Everything posted by HS30-H

-

1970 240Z Works Rally - the road to restoration

The gas struts certainly overpowered the tailgates on the lightweight Works cars, giving them a characteristic twist on the LH side: I can't recall a good photo of a 432-R Sports Option style prop rod setup on a Works rally Z, but I'll have a look for one. For my own FRP tailgate with acrylic window, I'm using a gas strut but discharged it by drilling a hole in the body (its a mixture of gas and oil in there, so be careful if you drill...) and then drilled a hole in the rod so that I can insert a big R pin in it to hold it up. I know a couple of cars which used the same solution in period. Seems to have eliminated the 'twist':

-

Datsun-240z Vs Fairlady-z432

Looks spot-on to me, Kats. Great colour choice too. FRP bonnet has to fit imperfectly to be perfectly authentic-feeling. That's what they were like!

-

Ask the eZperts

At some point (it may have already passed...) it will become necessary to define what market sub-variant is being referred to. Production date will also be a factor with regard to detail changes. For example: I have a no-hole 'splash pan' hanging up on the wall of one of my garages. Obviously the splash pans were part of the original design for the L-Series engined cars across the board (because the fixing points are there on each car and we see them in the early factory literature) so the question then becomes whether they were being fitted consistently across all markets and models. USA/Canada may have been an outlier here considering the other examples of de-contenting in those markets. I can't imagine why dealers would go to the trouble of removing them from new cars? Here in the UK the splash pans had a reputation for not being re-fitted after servicing (especially after an oil change) but that was typically laziness rather than any kind of policy. I remember we had several conversations on here about the splash pans in the past. The finish question (as far as I remember) concluded that the photos in the service manuals may have used unpainted (Zinc plated?) pans to allow them to be seen more clearly, but there were anecdotes of silver (?) pans being sighted on production cars too. My experience is that all of the 'early' style (no holes) pans I have come across were painted black and I have certainly seen black painted pans supplied as replacement parts, complete with Nissan parts sticker. So - in reference to this "eZperts" thread - I don't think it will be possible to make a definitive conclusion as to whether a particular car would have had a splash pan or not, apart from pointing out that it was part of the original design...

-

240Z restorations, what's right and what's not

So I don't want them. I'd rather see a broken original.

-

240Z restorations, what's right and what's not

I still think we are applying a slightly unfair level of scrutiny to it, and you yourself imply it was 'done wrong'. There's a big yawning gap between the new owner's comments on BaT and our nitpicking here. Where's the pragmatism? Winning bidder said: "I am convinced there isn’t another one in the world in this condition! I’ve waited a long time for the right one and I know I’m getting the best one!". I think BaT is something of an echo chamber in cases like this. This is why I still feel a patinated and lived-in unrestored car pleases me more than the average 'restored' car, in the same way that a lived-in human face - without surgery, 'fillers' and veneers - makes me feel. Done right? Only the original cars were "done right". Anything else is just simulation.

-

1970 240Z Works Rally - the road to restoration

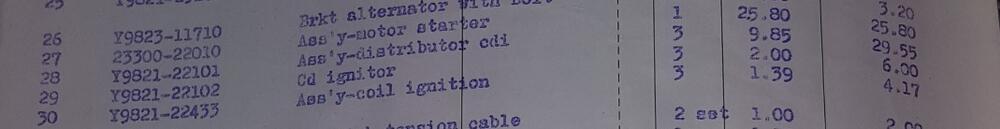

My own view is that the fitting of CDI is possibly one of those 'evolutionary' differences in the different batches of Works rally cars. The two earliest batches of cars (1970 RAC Rally batch and 1971 Monte Carlo Rallye batch) may or may not have had CDI ignition modules, but the 1971 Safari and 1971 RAC Rally batches certainly had them. Both were RHD batches and (most probably) used the E72 'Cowl Top Inner' 432-R type panel with the CDI mount bracket already in situ, but - apparently - without the heater inlet duct brackets (because full heater was fitted). The import carnet spare parts list for the Works team's entry on the 1971 RAC Rally included the following:

