Site will be going down for maintenance today

Everything posted by EuroDat

-

no spark on 1 or 5 when running

Are you sure its not firing? Have you checked for spark by holding a spark plug against the engine to see if its sparking correctly? A timing light could also check for spark pulses. It could be cross firing. 1 and 5 are next to each other in the distributer cap. Tha cap may be cracked and have carbon tracking between the two. Cracks can be hard to see. That could cause 1 and 5 to fire at the same time and when you do your test its giving confusing results. If you have a multi meter, you may be able to detect carbon tracking by removing the HT leads from the cap and measuring the resistance between all the poles. See if 1 to 5 is different from the others. Note the position of the leads before you remove them. Its easy to switch them and mess the firing order up. If it looks old, investing in a new distributor cap at this point probably be a good move, wouldn't hurt. Chas

-

Looking for Front & Rear bumper

Another option is the Harrington stainless bumpers. I have read good reviews about them, also on this forum. Datsun 240Z and 260Z Bumpers | Harrington Group Chas

-

260z u-joint question/ bad tranny noise.

Same here, if that website was a paperback, I would have worn it out by now and be looking for a new one. Priceless. Hats off to Blue for all the effort. Chas

-

Weak 240Z U-joint resolutions?

Apart from the very interesting Z guru. Dam thats a lot of Zeds. Your noises sound more like diff related. I would look at changing the oil and checking for metal depsoits in the oil. A bit more difficult would be checking the back lash in the diff. Excessive backlash can cause clunking noises during gear change and poor toe/heel paterns which cause whine and sometimes growling noises. Chas

-

Hls30 19821

I agree, it would make a great parts car. The dash looks like its in excellent condition for its age. I would like the scuff plates on the doors sills. So if someone buys it, hint hint. Chas

-

Noobie 73 240z WA

Just noticed the harmonic balancer in this thread and some comments how could it get this way. The damage shown in the photos is most likely a loose bolt at some time in the past. The harmonic balancer can be a tight fit when it cold, but when the engine warms up its not so tight on the crank shaft and can slip back and forward. This will happen a lot if the car is idling in traffic. The harmonic balancer wants to turn at a constant rate, but the engine sends it three pulses per revolution. The causes the balancer to "chatter" on the woodruff key wearing it out. It can also damage/crack the balancer as in this case. I have seen this happen on diessel engines. The four cylinder engines will damage a loose pulley much faster because of the more unstable idle. WARNING to all: If you manage to loosen the bolt while turning the engine with a socket wrench or forget to remove the wrench and start the engine. Tighten it to FSM specs. Don't tighten it to what ever you can get on a compression stoke and think it will be ok. If it comes loose it can do this damage. This happened to me long time ago when I was doing the injector pump timing (drip test) on a diessel engine. The balancer was stuffed 4 months later. Looks like your project is moving along. Good luck. Chas

-

260z u-joint question/ bad tranny noise.

That sentence might have been handy in the first post. Hard the get into reverse is a sign the clutch disc it not disengaging properly. Most common cause is the clutch hydraulic system or its adjustments. There are other problems like siezed spigot bearing, cracked clutch fork or dry/binding clutch disc splines not allowing the clutch disc to move away from the flywheel. Anyway good to see you found a simple fix with the clutch hydraulics. Maybe fresh oil and replacing the worn uni-joints will be all it needs. All the good quality oils that are suitable for our brass type synchros will generally cost more than oil for a modern style tranny. Im using red line fwiw. Chas

-

Yet Another Oil Pressure Post

Sounds like your thermostat could be sticking. If it sticks in a fixed position, say half open, it can cause overcooling (downhill no throttle) and overheating under heavy loads. Its easy to check without dismantling to much and they are not expensive. Chas

