Everything posted by Namerow

-

Correct Hatch Removal Method?

See photo. Engine hoist. Cargo straps. Bath towels wrapped around engine hoist boom arm and hatch to protect hatch paint and glass. With one set of cargo straps centred vertically and another centred horizontally, and using the cross-over point as the lift location, the hatch was pretty well balanced for a flat lift. I trimmed it out by adding small weights (socket wrench sockets) as required on the hatch surface. This wasn't so important during removal, but it was very important during re-installation in order to get the hinge bolt holes to line up.

- pictures not available in knowledge base

-

Parts for Sale: 4x reproduction Nissan Fairlady Z432 wheels in aluminum

I agree completely. And yet, we are dealing with a shift in consumer ethics that had/has no problem with bypassing copyrights to illegally download music and movies and photos. It seems like the transition from physical product (e.g. vinyl record) to digital product (in music, this was iterative: cassette tape to CD to online digital) has made people decide that the product is virtual, so the ownership is virtual/meaningless too. Complicated issue. Early days.

-

COVID-19

Then you're somewhere in between the two views, aren't you? Only the under 35's and the over-65's enjoy the certainties of their views.

-

COVID-19

I agree in general with your proposition. I would replace one word: ""That's is what the scientists should be working on". This nothing to do with scientists. It has everything to do generational politics. If you're under 35, your premise is this: 'I have a career and and a life to pursue and I won't be held back by a virus that statistics tell me is no more dangerous to me than dying of influenza." If you're older than 65, your premise is this: 'I worked hard to get where I am and now my life and my future is being jeopardized by a bunch of careless, selfish younger people who just don't care.'

-

1977 280z

I have read the following tips about using paint strippers: Results can be noticeably accelerated by laying cling-wrap over the treated areas. Using the cling-wrap technique, the best of the modern-formulation automotive strippers will get the job done nicely after an overnight soak. Keep the stripper application away from panel edges and seams (the stripper seeps into gaps and will re-surface later to ruin your paint job). Keep the stripper at least 1-1/2" away from these 'porous' areas. Use good-quality masking tape to protect them. After your final wipe-down of the chemically-stripped zones, remove the masking tape and use sandpaper (power and manual) to remove the remaining paint. For the aforementioned reason, the engine bay surfaces do not look like good candidates for chemical paint stripping.

-

Lowering Bottom Spring Perch

If possible, please mark the photo in Post #32 to show the area where the grinding needs to be done. Based on the earlier pix (Post #28), it looks like you just ground off the weld bead that sits immediately below the perch stamping. Is that sufficient to free up the perch? Just want to be sure I understand this correctly.

-

Price Check: 2" X 4" X 8' ?

The Toronto Globe & Mail newspaper recently ran an article in which these high lumber costs were blamed on a pandemic-driven surge in home renovations. Curiously, about a week later the same newspaper ran another article which said that a major mill on the Canadian west coast was temporarily shutting down because of an absence of demand. I drew these apparently conflicting stories to the attention of the newspaper but never got a reply. Thrown into this mix is the longstanding and ongoing battle between Canada and the US over the extent of protective duties imposed by the US on imported Canadian softwood lumber. It's my sense that there's a lot of planted story-telling going on here as part of various parties' attempts to manipulate things to their benefit. Here in central Canada, an 8' length of 2x4 is currently selling for Cdn$6.15 (that's $6.95 tax-in). If you're being charged 32% more than that in Atlantic Canada, it looks like a regional premium (which may depend very heavily on where your regional mills are finding their best market opportunity at the moment -- my guess being the U.S. northeast). SteveJ's report of US$6.00 sounds about the same as your NS pricing (converts to about Cdn $8.00, or Cdn$9.00 tax-in). One local lumber-department price that did catch my attention last weekend was that for a 10' strip of half-round 3/4" molding (plain, unfinished). About Cdn$12.00 !

