Everything posted by Jennys280Z

-

Compression Test questions

My biggest recommendation to anyone doing a valve adjustment for the first time, get this tool. It made the difference between an impossible job (I couldn't muscle the locking nuts loose with a regular wrench! Seriously??) and a highly pleasant job. The breaker bar was so long the handle was up over the fenders, so nothing under the hood could get in the way. Super-easy! Now that I've done them already and don't have bolts tightened by King Kong, I can do them again with just a regular 17mm wrench. 1/2" breaker bar 3/8" adapter 3/8" extension 17 mm crows foot

-

Compression Test questions

Update: Thanks you guys, you're awesome! :) I adjusted my valves and the cold idle issue is completely gone. Starting the motor sounds so much calmer and quieter now, almost like a new car. The first time I started the motor after adjustment, I had over 900RPM cold idle that held there throughout. Even though I couldn't warm it up all the way just idling, I checked manifold vacuum and it was already 16.25-16.50 mmHg. I adjusted the idle down to 800RPM and went for a drive. I agree that there's better power in the lower RPM ranges. When I got back from the store I was idling at 900+ RPM again on a fully-warmed motor! I am guessing vacuum is 17mm+ when warmed up so I'm very happy! Good early call from FastWoman who first spied my lean issues and warned me of the dangers. The car drove SOOOO perfect except for a couple of hesitations from 4th gear at low RPM the instant I tap the gas. Yes, I'm being hella picky right now I'm thinking one tooth richer mixture might eliminate that completely as well as raise my idle and vacuum even more. I hear the sewing machine on the top of the engine now, and that's okay Timing 10 deg BTDC, fuel pressure rock steady. I'm supposed to have full-time vacuum advance but I think the vacuum advance is dysfunctional on my distributor. I need to have it rejuvenated/rebuilt. Hey Zed, check these two photos out and tell me what you think. Looking great to me! Thanks for the tip to access the crank bolt from the bottom. I used my 3/8" drive click-style torque wrench, a 1/2" adapter and the 27mm hex socket to turn the motor. I wasn't sure how much torque was needed to turn it but I set the wrench for 50lb-ft and that was more than enough. I slowly did two rotations of the crank and got all 12 valves done in that amount of turning. Remote starters are for compression tests, not valve adjustments! Here's the results on my timing chain:

-

Compression Test questions

Yep you're right Zed, the notch on the damper pulley is at 12 o'clock. I might be able to see the groove shining a flashlight and looking through the window at an angle. If I am seeing that groove, it's really close to the v-notch when lined up. A lot closer than that drawing/diagram shows. When you say "back" the pulley notch, do you mean turn the motor backwards (counter-clockwise)? Also, I'm using a remote starter switch to turn the motor and even with the plugs in, it turns fast with even a blip of the trigger. I'm not going to get the precision I need to line it up that good, it'll be hit and miss, and most of all luck. So I don't want to keep turning it that way, I need to turn the motor by hand and slowly to get it right. What's the best/easiest way for me to do this? The bolt on the front of the camshaft?

-

Compression Test questions

Okay here's an update. I know I'm already beyond the scope of the subject line here and I hope that's okay with the webmaster(s). I measured all the lashes and I'm pretty disheartened at the results. No smoking guns, and they're all WAY too tight. These were the biggest gauges I could fit in each: Lash (inches) Cyl 1 E .009 I .005 Cyl 2 I .005 E .008 Cyl 3 I .004 E .007 Cyl 4 E .007 I .004 Cyl 5 E .008 I .004 Cyl 6 I .004 E .007 I wonder if any of you guys have ever seen (cold) lash this tight before? The clearances are pretty consistent across cylinders, but 3/1000ths or 4/1000ths of an inch too tight?? Seriously? I'm not going to start dramatically loosening everything until I hear back from you guys because it just doesn't seem like a good idea. Attached are photos of my timing sprocket with Cylinder 1 just past firing position (cam lobes just past 10:00 and 2:00) to check for timing chain stretch. I see the "location notch" through the "window" easily enough but I don't see the "oblong groove" to line it up with. There's supposed to be a little dash above the notch (according to img_2281). Can anyone advise what to look for here? Did I turn the motor a little bit too far perhaps? Is the groove obstructed by that bolt? Is there a different kind of marking on this one? Is it just dirty and hard to see? *shrugs*

