Everything posted by Captain Obvious

-

260z and 280z same Birthday

Hmmm.... Are you double dog sure that your 260 is really really 12/74? Looking at your door jamb nameplate, it looks like 1/74 to me and what you are considering a "12" is caused by some "two shaped" scratches on your nameplate. I'd be hard pressed to believe they were still making 260's that late in 74. I'd also be hard pressed to believe they were making 260's and 280's at the same time like that. Are you sure that's a "2"? If you look at the serial numbers, there are like 130 thousand cars between those two plates. Something seems amiss. As for the weight difference... That's the GVWR. Maybe they were assuming the passengers gained 20 lb each.

-

SB Needles to Resolve Lean WOT with SUs

Definitely keep us posted. It's an interesting project. Do you have a micrometer? I've tried a couple different measurement devices on needles and have found a good ol' micrometer to be the best of the bunch. Most accurate and most repeatable.

-

SB Needles to Resolve Lean WOT with SUs

Gotcha. If I were closer, I'd be happy to lend a hand. Problem is, this is going to be a "take a little off and try it... Take a little more off and try it again" kind of affair. Tough to do with two days shipping in each direction. One thing you can to do to help yourself out is figure out where you are on the needle when at WOT. By that, I mean... When you are at full load and the suction pistons are pulled all the way up, there should still be some needle sticking down into the nozzle. You could push the piston all the way up by hand and reach into the carb throat with a marker and Sharpie mark on the needle where it enters the nozzle hole. Then you would know where to concentrate your metal removal efforts. If you are running lean at WOT, you would want to concentrate your efforts where the WOT needle enters the nozzle and a little above and below that.

-

SB Needles to Resolve Lean WOT with SUs

Yeah, the advantage to spinning the needle is a probability for increased uniformity. I do enough metalworking that I feel like I could just "wing it" if I didn't have access to machines to help. Maybe lock your hand drill in a vice? Do you have a vice big enough?

-

SB Needles to Resolve Lean WOT with SUs

That is where the needle is supposed to be installed. If you had it pushed up flush with the groove in the piston, then you had it in too far. You can do all the needle modifications by hand. You don't really need a drill at all. You're only looking to take off one thousandth or so.

-

New Z Concept by Privateer Artist

I get a little lost with most of the "updated redesign" results of most cars. Including the Z. There are people that say they see the first gen Z in all of the revisions that came after the 280Z, but I'm not one of them. I "get it" with the ZX and can clearly see the lineage, but after that, I lose it. I see no original Z in anything that came after it. Not to say that some of the successors aren't nice cars, but I just don't look at them and think 240, 260, or 280. Lately though, there have been several manufacturers closely following the original visual design with a brand new car. Like the new Mustang, the Challenger, the Mini, etc... IMHO, they all represent the original visual design very well. So all that makes me wonder what would happen if they tried this:

- 1976 280Z Restoration Project

-

Z Cars On TV And In Movies

Yeah, I remember that metaphors episode. My work buddies and I spent the next couple weeks talking like that after that episode aired. Drove our boss nuts (since he didn't have any idea what was going on). Sitting in a meeting, nodding approvingly..... "Nancy at the Christmas party."

-

Z Cars On TV And In Movies

Really? They used the same window in both the old Rockford Files and that X-Files episode*? Did you actually remember that, or did you figure that out somehow? I would have a new level of respect for you (if that's even possible) if you remembered that just from watching those two shows!! * Hungry - Rob Roberts works at Lucky Boy and eats brains. I love the part when he's at the OA meeting describing his issues to the other attendees.

-

Home Built Z 'Full video build'

No, there's a rolled over metal beaded edge. I chucked it up in a lathe and cut the bead off just as exploratory surgery. Sorry if I gave you any false hope. It's an autopsy.

-

Picking up a 1977 280z 6 Hours Away. Tips?

If it truly has less than 30K miles, then your chances for success go up. Do you have the documentation to be sure that it's not 130K, or 230K?

-

Home Built Z 'Full video build'

Cool. Glad you got to the bottom of that and glad it was that simple. I've been inside of multiple ignition switches to date, and I believe it is time for everyone to replace their switches because they all look like this inside:

- 240z - fabbing new front rails

-

280Z fusible links

I don't remember where I got my links from last year, but they were just like the ones that Eurodat got from Courtesy. They're official Nissan issue, and they have the Yazaki part numbers on them. I don't know about the other vendors, especially that one pic above from ebay. Those certainly don't look like genuine Yazaki. Looks like something put together with parts bought at Home Depot.

-

Home Built Z 'Full video build'

I'm assuming we're talking about an early style inductive pickup style tacho? Back side looks like this, right?: If that's the case, then you really only need to make connection to two wires (not four). Just to get the engine to run, the only two you need to connect to are the two white wires. The one with the red tape should come from the ignition switch, and the one with the black stripe should go to the (+) side of the coil. If you don't connect the other two wires (Y/R and B), the tacho itself won't work, but that shouldn't keep the engine from running. Will just keep the tach at 0.

