Site will be going down for maintenance today

Everything posted by Namerow

-

The blue 510

After 12 or 13 beers with the boys at the local and then a couple of shots for the road, it probably seemed like the right thing to do.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Excellent! Nice parts storage rack, BTW.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

So: Two sets of well-executed/well-documented measurements with different results. They aren't quite apples and apples, though. CanTechZ has measured Series 1 front/rear fenders and floors and gets a pretty consistent 0.8mm result.. ConverTT has measured Series 2 door skins and gets an equally consistent result of 1.0mm. Others have reported 0.032" >> 0.8mm) for a couple of other panels : jfa.series1 for the front inner fender apron (i.e. engine compartment side wall), and me for my Series 1 front valence panel. I have a theory (untested and unproven so far)... ConverTT's photo of his Series 2 door where the outer skin has been cut off provides a great view of the side impact bar (and I use that term with some reservatyion when it comes to the piece used in the S30's doors ). As near as I can tell, that Series 2 impact bar looks exactly the same as the ones in the doors of my Series 1 (SN in the 3500's). And yet, it was always my understanding that those side impact bars weren't part of the early cars. Or maybe that was only the case for the early early cars? Or maybe my car is wearing replacement doors from a Series 2? Note that the online Parts Manual shows a change in part numbers for the two doors as of October 1971... although that doesn't really explain whether anything changed in the design. My theory, then: Is it possible that Nissan neither added nor changed the size of the side impact bars, but instead simply increased the thickness of both the outer door skins (and maybe the bars, too) from 0.8mm to 1.0mm? There would be a certain logic to this, because Nissan probably could have left their tooling unchanged and just changed the thickness of the panel stock. @ConVerTT Can you please take some measurements on a rear quarter at the opening for the side marker light? @CanTechZ Can you please take a measurement on one (or both) of your doors? Say, at the opening for the door handle? failing that, maybe on the lip the mounts the upper chrome moulding? If time permits, I'll do the same later with the doors on my car later today (I want to make a start on my income tax return this afternoon ).

-

What's the most needed Z part that's currently NLA?

A few of the well-known Z-car parts suppliers offer a rear valence panel that might meet your needs. However, I recall reading recently that the existing replacement panels aren't 100% accurate in certain details (e.g. shape of the cutout for the exhaust tip). Maybe that's what you're alluding to when you say that the panel isn't available?

-

1970 HLS30-06521 Re-Restoration

That cowl area looks remarkably clean! Lucky for you because all reports indicate that it's a really challenging area to repair. Your #1 photo is a nice reference guide for the shape of the foam panels that were added by Nissan as a running design change -- I believe in response to problems with the panel buckling if it was leaned on too hard (service techs, owners, bystanders) or, more likely, if it was stepped on (shippers). The on-line parts manual doesn't really provide any clues about the date when the wiper motor cover was replaced with the bag. Perhaps when the wiper motor was upgraded for a faster sweep rate in January 1971?

-

What's the most needed Z part that's currently NLA?

