Everything posted by motorman7

-

SN 00042 Restoration; The Older Twin

Shawn McNally is who I am planning on going with here in Boise. Customsbymiguel was my body guy in San Diego.

-

SN 00042 Restoration; The Older Twin

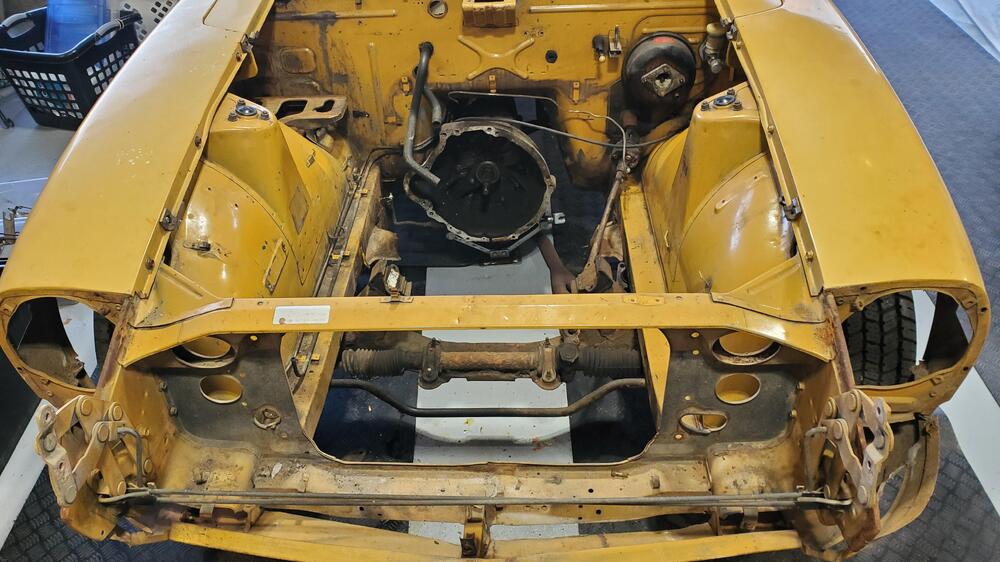

The body is just about ready to send to the body shop. I removed the glass, all items on the underside, and all of the body panels. I scraped off the old weather stripping and am now just doing final cleanup. I still need to drill and tap a few of the rusted out bolts as well. I will make an assessment of which patch panels we will need so shop can weld those in. The nice surprise on the car was the good condition of some of the interior parts. The headliner and A pillar vinyl is perfect as were all of the rear plastic panels, except for the rear panel which a PO had modified for speakers. Also, the doorsill plastic was in good shape and just needs to be cleaned. This will make the interior much easier to restore as some of the aftermarket items for these items are not the best. Often, aftermarket panel holes don't align and I have had headliners where the manufacturer's glue is poor with the vinyl detaching from the foam in hot weather. So, having these items in good condition will be a nice help. Latest photos are below.

-

SN 00042 Restoration; The Older Twin

Got the body up on rollers. This will make working on the underside much easier. Should have the final items removed over the next couple days. Pics are below.

-

SN 00042 Restoration; The Older Twin

-

SN 00042 Restoration; The Older Twin

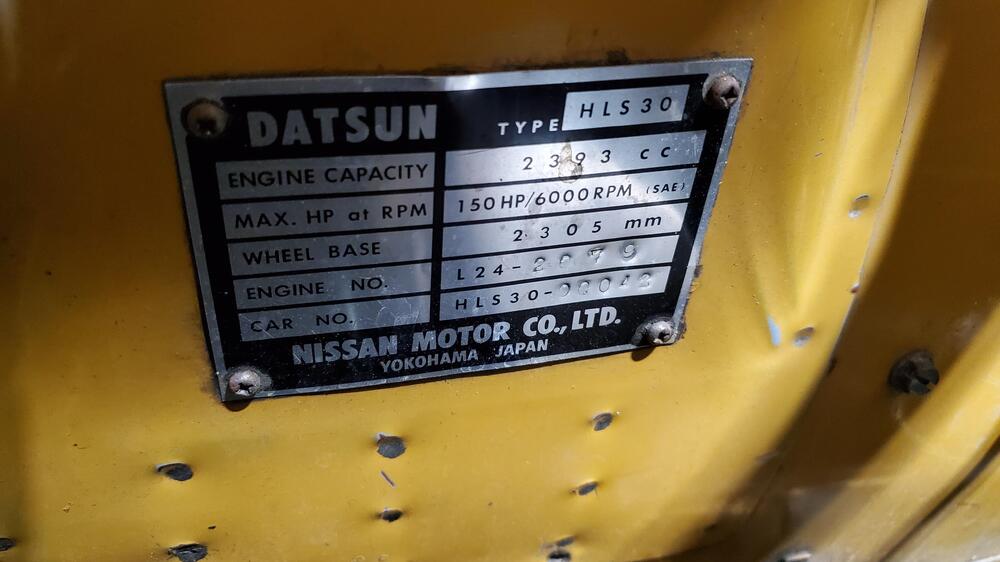

Thanks! Engine number is L24-2079. You can see it in one of the first set of pictures.