- 240z - fabbing new front rails

- 240z - fabbing new front rails

-

280Z fusible links

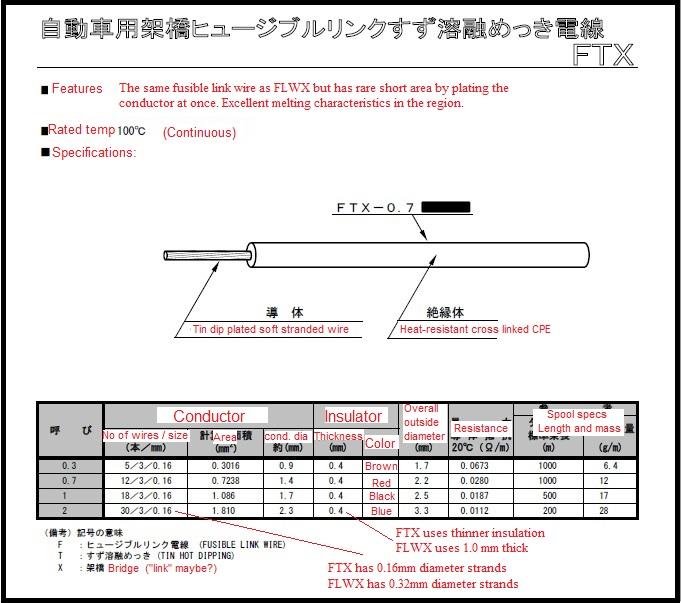

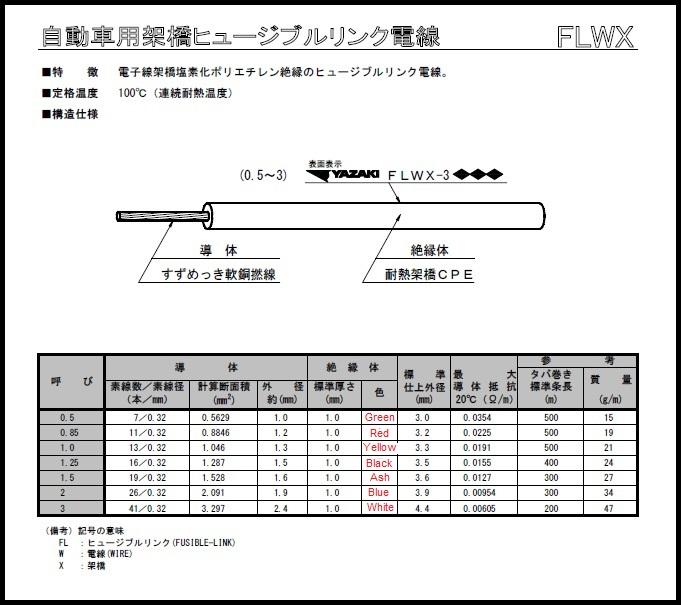

Assuming all of the links over the course of the Z were made by Yazaki (and I suspect that is the case), the you shouldn't have to measure the conducting part of the link. The insulation thickness difference between those two series was different enough that you should be able to tell the diff between the two just by measuring the insulation diameter. The overall outside diameter of the (red) FTX-0.7 is 2.2mm. While the overall outside diameter of the (also red) FLWX-0.85 is 3.2mm. Should be pretty easy to tell the difference. And as to the discussion about the quantities of #5's and #6's... It appears that it's just another mistake in the documentation. On the pic, they are clearly indicating that there exists three number fives and one number six. But in the details below, they have those quantities switched. It's just another mistake in the docs. I wish my stickers were readable. It would add one more level of confirmation to the discussion if someone with a 77 or 78 could post a pic of their readable stickers.

-

77 280Z color wiring diagram

Thanks Wayne!!! Looks great! This is a fantastic tool for all of us. Don't know what we would do without you.

- 280Z fusible links

-

280Z fusible links

I got the same impression about the melting spot as you did, but here's the rub... They clearly do the tin dip before they put the insulation on. And Yazaki don't know how long the end user is going to cut the length of wire. So if they are tin dipping just in select spots, they won't know where that dipped spot will end up (or how many will end up) in the finished product. I think the dip has to apply to the entire length. And as for measuring the resistance difference between the red and the brown, I don't have a meter anywhere near that good. Probably easiest to push an accurately known "highish" current through it and measure the voltage. But I gotta ask.... Why would you need to resort to measuring the resistance when you can just look at the jacket color or measure the diameter of the conductor with calipers? Based on the thicker insulation of the old style red links, I suspect they are the FLWX 0.85.

- 280Z fusible links

-

280Z fusible links

So for some additional info, I couldn't stand it anymore so I started playing around with some of the on-line translators. Everyone likes info, right? Here's a probably correct interpretation of most of the pertinent info on those Yazaki fusible link data sheets: The only thing I can't figure out is exactly what is the difference between the FLWX and the FTX series. It clearly has something to do with tin-dipping. My guess is that the FTX series uses smaller individual strands and then they tin dip the strands a second time once they are wound together. Might make them more accurate or have a sharper melt characteristic? Anyway, here's some datasheets. FTX (this is where the 0.3 brown comes from): And the FLWX (this is where the 1.25 black link comes from):

-

280Z fusible links

Well I'm pretty sure there isn't any 28 Ga wiring anywhere in the infrastructure. There might be some stuff that small as it enters components (like solenoids and the like), but I don't think actual wire in any harness is that small. In any event what you said about the 0.3... "if 0.3 hasn't been melting, what reason would you have to go to 0.5?" echoes exactly my note above when I said "anecdotally that the brand new 0.3 "sorta brown, sorta tan, sorta salmon" links I have installed run nice and cool. Implication being that they are large enough." So I agree... Why argue with success, right? Put the smallest, easiest to blow protective device in there that still allows the system to operate properly. The only thing I DON'T know is if I have ever operated my system under peak load. By that, I mean... I've never run the HVAC fan on full blast at night with the high beams on, while running the rear defrost, wipers, and hitting the brakes on a hot summer night while running the A/C and having the flashers on. Probably never will.

- 240z - fabbing new front rails