Everything posted by Nissanman

-

Voltmeter Pegged All The Way On +

Do you mean VOLTMETER or AMMETER? I really need to know which it is, VOLTS or AMPS. A Voltmeter is usually marked from say 9V to 15V no polarity indication whereas an Ammeter is centre zero with markings of -45, 0 and +45 for example. It sounds like your Alternator is running UNREGULATED:finger: This will cause the battery to EXPLODE if left too long! You need to check all the connections as a matter of urgency to rectify the problem. The squealing may be a misaligned belt/pulley, or it may be due to the extreme current draw mentioned above. The dim headlamp is probably due to a faulty ground for that lamp. It may be that both filaments are operating in series instead of using the ground circuit.

-

HELP!!! Tokico Illumina install issues

Usually, new strut cartridges should come with the necessary gland nuts. They should have a small sleeve on them to engage the taper you mention. This centers the cartridge and clamps it down firmly. In some circumstances, the insert may need a spacer at the bottom of the strut cartridge to make up any shortfall in cartridge length. The stock gland nut is of a different design since it is intended to provide an oil seal around the strut shaft and doesn't clamp down on anything as such. They should not be used for a cartridge insert. In my opinion, you have parts missing:rolleyes:

-

What happened to my parking lights?

The Park, Tail, Side Markers and all dash ILlumination is powered from the 20A PT fuse. You may need to check for 12V at the fuse, an eyeball check may not be sufficient. Glass fuses have a habit of being open circuit even if the fuse element looks intact. Use a test lamp or a multimeter.

-

Big blue smoke burst

WOT means Wide Open Throttle. The manifold has to be opened as much as possible to the atmosphere to get all the air it can to do the compression test. I addition to the points mentioned above, the engine should be at normal operating temperature. Crank it just long enough for the pressure reading to stabilise. Make sure you vent the gauge of pressure before doing the next cylinder:cheeky:

-

Fuse box/headlight/charging problem

Have a guess what I found in my Z parts?

-

Broken Mounting Insulator

Well, isn't that pooey:angry: Unfortunately, I don't think a back yard fix is possible. That item is originally a vulcanised rubber to metal part. Don't try to use the damaged strut top even if you do manage to glue it with anything:finger: No option in my opinion, but to get a replacement:rolleyes: Oh, you might need to seriously think about doing the other side too. I know you don't want to hear that but...

-

Big blue smoke burst

I guess the worse case is for the head to corrode or the head gasket to blow. The former depends a lot on the quality of the coolant you have used over the years. The latter may just happen due to age and brittleness of the gasket. It may never happen:paranoid: Can't quote you any $. In your position I would rebuild the matching number engine. The car will retain a lot of value that way. You might be able to find a 1/2 reasonable used L6 engine to use temporarily but bear in mind they are all getting old now.

-

Big blue smoke burst

I think you have answered your own question, it is showing its' age:rolleyes: Unless it develops a major problem, you could keep driving it for a while yet. However, with those numbers in the compression test, it will certainly benefit from a complete overhaul. My reference says that on a '72 in good condition the compression should be ~180psi. More importantly, the lowest reading should be at least 75% of the highest. 0.75 x 135 = 97.5. Your lowest is 90psi:ermm: #4 cylinder may also have a valve sealing issue which a Leakdown test should verify. However, it is probably academic considering the low readings across all the other cylinders. Your attention to regular and frequent oil changes almost guarantees an engine that will not require a great deal of machining to it. My guess is a fresh set of main and big end bearings, new rings with cylinder hone, and a reconditioned head. The last bit will probably be the most labour intensive and possibly the most costly if you have a Shop do it. Just make sure you do it all at the same time, it is too important to do by 1/2 measures. When done it will be a quantum leap in engine performance, it will be better than new:D:D

-

Big blue smoke burst

A1 Yes. A2 Perhaps. A3 Find that hard to believe but, WOW:surprised:surprised A4 & A5 Good signs both. Your diagnosis of valve seals is one that I concur with. The high vacuum generated on coast and at idle can suck in quite a bit of oil through worn intake valve guides and/or deteriorating seals. The increase of the smoke after the piston ring treatment is reasonable proof that the rings are now sealing a lot better than before, thus increasing the vacuum the engine can pull. You could probably live with the valve seal issue for some time, I wouldn't call it an urgent repair or an impending disaster:nervous: Bear in mind that even though the seals are now becoming ineffective, you must expect to re-condition the entire engine when you decide to repair it. It is false economy to do the bare minimum.