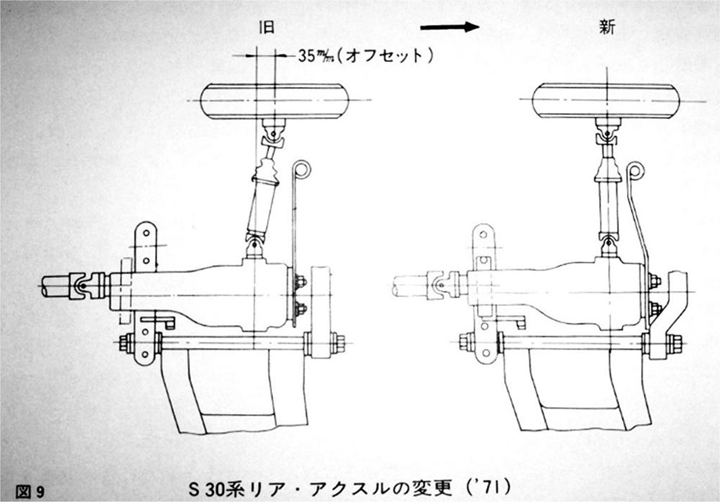

No, you're not crazy (although we should perhaps let your wife comment on this ). The answer, I think, lies in the fact that there is also a difference between the 'old' vs. 'new' designs for the diff's front crossmember. The locations for the bolt holes changed. I have never seen anyone produce a proper sketch in plan or elevation view that makes the differences in all of the bolt hole and mount stud locations obvious (and I'm not about to try). However, I have never heard anyone come up with an easy fix for replacing the early-style front diff mount (and don't forget that this issue has been in play now for about 40 years). According to my notes, here's what needs to be replaced in order to 'fix' things so that the newer-style mount can be used: · Diff Front Crossmember · Diff Arrester Belt Brackets (lhs & rhs), bolts, and sleeves (the design of the belt itself was not changed) · Moustache Bar · Suspension Lower Transverse Crossmember (new design was dished and bowed outwards towards the rear so as to clear the rear of the diff case) · Driveshaft (the S2 driveshaft is 20mm longer) · Moustache Bar Rubber Bushings, sleeves & hardware (might not be mandatory, but the PN’s certainly changed)

-

What's the most needed Z part that's currently NLA?

I thought that our CZCC members might like to contribute their thoughts here. Who knows? We might inspire someone out there to start making some of these items. My nomination would be: Differential Mount Insulator for the early-design cars with angled rear halfshafts (Nissan PN 55415 E4102) This part was used up until 71-06, so it was installed on about 30,000 Z's. If 5% of those cars are still in running or restorable condition, that would mean there's a ready market for perhaps 1,000 of these early-style diff mounts. To the best of my knowledge, there's no way that any of the later-style mounts can be modified to fit. Typical owner solutions seem to be either: replace all of the diff carrier pieces with conveniently-available, newer-design parts (expensive, and not correct for a proper restoration) ignore it and pretend that running with a worn-out original mount isn't a problem Given that the metal parts are usually quite salvageable, perhaps all that's required to restore the mount is for someone to reproduce the rubber core. With a new core, it would be a fairly simple matter to burn out the worn-out original, clean up the metal, and then glue a new core (should be fine, given that the bonding area is big and the joint wouldn't experience any shear loads -- just compression/tension). Early-style mount on the top Early-style mount on the left (apologies for not being able to provide photo credits)

-

COVID-19

Seeing the curve starting to flatten is all very nice, but it really only addresses the issue of exceeding the healthcare system being overwhelmed. When we start to go down the backside of the curve, what then? Here in Canada, the number of reported cases stands at roughly 80 per 100,000. That's less than 1/10th of one percent. Even if that number is low by a factor of 10 (and it may very well be), it means that 99% of the population has not yet been infected and therefore lacks immunity. I see no reason to believe that American figures will prove much different. If we/you decide to just, 'Let 'er rip' (see Donald Trump playbook), that curve is going to un-flatten in a hurry. No easy answers here.

-

COVID-19

The last of those three shoe styles is worrisome.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

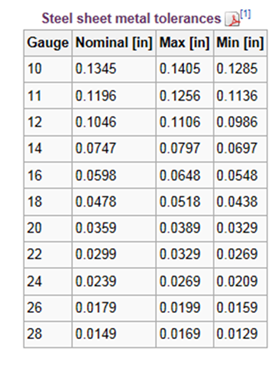

Meticulous measurements, backed up by supporting info re panel originality and paint application, so pretty hard to argue with. I am inclined to agree, then, with your conclusion that the factory panels appear to have been made from 0.8mm sheet. That sits right in the middle of the spec range for 22-gauge. How do we reconcile this with @ConVerTT's values of 20-gauge for the door skins?