-

1970 240Z Works Rally - the road to restoration

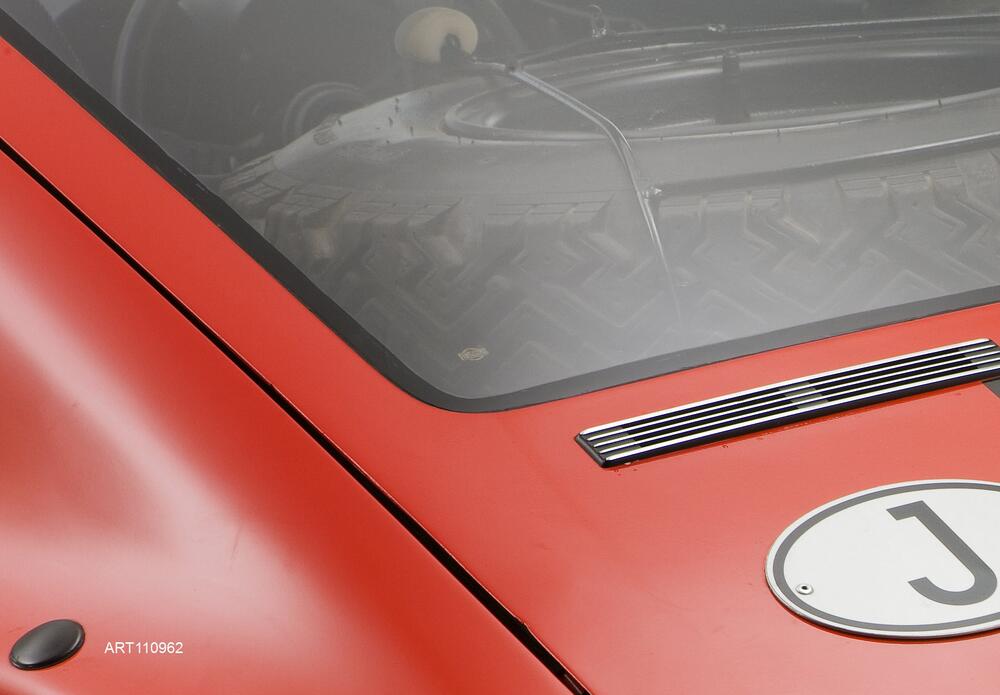

Perhaps it is not so surprising that the heater inlet duct 'chimney' doesn't have 432-R style captive nuts? After all, this is an LHD car and there were no LHD versions of the 432-R's E72 'Cowl Top Inner' to use. Additionally, a Works rally car would most definitely need a fully operating heating and ventilation system (and more!). All the roadgoing 432-Rs I've seen had the fresh air ducts, flaps and cables. There's not much weight in them and they would certainly be a welcome presence on a road car driven in Summer. I don't know if it will have been done on xs10shl's car, but other (later) Works rally 240Zs had 'overclocked' fan motors with extra windings, allowing them to push more air. They also enlarged the ducts under the windscreen and put wire mesh in them to stop them swallowing up anything important... There's some evidence of Namba san's mentioned ventilation system mods on cars later than the '71 Safari winner. '7924' is the '73 Safari winning car of Shekhar Mehta. LHD, but it was originally built in order to take part in the 1972 RAC Rally (driven by Rauno Aaltonen) and it shows the much-modified heater box and blower motor mounting position they used. This Works rally-specific mod hides its light under a bushel, and its full splendour would only be revealed if the dash was removed...

-

1970 240Z Works Rally - the road to restoration

Stock (roadgoing) 432-R tailgate was steel, of course. It had the acrylic window and used the stock window rubber (sans stainless trim) to hold it in. Nissan Sports/Race Option tailgate was FRP and had the standard shape lip, so could accept the stock window rubber and either stock glass or acrylic window. That matches what I've seen too. The FRP tailgate used by the early Works rally cars must have been a dedicated moulding because of that different window-mounting lip. It allows the bonded acrylic window to sit pretty much flush with the outer surface of the tailgate. Somewhere I've got photos of a Works lightweight car with a bonded window that has very small screws embedded (covered) in the bonding material for a belt-and-braces solution.

-

1970 240Z Works Rally - the road to restoration

Did it have any of the venting/draining gubbins inside it. Other Works FRP tailgates I have seen had the vents blocked off and therefore didn't have any of the usual internals.

-

240Z restorations, what's right and what's not

Since that's an electrical part from a Works rally car, I would not place too much faith in any level of industrial standardisation being directly applicable. They are a law unto themselves! A lot of that stuff was either hand-made or involved some level of modification over stock. I doubt the dots on those screw heads are anything to do with JIS standards.

-

Z's on BAT and other places collection

Thought they were too 'gay'. Stuff like that has no place on a car proudly MADE FOR THE USA. Those guys in Japan tried to get 'Fairlady Z' emblems past him too, but he headed them off at the pass. Real men don't need no pesky splash pans.

-

Z's on BAT and other places collection

Mr K. removed them. Personally. He carried tools with him all the time. Did it at the ports of entry. Jumped up and down on them a few times just to make sure. A few might have got through when he was having lunch though. This works for lots of other inexplicably missing items too...

