Everything posted by inline6

-

Restoration of BringaTrailer 240z - HLS30-35883

Oh, interesting! I believe I have many that have a 7 on the head and are only 25mm long. Thanks for the offer! I will take a look again at what I have on hand today, and let you know.

-

Original carpet --- and Chester and Herrod

Interesting. My car is a 6/71. Thank you for those pics. Very helpful to me. Those are loop. And from 4/71 also. Wild. I have never seen that type of jute (reused carpet) on the back of original carpets. Perhaps a prior owner added that? Why are you thinking of re-dying and using them? Just, they aren't that bad? Or, is part of the reason the lack of availability of new carpets that look enough like the old ones? Other reasons?

-

Original carpet --- and Chester and Herrod

I found this carpet and matching jute on eBay. It looked original to me, and I was interested in getting it for the purpose of using it as a pattern for having some custom carpet made because my opinion is that the kits that are available these days are rather lackluster. When I spread it out and took a close look at it, I was surprised. I was expecting it to be loop carpet. However, it seems like it is more of a pile carpet type. To my understanding, one of the most "authentic" carpet kits currently available is this. But, that is loop carpet - it is very different. While from pictures, it may be hard to tell, this carpet definitely isn't compose of upside down "U"s. It is more like each twisted strand of carpet has had it's top lopped off: Since receiving it, I searched for information about original carpeting and come across various posts on this forum. It seems, that original carpets included both a "pile loop" as well as "loop" versions, though it is not entirely clear to me which year cars got which. From the information I found, I believe this carpet to be original. I am mainly basing this on the color of the backing (underside) and the age, as apparent from the fading. It is actually in pretty good condition compared to many I have seen in pictures. I have seen several with more color fading, and several with more wear. Additionally, it came with one "block" of dense material. This piece is normally glued to the hatch floor. It is about the same thickness as the jute... roughly 1 centimeter. A few days ago, I became aware that Chester and Herod is still in business. I thought they were out of business. This was another reason I was thinking about having custom carpet made. However, now that I have been looking through various carpet related posts, I have some new concerns. From the most recent pictures and comments I have seen, I am wondering if the Chester and Herod kit's fit has degraded over the years, and if the loop or pile options they have are very different than this original carpet. Does anyone have any info to address my concerns? I'll likely attempt to get some current samples from C and H to evaluate how similar or different it is, but I looking for additional opinions/info from anyone with recent C and H 240z carpet purchases.

-

Restoration of BringaTrailer 240z - HLS30-35883

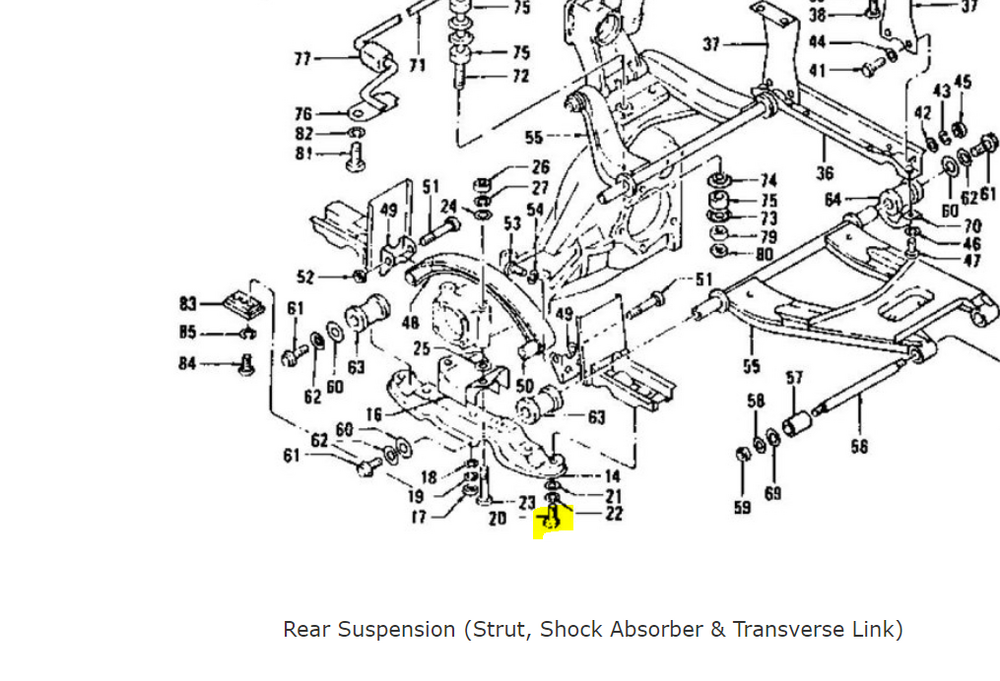

I found two of them - I think. They are 30 mm long, but the threaded portion is more like 23 mm instead of 21, by my measurement. The prior owner of the car had done some rear suspension work and apparently, while going through that work, was replacing most of the factory hardware with 8.8 grade stuff. Luckily nearly all the stock hardware was kept with the car. But, two of the bolts I do not have. And interestingly, my transmission crossmember bolts are similar, but have 9's on them. So they aren't right either, I guess. For now, I'll use two of the grade 8.8 bolts (pictured). While I'd like to get 4 of these (two for the crossmember and two for the transmission), it isn't the end of the world if I can't track some down. I also ran into this unexpected problem tonight - the "240z" OEM brake shoes I bought are for some other Nissan model. Note the location of the "eyelet" holes in the metal stamping for the two inner (OEM) vs the two outer (black) shoes (aftermarket) that were installed in the car when I got it. Whatever B701 FE is, it isn't unique to the correct OEM versions of the shoes for a 240z. Brake shoes are pretty cheap parts for this car, comparatively. I'd like to have some OEM ones. So, I found some online in Austria. I'll see if those are legit. Otherwise, I guess I will install the ones that were installed by the previous owner. A few pics of the brake cylinder I also installed tonight:

-

Restoration of BringaTrailer 240z - HLS30-35883

Awesome. Thanks for the quick responses!

-

Restoration of BringaTrailer 240z - HLS30-35883

It seems I have not recorded any details about this suspension bolt. Can anyone help me with info? I need the number if any on the head of the bolt and the overall and threaded lengths. Should be M10 and 1.25 mm thread pitch.

-

Restoration of BringaTrailer 240z - HLS30-35883

Thanks for the info. I had come across the info about the sleeve in the bushing being offset and installed all of mine so the longer part faces outward... both front and back. With the shorter part facing outward, the crush on the rubber washer would be greater. Glad I installed those correctly.

-

Restoration of BringaTrailer 240z - HLS30-35883

I revisited the job of getting the rear control arm bushings out and was able to accomplish it this time. The issue turned out to be that the socket I was using was a bit too big in diameter. On my first attempt many months ago, I must have had it slightly misaligned as well. This time, though I measured the socket to be about 3-4 thousandths smaller in diameter than the new bushings, I obviously got it aligned better, because I was able to get the bushing to move this time. And this, with the same 12 ton capacity press. However, as the bushing was nearly pushed out, the resistance did not lessen. Sure enough, as I got to the end pressing out the first bushing, I found that I had pressed the socket into the control arm. Clearly the socket varies in diameter a bit along its length. But I didn't bother checking that, I just used a different socket of a slightly smaller diameter for the rest of the bushings. To get the socket out of the arm, I used my bench vise and removed it without any difficulty. I didn't have any problems pressing the new bushing in - all went in the same. After the new bushings were installed, I epoxy primed, and then painted the rear control arms, the rear axles, the gas tank and a few other bits. Tonight, I only had about an hour to play, so I worked on partial installation of one of the control arms: As before, I put some silicone rubber in a few places to keep water from entering. This included both sides of each of the outer control arm bushings. With regard to the rubber washers, they fit best with the taper facing inwards, like in this first picture. Is that correct?