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Thanks for the additional efforts. However, it's just hard for me to believe that the factory used a thinner sheet for floor pans than what they seem to have used for body panels like the rear quarters. At least, that's what your measurements are saying (i.e. 1.1mm for the rear quarter panel vs. 0.8mm for the floor pan). It's worth noting that the difference between 1.1mm and 0.8mm is just .012" (sorry for the switch from metric to inches, but most of us understand tolerances best when they're in thousandths of an inch rather than tenths or hundredths of a millimeter). How thick is the factory primer and paint? Or maybe that's an aftermarket paint job on your rear quarter? We're left two possibilities to ponder: 1. The factory floor pans really are made of thinner sheet than the factory body panels. or, 2. One (or maybe both) of your measurements (floor pan vs quarter panel) doesn't represent 'reality'. Maybe your quarter panel measurement was too high because the metal wasn't bare? Or maybe your floor pan measurement is too low because you accidentally abraded away some of the metal in the effort to get rid of the paint? Maybe both? In inches, you have the rear quarter panel and front fender measured at an average of 1.1mm, or 0.043". As I mentioned earlier in this thread, that would equate to a thinnish 18-gauge. Your new 0.8mm measurement for the floor pan works out to 0.031" which would suggest really thin 20-gauge is right in the middle of the spec range for 22-gauge.. FWIW, I continue to like 1.0mm (0.039") for the factory floors and body panels because: a) 0.8mm sounds too thin, and; b) 1.1mm seems like an illogical (off-spec) choice that would have struck the Nissan engineers as being not only more expensive to buy from the mill but also adding 10% more weight than 1.0mm and requiring higher stamping forces. That said, it's interesting to see ConverTT's report that the Klokkerholm rear quarter repair panels are made from 22 gauge! As always, comments welcomed

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Table updated to show revised (refined) measurement for the lower front frame rail reinforcement piece... Panel Location Measured Thickness (t) Source Gauge (derived from ‘t’) Gauge (reported) Source Front Apron (engine compartment) 0.032” Jfa.series1 20 20 Grannyknot Tabco repair panels (all) 20 Manufacturer ConverTT Klokkerholm repair panels (rear quarter) 22 ConverTT Thick-gauge panels & pieces (which ones?) 18 2manyZs kmack Lower Front Frame Rail (OE) 0.050” Carl Beck 18 18 ConverTT Lower Front Frame Rail (ZeddFindings) 0.062” Namerow 16 Lower Front Frame Rail - Reinforcement plate (‘pocket’) at front crossmember mounting point 0.0787” (2.0mm) AZStory ~ 14 Upper Front Frame Rail (‘horn’) 0.054” Carl Beck ~ 16 Front Valence Panel 0.032” Namerow ~ 20 Front Crossmember 0.076” Namerow ~ 14 Door – outer skin 20 ConverTT Inner Rocker Panel 18 ConverTT Radiator Support 18 + 20 ConverTT Floor Pan (OE) 0.044” CanTechZ ~ 18 Floor Pan (ZCar Depot) 0.045” vendor ~ 18 Floor Pan Bottom Rail (ZCar Depot) 0.060” vendor 16

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Point noted. However, 14-gauge sheet can be anywhere from 0.0697" to 0.0797" so your measuring gauge (sized at the median thickness of 0.0747") could register a 'no-go' even though the piece actually was made from "14-gauge" steel. More likely, however, is that this piece (like most of the other steel used in the S30) was made from sheet steel rolled to the metric standard by a Japanese steel mill. It seems very like that this doubler/reinforcement piece was stamped from 2.0mm stock (which nominally converts to 0.079" and would therefore likely register as 'too thick' for your measurement gauge's '14-gge/0.0747"' slot). Note also that 12-gauge is a big jump up in thickness from 14-gauge... 0.1046" vs. 0.0747", so an increase of 0.0299"... which is almost 1/32". From your picture, it doesn't look like your there's a mismatch of 0.03" between the S30 part and the 14-gge slot in your measurement gauge. It also looks like your 12-gauge slot would be way too big... All things considered, then, I like "14-gauge" for this part because it's very close* to what is most likely the real truth -- which I think is 2.0mm. (* 2.0mm/0.0787" vs. 14-gge/0.0747", so within 5% using the nominal design thicknesses). My purpose in starting this thread was to create a reference chart for selecting the right** sheet thickness to use for panel repairs. Since very few of us (in Canada and the US) have convenient access to metric-standard sheet steel, the best guidance for repair panel thickness comes in the form of 'gauge'. I suppose I could add a "mm" column, but that would confuse the heck out of everyone. (** Let me qualify my use of the word 'right' by adding that there's sometimes an incentive for using a thicker steel than the factory did. A good and common example is the bottom rail ('support') for the floor pans, where some owners choose to go with a thicker-than-factory steel and go full-length in an effort to better tie the front and rear sections of the 'chassis' rails together.)