-

Last try on this issue

You could be having a similar problem to what I was having. Mine didn't stop when it warmed up, but I wouldn't call it drivable either. It barley made it home in 1st & 2nd gear. The problem I had passed all the FSM test "I could do" when it was cold. It wasn't predictable, sometimes after 5 minutes of driving and other times after 30minutes. If I pulled over on the side of the road it would idle and rev ok, but once it was under load it would start playing up again. It might sound strange, but you do have some luck on your side. If its stopping all together something has temporarly failed and that should be easier to find. Here is the thread explaining my efforts with the HEI module. It wouldn't be hard to install a tempory unit next to the coil to isolate the TIU. http://www.classiczcars.com/forums/electrical-s30/52621-fitting-hei-module-transistor-ignition-unit-1977-280z.html Good luck hunting it down.

-

Swapped clutch.... no engagement!

For reference: The slave piston should be bottomed out when adjusting the push rod. The return spring will bottom it out when it returns and releases the throw out bearing from the pressure plate. They changed the push rod design to a non adjustable system in July 72. That system should not bottom out and should have about 5mm free piston travel in the slave depending in clutch wear. Good to hear it was an easy fix. Im suprised the system could disengage the clutch when the old clutch disc was in it. The old disc must have been very worn to help compensate for the shorter travel in the MC. Thats becoming more of a problem with parts stores these days. They are not experienced in these older cars. The clutch MC is used on various vehicles, but then with different length push rods. Chas

-

Swapped clutch.... no engagement!

Are you using the slave cylinder with the return spring? If so, you probably need to adjust it for the "new" disc. When the clutch disc wears, it moves the clutch fork towards the slave cylinder and the push rod need the be adjusted accordingly to fully engage the clutch. The new disc will move the fork away from the slave cylinder, but the spring on the slave cylinder will pull it back. the throw out bearing is probably some distance off the pressure plate fingers. You can check this by removing the spring and checking how far you can move the clutch fork. Adjustment: 1.5 turns on the adjusting nut is 2mm on the throw out bearing to pressure plate distance. The correct adjustment is to screw the adjusting nut until the throw out bearing contacts pressure plate and then turn back 1.5 turns which will give you 2mm clearance at the pressure plate. Chas

-

Relay Bracket Details - What Relays Go Where?

Mine the fastest Zed in town. Oh wait a minute, its the only Zed in "my" town. Does that still count:)

-

Fuel Injection/Fuel pump combination relay options

I found some old photos of the JECS when I had it apart. I have been using the Bosch version for two years and no issues. I changed them because I suspected the relay, but it turned out to be a loose terminal plug in the AFM cable. Chas

-

Relay Bracket Details - What Relays Go Where?

Captain, Here are some photos of my relay bracket. The car is a stock Californian 5/77 manual transmission with A/C.

-

78 280Z - no injector pulse

I think they changed over to the Oil pressure sender around August 77. Mine is May 77 and has it in the AFM. If the treminals on the sender are damaged, they could be causing problems with fuel delivery or lack of it. It must be frustrating not being able to dash out and try things. Good luck getting her back home. Chas

-

260z u-joint question/ bad tranny noise.

If its a throw out bearing or pilot bearing problem, you could test it by warming up the engine with it in gear and the clutch disengaged. That will heat the two bearings without heating the transmission. Shouldn't take more than a couple of minutes. Then take it for a drive while the tranny is still cold. While your under the bonnet, climb under and pull back the rubber boot on the clutch fork back. It helps the noise escape and you can hear the bearings a little better. Its a dust cover, but it also does a good job muffling the sounds in there. Could also be the clutch plate torsion springs, but seems unlikly they would wear out before the clutch starts slipping. Chas

-

Relay Bracket Details - What Relays Go Where?

I have some photos of mine when I was cleaning it up. Im at work so I can post then this evening if you want. From what I can recall, its like Rob says. Voltage regulator en A/C relay in the manual trans model.

-

260z u-joint question/ bad tranny noise.