-

240Z restorations, what's right and what's not

Here's where I start narrowing my eyes and looking at you a little sideways. I think - certainly with some of the things being pointed at here - that people sometimes want to be a little too definitive. In late 1969 and early 1970 Nissan Shatai's Hiratsuka plant was not quite the super-efficient sausage machine that some seem to believe. It was - clearly - a little more chaotic than that. The rear bumper end packing pieces certainly existed by mid-1969 and were present on some of the very first show and production cars. We might say that Nissan never intended for them to be fitted to North American market variants, but - I think I am correct in saying - they did show up on some early Exports, did they not?

-

Z's on BAT and other places collection

Article said: "Each of the Datsun 240Z Super Samuris were built by Spike Anderson, a sort of British equivalent to Carroll Shelby..." Ha Ha! That's a reach even Stretch Armstrong would struggle to achieve. And the car in question was in fact not built by Mr Spike Anderson. Built with 'his blessing' might be more accurate. I believe it just sold for 50.5k GBP plus 3.03k GBP in fees, and is now on its way to a new owner in the USA. It'll need an extra 40ft sea container to ship all the nonsense written about Samuri Conversions over the years.

-

240Z restorations, what's right and what's not

Please expand. Are you saying wrong for this particular car, or wrong for 1969/70 production date?

-

1973 Rebuild

Almost inconceivable that they would not, as that is certainly what they were designed and manufactured to work with (rather than stock Hitachi SUs). Several people in Japan are using the Spirit Garage LHD-specific exhaust manifold on LHD Zs with Harada inlet manifolds and triple carburettors. Should be fine, but a heat shield/drip tray would still be recommended.

-

1973 Rebuild

There are studs (six I think?) that are shared to clamp both in the inlet and the exhaust manifold. They use a dedicated washer (Nissan called it a 'Yoke') that is thicker and wider than normal, and with a distinctive dish shape. They bridge the inlet and exhaust manifold flanges, using a single stud for clamping force. You should still have them if you took the engine apart? The usual problem with these 'Yoke' washers is that aftermarket inlet and exhaust manifolds sometimes have differing flange thicknesses. The solution is either to machine the flange thicknesses so that they match at the shared stud locations, or to machine/grind a step into the 'Yoke' washers on the manifold side. I've used the latter option successfully in the past but the former is undoubtedly a better solution. That's not ideal. Quite apart from the interference in fit, you'll get a lot of heat transfer from the exhaust manifold into the inlet manifold. Could lead to fuel percolation problems. A heat shield might help that, but with so little clearance you'll struggle to fit one. I would investigate the possibilities for moving your inlet manifold up slightly, and the exhaust manifold down. A little clearancing of stud holes and flanges might allow you a few mm of shuffle without too much in the way of port misalignment? Every little will help. You could certainly shave some material off the inlet manifold casting at the points you indicated too. The casting is fairly thick at those points. Spirit Garage 'tacoashi' looks great!

-

Red 69 production date car on BAT

Indeed. The author cannot have done much in the way of checking the bona fides of 'The Z Guild' and Mr Robert Jackson, and he certainly didn't do much fact-checking for the rest of the book either. The book was endorsed by Nissan themselves, which - in my opinion - illustrates how low calibre some sections of that company became under Ghosn's time as CEO.

-

1972 rear bumper guard position

Interestingly fast evolution. Yesterday they didn't exist on Japanese cars, and today they do, but only because of..... reasons. Within a few more days we may well see them blamed for Covid-19, the war in Ukraine, Global Warming and wearing Flip Flops on public transport. Impossible to know. Good luck with your quest. Me, I rather like them in the right context. Unlike the AMCO towel rails, which only their mother can love.