-

Restoration of BringaTrailer 240z - HLS30-35883

I am working my way towards getting the car off the lift and sitting on its own suspension. I was able to assemble the rear struts two nights ago and get them on the car. I had to order bump stops as I had forgotten about those - $100 plus shipping for these Koni ones. It was nice not having to compress the Suspension Techniques springs for the rear to get the strut assembled. Somewhere, I believe I have the spring rates written down for these. The rear springs have a thicker coil wire. And they are a bit stiffer than the fronts if I recall correctly. Lock washers pictured are a bit small - I had to swap those out. Note the "9"s on the strut to body nuts. I still haven't done anything about my rear control arms - not being able to remove the bushings. And therefore, they have not been painted black yet either. And I did hear back from Motorsport Auto. They are sending me modified gland nuts for the front struts. They are coming from CA, so will have to wait a bit for them. I think those are the only parts that are holding me back now from mounting the wheels and tires and setting this thing on the ground.

-

Restoration of BringaTrailer 240z - HLS30-35883

Hmmmm. Whoops! I recall finding out about them a couple of years ago, and seeing that they were no longer answering their phone? Did they move from CA to TX? Maybe I was trying to reach them while they were "offline" for the move? Anyway, I am excited to see that they appear to be in business still.

-

Restoration of BringaTrailer 240z - HLS30-35883

Unfortunately, Chester and Herod went out of business several years ago. So, they are no longer an option. I have a scanner somewhere. Will have to see if I can get that to work.

-

Restoration of BringaTrailer 240z - HLS30-35883

I found this carpet and jute on eBay. It looked to be original to me, and I was interested in getting it for the purpose of using it as a pattern for having some custom carpet made. I have come across various posts on this forum about original carpeting, and am spending time researching further. To me, this carpet appears to be original. I am mainly basing this on the color of the backing (underside) and the age, as apparent from the fading. It is actually in pretty good condition compared to many I have seen in pictures. I have seen several with more color fading, and several with more wear. Anyway, something I was not expecting: this carpet is not "loop". Instead, I think the best description for it may be "cut pile". To my understanding, the most "authentic" carpet kit currently available currently is this. But, that is loop carpet - it is very different. While from pictures, it may be hard to tell, this carpet definitely isn't compose of upside down "U"s. It is more like each twisted strand of carpet has had it's top lopped off. Some more pics: Additionally, it came with one "block" of material that is normally glued to the hatch floor. It is about the same thickness as the jute... roughly 1 centimeter. So, original? And, has anyone pursued getting carpet that is more like this vs. the kits that are available?

-

Restoration of BringaTrailer 240z - HLS30-35883

I took a lot of measurements of the example I had and basically drew it free hand. No objection to sharing, but how is best to do that? Uploading a photo isn't going to be very helpful. Is there a way to share it in actual size?

-

Restoration of BringaTrailer 240z - HLS30-35883

It looks like a drip. However, the odd thing is that there are two... one each side of the bar. They look to be equally distanced from the center line of the bar. I saw this pic that @kats provided at some point which has a solid yellow stripe: Looking again, it looks to me like there are two yellow lines on each side. And the width of the reproduction stripe on his bar looks close to the width of what I see on my bar. Very different locations though.