-

Bad Dog Framerails

Link to topic 2nd to last post:ermm:

-

Need help Running lights and dash light issues!!

Electrickery can be very frustrating:tapemouth:tapemouth What you need to do is attack the issues you have in a methodical way. Be patient and you will get there. Instead of blowing fuses, try clipping a 12V globe across the fuse contacts. It will still protect the wiring from overload, gives a visual on short circuits and saves the fuses for another day. The short may be as simple as a dash, park or brake globe inserted incorrectly or the wrong globe used. e.g. a dual filament globe in a single filament socket or vice versa. That can cause the supply and ground sides of the harness to be shorted together. I suggest you remove all the globes, check the integrity of the test lamp [fuse] then replace the globes one by one. You may have to undo some of the connections you have made to isolate the problem. When doing projects like this, I find that it is necessary to do one wire at a time, test its' function, then move on to the next. If you don't, then you have to go back to the beginning and do it one at a time, just like you should have:disappoin The attachment shows you how to make a simple 12V test lamp. With a few of these and a decent Multi Meter, you should be able to find your problems:devious:

-

Well, THERE'S the problem...

Usually, caused by severe detonation and/or uncontrolled boost:rolleyes::rolleyes: Was the engine boosted or not? Pic. shows a piston from the engine of a Nissan N14 Pulsar GTiR which was driven with the Electronic Boost Control "inadvertantly" disconnected:ermm: Oh, that piston will need replacing:nervous:

-

Alternator Upgrade

Here is a similar topic discussed previously: - Ammeter Question Essentially, the ammeter measures what is going into or out of the battery, NOT the load on the electrical system. [if it did measure the total load, then, yes, it would have to be ranged to match the capacity of the alternator]. The ONLY time an ammeter DOES measure the total load, is when the engine is OFF and the ignition is ON. In this case, it will read "-" always, since the storage battery is DISCHARGING. So, in a normal system, the battery is a storage device which provides a ready current source to turn the starter. Also, it provides enough reserve to power up any electrical circuit/accessory, including the alternator exciter windings, until the alternator starts to function at a certain RPM. Then the alternator can take over the load, which may only be 20A or so, right up to its' rated capacity under extreme conditions. What you then see on the ammeter, is not that total load, but the charge current that the alternator feeds into the battery, the trickle current. This current is determined by the potential difference of the battery voltage to the alternator voltage, the potential difference, PD. The storage battery is nominally 12V, the alternator normally supplies a voltage of 13.6 - 13.8V. Hence the flow of current INTO the battery or ammeter reading slightly on the "+" side of "0'. In a normal system , a simple test to demonstrate the workings, is to have the engine idling with a "+" indication on the ammeter. Then, switch on the headlamps. You will observe a quick but definite flick of the ammeter back to "0", maybe even go "-" but it will recover and settle back to the small "+" value. This is the alternator not supplying the extra load, the battery supplying the shortfall current, the regulator sensing the increased load and then compensating for it by increasing the alternators current output. Quid pro quo. If the ammeter doesn't settle back to the "+" reading, there is a regulatory/charging issue. If you don't already have one, the installation of a maxi-fuse/fuseable link on the output of the alternator, to match the cabling rating is alwas a good idea. A 85A alternator will make short work of a cable system with a rating of 30A. Any fuse is there to protect the wiring, period.

-

Alternator Upgrade

An alternator usually outputs a maximum of around 14.2V, generally 13.2-13.8V. The internal windings and diode characteristics dictate what sort of current it can produce. So, while an alternator can be tweaked to produce more power, it is the current capability that is increased, not the output voltage. That of course leads to the next question, why do you need more alternator output power? Unless/until you fit an aftermarket sound system or some other power hungry accessory, the original alternator power should be adequate. I know a lot of folks fit seriously large alternators to old cars, for whatever reason, but unless you have a need for that extra capacity, it doesn't get used. You also need to consider the likelihood of the increased alternator output overloading the factory wiring loom. Wiring that was designed for an 85A alternator for example will, without suitable protection, burn out when connected to a 100A alternator and the load is also increased:finger: Ideally, the additional load should be via new, correctly protected and dimensioned wiring, directly from the battery post.

