Z. Looks like the EFI pump and the Air Regulator both get power via that large MAIN RELAY. Check to see or hear if it operates when the key is turned ON. The other wiring diagrams I have are just hopeless to read:sick: You might want to check for a blown fuse or fuseable link that feeds the EFI system.

-

front lower control arms

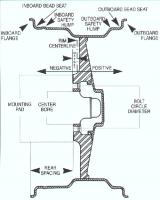

I think they are indeed identical pressings...BUT you will see that the pivot bush is biased to one side in the LCA. That then will make the LCA a LEFT or RIGHT fitting. [The narrow side faces the front]

-

Progress on engine.

The trick is, if you want to call it that, with honing, is to move the machine up and down the bore at the right rate to cause the correct crosshatch pattern on the bore surface. Also the grit used is dependant on the type of rings to be fitted. One reference I have [HP Books, "How to Rebuild Your NISSAN/DATSUN OHC Engine" by Tom Monroe] says, "If plain or chrome rings are used, the bore should be finish-honed with a 280-grit stone. A 400-grit stone is good for moly rings. A 30deg. crosshatch is suitable for all ring types." I'm sure it is not hard to do, I just prefer, and advise others, to have a competent Shop do the job, just my input. That piston in my opinion has seen some detonation, I reckon that is what caused the pitting. Or maybe a little coolant leak injecting some water into #6. Unless the ring lands are damaged, I don't see anything wrong with re-using it:ermm: Your choice of course. The attachment shows a piston I removed from a Nissan N14 Pulsar GTiR, son of Godzilla, with an SR20DET engine. The result of uncontrolled boost:finger: Now THAT is detonation damage:dead::dead:

-

How concerned should I be about my wheels falling off?

The nuts should have a ring around the circumference on the opposite end to the flange. The stub axle should have flats on the end, 180deg apart. The idea is to "stake" the nut against the flats to lock it in position. I had a look at a couple of my Z references and they curiously omit this detail:ermm: The Nissan FSM for the 810 says: - "Lock the nut using a punch" so that is as good as it gets!

-

Progress on engine.

I wouldn't bother replacing it, unless you really want to. For new rings you will have to get the bores honed. The machinist will determine if the bores are OK or you need to go to oversize pistons. If the block requires a rebore then of course, you will be up for 6 new pistons:ermm: If you intend to do the main bearing set, then do the big ends as well. Replace the whole deal, they are not expensive and it is good insurance:paranoid: Let the machinist see all the old parts and the crank shaft. Unless you have the necessary expertise to inspect and repair these bits, let a competent Machine Shop do the work and provide the correct new parts for re-assembly. The Shop may want to linish the bearing journals to make them ideal for a fresh set of bearing shells.

-

dont hate me

Welcome Freaky510:) Would like to see some pics. of what you have done to your 510. I have 2. A 1971 P510 4 door, first car I ever owned, still got it:love: It has a Nissan FJ20DE and 5 speed. A 1972 PL510 2 door, one day to be a race car with a Supercharged VG30 on Autogas with 3 speed auto. Hope you enjoy the Ride with this Forum:knockedou

-

Starting issue

The factory tacho. is an impulse type and detects the primary coil current impulses when the ignition points operate. It is in series with the primary circuit, any discontinuity here and NO GO:disappoin Watch the tacho. when you attempt to start the engine. Usually you will see it kick and read the cranking rpm. If no joy then the tacho. is indeed "out of the loop".

-

Transmission rear oil sal

This is from another Nissan FSM but gives you the idea. Make sure you don't scrape the output shaft or the gearbox internal surface with the Special Tool, Screwdriver, flat blade NISSAN brand:finger: Instead of ST33400001 you can use a large socket. It needs to be the same diameter as the OD of the new seal or slightly smaller. Use oil on the seal surfaces before inserting the seal and the prop shaft tube.

-

auto transmission/starting

Well done, and the price was right:)

-

Transmission front cover stuck

If you are confidant that you have removed all the necessary fasteners.......:paranoid: Try clamping the bell housing face down onto a flat surface like a benchtop, or back onto an engine block and wriggling the rest of the box to work it loose.

-

auto transmission/starting

-

auto transmission/starting

You need to check and adjust the linkage and inhibitor switch. Not at all difficult. I can't upload any pics. for some reason, I'll try later.

-

Water Temp Gauge - Immediately Pegs Needle

Mmmmmmm, methinks the sender is KAPUT! To test: - A] Disconnect the wire from the sender, gauge should not register at all. If so, gauge good. If not, gauge wire is earthing somewhere. B] Earth wire for sender, gauge should max out. If so, gauge good. C] Reconnect wire to sender. If the gauge still reads max. then the sender has developed an earth fault and is NBG. You could confirm that by reading the resistance of the sender with an Ohm meter to earth. That is my story anyway:D

-

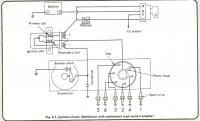

Ignition coil/ballast resistor

Just to clarify the function of a ballast resistor. This device is switched OUT when the key is in the START position. That allows the ignition coil to be connected to full battery voltage to enable starting the engine. Then it is switched IN when the key is returned to ON position after the engine fires up. That allows the ignition coil to be connected to a reduced battery voltage for running the engine. This type of coil must not be used without the correct use of the ballast resistor. If it is connected to full battery voltage all the time it will burn out. The protection of the ignition points is achieved by the use of the points condenser. This device, technically an electrical capacitor, absorbs the back EMF generated when the points open. [The primary coil circuit that the points energise, is highly inductive and interrupting an inductive circuit will generate very high voltages due to the collapse of the magnetic flux in the associated circuit.] Without an effective capacitor, there will be horrendous sparking of the opening points and they will quickly burn out. Of course there are ignition coils which are designed to operate without a ballast resistor [with points] and ignition coils designed to be used with transistorised ignition systems [without points]. These are two different devices as well and must not be confused. A points coil used on a transistorised ignition is a bomb waiting to go off:finger:

-

Fuel sending unit ohms

On my '73, the FULL reading is ~65ohm, EMPTY is ~135ohm. There is a small collar held in place with a set screw which you can adjust to vary those values.

-

Crank bolt thread size

If you are going to fit a new crank bolt, why not use the old one to chase the thread? I'm guessing a tap that size will cost a kidney:tapemouth Just grind a few flats on the old bolt to give the swarf somewhere to go, dose it up with some cutting lubricant and away you go. Just use the bolt like a tap, turn forward and back to clean the threads. Providing you are not trying to CUT a thread and just want to CLEAN, it should do the trick:classic:

-

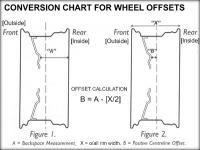

Tire size question

Like he said^^^^^^ Here are a couple of charts which help explain OFFSET and BACKSPACING. You have to realise that as the rim width increases, the above dimensions may also have to change, to position the rim away from: - A] suspension components on the inboard side and B] wheel arch/body work on the outboard side. Don't get a set of wheels without knowing all these dimensions and applying them to your suspension and bodywork, or your current wheels:classic:

-

Speedometer - Which Gear Needed To Fix Readout?

-

1975 Fuse Box Cover

Don't get too excited about the Haynes. Their wiring diagrams are plain awful to read:sick: However the remainder of the Manual is reasonable.