-

Compression Test questions

Hi guys, Cylinder #3 is alive and well. At the time the photos were taken, I had only 15-20 miles on those spark plugs! Zed Head: Swapping connectors and following the problem is great stuff! I have a digital tach on my timing light which would make it a cinch. I have very little experience with reading plugs and next to no frame of reference here, but it just seems plausible to me that one can still have a brand-new looking plug after only ~15 miles. #2 and #6 looked WHITE to the naked eye even though they don't look too bad in the photo. After only 15 miles and looking that bad already, something has got to be messed up. What about valve lash? If the intake valve is tight, I'm presuming the valve is opening too much/long allowing too much air into the combustion chamber? If the exhaust lash on the same cylinder is too loose wouldn't this compound the lean problem even further and perhaps even more dramatically? I know what running on five cylinders feels like when I once lost spark in my #1 cylinder due to a fouled plug (and BTW, #1 looks too wet to me, it looks like evidence that could explain #1 fouling in the past). The motor purrs at a steady 900 RPM when warmed up. It sounded great the last I drove it. Revved it to 5000+ for the first time this year and it was smooth all the way up and back down again. It had an infrequent front or backfire issue on a previous drive but even that was gone completely the last time I drove it. Fastwoman: performance-wise, I get an occasional hesitation when I first hit the throttle. This symptom was more pronounced when my AFM was a couple teeth leaner, so I suspect that after adjusting valves I'll move the AFM another tooth richer. Oh and drive the car harder than just a lot of wimpy idling and stop n' go so I don't foul my plugs again I've replaced my coolant temp sensor but I may well have some "lean drift" in the circuit there, I dunno. What the heck causes that anyway? ECU? A faulty CTS resistance still wouldn't explain the differences in compression and plug conditions between the cylinders. BTW I checked vacuum a few days ago and I'm only getting 15.25-15.5 inches at the intake manifold. Pretty steady but it fluctuates about a quarter inch back and forth. So we have the compression #s, photos of brand-newish spark plugs, manifold vacuum, and #3 alive and well. I am hoping that massaging the valves will bring vacuum to 17.5" or more. My expectations are rose-colored. I think I'm going to get 136+psi out of all of my cylinders COLD after my valve adjustment. Am I crazy? lolz

-

Video: 2012 Nissan Project 370Z vs 1970 240Z

'Nissan Project 370Z' vs Gordon Macswain's 1970 240Z! - from 'The Downshift' Episode 54 Many months ago, Nissan asked their fans to help them create the ultimate 370Z track car. They called it Project 370Z. To put it to the test, Nissan fans were asked to vote for a challenger to compete against it. They chose a 1970 Datsun 240Z with an RB26 engine transplant built by Gordon MacSwain. On this episode of The Downshift, we head to Las Vegas Motor Speedway for an epic David vs Goliath battle between these two amazing machines.The Downshift appears every other Tuesday on the Motor Trend channel.http://www.youtube.com/motortrendSubscribe now to make sure you're in on all the action!http://www.youtube.com/subscription_c...Facebook - http://facebook.com/motortrendmagTwitter - http://twitter.com/motortrendGoogle+ - https://plus.google.com/1018679678590...Website - http://www.motortrend.com

- Compression Test questions

- Compression Test questions

-

Compression Test questions

Hi guys, well I completed a compression test and here are the results: Spark plugs NGK-BPR6ES after 20-25 miles of driving Plug #1: Gassy smelling, wet Plug #2: White and dry ground electrode Plug #3: Looks brand new Plug #4: unremarkable, like a barely used plug should look Plug #5: The white insulator is mostly grey already except near the tip; some black residue along the rim. Plug #6: Looks exactly like plug #2 Compression (psi) Cyl1 : 136 Cyl2 : 127 Cyl3 : 147 Cyl4 : 138 Cyl5 : 136 Cyl6 : 127 The motor was cold for this test. I tested 2 and 6 twice to make sure the results were consistent and accurate. It's interesting to me how the spark plugs from 2 and 6 looked identical and they had identical but low compression numbers. Also interesting how 3 has the highest compression and the spark plug looked brand new (tip still shiny silver, electrode pure white). I went to the store and bought a 17 mm crows foot and a few cans of Sea Foam. Poured about 2/3 of a can in the tank with about 12 gallons of premium gasoline. The car ran good tonight. It gets up into the power band and pulls nicely. I would say it ran perfectly except I noticed when I am in gear (2nd or 3rd) and let off the gas and just coast, I hear the occasional backfire, which I think is actually a frontfire unless my ears are playing tricks on me. They were gentle tapping sounds so probably no big deal but still annoying. Well the frontfiring is a big deal...I'd rather err on the side of backfiring if I had to choose one Valve adjustment is next, hopefully in the next 4 weeks. I'm just going to measure all the lashes first and post the results. I'm going to do this cold as well. No major surgery, just a fact-finding mission. I expect I'll adjust a few of the valves at least but not all of them. I'll take pictures of the valve train and post them if I think anything looks weird. Got a new cam cover gasket too just in case. After the valve-adjust I'm considering feeding Sea Foam via vacuum through the intake manifold to give the valves a good cleaning.