-

SN 00042 Restoration; The Older Twin

I have been stripping the car of parts so that I can send just the body to the paint shop. Tear down has gone pretty smooth with only a few bolt heads torquing off due to rust. I will drill and tap those spots. I posted a couple pics of some of the unique early Z items that i have noticed. Some of the unique items so far (to the best of my knowledge) include: form fitting washer motor cover (versus the later bag), hood rubber bumpers, air duct attach bracket (versus tab) , and nice interior hangers. There is a lot of rust, so we will need a number of patch panels in the usual places. Pictures of some of the rust areas are also below. The interior plastic panels were in great shape, much to my surprise. No need for new ones except for the rear panel that was damaged during a speaker installation. Engine came out easy. Looks like the car had AC at one time as there is a third pulley wheel on the crank and a large hole in the firewall which was plugged with plumbers putty as shown below...🙃 Pictures of progress are below.

-

SN 00042 Restoration; The Older Twin

Thanks for the feedback. That's why I like posting here. It helps make the restoration the best it can be, especially with this early a serial number. I actually read up on the crankshaft issue this morning, which seems like it would be more of a concern if we were racing this car. More than likely, this will be more for show and my goal is to keep as much of the original parts as possible. I will have the machine shop balance the original as that is the best option. Glad you mentioned it. I will check with the owner on the paint versus powdercoating. I lean towards powdercoating due to it's better resistance to fluid damage caused by fuel and brake fluid. However, I do want to keep this as close to original as possible, so I may just go with the original paint finish. I will have the owner make the call on that one.

-

1971 HLS30-14938 "Lily" build

I usually use the vacuum bleeder for clutch and brakes. The one time that the clutch didn't bleed was when the clutch hard line didn't seal with the flex line. I had to tighten the flare nut more.....took me a while to figure out the problem though.

-

SN 00042 Restoration; The Older Twin

HLS30-00042 arrived this afternoon for a complete restoration. Boy, this an early one, complete with the original clear rear window. It's a little beat up, but most of the parts are there. I own HLS30-02614 in the same color, so by the time I am finished they should be looking like twins. The motor runs, which is great, but it will undergo a complete rebuild. Amazingly, the head still has the overspray on the lower portion, which is pretty rare to see. I will see if the machine shop can leave that intact. There are still a few wire clamps in there and the owner has a metal fan (and a number of other key parts), so we should be able to get the engine bay looking like the original. Looks like the hood has been replaced by a later series that was orange. The drivers side door may have been replaced as well, as there appears to be blue paint under the Safari Gold re-spray. Also, the rear panel under the rear bumper is pretty beat up and front bumper is missing. We will need to get one of those. Rear bumper looks to be in pretty good shape. Both headlight buckets are fiberglass and cracked. Both fenders are pretty rusted out in the standard places. Rear hatch panel is also rusted out (as usual) and will need to be replaced by the body shop. The interior will need to be completely restored as most items are severely cracked or worn. The original dash has just one crack in the middle unfortunately. Not sure if that is repairable, I will have to look into that as the single crack is about 2 inches long. The seats have the original vinyl material which is cool, but not usable obviously (from the pics). So the plan here is to completely strip the car over the next two weeks and get the body to the body shop ASAP as that is typically the long pole in the process. I am estimating about 6 months for the body shop to complete all its work. While the body is out, I will send the block and head to the machine shop to get that all in order for me to re-build. All the undercarriage parts will be sent to the powder coater, and all of the nuts and bolts will go out for re-plating. I will re-upholster the seats, clean up the wiring harnesses and replace the connector housings, and then start re-assembling items as they return from the shops so that once the body arrives, everything will be ready to assemble. I will post progress on here and pics as things move along. As always, feel free to comment.

-

1971 HLS30-14938 "Lily" build

But you know it's there. Just one more thing to take care of.

-

1971 HLS30-14938 "Lily" build

That is such a bummer. I have had that happen as well, but not on such large a scale. Ugh! I hate brake fluid.