-

Intermittent Voltage Issue

Short answer, yes:( It may be that the regulator needs adjustment. I posted the instructions for that procedure on this site some time ago. It is the job of the regulator to tell the alternator what to do. I suggest you have the charging system checked by a competent shop. It is important to rectify the fault ASAP in order to avoid either a flat battery or worse, an overcharged battery which could explode:dead:

-

Rocker Arm? Valve Adjustment

Let's just assume that the piston pushed the valve gently back into position:classic: Valve clearance info: -

-

Need Help with Turn Signals

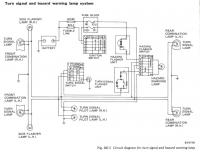

The fact that the Hazards function OK is reassuring, at least you know that the wiring and globes at all four corners is OK. That gets you back to the individual turn signals. You say you changed a relay. I assume that it is the flasher relay? Is the relay is clicking when you operate the indicator stalk? If it does then you need to look in to why the relay isn't powering the indicators. If it is not then the fault is likely to be the column indicator stalk. Make sure that the replacement relay you used is a proper replacement part. Just because it may fit into the wiring socket doesn't mean it will perform the correct function when powered on. The attached pic. is a diagram from the 810 Nissan FSM and shows the principal of turn signal and hazard flasher operation. It is intended as a guide on what to look for and where to look when trouble shooting this system. Note that the Hazard switch, when OFF, needs to connect two wires together for normal turn signal operation. Unfortunately, the wiring diagrams in a lot of aftermarket Manuals are absolute crap. That is why I prefer the Nissan FSMs, they tend to break things down into nice little schematics like this one:classic:

-

Head Removal

DON"T FORGET TO REMOVE THE TWO 6mm BOLTS AT THE FRONT COVER!!!!!!

-

Testing Gauges

That is the typical property of an NTC type sensor, Negative Temperature Coefficient. Simply put it means that the sensor resistance to earth reduces as the temperature increases. The attached thumbnail shows the behaviour of such a device. Don't expect these values to be exactly those of your sensor but it is what it should do with temperature variations. The oil pressure sensor is usually exactly the opposite. As the the pressure increases the resistance of the sensor also increases, Positive Pressure Coefficient. That is why unplugging the sensor wire, introducing maximum resistance to earth, results in the Oil Pressure gauge maxing out. The typical symptom of a faulty oil pressure sensor as it deteriorates, is the wiper inside it wears an open circuit at the "normal pressure" point of the sensor resistance coil. That causes an intermittent open circuit to be read and the gauge needle jerks and jumps about the faulty position. Usually the only remedy is a new sensor since they are not repairable to my knowledge.

-

Timing Chain Help!

The shimming that you describe is referred to as "head saver shims". When the alloy head is machined too much, the cam drive mechanism dimensions are restored by raising the cam towers in relation to the top head surface. Usually, the machine shop does the necessary machining then supplies the necessary shims to correct the cam height issue. All this is quite separate from setting the valve clearances. This is done by adjusting the tappets for each valve to the recommended clearance. In your case, the tappets may be so tight that there is no clearance, preventing the valves from closing and therefore sealing.

-

Timing Chain Help!

Just a quick thought, make sure that the valve clearance is set correctly. If there is none, the valves won't seal, therefore no compression.

-

additional water temp gauge

In my experience, this would be the only way to get the accurate reading you are wanting. Any electrical gauge is, by nature, somewhat vague. A mechanical gauge will read temperature all the time so you can monitor heat soak after shutdown etc. Upper radiator hose is good or if you can, mount the sensor in the thermostat housing. The thermostats for the fans work on the same principal usually, an alcohol filled sensor and capillary tube. Personally, I wouldn't get another electrical gauge. I don't think the accuracy is any where near that of a good quality mechanical gauge.

-

Quick Question (Hopefully)

Pinch the hose closed between the manifold and the valve and see if the engine behaves better. Or remove the hose at the manifold and plug the nipple. The hose may have a split in it somewhere. If the booster tank leaks then your brakes won't feel any different with the vacuum hose inoperative.

-

Harmonic balancer and valve noise

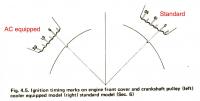

Apart from having an extra pulley on the crank damper, the ignition timing marks are located in a different place. Take this into account if you are mix and matching:ermm:

-

Vacuum advance with triple carbs

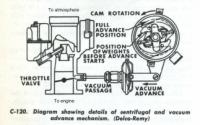

It sure isn't:disappoin The distributor requires a PORTED connection for the vacuum advance. That means a connection that is physically opened and closed by the operation of the throttle butterfly. A manifold connection is NOT suitable, and will give totally erroneous signals to the advance mechanism. Unless there is the necessary connection available on the side draughts then it can't be done.