-

Compression Test questions

Hi FastWoman! I've got enough info. to proceed. Thank you! Just a matter of waiting for my starter now. siteunseen, I already have a vacuum gauge and have run tests, primarily from the intake manifold to brake booster connection. The only time I saw 17-18mm Hg was when I jumped the TPS wires to go full rich. The car belched grey smoke and stank of gasoline but the idle vacuum looked great for the first time ever Eurodat, I'll consider the leak down test as well, thank you. I did FastWoman's infamous yogurt-cup test and couldn't detect any vacuum leaks. I saw a cool trick a guy on Youtube used to test for leaks with cigar smoke. Anyway, replacing vacuum lines was one of the very first things I did along with cleaning most of the electrical connectors. Before the yogurt test I considered the only possible place for a vacuum leak would be the bottom of the intake manifold gasket but now I have further evidence with the compression test to suggest that the low vacuum likely coincides with the low compression. The problems that have plagued me from the beginning are poor cold idle, low manifold vacuum, and now the compression readings. Timing, mixture, fuel pressure and ignition are all healthy and accurate. I do want to get a look at the camshaft and valves. Looking at repair records, the valves were last adjusted (allegedly) around 18,000 miles ago and 15 years ago. The car barely has any mileage on it since then as it was stored in a garage for over 10 of the past 15 years. If I see anything unusual about the valve train I'll post pictures of possible problems or if anything might look burned. Before I start making adjustments I might just take the cam cover off, turn the motor with the starter and take measurements and then post my cold results. If one valve is majorly out of wack I'll probably adjust it when cold to match the other valves. I'm sure I'll have more questions upon my visual inspection and will likely do a cold adjustment myself thanks to this gem of a website. I won't do a hot adjustment though....maybe on my 3rd adjustment....maybe my 2nd The brass hammer was mostly intended for the valve adjustment screws so I can deal with things with finesse if I find them sticky When I have the cam cover off for the compression test, I am also considering torquing the head bolts to 61 lb-ft per Tom Monroe's "How to Rebuild Your Nissan/Datsun OHC Engine". I have a 3/8" Torque Wrench good for 80 lb-ft. which should suffice. Monroe also mentions a trick to hold a dollar bill over your exhaust pipe and if the exhaust sucks the bill in at times, there's likely a burned exhaust valve. LeonV, wasn't sure that flood clear mode applied to the fuel-injected cars. Hope all are having a good weekend. This website rocks btw!