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Not that the metric system doesn't have its own moments. Consider the standard for determining the metre length unit. The basic unit of length in the metric system; it was originally planned so that the circumference of the Earth would be measured at about forty million meters. A meter is 39.37 inches. Today, the meter is defined to be the distance light travels in 1 / 299,792,458 seconds. Based in science? Yes. Intuitive? Not hardly. I like the definition of the kilogram better: The kilogram is almost exactly the mass of one litre of water. Consider, by contrast, the definition of the inch: The old English ynce was defined by King David I of Scotland about 1150 as the breadth of a man’s thumb at the base of the nail. To help maintain consistency of the unit, the measure was usually achieved by adding the thumb breadth of three men—one small, one medium, and one large—and then dividing the figure by three. During the reign of King Edward II, in the early 14th century, the inch was defined as “three grains of barley, dry and round, placed end to end lengthwise.” At various times the inch has also been defined as the combined lengths of 12 poppyseeds. Makes one pause when considering the implications of having a 427 cubic inch engine in your car.?

-

The positives of quarantine

What was the rusted out mount shown in the #3 picture in your original post?

-

240z gets jiggy

Every time I see how clean and open your workspace is, I want to cry. I have my garaged Z supported on wheel caddies (one caddy per corner, four caster wheels per caddy) and I have brace myself against a wall to generate enough force to make the car move. Looking on the brighter side, I'm thankful to have a paved floor, a roof over my head, decent lighting, and locking doors so that my tools won't vanish when I'm away from home. No social distancing issues either!

-

COVID-19

I read that coverage and I found it unconvincing. Conclusions being drawn far too early by media ("If it bleeds, it reads"). The Korean source cautioned that they weren't sure whether what they were seeing really was reinfection. And I'm certainly inclined to trust an official source from South Korea rather than one from, say, the Chinese government and media. As for the people who refuse to acknowledge the need for safe distancing, perhaps we should have them explain their 'Doesn't apply to me' attitude to an audience made up of doctors and nurses from their local hospital. Alternatively, offenders who contract the virus and require medical care should be instructed to join the special line at their hospital that serves members of the 'Doesn't apply to me' group. That would be the line that leads to a door opening out onto the back parking lot.

-

The positives of quarantine

Maybe when June rolls around and your wife's honey-do list has finally been cleared and we're still locked down, you could spend some quality time inventorying your unwanted parts and putting them up for sale here on the CZCC virtual 'yard'. Might raise enough cash to pay for that that epoxy floor coating you've been promising yourself for the garage. Or maybe some of that cool, rich-guy modular flooring laid down in a chequered flag pattern? Or a giant 'Z'.

-

The positives of quarantine

Did the aluminum spider fracture from vibration or was there actually corrosion going on? Reason I ask is that picture #3 appears to show another part of the drum drivetrain and there doesn't seem to be much doubt that that mount has failed because of corrosion. Did its failure then lead to stress fracturing of the spider?

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

New of my chart, updated with most recent contributions... Panel Location Measured Thickness (t) Source Gauge (derived from ‘t’) Gauge (reported) Source Front Apron (engine compartment) 0.032” Jfa.series1 20 20 Grannyknot Tabco repair panels (all) 20 Manufacturer ConverTT Klokkerholm repair panels (rear quarter) 22 ConverTT Thick-gauge panels & pieces (which ones?) 18 2manyZs kmack Lower Front Frame Rail (OE) 0.050” Carl Beck 18 18 ConverTT Lower Front Frame Rail (ZeddFindings) 0.062” Namerow 16 Lower Front Frame Rail - Reinforcement plate (‘pocket’) at front crossmember mounting point 0.0747 AZStory 14 Upper Front Frame Rail (‘horn’) 0.054” Carl Beck ~ 16 Front Valence Panel 0.032” Namerow ~ 20 Front Crossmember 0.076” Namerow ~ 14 Door – outer skin 20 ConverTT Inner Rocker Panel 18 ConverTT Radiator Support 18 + 20 ConverTT Floor Pan (OE) 0.044” CanTechZ ~ 18 Floor Pan (ZCar Depot) 0.045” vendor ~ 18 Floor Pan Bottom Rail (ZCar Depot) 0.060” vendor 16