-

Restoration of BringaTrailer 240z - HLS30-35883

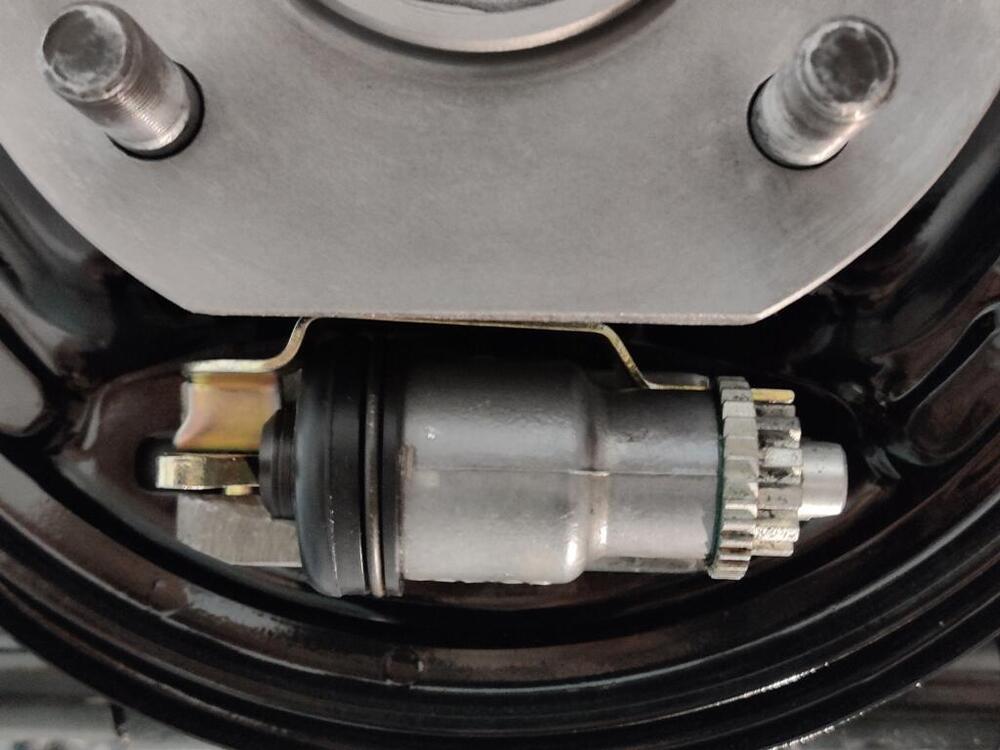

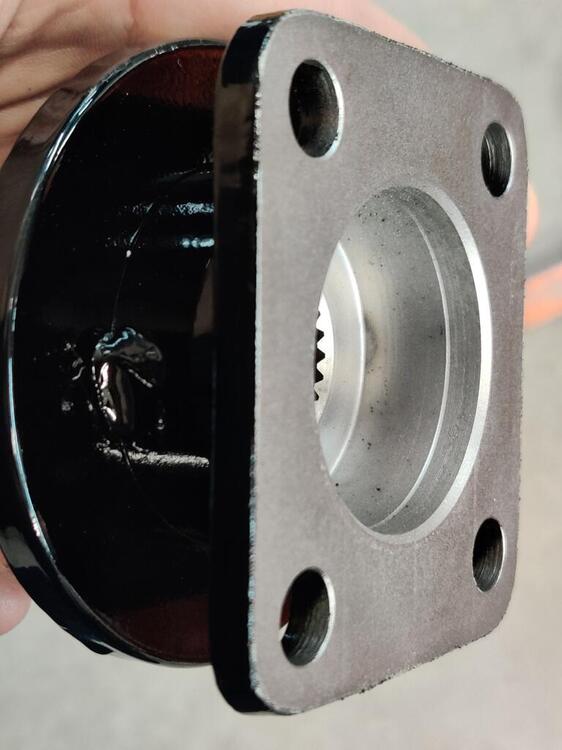

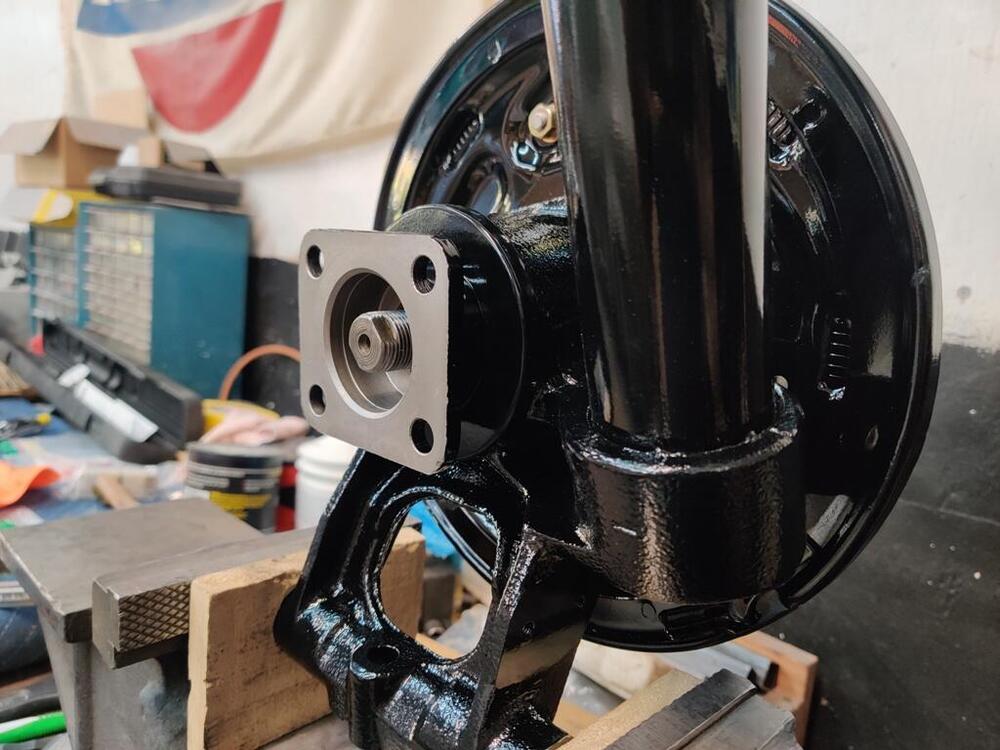

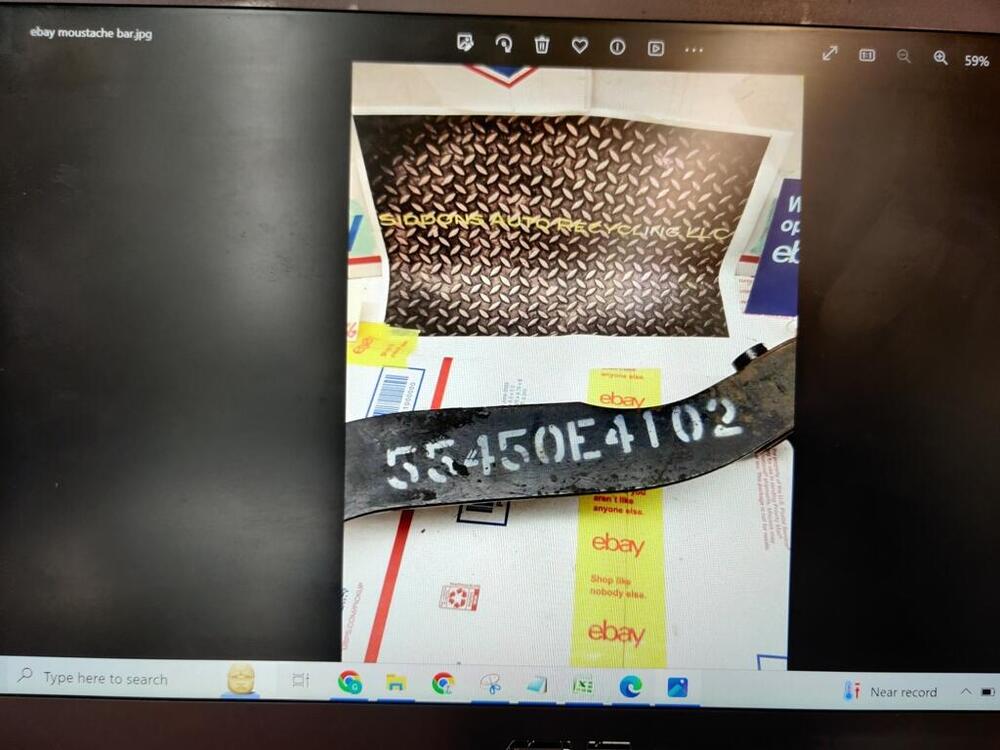

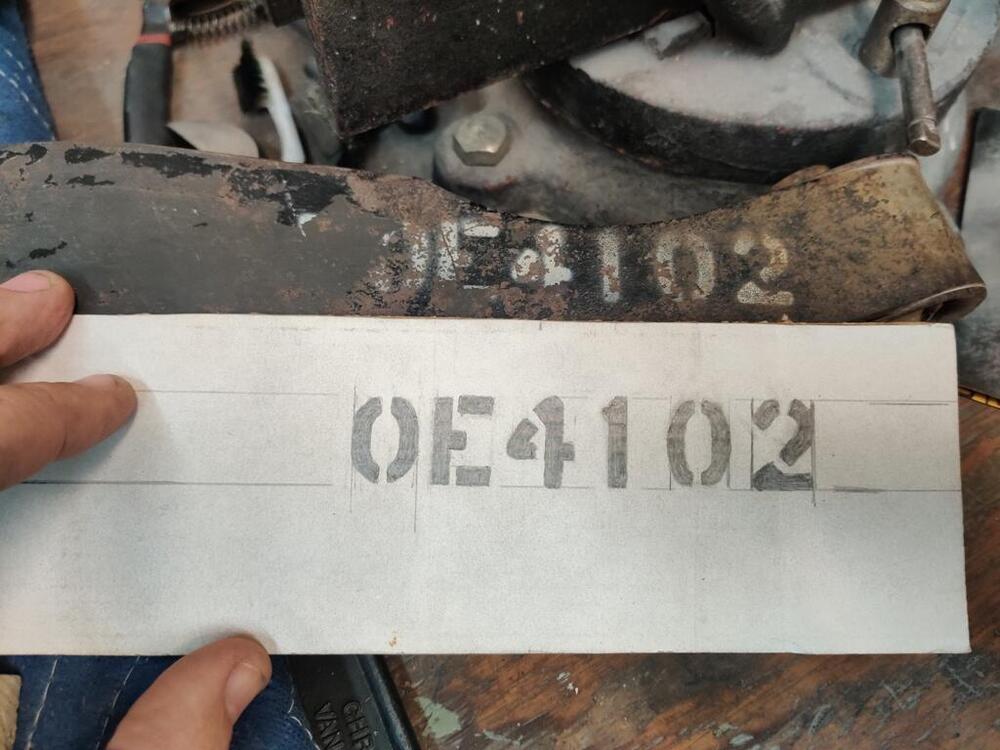

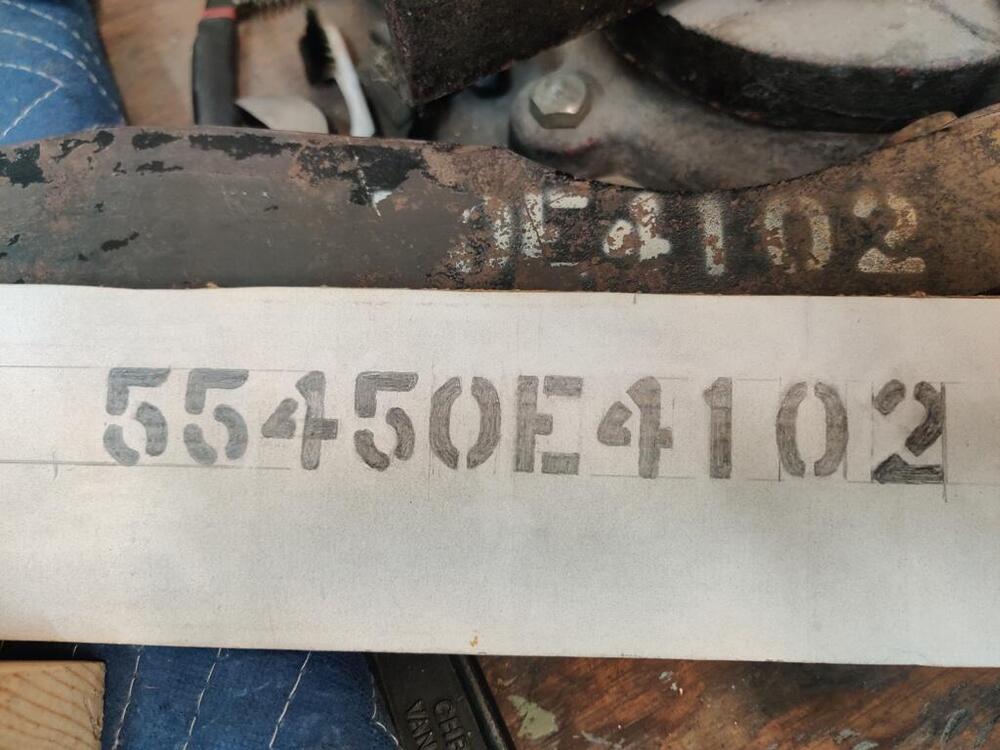

Today, I finished installing the rear axles. Thanks for the info about not using too much grease @Captain Obvious! 12 ton press in use - and a nice close up of the rear back plate going onto the strut I like to use silicone on some parts such as the brake shoe "block" to keep water from entering and to keep rust from occurring on the threads of such parts. Note that I have a new style axle nut (third pic): Axle flange is freshly painted and looking good! Because the axle nut is a newer style, I did not use the large flat washer above. Note axle orientation - axle flange is aligned with hub to minimize weight imbalance. In addition to finishing with greasing the bearings and installing the axles, I worked on a stencil for the part number of the mustache bar. This bar came with the car. Note the vertical streaks - are these yellow paint marks from the factory? Some of the part number did not survive, so I was also looking at an image from an eBay auction I saved a long time ago as a reference image. It's not perfect, but it is closer in size to the original than the picture shows - it is a bit closer to the camera lens that the bar.

-