-

Compression Test questions

Hi everyone! It's been awhile. I'm surprised I remembered my password! A few years ago, I was plagued with a cold idle issue, low manifold vacuum, a lean-mixture issue, all kinds of fun stuff. I learned so much about the EFI, tested my AFM as an issue, replaced it with a new one from Motorsport, and adjusted it to its ideal setting. Though I'm still surprised how big a difference a few teeth make going either direction. This sensitivity might be symptomatic of other deeper issues that I've discovered recently. So I had my car in the shop last week for a brake job. Got new pads, shoes, shims, springs all the way around and when I was getting this done I also asked for a compression test. The results were not good I'm afraid. Cyl 1: 100lb Cyl 2: 105lb Cyl3: 95lb Cyl4: 100lb Cyl5: 90lb Cyl6: 105lb A little history behind the car: The motor has 140k original miles. INo head work, never been rebuilt. I bought the car from a schoolteacher in 1990 when it had around 85k on it. I put the 55k on myself. The car has always been maintained, never raced or abused. I've always changed the oil every 2-3k miles. Faulting the air regulator for the cold idle issue, the car gives about 1k RPM on startup but quickly bogs down to 600 and slowly rises as the engine temp rises. When it's fully warmed up I get a healthy idle as well as a healthy performance though I admit I haven't run it at high RPMs to know for sure. This could be a feeling relative to how bad it is when cold. What I'm wondering now is if the issues I'm having with a cold engine are compression related. When the engine warms up, the piston rings would seal up in the cylinders and presumably give an extra 10+psi or so and I presume this make a noticable difference with the way the car runs, however I also read that motors with compression this low would be hard to start, if they even run at all. Is it even possible to have a motor running this good with compression this bad? My car starts up quickly every time. I'm not completely confident that the low numbers aren't the fault of the mechanic doing the test so that lack of trust has made me want to test the compression again myself. Before I do, I will need a few extra tools. I already have a compression tester I bought from Actron. I am going to get an Actron remote starter and I hope that would be appropriate to the task. For posterity, here is an excellent guide to doing a compression test on AtlanticZ: http://atlanticz.ca/zclub/techtips/compressiontest/index.html But as newbie proof as that might be, I still have a few questions I hope you guys can help me out with. 1. With the plugs removed, do I just leave the spark plug wires dangling? I'd like to leave them plugged into the distributor but if the coil steps up the voltage to whatever the spark plugs need and the plugs aren't there, is there any danger in this? Can this hurt the coil or the distributor? Or me? 2. What is the electric fuel pump going to be doing during this operation? Since the remote starter is going to be cranking the engine, won't there be fuel spraying into the cylinders? I'm guessing if I need about 30-40 seconds of cranking to finish the test in all cylinders, won't the cylinders be flooded with gas? 3. The guide says to hold the throttle linkage open. Does this mean to have someone else hold the linkage to full throttle? Is this necessary or does it just aid with the reliability of the test? Does this keep gasoline from injecting into the cylinders the same way a carbureted car would work? I read another post on here where someone was getting really low compression numbers and when they corrected their stretched timing chain they got 40-50 lbs back. I wish I could say the numbers are tight if low but with cylinder 5, I can't even say that. I'm not sure why all the numbers are divisible by 5. I guess that's as closely as the guy wanted to look at the gauge when he was doing it. 90/105 is still 85.7%, so likely not a "problem" that AtlanticZ referred to. Let's say those low numbers are accurate. How is that possible? The cylinders/rings all wore down that much? That just doesn't seem plausible knowing the history of the motor. I've done everything I can to tune the car up at this point (new plugs, wires, cap, rotor, filters, timing, AFM, connectors cleaned). The only part of the tuneup I haven't done yet is the valve adjustment. I need a few more tools before I do that (a torque wrench and maybe a brass hammer to tap off the cam cover if it's too sticky). My questions above would enlighten me to doing the valve adjustment myself as I presume I can use the remote starter to turn the camshaft. I'm unnerved about this too because I don't know what steps to take to make sure the engine doesn't start when I'm playing with the valvetrain I'm sorry again for being so wordy here. I know I sometimes write disjointedly and my racing thoughts wind up splattered all over the place. Maybe thinking out loud has its merits when things need to get technical hehe. Really, I only need enlightenment on the three questions I numbered above. I hope a few of you can handhold me through my questions even if they're not that good. Per AtlanticZ, to get my results as high as possible, I intend to: Test on a warmed up engine Remove all spark plugs Keep my connection fittings tight Keep throttle open Test cylinder 5 twice if the results are relatively poor for me too, the 2nd time with a squirt of oil in the cylinder Thank you all in advance! FastWoman and Zed Head and others gave me more help than I was worth about a year or two ago.

-

'76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

Nope just a boring little town in GA. But I'm a little jealous that you were there

-

'76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

Phew! xoxo

-

'76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

In my '76 FSM it says to do it the old fashioned way like brakes. But I did it your way and it seemed to work great! I didn't install any clutch parts yet but I did flush and bleed the system. There was a layer of thick black in the brake fluid about 2" deep by the time the fluid in the clutch MC stayed clear. Thanks for the warning how quickly the MC evacuates of fluid too. Either three quick pumps of the pedal or two slow ones and it was already time to top it off again. I'm a little worried if my old master cylinder can stand the strain of what is likely greater pressure from this cleaner fluid in a bled system. I gathered some of the dark spots in the fluid together and it's definitely black rubber. I don't expect the fluid to stay clear for long. But for my first experience this was great. The clevis pin for the clutch pedal under the dash looks extraordinarily difficult to get at (the reason why I didn't install the new MC when I bled). I thought the one for the brake pedal was hard

-

Carpet Kit and Speaker Panel

I bought a carpet kit from a vendor on Ebay for about $100 less than those prices, for an 801 cut pile complete kit.

-

Buying my first z today!!

Oh! I wonder what % of those two model years had 5s?

-

Buying my first z today!!