-

1970 240Z Works Rally - the road to restoration

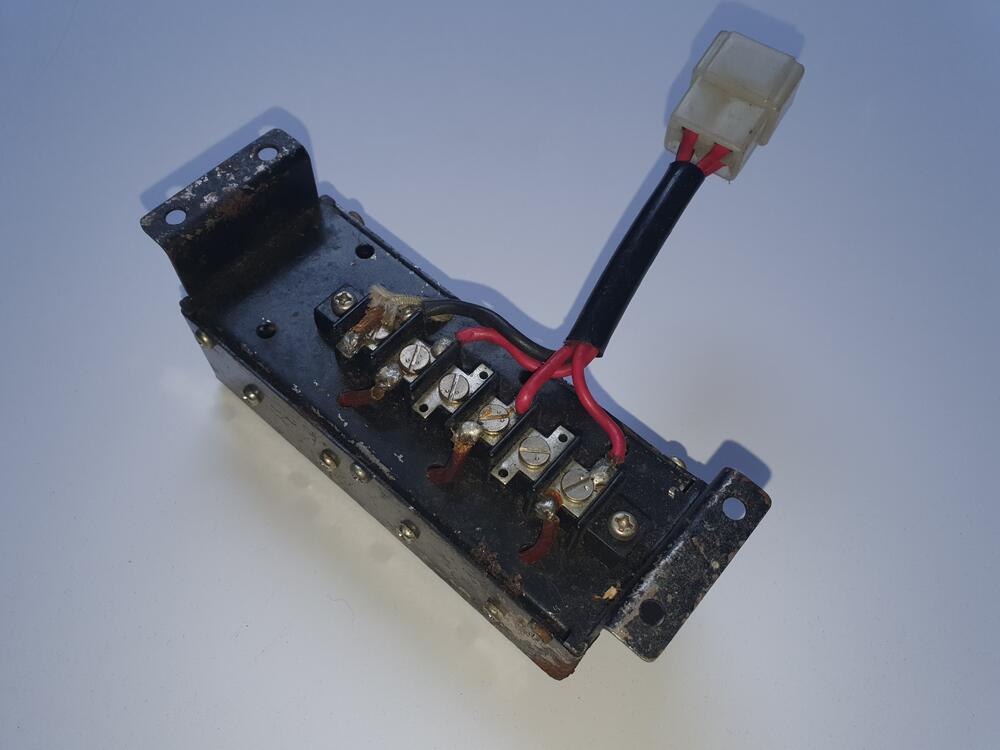

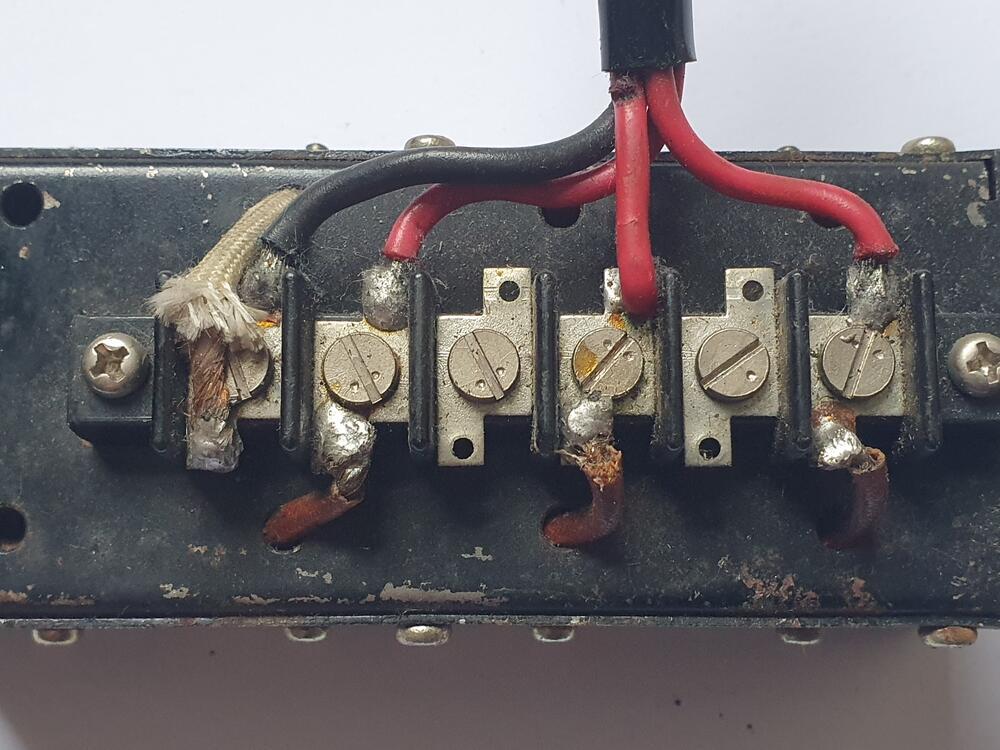

As mentioned privately, I honestly think this is case of mistaken identity. The dash control labelled 'Head Rheo' is - surely? - the dimmer switch for the navigator-specific auxiliary lighting ('P' Light illumination for maps, timers and Haldas). I don't see any reason why it would be necessary to have a rheostat-controlled dimming function of headlamps, spot lamps and fog lamps on a rally car. I've got one of the 'mystery' boxes too (leftovers from Works activities here in the UK) and - notably - the wire colours are different than on yours. I have three reds and a black going into a square 4-spade male connector: Referencing a factory carnet import inventory for the 1971 RAC Rally, I see Works part number 'Y9821-22438 Diode a**'y' which seems to fit the bill as it is listed amongst other auxiliary lighting parts. Would it not be more likely that this Diode box acts as a one-way 'gate' in the lighting system of the car, helping to protect against switching combinations that would otherwise overload/mess up the wiring? I'm absolutely not any kind of expert on auto electrics, but it seems to me that there's a lot going on with the Works rally car lighting system that is not apparent to us on the outside looking in, and certainly so with regard to the different combinations of lighting possible with the column switch, the individual fog & spot lamp switches, a master lighting switch and the push-to-pass momentary switch that (I think?) you have on the end of your car's indicator stalk?