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Sorry, I missed this earlier note from @grannyknot. Wish I could remember where I got my gauge chart from (it dates back several years). The discrepancy between GK's values and those from my chart are large, so I just went looking for another source and came up with this one from machinemfg.com (website for a machine manufacturer). I wouldn't call it a definitive source, but the values coincide with the chart that I posted... www.machinemfg.com/sheet-metal-gauge-sizes-chart-inch-mm/#Sheet_metal_GAUGE_thickness_chart So then I searched for a chart for the American Wire Gauge (AWG) and discovered that its values agree with GK's... www.powerstream.com/Wire_Size.htm None of my sources are definitive. If someone wants to post the tables from an accepted engineering reference like Shigley's, that would resolve the issue once and for all (I never could afford that book when I was in school and just used my employer's copy after I got out into the workforce). It appears, though, that we've tripped over yet another facet of wacky world of 'gauge' measurements -- that is, that gauges have different 'thickness' values, depending on whether you're looking a wire diameter vs. sheet thickness. Another vote in favor of metric.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

Truly harrowing how such a thick piece of steel can be eaten through by rust. I suppose it has to do with its location (up front and down low) and the moisture-retaining space created in the gap between it and the inner fender apron. Maybe residual warmth from the engine after being parked helped out too. There must have been a lot of salt-belt Z's that were just one pothole-in-the-middle-a-hard-corner away from having the front crossmember part company with the frame rails. On a similar note, I remember back in the day hearing a story about a Z in Montreal that broke in half after a minor fender-bender ?

-

COVID-19

I went over to my local small supermarket (would that be a 'mini-market', or just a 'market'?) on Tuesday morning. Arrived at 8:00AM for the seniors' hours (yes, I qualify -- and by a large margin, unfortunately). The store management had decided that they could handle 30 people inside at a time without getting people too close to one another. At 8:00AM (store opening time), the first 30 customers had already been let inside and I ended up at the back of a 15-person queue lined up outside. The speed of the line was painfully slow. Or so it seemed anyway. It took well over 30 minutes before I got into the store, meaning that the line was advancing in increments of about 2 minutes. Next time, I'm going to arrive 15 minutes early so that I can be in the group of 30 who are allowed in en masse when the store opens at 8:00.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

One of the build threads on this site provided a step-by-step fabrication procedure for this exact piece. Unfortunately, I don't remember which thread it was. Maybe someone else will. It basically made up the piece in the form of a set of flat panels. Only straight-line bends and cuts were used. He had to weld in filler pieces to create the floor and the front and rear vertical walls of the pocket. If you think of how you could create the piece using cardboard and tape, you'll get the idea. It's too bad that the answer to this kind of question has to rely on the memory of other readers and contributors. One of the weaknesses of sites like CZCC is that the search tool depends on the words that the tread's author uses to describe their work. For example, what would you call this particular piece? One person might call it a 'doubler'. Another might call it a 'reinforcement' or an 'insert'. There's also the distinct possibility that the author of the build thread that I'm thinking of may have described his procedure without ever giving the piece a name.

-

S30 Sheet Metal - Body and Chassis Panel Thicknesses

I like the second table, esp. the fact that the standard dates back to 1922 and therefore encompasses the period when the S30 was being built. It indicates that the 1.1mm thickness offered by contemporary supplier Parker Steel (see my earlier entry in this thread) is not really relevant to the sheet used for the S30 body panels. It looks, instead, like 1.2mm (0.0472") would be closer to the truth. The JFE brochure provides some interesting insights into the cross-section of sheet steels available to modern-day automotive/manufacturing engineers for body pressings. With techniques like hydroforming and materials like high-strength and ultra-high-strength now available, things are a lot different than they were back in 1969.