- '76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

Are you building a track car cozye? Okay so FastWoman makes a good point that if my car is just for the street I shouldn't install polyurethane, but in the interests of better handling, is there any "weak spot" in the Z's suspension that would really benefit from some polyurethane bushings? That is, go with rubber bushings, but use polyurethane ones in two or three places that will still be "Streetable" but will make a noticeable difference in handling? I'm not saying I don't want to take my car to the track either. I would LOVE that!!! And a teacher sitting next to me while I'm driving please! That job is above me, cozye. You're a pro compared to me and if it took you that long, it'd take me 3 months or most likely never because I'd get stuck and not be able to finish. Plus, I have no experience with torches and saws (or PB Blaster either for that matter). And I'm not physically strong compared to the average human so I better just find someone else to do it. But who? Are there suspension specialists? Should I try to find some racing company? They'd probably have the experience to do it. Bushings, Coilovers, and fatter sway bars! Should that about do it for a rebuilt suspension? Oh God I can see the money going out the window already. NOOOOOOO!- '76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

Well the car feels so good it must be close to as good as it can be. After I drive it for awhile it keeps running better and better. After long drives (10 miles or more) it always comes into the garage idling at a very steady 900-950 RPM but just warming up isn't good enough to do that. It has to be driven. Maybe this will change soon as I drive it more frequently...but anyway the drive tonight was so much fun. I can barely feel my foot on the gas and the car just moves out in every gear. Feels like a sports car again! Oh I still have the cold idle issue, only now it's at 700 RPM and not 550 RPM. Dunno why. Maybe my air regulator cleaning made that much of a difference. I tried to manipulate that idle mixture screw and just like yours, it didn't do anything. I had the digital tach hooked up, was listening closely. I cranked on it CW for a while and just about all that happened was I smelled gasoline after a point. And I hate how there's no frames of reference on this thing! Oh and as for the AFM wheel, I think you're right. I got a flashlight and a magnifying glass and looked at the meter I bought very carefully and I could see some of the other teeth "dug" into a little bit too. I loosened the locking nut and I was wrong. The glue had been broken. But there is one very prominent semisphere carved into the wheel and like you said that is likely where the locking nut was for most of the AFM's life. Which means that wow, my AFM was adjusted way farther towards lean than I thought it was. (And still is). That tooth is at 11:55 right now, where on the locking nut it's what? 10:00 or 10:30?- 3 years of sitting... what to do first?

agreed!- '76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

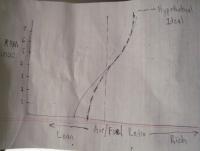

Got a new computer put together over the weekend and forgot my password to log on here! FastWoman: Some maniac almost hit you, oh no!! :mad: You've got a stable full of rides on your hands now to play with. You'll get all Mazda'd and then not be here as often! cozye: It's good to see you're back. I'm still reading your posts on other threads so your wisdom succeeds you! But I'm salivating over this now: http://cgi.ebay.com/ebaymotors/DATSUN-280Z-TOTAL-Polyurethane-Bushing-Kit-14-2002-B-_W0QQcmdZViewItemQQhashZitem53d3c533c5QQitemZ360035201989QQptZMotorsQ5fCarQ5fTruckQ5fPartsQ5fAccessories Do you think I could handle putting this stuff on my car? At least part of it? All: The good: Okay so after a few more road tests...I was puttering out the tailpipe a little more frequently, so I backed the timing off from 12 back to 10 and that stopped completely. Running smooth on the road...no smoke, no smell, no backfire. The bad: I drew a little graph of what I think is still happening with my car. It maps mixture to engine speed. The curve shape is conjectural. Maybe I drew the shape backwards. But I think I have the bug of it right. A little history: I started out focusing too much on the idle, realized that enriching the idle could get me from 14 to 17inHg but the car ran pig rich on the road like that. If a lean mixture is causing my idle problems, and a rich mixture while driving is causing dead cylinders via fouled plugs (a repetitive event in my car's history), then maybe the way in which my AFM is defective is altering the mixture curve. Referring to the graph, the dark dotted curve is where I should be. The curve with the solid line is where I am now. The error in mixture at lower RPMs (idle) is more severe, whereas the error at higher RPMs is barely noticeable. But I'm questioning if it's possible to pull the ends out in both directions, "stretching" out the curve to exhibit two symptoms simultaneously and making my car a biach to diagnose. What do you guys think? Plausible? I just realized yesterday that I still haven't tried the idle adjuster on the AFM yet. I'll do that tomorrow. I fingertipped the chuck of metal on my AFM again yesterday and the idle increased dramatically with a few millimeters of adjustment open. Idle decreased very quickly with a mm or two closed. Manifold vacuum still below 15inHg at warm idle. But on the road the car runs well again. For the first time since I've participated in these boards, I got three consistent test drive results! And the car responding very well to changes like retarding the timing.- '76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