-

Paint Code Sticker - 115

You're welcome Keith 😊

-

Paint Code Sticker - 115

-

Paint Code Sticker - 115

-

Paint Code Sticker - 115

Hi Kieth, I still have the stickers in my toolbox in the original package, but I am out of town right now, so no access. I can get back to you on Monday when I return. Rich

-

1971 HLS30-14938 "Lily" build

My guess is that the Datsun garage dash is supplied by Vintage Dashes. Perhaps they got a bulk order discount at the time. I know that Jay, owner of jdmcarparts.com, distributes his parts to Motorsports and other Z suppliers. I think Vintage Dashes does the same thing. Not a lot of people out there making Dashes. Datsun Garage dash may be a blem. Also, FWIW, I love the Vintage Dashes. I have assembled and installed 4 of them and they look great. I have done 2 Just Dashes and they are good, but do not maintain the shape of the original dash. I was not happy with how they shaved the foam over the 3 center gauges. The foam was thicker in that location than the original. I posted pics of the difference on one of my blogs here. Both companies use the same black plastic overwrap and have the same grain, which is different from the original but not a big deal. Only nerds like me pay attention to material textures. Also, I can relate to your windshield loss. I accidentally dropped a head onto an original Z windshield when working in tight quarters at my old house. I was crushed.

-

1971 HLS30-14938 "Lily" build

@grannyknot I use the weatherstrip glue in the corners only, in the outside channel of the pinch weld, on all 4 corners. The bead of sealant extends about 6 to 8 inches from each corner. The corners seem to typically have the worst fit, so I think the sealant in those locations helps. Also, regarding installation, the condition of the gasket is probably a big factor. The soft ones make for a pretty easy install. The hard ones can be a bear.

-

1971 HLS30-14938 "Lily" build

Also, not a fan of trimmer filament. It is a small diameter and has a tendency to cling to the rubber lip and potentially tear the gasket lip (ask me how I know). I prefer to use a quarter inch diameter nylon cord/rope for the process. It's a bit more gentle on the rubber and comes out of the groove easier during the install process.

-

1971 HLS30-14938 "Lily" build

I have always installed the stainless steel trim AFTER getting the windshield installed on the car. When I tried to put the trim in before installing the windshield onto the car, the trim came out during the installation process. The key to installing the trim after is using lots of Windex. I will typically install one trim edge in the rubber gasket groove, I then lube the other rubber groove generously with Windex and use a small screwdriver to lift the other rubber groove over the stainless steel trim edge. With a nice soft gasket, the second groove will lift over and secure the trim almost like a zipper. Hard gaskets are a bit more difficult, but not bad. For what it's worth, I have installed at least 10 sets of windshields and hatch glass and their respective trim so I am pretty comfortable with it. Also, I blogged the process somewhere on the site here.

-

240Z BRE Replica Build-Continued

Thanks everyone. I will probably take a short break here and then work on another. I really enjoy the entire restoration process. It's nice to have a hobby that you truly enjoy. Have a Happy New Year everyone 😊

-

240Z BRE Replica Build-Continued

So I finally got the BRE replica Z finished up and sent off to the owner. Below are some of the final pictures of the car and photos of the car in the trailer. The Z and its' traveling companion, a SEMA McLaren, are headed on their way down to Texas.

-

240Z BRE Replica Build-Continued

Thanks! Wishing you and your family a great Christmas and New Year.