Restoration of BringaTrailer 240z - HLS30-35883

Thanks Steve! I have a windshield to install... and a hood... and possibly some other things that I will need help with. Appreciate the offer and will ask for help before long.

-

Restoration of BringaTrailer 240z - HLS30-35883

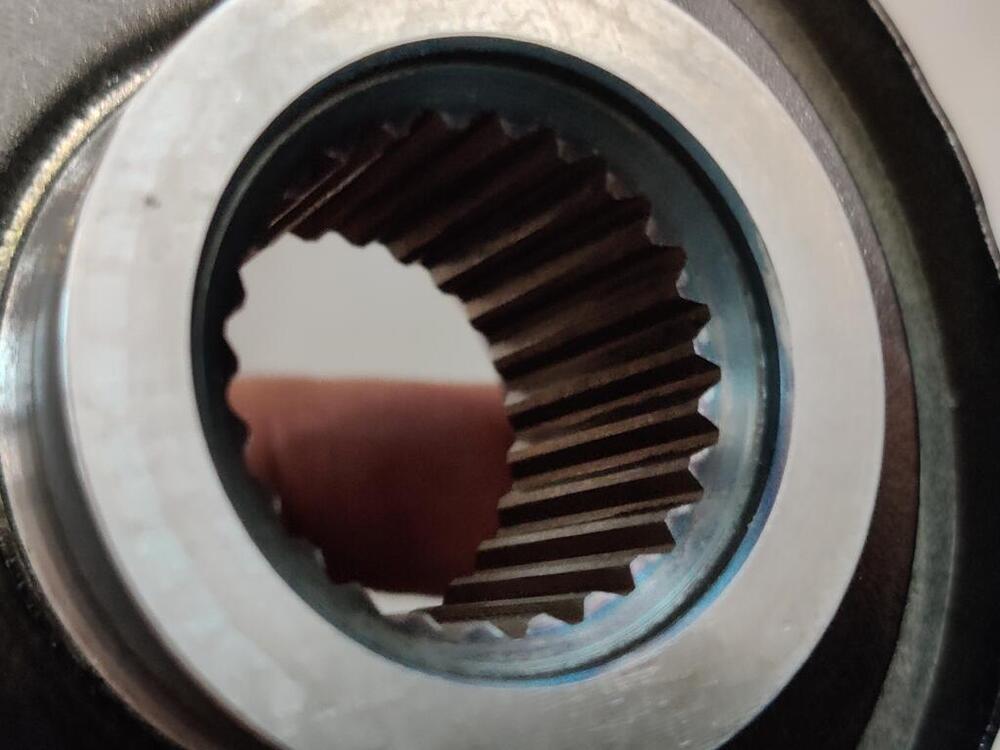

I was able to find the time to swing by a local Nissan dealer and pickup the throw out bearing collar I ordered last week. This is the short collar - correct for use with a 240z clutch assembly: re I got new springs for that collar and the clutch fork as well for good measure, and I ordered a speedometer drive gear assembly. The one I ordered has a red gear to match the 4.11 diff. gear ratio. The throw out bearing was the last thing keeping me from installing the engine and transmission in the car... so, I did that tonight! It was a bit tricky to maneuver everything. Engine and transmission are sitting on car dollies, with wood stacked to get sufficient height and stability for mating up with the car body coming down from above using my lift. Having the assembly on wheels was important for alignment with the car body. I shot some video, but it sucks. Those Youtube people have talent. I will explore editing them and see if I can salvage anything worth viewing. Front crossmember hardware: Transmission to engine and transmission mount hardware - one of the transmission to engine bolts is extra. It only requires 4: The engine is in!