-

window defrost grid

I'm sure others have succeeded at this task. In my case, I used my engine hoist. I wrapped the hatch using HF-quality cargo straps -- one strap along the vertical centreline, the other along the horizontal CL. I used zip-ties at the crossover points so as to make sure that the straps didn't walk under load. Lift cautiously. Study the balance. Watch to ensure that nothing shifts. Make sure in advance that you know where you're going to drop the hatch panel after removing it. A set of movers' blankets is a good idea for protecting the hatch paint once in storage. BTW, I successfully re-installed my hatch (a much bigger challenge, BTW) using the same process in reverse.

-

240ZBUILTBYME 1971 240z HS-001063 Project Georgia

I also have a shipment from KFVintageJDM on the way. As per your experience, the shipment emanated from Bogota. I, too, have found the company's customer service to be excellent -- fast replies, helpful and on-topic information. Shipping was by way of FedEx and the costs were surprisingly modest. I'm using a USA-to-Canada cross-border trans-shipper service recommended to me by Grannyknot and hope to take delivery at their Toronto drop site sometime next week.

-

window defrost grid

One potential issue that I didn't see discussed in the FrostFighter online materials: Is the stick-on grid sufficiently thin*-yet-robust that it will tolerate occasional cleaning of the rear glass surface with glass cleaner? That's one of the strong points of the OEM grids -- they seem to be ok with paper-towel-and-windex cleaning from time to time. (* by 'thin', I mean height above the glass surface)

-

window defrost grid

Answer is found at 0:40 in this slightly grainy PPG promo video... https://youtu.be/SdHYcXGx4bw

-

window defrost grid

Done with a stencil and a liquid-copper spray would be my guess. Anybody have OEM automotive glass experience?

-

COVID-19

If I'm reading that graph correctly, that would be over six times as many, based on the August numbers. And I don't think the jump in U.S. numbers during July should be misconstrued as the 'second wave'. I think the real second wave is waiting to emerge in October -- and it may not be pretty. Conedodger's story and the accompanying picture are first person and compelling.

-

window defrost grid

The Loctite brand used to offer a product specifically for repairing rear window defrost grids. Came in a small glass bottle with a little applicator brush built into the cap.

-

Prep fore repaint

Putting the bodyside mouldings back in place will avoid the need to weld up the mounting holes (probably a couple of hours of shop time). Suggest you consider using steel rivets rather than aluminum, so as to avoid dissimilar-metal corrosion issues. Plain-steel rivets will have their own bare-metal corrosion issues, though. Check to see whether stainless or galvanized types are available. If not, the rivets can be phosphate-dipped to provide at least a degree of corrosion protection.

-

Finishing Panel Clips

This reminds me of the discussion here a year or two back regarding the clips that hold the Series 1 hatch vent diffusers in place. They were -- and I believe still are -- NLA. One of the CZCC members gathered advance orders from a few other members and then had a batch order made by a local shop. IIRC, the price per piece was nowhere close to $30.

-

Which Header?

So perhaps a new header thread, titled: 'Show Us Your Tubes'

-

Which Header?

Reminds me that one of the foremost names in headers back in the day was 'Hooker'.

-

Which Header?

Way back in 2011, long-time contributor, LeonV, led an informative thread on the topic of headers vs manifold and on exhaust systems (pipe diameters, dual vs single-pipe). The discussion is backed up with dyno test results (note: the quoted Hp numbers are 'road horsepower', so net of all driveline losses -- which typically run at about 10%). The test vehicle was a 260Z that had been retrofitted with a 2.4/E88 engine fitted with triple 40mm Webers and a Datsun Competition header (which I assume is the same as the Nissan Motorsports header just mentioned by Conedodger). Exhaust system theory hasn't changed over the years, so the info in this old thread is still relevant. Included is a video of the dyno test. The car sounds great... although it's informative to listen to the resonance periods as the engine is powered up to max revs.