-

240Z BRE Replica Build-Continued

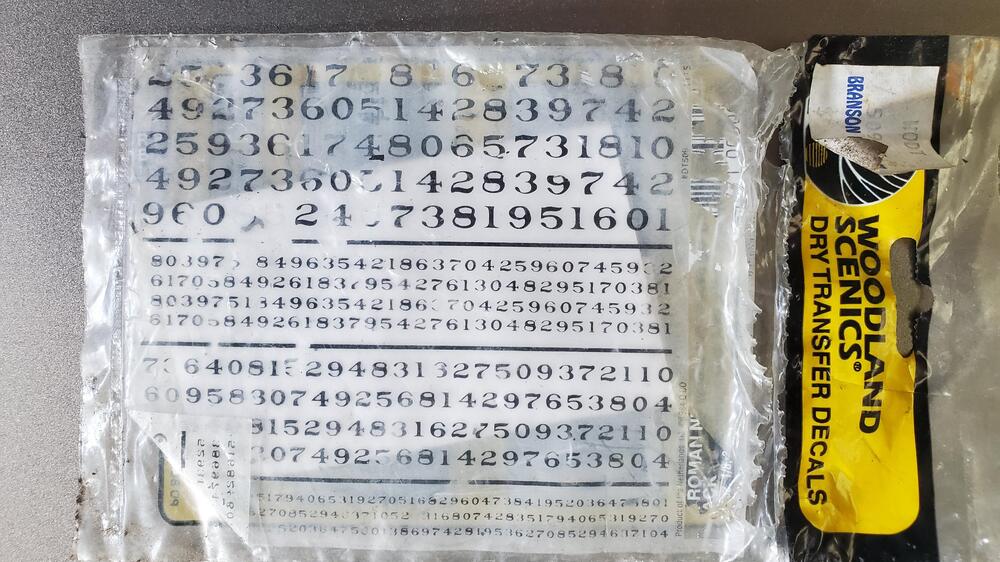

I am getting close to the finish on this. One of the items I had to do was install the door hinge detent springs. Not sure why, but the hinges that were installed on the car did not have springs and detents once I received the car. So, I removed the springs and detent from a later model car (different pin size) and drilled out the early model hinge to accomodate the larger pins. Also painted parts white to match car color. The only way to install the assembly was to remove the door as the the spring and detent assembly can most easily be installed when the hinge is in the closed position. Door was removed very carefully with the help of my wife and bucket appropriatley sized for the door to rest on. I installed the spring and detent on the bench after I drilled the holes for the larger pin. Once the hinges were complete I re-assembled everything and re-aligned the doors. Once the car was color sanded and polished, I started applying the decals. The larger ones were attached using a light soapy spray on the car before aligning and squeegying (learned this from youtube videos). The smaller ones are easy enough to do without the spray. location of the decals was done mostly by eyeballing on line pictures of the original car. The number on the right front of the hood was the most difficult to install due to the curvature of the hood. The rest were pretty straight forward. The BRE on the fuel door worked out better than expected. We did run into one issue as BRE accidently sent us the numbers for the 510 race car and not the 240Z. The 510 numbers are about 20% larger than the 240Z numbers and obviously were oversized (see pics). I contacted BRE and was advised to "cut the numbers with scissors" to make them fit. Not the best customer service (my wife was a little more opinionated about their response so I will leave that out). Anyway, I had the owner contact BRE to work out the numbers issue, and the correct ones were sent a week later. I am very happy with how everything turned out. My first time installing vinyl decals. I took the car to a local car show just to show it off. Needless to say, the car went over very well with the spectators. Boise likes flashy race cars....not so much original stock cars. I installed two sets of seat belts. Racing Sparco belts that can be unclipped, and an aftermarket roller tensioned belt system that is a bit closer to stock. The heater works great which is a good sign as it is part of the VintageAir system. I still need to charge the AC system and also get the front end aligned. I will use outside services for those. All the electrical is in good shape. The car has a number of aftermarket electrical items including the Headlight relay upgrade, parking light upgrade, and front blinker/running light upgrade. All fairly easy to install, 2 independently fused for their respective relays. The only item that took a little work was the front blinker/running light upgrade. The housing of the running lights need to be electrically 'floating' and not grounded to the car body. To make the housings electrically floating, I just oversized the holes in the running light housing so the 2 attach screws did not contact the body and ground it to the fender. I will continue to finish up some of the little details here. Pics are below.

-

240Z BRE Replica Build-Continued

Thanks, I will talk with the print guy about this. Here is what the files look like. I went custom on the choke panel for now as it was easier. May modify that one later if i dont like this one.