-

Restoration of BringaTrailer 240z - HLS30-35883

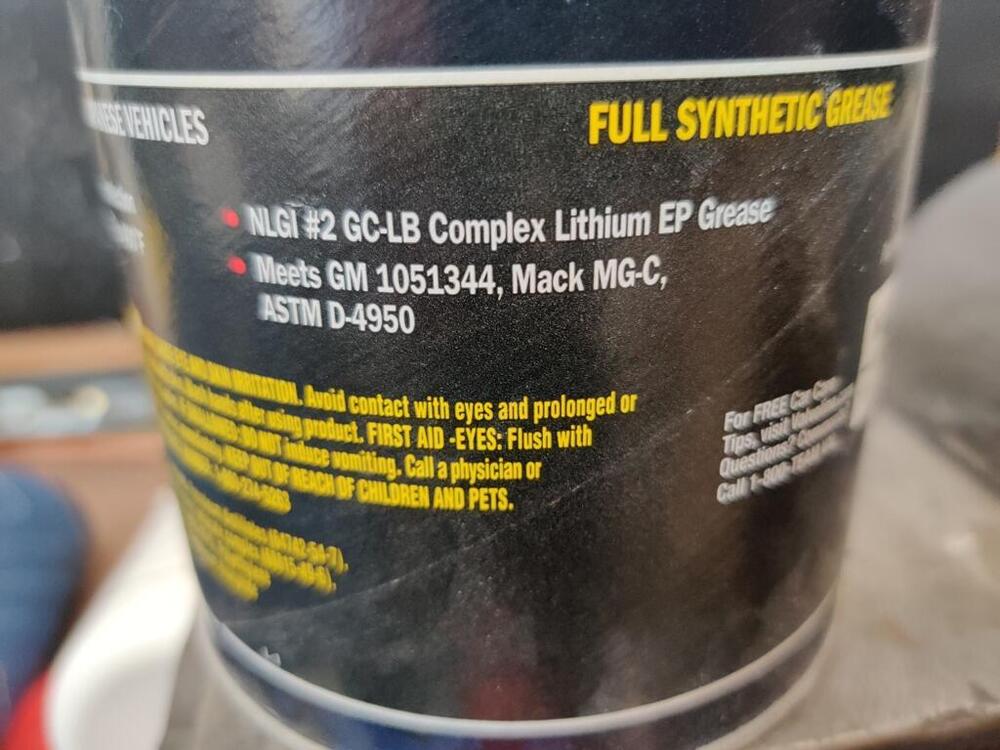

Thanks for this info. I was thinking to jam pack the thing. However, I saw the factory manual picture which indicated only a few areas to grease. I am having a hard time believing that, comparatively, a small amount of grease packed onto the bearing is sufficient for 4 or more trips around the globe, mileage-wise (25,000 miles around at the equator). So basically, the amount of grease I already have on the bearings and the seal... plus a little in the cavity to keep it from surface rusting is the way to go?

-

Restoration of BringaTrailer 240z - HLS30-35883

Thanks for the math. I suspected that at the installed spec, they may have very similar installed loads. I am guessing a production run change occurred. As to why, perhaps the shorter spring with thicker wire is more durable - less likely to fatigue?

