Everything posted by hls30.com

-

Side Mirror Removal - Replacement

Use a ujoint and an extension-I am headed out at the moment, but I'll be back in an hour or so if you want my to take some pics... Will

-

Speedhut gauge faces installed, finally!

Right on Chris, the switch changes the oscilation frequency, changing the color and the rheostat adjusts the brightness Will

-

Side Mirror Removal - Replacement

Gnose-remember my upgrade list....or maybe I left it off... http://www.classiczcars.com/forums/showthread.php?t=18525&highlight=96301-E4600 See post #12 Several of these will be accompanying my and my '72 on our pilgrimage to Daytona in early October. One will also be mailed to A guy of recent 510 film fame in Cali in the same timeframe...I haven't forgotten Victor. Will

-

Speedhut gauge faces installed, finally!

That is very interesting! Will

-

Side Mirror Removal - Replacement

It is not necessary to dissassemble the innards of the door, but it may be easier to do so-depending on what tools you have. If memory serves, roll the window all the way up. A 12 or a 14mm socket and a 1/4 drive wrench will take care of it-to start the removal put the socket on the driver but don't snap it on (to allow it to meet the offset of the bolt) I taped the mirror to the glass so it would not fall offwhen the nut was off. I have used 3 mill plastic sheet from Home Depot/Lowes to recreate the vapor barrier, lay the inner door trim on it and trace with a sharpie for a pattern, cut 1/2-1 inch inside your tracing and you are there. Use black 3M weatherstrip adhesive to put the barrier on the door. Will

-

Body repair panels?

The compound curvature is different between the coupe and the 2+2, using one in place of the other would be noticeable. Will

-

Grinding - Sanding - POR - Painting

Nate, Please don't think I have been ignoring you! As a part of a tailight hardware project I am in the middle if, I am evaluating a different rust disolver-it may be just the thing for keeping round the house for mechanical work-and perfect for your needs in this! I'll post tomorrow morning when my test isthrough-I think you will be enthusiasticly suprised! Will

-

Grinding - Sanding - POR - Painting

Nate, Those Doglegs(at least one of them) are probably just holding on, and need to be replaced. Unless that is your intention, I would attack them (and the cowl) from the inside with metal ready and some POR to stablize them for the next 5 years and get the job done once, right. POR is a roysl psin in the A$$ to remove, and is made for permanent not temporary repairs. Will

-

What S30 parts are the most difficult to find?

The hardest part for me to find on my '72 has been and is a NOS ashtray cover-It is the only NOS part have been consistantly searching for that I have not found. I have not found a used one that is in good enough shape to satisfy me-though I have several. Next would be some of the oem parts made for other countries-but I don't feel they really count for the purpose of this poll(only relative to my having a USA version), so listing them would be for one of you lot 'cross the pond! The next part was recently brought up in another thread-the fusebox area console cover-it took a couple of years to find one, then several popped up! I have had a difficult time finding some other NOS parts(ok it is harder to pay for them than to find them). I have found most of the series one parts(due in no small part to members here) I thought would be difficult to find, but then that project is waiting for a low vin chassis, and I am sure when I get serious about sewing up the parts hunt for it there will be more "holes to fill". Will

-

What S30 parts are the most difficult to find?

I was sitting here wondering what experiences you have in the frustration of finding parts. I am in the process of getting everything together to reassemble my '72, and went looking for the few missing pieces I need to have everything(except those one or two thinga majigs that will remain hiden until I reach for them and they are not there). WHat pieces have you found the most dificult to find? While my selections are somewhat general, please include specifics. Will

-

A good screw just isn't enough-it must oscillate!

I emailed them right back to see if they needed both pieces of the assy. No response as of yet. With your answer, I have the "OK" to send in both pieces. I am going to do some figuring ratios and such before I send anything off so that I can keep working for an answer while they take a look. I don't know of any reason the clock could not be updated with a small unit inside the case, or a very small piggyback driver. Will

-

A good screw just isn't enough-it must oscillate!

The issue with the oscillator I have borrowed appears to be the driver for the tuning fork-or the tune of the fork-I'd be willing to bet the same issue is the common demise of most. The right answer to me is an updated motor/timer for the clock, that way there won't be future maintenance issues with a timer that is without a supply of its primary and pivotal part. Will

-

A good screw just isn't enough-it must oscillate!

I just heard from them. "Unfortunately, we can't tell you whether we can do anything with it for sure based on the pictures. We have not done this clock but if you would send it in we'd be glad to take a look at it at no charge. Sincerely, Connie Instrument Services, Inc." I think sending the clock in might be the quickest way to an answer-I'll get with those whose parts I have and get their take, but what is the general consensus? Will

-

A good screw just isn't enough-it must oscillate!