-

73 240z upper door sill repair

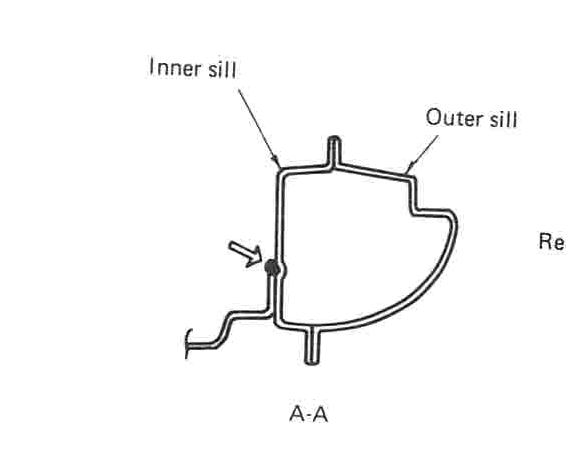

As Dutchzcarguy mentioned, the 'Body' chapter of the FSM contains sectional drawings for most of the Z's key sheet metal assemblies. Here's the one for the rocker/floor assembly:

-

73 240z upper door sill repair

Another build thread: Disepzeon (or something like that). He fabricated his own replacement panels. Great workmanship.

-

Lowering Bottom Spring Perch

A little off-topic, but your experience with height gain reminds me of the very first column that Peter Egan wrote for Road & Track magazine about 20 years ago... or maybe it was 30 years ago (time flies). In it, he describes his very first efforts as a teenager to get into the local racing scene ('jalopy racing' on a local 1/2-mile dirt track). For that purpose, he and his buddy secured a mid-1950's Buick sedan from the local wrecking yard. Reasoning (like Colin Chapman) that 'adding lightness' would improve not just acceleration, but also cornering and braking, they set about removing all of the Buick's unnecessary bodywork -- including the (massive) front and rear bumpers and the also-massive chrome front grill. They were dismayed to find that the result was a car with about 1 foot of ground clearance and a center of gravity that was probably 30 inches above the ground. Great read if you an find it online.

-

73 240z upper door sill repair

You can get what you need from this Florida-based supplier: KlassicFab Vintage JDM https://kfvintagejdm.com/product-category/datsun/ KFV are relatively new to the Datsun Z market (since 2019?), but well-known for their line of replacement panels for VW Kombi buses. The traditional supplier of replacement outer-body panels is Tabco. Based on reports from others, Tabco's panels offer a fit that is just 'ok'. Tabco doesn't offer the inner rocker -- just the outer. If you use the 'search' function, you'll find some excellent threads within this website that illustrate the repair of this area in detail (lots of photos and lots of great pointers). Members whose build threads come to mind include: wheee, convertt, grannyknot, eurodat and patcon.

-

vinyl paint interior...?

I'm having trouble with my photo storage software right now, but I had these pix stored separately. They'll give you an idea of how the vinyl paint goes on. As you'll see, the coverage is very good and I was able to transition these panels from the original black to butterscotch without any issues. The third photo, taken in natural sunlight, shows you just how good the coverage really is (and the paint is quite durable, too). IIRC, it required at least three coats, maybe four, to cover my black trim pieces properly. The hard-plastic panels are pretty easy to clean and prep. It's the soft-vinyl pieces with the faux 'quilting' that take so much effort -- made even more difficult in the case of the shock tower covers because they won't lay out flat for either cleaning or painting. BTW, these pix just show that parts lying on the grass after the paint coat was applied. I had them hanging vertically during the actual paint application. Unlike gwri8, I used an HVLP gun to apply the paint. Nothing too difficult about this. The vinyl paint is water-based. It mixes, pours, and sprays very easily. You need to manage the overall process so that you can spray all the parts, coat by coat, in a steady rotation without any interruptions. This is partly because you need to clean up the gun right after you stop. You do not want the vinyl paint to cure inside the spray gun. I sprayed all of my hard plastic parts on one day, then did the soft-vinyl pieces on a separate day. One final word of caution: There are some interesting fumes given off by this paint during the spray application. You won't smell them, but you will certainly feel them. Make sure you have good ventilation. And use a good mask. Your spray gun is not the only place where you don't want this paint to cure. If I can fix my photo software, I'll post a few pix of the soft-vinyl pieces on the weekend.