Good point! I think my RPM was right around 2000-2500 when it did that. Thanks hon! So do you think that another AFM set to specs would do any good at all? I now have to question if it's possible for my car to run better than it is. I didn't do any WOT driving...just stretching the car's legs for the first time in a while. I suppose I'll have to do that a few times and save that for my final judgment on whether it's strong or not. xx I cleaned the engine up with Simple Green, and I started the motor wet after rinsing it off and I noticed the idle was low. I tapped the gas pedal a little bit with my fingers and my car went right up to 1300RPM for the first time in forever, indicating a functioning Auxiliary Air Valve. What I'm wondering now is, do these AAVs get "activated" by the throttle somehow? Or they "stick" to that a little throttle wakes them up perhaps?- '76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

Update: A new coolant temp sensor and I feel like I'm 99% again. Every part of a major tune up was done to my car save a valve adjustment that I just had 16,000 miles ago. I'll do that in another 10,000-14,000 miles and it looks imminent my Z will now be a part-time driver. I was on the road today at about 45 mph in 4th gear and I let off the gas to slow down for the light ahead and I "felt" something with the motor "work itself out" and after that it felt like a brand new car. The drive was amazing today. Smooth, smooth smooth! How much HP does this engine have? 148 HP? I've got to be getting every last one of those! Though my Z is lightened up about 200 pounds. I'm probably 200 pounds lighter than some of the boys on this site (I'm tiny) so on balance my car is weighted about like a 240Z with a heavy driver. Incidentally, my AFM was adjusted back to the 'sphere' at the 12'oclock position on the wheel at the same time the new sensor went on. Based on how well my car is running, I see no reason not to use this AFM with the 126 and 226 ohm metrics. Confirming what you've been saying all along FastWoman, that the ohm shift doesn't even matter! You too Cozy wherever you are. btw the work you do on your Z is mindblowing. OMG And you too Zed Head your advice has been so good at times I felt like doing backflips. My intuition tells me I might be running a pinch too rich still. Every now and then I smelled gas, and when I was going down a steep hill, off the throttle and in 3rd, I could hear a few gentle pops out the tailpipe. But as far as pickup it's running so right I'm just going to leave it like this. Thank you all! xxx You guys have made this the best website on the planet for old Z cars. When I can afford it in the near future I'm going to help it for helping me. But the three of you deserve personal accolades. FastWoman, Cozye, and Zed Head.- '76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

I'm going to retire this PC over to one of my parents...I should probably give it another dose of RAM first. Regarding your spherical notch: I have one too. It's just a depression made throughout the years by the pressure of the set screw. The locking screw? I doubt that. The screw is spherical underneath? Remember, I tested the spring resistance of both AFMs per Atlantic. Both were a tad too loose at the midpoint and prescribed water volume, that is, I was slightly past the midpoint with each unit where I should have been right at the middle. It is so slight though that this could be attributed to user error. To have the most consistent results, it'd be nice to have the same tester with multiple units using the exact same criteria, even taking photos for comparison. It's easy to be accurate with small units of measure like pennies or mL of water, however it's on faith how we're reading the angle of the wheel with our eyeballs. No matter how careful and precise we are, there WILL be experimental error, or let's call it variance, across our individual data sets. There's a million reasons why, including what kind of chairs were sitting in when we do the tests. But to be short, it's not just the differences in the numbers in the data, it's the differences across the data sets. Yes the needle would be far better than the digital but I carefully observed smooth (and identical across AFMS) ohmage increases motion of the flap. Here is a case where you are trusting my eyeballs, but even if you don't, I'm still confident with what I saw and tested myself. Incidentally, the readout from 6-9 on the Python was 352 like I expected it would be (126+226). Yes I can add a resistor to the water temp sensor circuit....it seems easiest just to pull off the bullet connector, gently solder a resistor onto that and test accordingly. When I get good results on the road, tape it up and be done with it....but I'm not at the point of concluding I need any resistors anywhere at all. My car needs to enjoy a new CTS first...the one I have on the car now is pretty gross looking.- Not much power

Tstone: How many miles are on your motor? Maybe you didn't do/see the compression test right? Did you use a threaded tester? - '76 280Z Question on dist/manifold vacuum, dist timing, fuel pressure, brake booster

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.