-

Restoration of BringaTrailer 240z - HLS30-35883

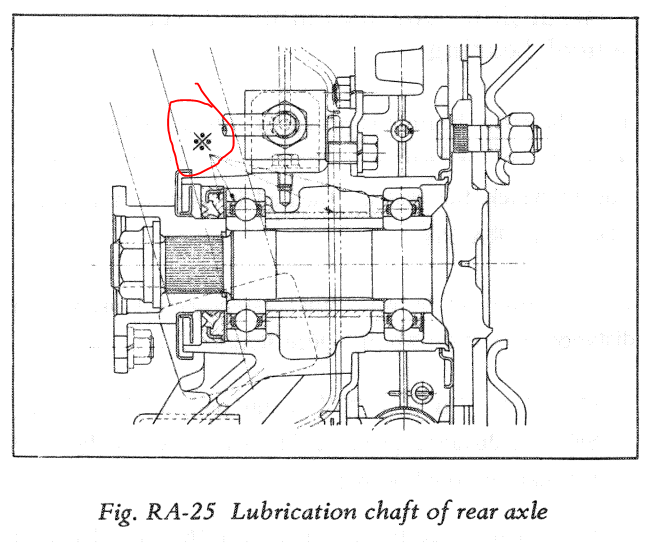

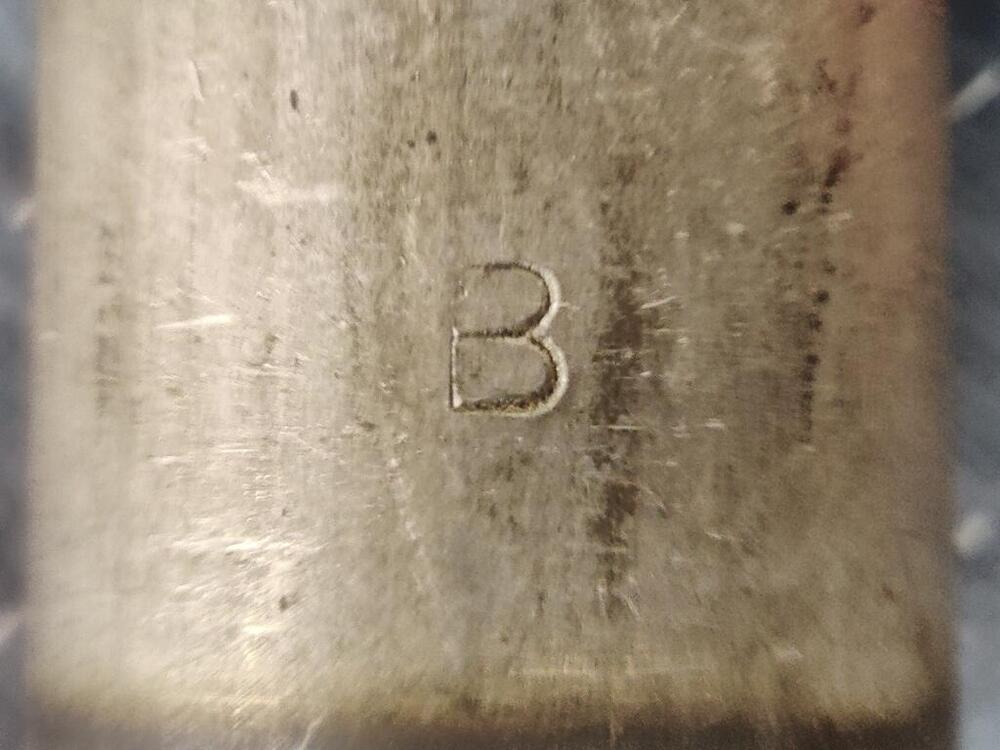

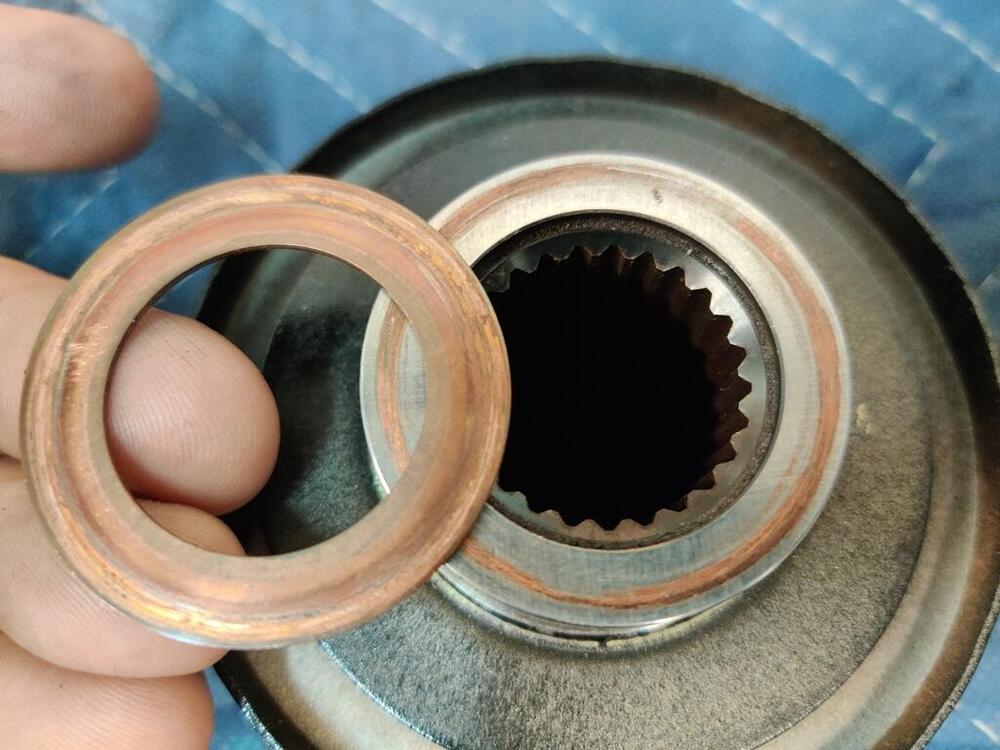

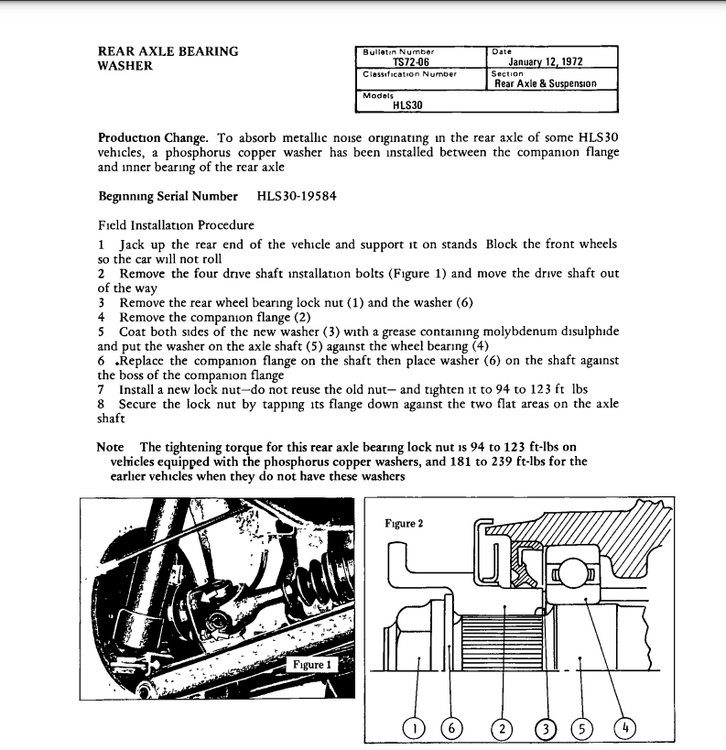

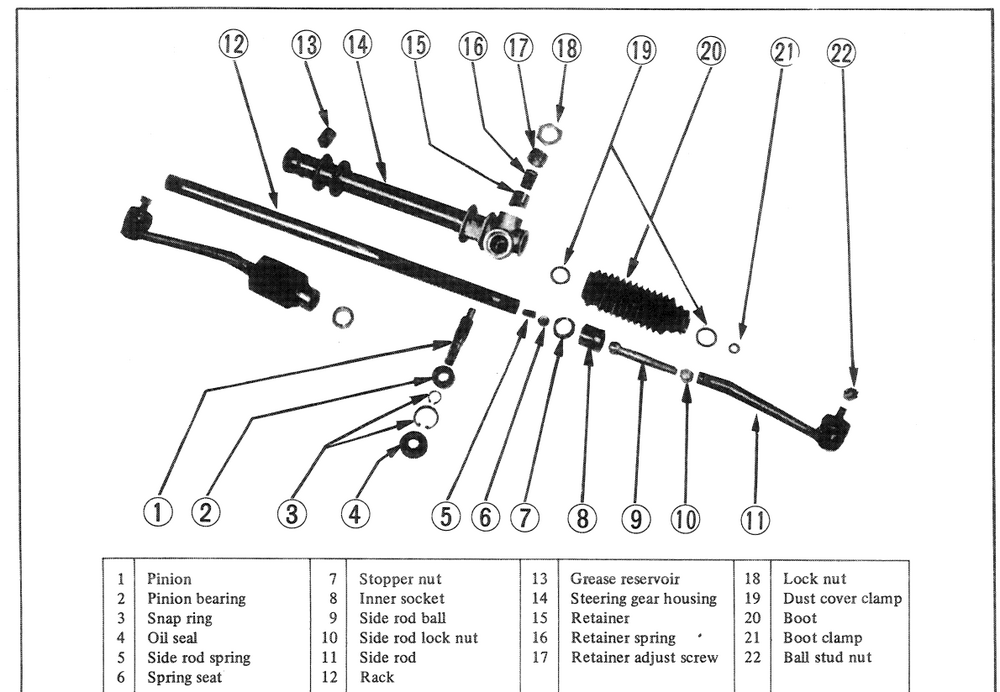

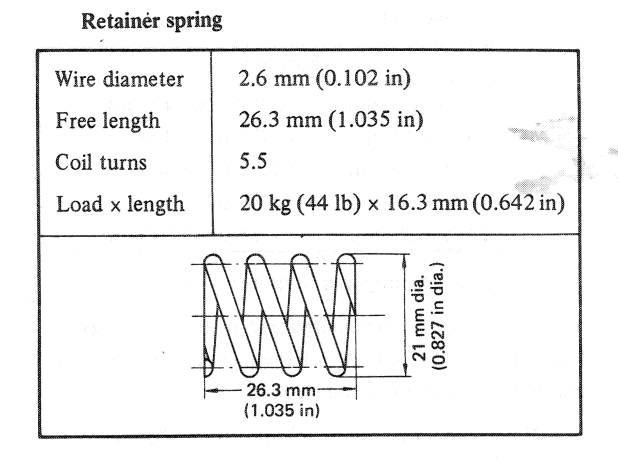

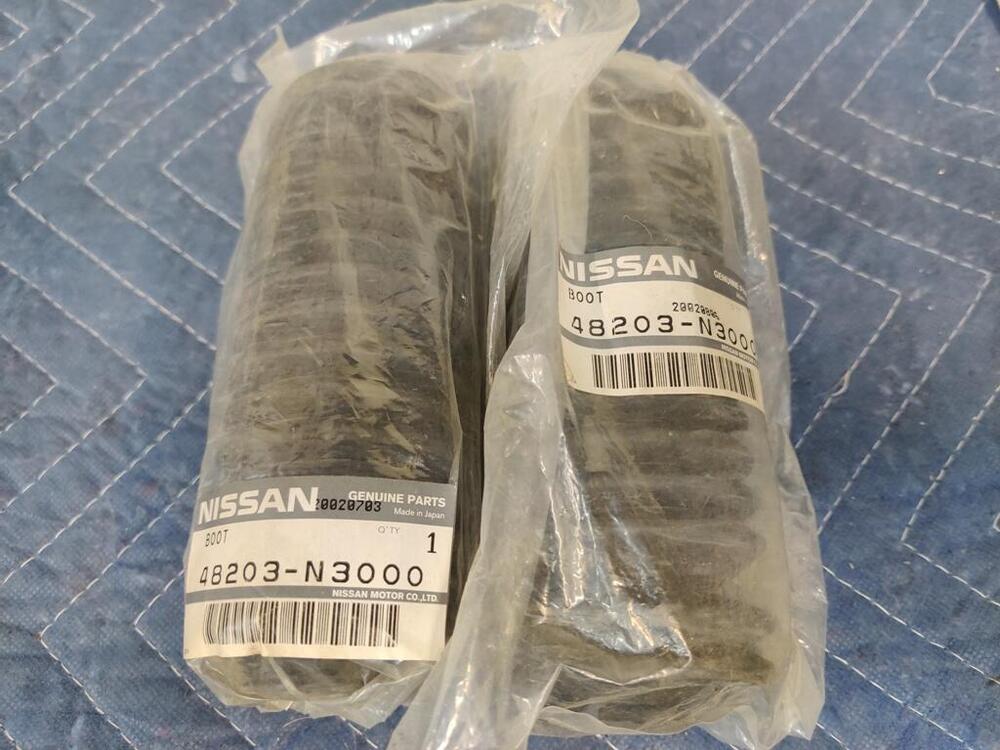

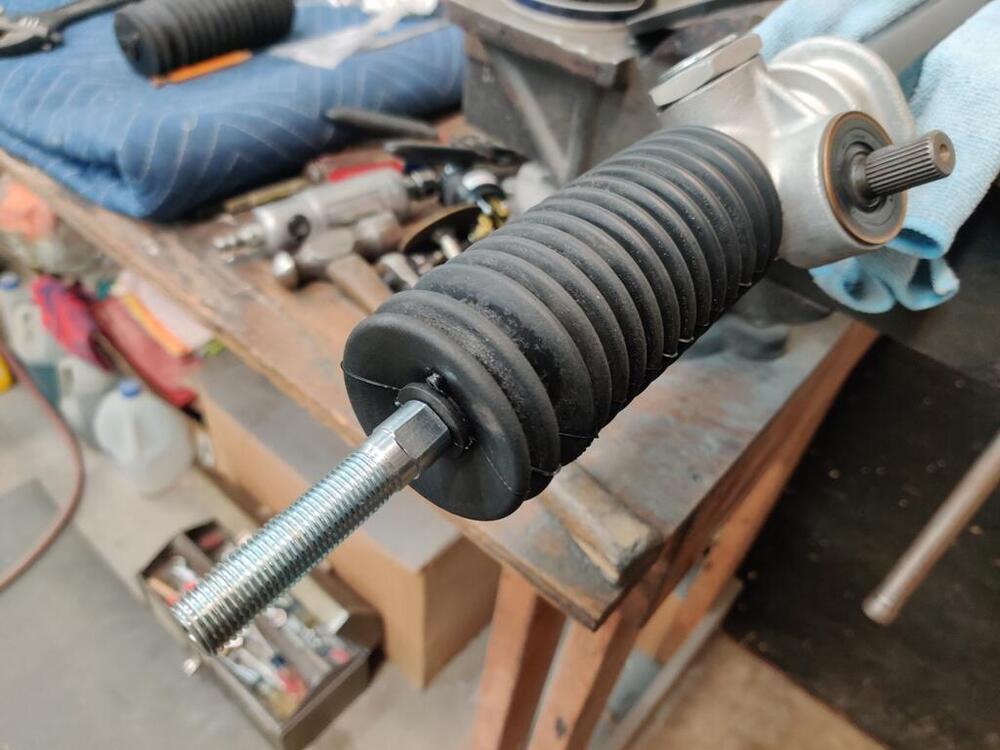

Tonight, I swapped the short spring in my rack out for the longer one that matches the factory manual. I also put one thin shim between the bronze bushing and the spring, and then, the thick and thin shims, in that order, and then the retainer. The factory manual specifies that you tighten the retainer screw "until it stops". What makes it stop is that it bottoms out on the retainer (bronze piece). Then, you back off the retainer screw 20-25 degrees. I shifted the rack fully to one side, and then set the retainer screw per the factory manual. Doing this, I feel, sets the spec for the rack in a "low wear" zone. I think this would be closest to what the rack was like when it was new. My rack doesn't have much wear that I could see, but when you are talking about "retainer floating play" (clearance between the retainer screw and the retainer) of .0035", I think it is best to set the distance the way I did for a used rack. I also replaced the coolant in the rear struts with 10W30 oil. And I started to install one of the rear wheel hub/axles. From the factory, axles were not painted. They were installed in a freshly machined state. I decided to glass bead mine and then put a light clear coat on them to provide some rust resistance. I clear coated only one of the axles several weeks ago after both were glass bead blasted. With that time sitting in my garage, the non-clear coated one started rusting noticeably - the clear coated one has studs installed: New parts and the hardware for the brake shoe backing plates: Starting axle installation "B" on spacer and on strut housing: I believe this washer I am holding is the phosphorous copper washer mentioned in the TSB below. It is pretty clear from the transfer of material to the axle flange where it was located. Note that the torque setting on the rear axle bearing lock nut is far lower - only 93 to 124 ft-lbs vs. 181-239 for VINs HLS30-19584 and prior. I am at the point of the axle installation where I need to add more grease. I have filled the inside of the outer rear bearing, both sides of the inner bearing, and the inner oil seal. Look right? Thoughts on how much grease to put in the axle housing? Do I fill the whole strut housing cavity, attempting to eliminate any air pockets?

-

Restoration of BringaTrailer 240z - HLS30-35883

Yes, the shorter spring has a wire thickness of .116". It may be possible that at the same installed height inside the rack, each spring is close to the same pressure/load.