-

240Z BRE Replica Build-Continued

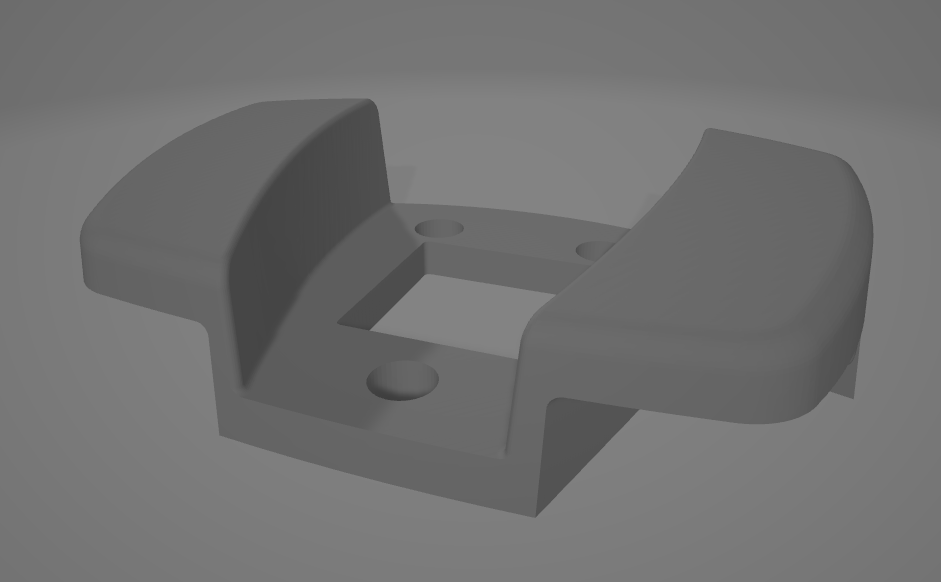

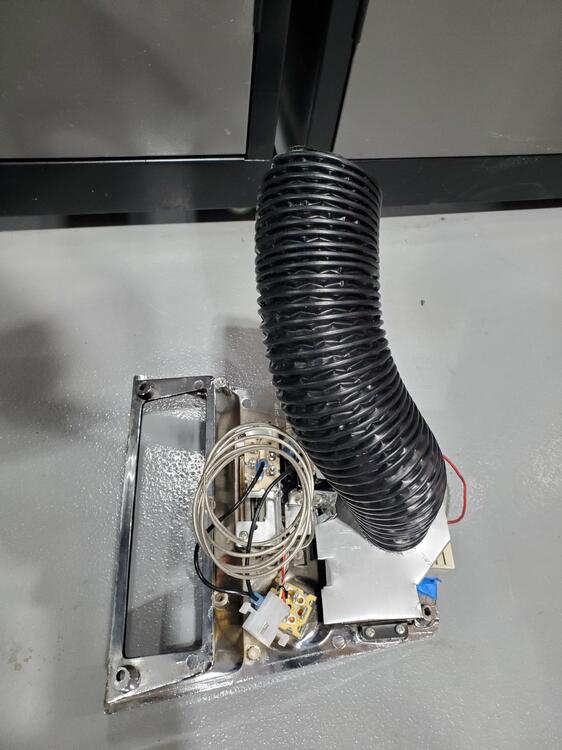

I figured out the issue with the brakes. The post that sticks out of the Brake Booster was pushing into the master cylinder about half an inch on installation. Once I shortened the post so that it was not pushing into the master cylinder on installation, everything worked fine. Both reservoirs bled well as did all four disc brake bleed valves. I used my trusty Harbor Freight vacuum bleeder on all of the bleed valves. Brakes are nice and firm and work well. With the brakes complete, I took the car for a spirited drive around the neighborhood running it through alll 5 gears. It runs very strong as it has the 280Z motor, a milled cam, high compression and a 3.94:1(?) rear end among other things. The motor was built by the same shop that does Adam Corolla's motors. I finished the heater panel installation (mostly- no radio or light bezel). I fabbed a small bracket that clips to the center vent and has an oval opening for the vent duct. See pictures below. The vent duct connects to the center opening on the evaporator and was connected on installation. The final electrical connections were finished and the panel put in place. I switched the ignition to ACC and checked out the operation of the fan and vents. The fan appears to put out more air than the stock unit, especially in the defrost mode. The only thing that takes getting used to is when switching from defrost, to vent, to room/center air there is a couple second delay as the actuators or the system open and close the valves. Unlike the stock manual cable system that operates immediately. Overall, I am very happy with the system and found it fairly simple to retro-fit into the Z. I finished up the panel install and cleaned up the wiring a bit. Also added the parking brake light upgrade kit, that was a prettty easy install. Also installed the window mounted mirrors which I think look pretty sporty. The install of the mirrors is prettty easy with the correct rivets. I am now color sanding and buffing out the paint which really makes the car look awesome. I am hoping to install the decals by the middle to end of next week in time for a car club grand opening car show here in Boise on December 16th. I know the manager and he said that he would set me up with a nice spot for the car. https://www.toyboxcarclub.com/ Pics of progress are below. Also, I will be 3D modeling the mirror mount and the choke center plate as the mirror mount is broken and the choke plate is missing. My neighbor has several types of 3D printers and said that he would print these for me. Assuming they turn out well, I may make several copies just in case they are needed.

Subscriber

Subscriber

.thumb.jpg.b06d848de3a182447f37a3736f61ad39.jpg)

.thumb.jpg.ec8a5efa93ff12430f99926668938dac.jpg)

.thumb.jpg.f70075449a254e1f05b51897c14e5f0e.jpg)