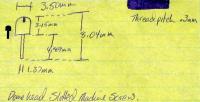

Here are is a "Readers Digest" version of email and the full attatchments I sent-sans the patent info(too problematic to attatch, and a quick way to a headache!) "Dear Sir, In a phone call to Instrument Service today, I related some particulars about a clock I would like updated, and was asked to send some photographs. Attatched to this email, please find several photos. The clock in question is a two part "Nissan Rally Clock" from 1970. It is a clock that Nissan Competition parts offered as an optional replacement for the standard clock in a few models of cars in the USA, and it came standard on a few models abroad. The clock has special features and two knobs. One knob make an "elapsed time wheel" rotate, and the other one resets the second sweep hand when pressed. When pulled it is used to set the clock hands. There are two parts to the clock, and external oscillator unit, and the actual mechanism. The oscillator unit is actually a derivative of the Bulova accutron, and as such utilizes a tuning fork to generate timing pulses. Bulova and Citizen(Jeco) had a buyin at this time period, and that technology was part of the swap. I believe the tuning fork is used to generate A/C pulses to drive the motor in the mechanism. I have both an oscillator unit and the clock pictured. If this conversion is successful, I feel sure that between four and seven of my peers will also have it done as they are either missing the oscillator, or it is broken-rendering the clock an interesting paperweight! Several of my peers are also missing one Knob and screw for the clock. I have found suitable knobs, but the screw has been more difficult. I have included a photo of a spec sheet for the screw-I can make a suitable washer to make a similar sized screw fit. Thank you for your consideration, please contact me if I have left out anything that would be helpful. William Stokes"

-

A good screw just isn't enough-it must oscillate!

I have called them, and will be sending out some hires pics and a copy of the patent used for the mechanism this evening. If these guys can come up with a quartz driven replacement for the motor(And I am reasonably sure I could with time) then turning the Rally clock into a stand alone unit will not be that tough. With the info from the patent, and access to the replacement drive units these guys use, the answer is probably only days away instead of months! The one trade off appears to be the conversion will give a constant motion second hand instead of the flick motion the clock has as delivered from Nissan. If you are interested... The readers digest version of the first patent of the technology used in the clock, and an abreviated history of the watch technology it came from. The oscilator is a driven tuning fork that is adjustable, and used to establish and hold an extreemly accurate(for 1970) timing pulse. one side to fork is driven and the other side is sensed and converted into AC to drive an ac motor at the specific timing(a precursor to a stepper motor if you will) Using a tuning fork tuned to 360hz gave an extreemly accurate, and more importantly, shock proof mechanism that was well suited for the beating it would take in the rally car environment. This technology was used by Citizen as a result of a then pending buyin from Bulova in 1970. The clock is a direct progression of the technology used in the original Bulova Accutron and the Citizen Hi-Sonic series of watches. My original thought was replace the motor with a current equivalent to both the driver(osciillator) and the stepper(ac Motor) and that is all there is looks to be dead on! I'll keep everyone up to date. Will

-

#357 hits eBay

Someone hung an evaporator in the pass. footwell even though it apparently has nothing plumbed to it! WIll

-

Hi, I'm new here

Could be a nice car! Looks like it should fare well in the hands of someone familiar with shaping metal. Mighten you know Eric Whitaker? He could easily be one of your customers he is into the warfare sceene, and has all types of reproduction armorment. He moved to Savannah from Wisconsin severalyears ago-just to wizz me off(by his own word!) Will

-

#357 hits eBay

Ditto on the data plates...the car is a mix of early and late 240Z-late fuse box lid in leu of an ashtray, late dash, hub caps, seats, and steeringwheel, with the rest of the wear inside, probably a dash cover...I think a picture of the firewall stamp would be in order... Will

-

No William Don't do it!

Haahaaahaaaa! Will

-

No William Don't do it!

Bill, I don't want to follow your other advice where you said: "one in the hand is worth two in the bush!" Butt I am not sure I understand it the way you ment it-care to explain? The neighbor with the green "thumb" just wanted to make sure he always best side to his other neighbor.... Will

-

A good screw just isn't enough-it must oscillate!

I'm narrowing in on what goes on in the clock circuit. It definitely looks like the oscillator is an AC converter. Will

-

1971 w/Original Hard Cover for Dash!

Lets not forget custom interior...missing door weatherstripping(and the distinct poss. of everything that goes with themfurther garanteed by the pic of the pass footwell missing the sil cover, but sporting a healty dose of rust! Will

-

A good screw just isn't enough-it must oscillate!

Chris, Rather than possibly pull something out(the board is secured to three brass spacer posts that are swagged to the case by a combination of E clips and solder, but it looks like there is only one item that I could not readily identify as a resistor, Cap, or Transistor. All of the pieces I can see are typically identified with color code or printing! Other than the one oddity, there does not seem to be anything that will stop this from happening-though I DO RESERVE THE RIGHT TO BE WRONG ABOUT THAT! Trust me Chis, You don't want to dig into this any more than I do! But as this is not mine, I won't risk doing further damage to something that someone was kind enough to loan me/us! Will

-

Custom braided stainless brake lines??

Yep, I missed that! Will

-

A good screw just isn't enough-it must oscillate!

Naked Oscillator! This morning I received a broken Oscillator in the mail. Here is the progress on it! I have stopped at the point that I need to hunt down and clean my desoldering station-despite my enthusiasm! I don't want to create an issue from using the wrong tool, or have to stop again while I look for it, so I am parked until I find the right box and service its contents! Will