You should have the replacable type in the early model 260Z. It is easy to check by checking for circlips on the inside of the yoke flange. The "280Z" model had indents on the outside to hold the caps in place. The caps are also smaller in diameter than the 240Z type. Spider cap diameter: 240Z to 260Z nov 74 are 25mm. 280Z 22mm and non servicable. Does the tranny noise reduce or change when you put pressure on the gear shift? You mentioned brass bushings in the selector. A lot of people like changing the plastic bushes for brass, but if they wear they can rattle. Its almost unbelievable how much noise can be generated from two metalic components chattering. Its could be possable after the tranny warms up and the oil thins, transfering your uni-joint vibration through to the selector. I think it was Grannyknot that had a similar rattle noise caused by the gear knob. Something to check. Chas

-

Fuel Injection/Fuel pump combination relay options

If it is the relay, and I doubt it, you can try the bosch type 0 332 514 120 New Porsche 912E96 Fuel Injection Relay 0 332 514 120 | eBay It works on the 77 280Z. I know because Im using one. I have a couple of spares (Jecs and Bosch) and Im with Zed Head, they don't seem to go bad very often. Chas

-

U-joint greasing problem

Welcome to the forum Mike. You don't need to keep pumping until it comes out the caps. Just a little inside the spider and centrifugal force will do the work for you. It will work its way out to the ends of the spider when the uni is warm and turning. Its not good to pop the seals each time you grease them. They can stay dislodge and allow dust and grime to get in and destroy the uni-joint. I have used the GMB uni-joints on half shafts before. They came with an extended zerk fitting, but no plug to cap the uni-joint after greasing. I replaced all four zerk fittings with grub screws. Probably wouldn't effect vibrations, but one less source the better. That was my theory. Chas

-

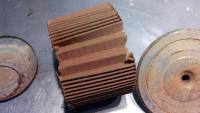

Check your fuel filter!

I don't know if the filter was original Nissan or they outsource and slap a sticker on it. One thing is for sure, Ill be changing it more often. Thank you Sarah. Two were in our department and going on holiday, the other two were external (I didn't know personally) and were on their way to an Aids conference. Keytruda is for treatment of skin cancer. Its one of the Anti PD1 therapy drugs. You will find it by googling MK3475. Pembrolizumab - Wikipedia, the free encyclopedia Chas

-

Check your fuel filter!

I was too late home from work yesterday after celebrating the release of a new product and team building after the loss of four colleges in MH17. I found the old filter. It had a "Nissan" sticker, but its no longer readable. More alarming was the rattle it had when you shook it. Something was loose inside. I can't remeber it rattling like that when I removed it, but then I was more concerned with the water I had in the fuel. Looks like the element had let go from the metal sections. Certainly wasn't filtering well like that. The filter is two years old. Here are the photos of the filter and the contents. Chas

-

79 280 into 72 240

Hi Diseazd, Will the exhaust manifold line up ok one the N47 head? It has the round exhaust ports and the head he has now has square ports. On a stock engine it probably won't make a noticable difference in performance and he is going to L28 which will more than compensate. Chas

-

Check your fuel filter!

I still have the one I changed when I had water in my fuel at the beginning of the summer. Its an original Nissan or at least it came from Nissan in a cardboard box with their name on it. Can't remember seeing any Nissan part numbers on it, so they could be sourcing them elsewhere these days. Ill cut it open tonight and see whats in it. Chas.

-

Noobie 73 240z WA

Im not sure why O Reilly is offering two different seals. Nissan quotes one for the L24 through to the L28 at $6.21 P/N: 13042-A8600 For 6 bucks I would go original. That way you will know it fits. Here is a link to the parts manual for the S30 Datsun 240Z/260Z Cylinder Block & Fitting L24, L26 (To Nov.-'74) SEAL-OIL :: Nissan Parts, NISMO and Nissan Accessories - Courtesyparts.com Good luck with your project. Looks like a good find. Chas