-

Restoration of BringaTrailer 240z - HLS30-35883

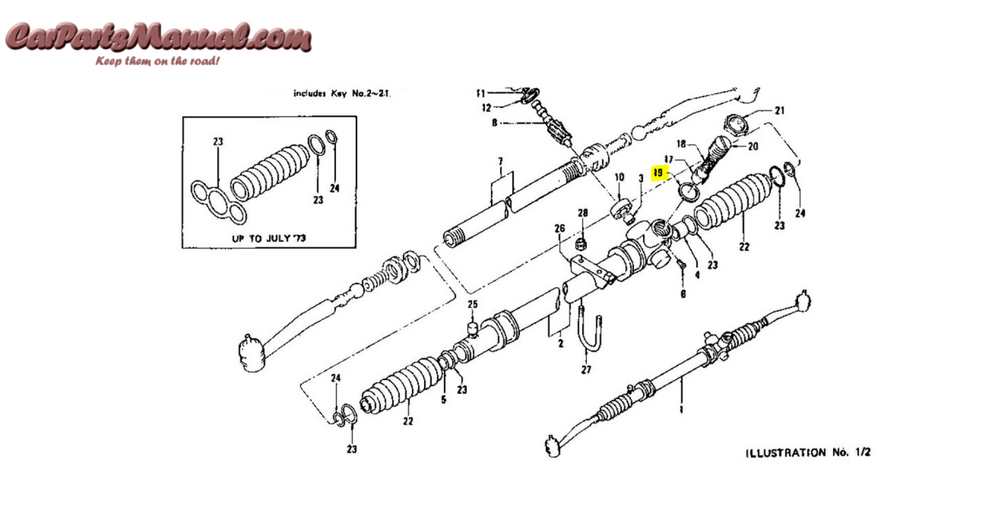

There are part numbers for shims shown in the parts book, but the location in the drawing is inaccurate - they do not go below or around the bronze bushing: I see that the retainer spring in the rack I reassembled yesterday has a spring just like the one I removed from the rack today - not quite four coils. Interestingly, I do have one of the springs that matches the retainer spring specification from the factory workshop manual. I may have ordered that spring from Nissan around 1994 when I rebuilt the rack on my original 240z. At that time, I was able to source new bronze rack bushings, new pinion bushing, new bronze retainer, a new pinion gear and pinion gear bearing. I think it likely that I ordered a new retainer spring while I was replacing all of those parts. I had a slight shimmy in that car for years even after rebuilding the rack, and it wore the rack considerably at dead center. Only later did I found out that the ball joints (appeared to be new, so I looked at other things first) were the cause. Because that rack was worn, I swapped it for another, which is still in that car. Salvage car rack - as retainer was removed - thin shim against retainer, thick shim against spring: Spring on the right is from the salvage rack - looks to be the same spring spec (even white paint on it) as the retainer spring in the rack I assembled yesterday. Spring on the left matches the specification from the workshop manual for the retainer spring. Coil diameter measures right at .102" . Free length was 1.015" instead of 1.035". But it has been compressed in a rack for about 30 years, so maybe that is why the free length is a little short. These springs have very different lengths and loads. I wonder what the deal is - why these differ so much from the specification in the workshop manual.

-

Restoration of BringaTrailer 240z - HLS30-35883

Many years ago, I grabbed 240z steering rack from a salvage car in a yard. My thinking at the time was that I could send it in as a core on rebuild exchange some day. Tonight, I removed the retainer nut and screw, and found two washers - one thin and one thick sitting on top of the spring. There was no shim under the spring - the spring was sitting on the bronze retainer. Since the rack has been in my possession since the 90's and is covered in tons of gunk, I assume it has never been apart. Of the three youtube videos I can see, one puts the washer(s) under the spring against the bronze bushing, one puts the washer(s) on top of the spring, and one has no washers. There are no shims in the picture in the factory shop manual which identifies all of the parts to the rack (15, 16, 17): I suppose it is possible that the shims were used to adjust the amount of spring tension pushing the retainer against the rack... with the retainer screw in the precise installed position per the factory manual instructions. Steps 12-15 pertain to the retainer and retainer screw installation: Perhaps originally, they were added by factory worker in a fashion such that, the retainer screw was set per factory instructions, and then some type of resistance check was made. Then this was followed by adding shims (remove the retainer screw, add a shim, replace retainer screw, then check resistance again... Anyway, that is my guess. Another interesting thing I am just now seeing: the retainer spring I took out of my "undisturbed" rack does not match the specs for the 71 manual, which are here: Free length is about .890" and it is only composed of just under 4 coils. Odd!

-

Restoration of BringaTrailer 240z - HLS30-35883

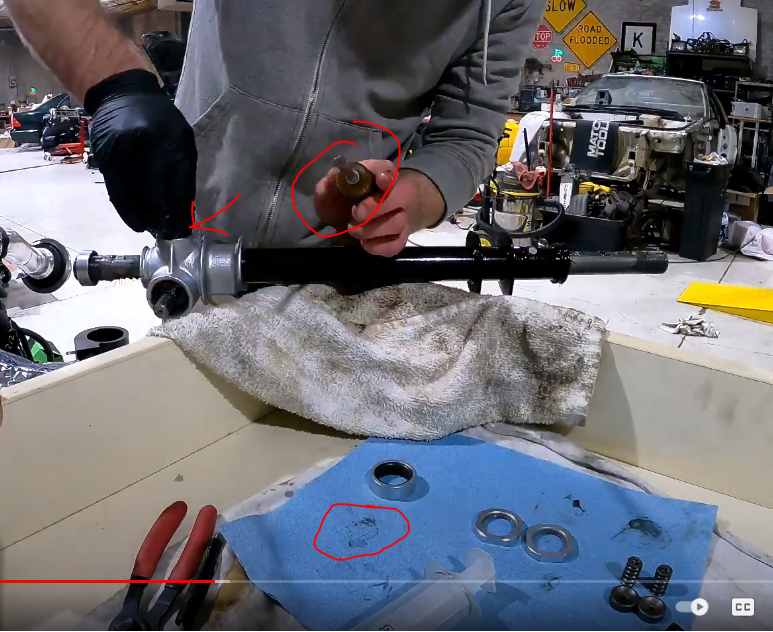

I can confirm that the washers do not fit on the pinion gear/shaft. The factory workshop manual provides information about selection of different snap ring thicknesses to achieve pinion gear end play of no more than .003 something. In the Youtube video above, it is a little difficult to determine where that guy put the washers even slowing the video to .25 speed, but I see that he puts them (it looks like he has two) directly between the spring and the large retainer screw. These two freeze frames show, bronze shoe missing from parts on rag and spring is in the "well" - retainer screw in hand... Washer now missing from rag, retainer screw being threaded in, screwdriver in left hand. I have a spare rack, and will pull the retainer on that one to see what I find.

-

Restoration of BringaTrailer 240z - HLS30-35883

Today, my focus was on the steering rack. I was unable to find any pictures of the shims in this third picture, neither in my disassembly pictures, nor online. They aren't in the pictures in the factory shop manual either. It seems incorrect to me that the spring would push directly on the brass/bronze bushing, and there were no wear marks from the spring in that surface. There were two very thin washers and one thicker one. I stacked them - thin - thick - thin and put them between the spring and the bushing. Is that correct? Other than keeping the spring from eating into the bushing, I don't know why these would be needed. If there were just the two thin ones, I'd have put one on each end of the spring. Given that the larger retainer screw adjusts down against the spring, I see no reason for a spacer, or shim in this location.

Subscriber

Subscriber