-

1972 rear bumper guard position

In Japan they were a buyer's choice. You might agree that it was nice to have a factory showroom options list to choose from rather than an independent dealer's choice of additions adding to your bottom line.

-

1972 rear bumper guard position

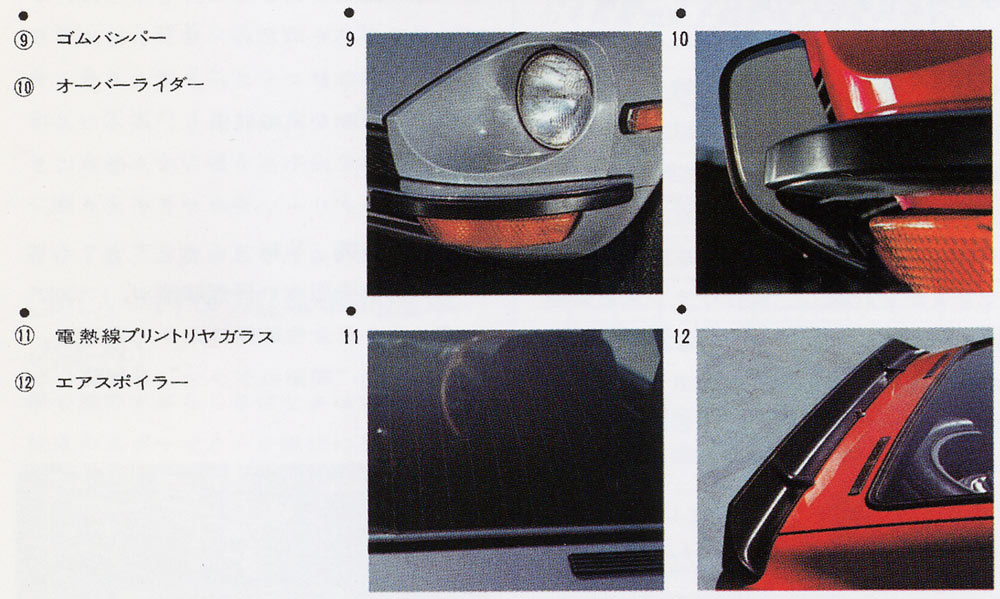

Overriders were an extra cost showroom option on Japanese market variants. They were listed in the sales brochures and in the factory parts lists.

-

Red 69 production date car on BAT

'The 240Z Guild' is a restoration/sales business owned by a Mr Robert Jackson and based in Madill, Oklahoma, USA. Mr Jackson has a certain amount of 'baggage'... https://www.swedespeed.com/threads/robert-jackson-scam.219934/ http://forums.turbobricks.com/showthread.php?t=343369

-

1970 240Z Works Rally - the road to restoration

You would only have been able to fit 4-point harnesses on the driver's side, as there were no shoulder strap mounts/anchor points on the passenger side. Mounts could feasibly be added after the fact (I've done this on my 432-R replica project car because I wanted both sides the same) but they need a doubler underneath or - preferably - the welded-in L-shaped factory reinforcements and captive nuts as seen on the driver's side. So this is another one of those Works rally car-specific differences. The Works rally team fabricators were able to specify non-standard additions and modifications literally before the bodyshells were welded together.

-

1970 240Z Works Rally - the road to restoration

Yes! 432-R was certainly 'driver focused' and standard equipment 4-point Takata harness was only provided on driver's side. Similarly, 432-R only got a headrest on the driver's side. Early Works rally 240Zs were a kind of 'hybrid' of 432-R bodyshell parts mixed with upgraded details, Sports/Race Option parts and hand fabrication. The bodyshells were built in small batches designated as rally cars and therefore could incorporate a little extra attention and detailing on the line at Hiratsuka (such as the extra doublers for the passenger side four-point harness shoulder strap mounts under the 'cheesegrater' deck panel) before being transported as bare shells to the Works rally shop at Oppama where the build-up could begin. Attached photo shows stock 1970 432-R rear 'cheesegrater' deck with shoulder harness mounts on driver's side only: