Site will be going down for maintenance today

Everything posted by Zed Head

-

1977, 280z with FS5W71B transmission

Did you do these three things at the same time? Maybe there's a problem with the transmission, not the rims or tires. Or maybe something got bent when the car was lifted to put the wheels on. If you used the rebuilt transmission with the old wheels and didn't have the problem then you can narrow it down to what happened when the wheels were put on. Since it worked well before it is most likely a problem that was created when the recent work was done. Don't get distracted by other things. Look at the work that was just done.

-

The Dreaded Vapor Lock

So, considering your last post about deadheading the metal rail, it seems that the big difference might be the rubber hose versus metal lines. Maybe the key is fuel temperature before it gets to the bowls. The cooler the better. We've talked about fuel differences in the various EFI heat soak threads. Fuel quality varies across the country. Might explain the AL versus MI difference. Could be a winter blend thing also. Jeff G were you running aviation or race fuel, or pump fuel?

-

The Dreaded Vapor Lock

That is pretty severe "vapor lock" if it happens just sitting at idle. Is this on a car without a fan shroud? Sitting out in the hot sun with the hood closed? The carbs need air flowing past them to cool, the coolant flow is for the engine. A quick test might be an electric fan under the hood pointing at the carbs. See what happens. Jeff G, is your deadhead mod using the mechanical pump or an electric pump? Your solution creates more pressure in the supply lines. I wonder if VaCat33 has the proper orifice in his return line. Or if a smaller one would help. A quick test might be to clamp the return line to create a deadhead system. If it helps then your solution should do the same. Things to "try" that might shed some "light".

-

Hot/Cold knob not moving

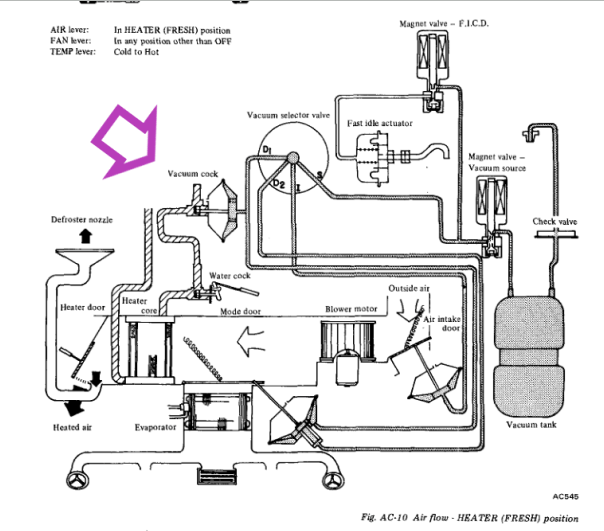

Yes, they're both up under the dash behind the glove box. Easy to see. The vacuum cark has a vacuum hose connected to it. If I remember right if you lose vacuum to the vacuum tank it stops working, no heat. So your problem might be under the hood. I had a problem with the hose splitting, and got used to fixing it when I suddenly didn't have heat.

-

Hot/Cold knob not moving

-

Need clutch disc, not kit

-

Need clutch disc, not kit

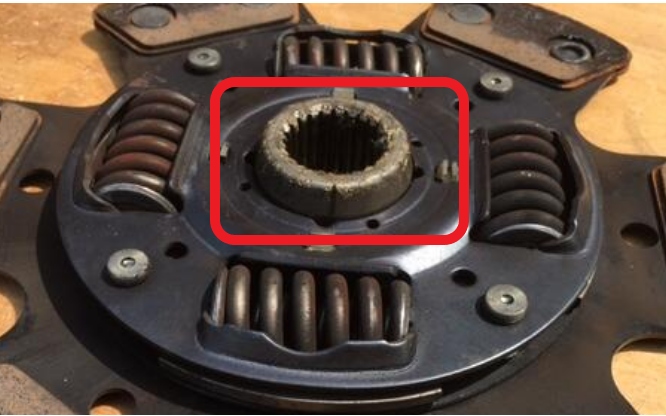

A picture would be neat. You're saying that Mcleod's products are of low quality. Which do you have, it looks like there are two types of disc. https://www.mcleodracing.com/sport-compact/c28 Any aftermarket disc should work. Pick your favorite brand. https://www.rockauto.com/en/catalog/nissan,1976,280z,2.8l+l6,1209226,transmission-manual,clutch+friction+disc,10605

-

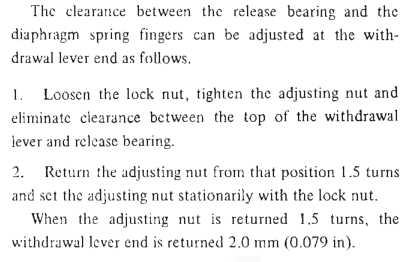

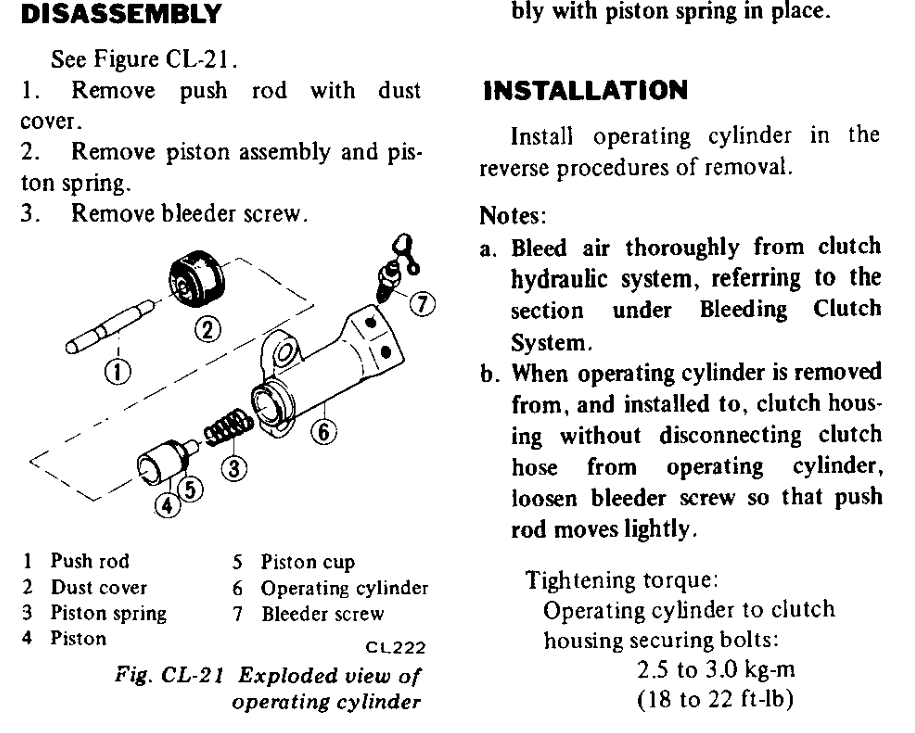

Clutch Won't Disengage

The play looks okay, but does it work? Don't forget to put the return spring back on. Also, with the rubber boot off it's more apparent that you probably have a short throwout sleeve/collar. The fork should start a little ahead of the middle of the hole. Yours is pretty far back. Probably close to hitting the back of the hole at full stroke. It will probably work. Earlier I think I said that problems might happen as the disc wears. But actually things should get better since the fingers get closer to the TOB as the disc wears.

-

Clutch Won't Disengage

The leak in the MC would be internal. Unable to build pressure at a certain point in its travel, then lets the fluid back in to the chamber as the piston retracts. The slave cylinder can contain a lot of fluid inside the dust boot without leaking. You need to get proper travel from the hydraulics. It's critical.

-

Clutch Won't Disengage

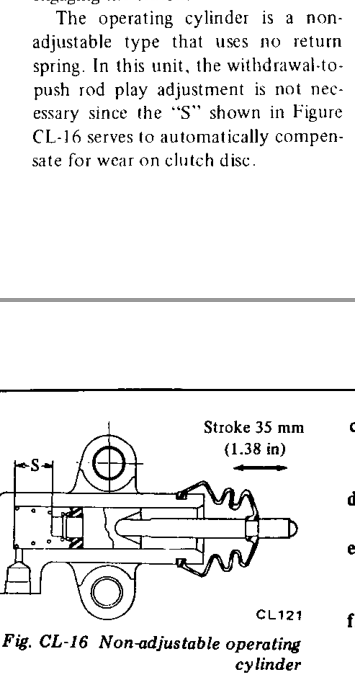

I had a weird situation where the slave cylinder was leaking and I only got 1/2 of the expected travel from the cylinder. It moved when I watched it but it wasn't moving far enough. Could also be a leaky spot in your MC. I would measure the travel distance to be sure that you don't have a hydraulic problem. I think that EuroDat has published the distance that the slave piston should travel. I haven't figured out if Nissan meant that available/possible travel was 1.38" or if the piston was supposed to travel 1.38" when the pedal was pushed. Not clear.. I think that they must mean that it should be 1.38" when you press the pedal, since the end of the bore is open, and full stroke would be essentially unmeasurable. Either way, it would be good for you to know the number. And, if you do take it apart consider getting a later clutch fork and use a self-adjusting slave cylinder. It's an improvement.

-

Clutch Won't Disengage

Never mind. That wouldn't work.

-

Clutch Won't Disengage

-

Clutch Won't Disengage

-

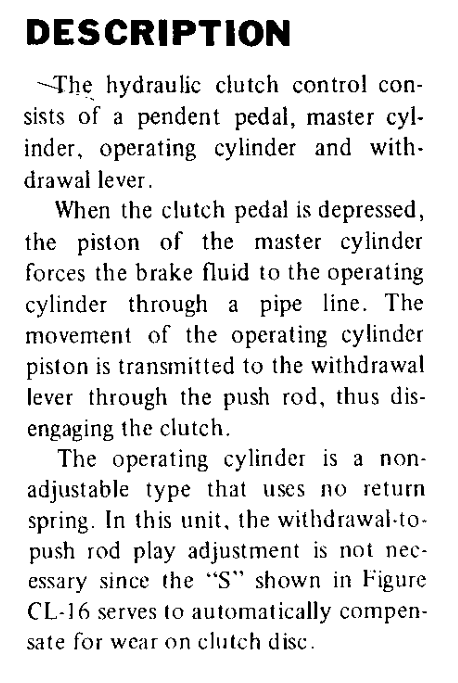

Clutch Won't Disengage

It's interesting that when Nissan went to the self-adjusting operating (slave) cylinder that they put a very light weight spring in the cylinder to take up the play. Which means that the gap gets reduced to zero, but with no significant force. I wonder if that has something to do with the noise that people often hear, that many have assumed is the countershaft bearing. Maybe it's the clutch fork rubbing on the throwout bearing. A person would have to hear the noise, open the hood and reach down to the cylinder and pull the rod back to be sure, I'd guess. Or get a helper to do it. Just a thought I had when looking at how the self-adjuster works. There is no 2 mm gap.

-

resurrecting a 1977 280Z

There's probably no countersink.

-

Clutch Won't Disengage

There's no real "sweet spot" to find. Pressure cannot be maintained on the clutch fork once the pedal is released because the fluid will return to the reservoir. The beauty of the hydraulic system. In other words when you make the rod longer once it touches the fork, (edit) and the fork is touching the pressure plate fingers, you're just using up potential travel if you extend it further. There's no reason for the clutch to slip. If it is releasing fully you should be fine. Good luck.

-

resurrecting a 1977 280Z

There are several. They call it a "friction kit". Use that term. https://www.fidanza.com/pages/catalog-search-sd

-

resurrecting a 1977 280Z

Fidanza's web site is pretty poor, the search engine doesn't find anything, but Google did. Here's an example of a replacement plate. Not sure if it's right for yours or not. Probably best to call them. https://www.fidanza.com/products/copy-of-flywheel-friction-kit-229501?variant=14995559841835

-

Which GM HEI Module ?

1976 Camaro will work. https://www.rockauto.com/en/catalog/chevrolet,1976,camaro,5.0l+305cid+v8,1035065,ignition,ignition+control+module+(icm),7172

-

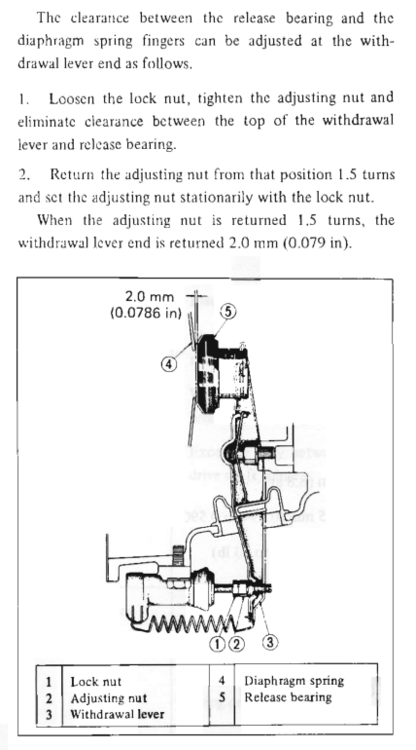

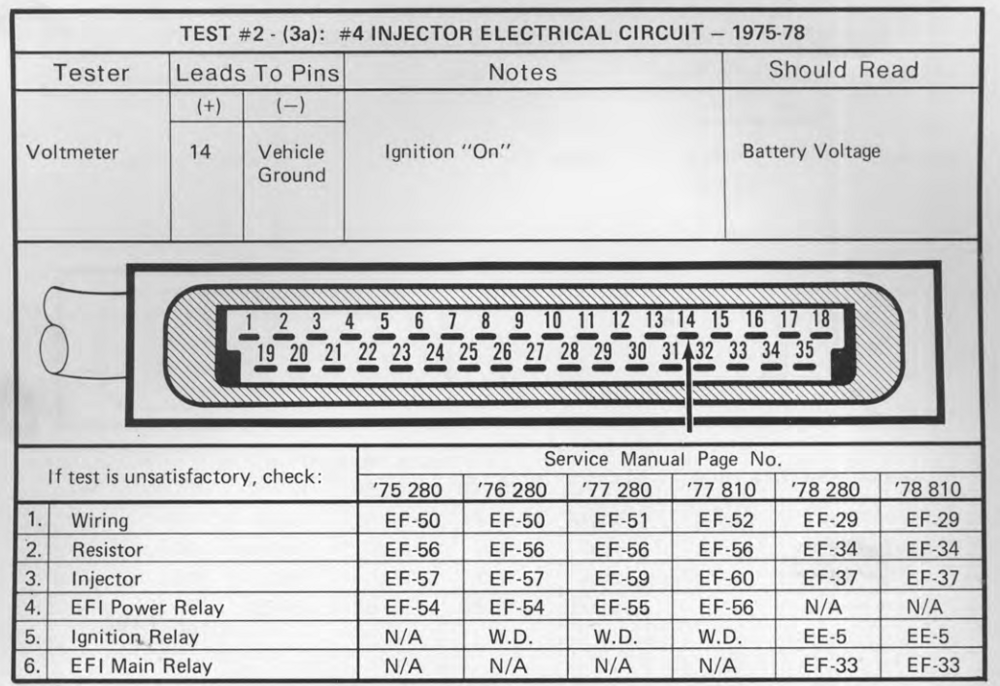

Injector Voltage

Low fuel pressure comes to mind. Clogs, bad pump, bad filter. Easy to check. Very important.

-

Injector Voltage

The gasoline was fine. The injectors just didn't flow evenly. I drove it that way for quite a while. If you told use what "not great" means we could have more fun.

-

Injector Voltage

How long has it been sitting? Here is what my six injectors produced at full flow on my engine after I bought a long-sitting car. That's gasoline.

-

Injector Voltage

Have you calibrated your eyeballs?

-

Injector Voltage

-

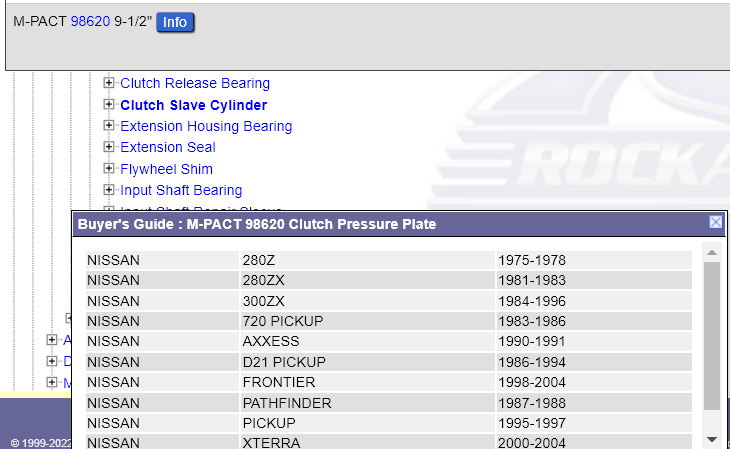

Clutch Won't Disengage

The last 1/2 inch might be the pilot bushing in the crankshaft. You haven't said if the fork is hitting the back of the hole. Looks like the vendor might be right. The 240 mm pressure plate does fit many different applications. I think I might have known that once in the past. https://www.rockauto.com/en/catalog/nissan,1990,300zx,3.0l+v6,1209686,transmission-manual,clutch+pressure+plate,1988