Everything posted by Zed Head

-

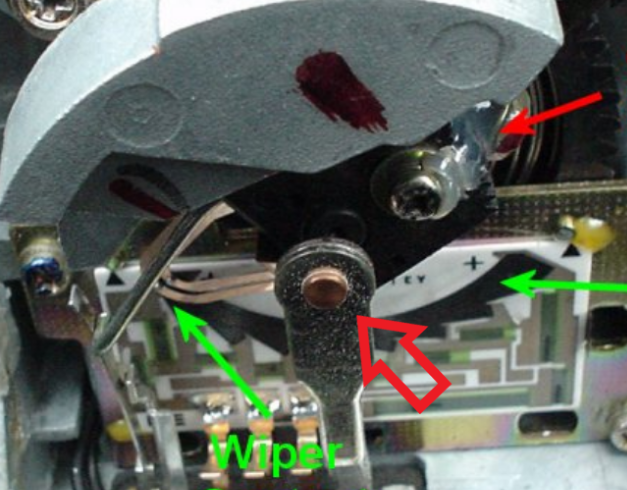

AFM Loose Arm

That's not really tuning. It's just messing with things. When you change the tension on the spring you alter the air-fuel ratio curve over the whole of the air flow range. You can't pick a spot and "tune" it in. p.s. the procedure from atlanticz is meant to get the AFM back in spec after people mess with the spring and ruin the AFM performance.

-

AFM Loose Arm

I think I answered the question earlier. If you really believe that there is play that is causing the wiper arm to lose contact with the conductive trace then you'll have to find a way to take it apart. The AFM rebuild guys do it. But they have skills and special tools. There's almost always a way to get things done.

-

Won't run if tach connect?

Probably messing with the make/break circuit to the coil. Have to see how the whole system is wired to know what's really going on.

-

AFM Loose Arm

Might be that there's a problem and you're assuming that it's caused by some wiggle you see in a part. Probably better off to describe the actual problem and see where other people end up as far as the cause. And, p.s., these EFI systems aren't really "tunable". So, not sure what you guys are trying to do . Good luck.

-

AFM Loose Arm

Actually, not sure how this translates to losing contact with the wiper. Not really sure what the problem is. Posting anyway even though there's a reply...

-

AFM Loose Arm

It's worth big money as a core though. Don't throw it away or smash it up.

-

AFM Loose Arm

The vane should be binding up in the housing then. From the pictures it looks they stake the ends of the shaft. Doesn't look like it's meant to be disassembled. You'd have to wing it and get creative. Basically, it sounds trashed otherwise.

-

AFM Loose Arm

I don't think the AFM would even work if the contact arm is losing contact. Are you sure you're not watching the weight move? It might have play. The vane would probably bind if it was loose on the shaft. A picture or video might help the cause. I see rivets. Here's some links. http://www.atlanticz.ca/zclub/techtips/afm/index.html http://www.atlanticz.ca/zclub/techtips/afm/sizeupgrade/index.html

-

‘77 280z signal fuse keeps blowing up

Actually, it might be a direct short that only happens every few days. Second-guessing myself... Touch the fuse after driving for a while and see how hot it is. Be careful, it might be really hot. That will be a clue if it's a fuse on the edge of melting that finally does after a few days, or if it's a sudden direct short.

-

‘77 280z signal fuse keeps blowing up

The plastic bulb sockets have been known to get hot and deform allowing the electrodes to move and touch things they shouldn't touch. You might pull all of your bulbs and check the sockets. The fact that the fuse lasts a few days suggests that it's not a direct short. It is a current leak to ground or another circuit that is overheating the fuse. See if any filaments are lit up that should not be or that are dimmer than expected. Might be a clue.

-

4 Speed Bell Housing swap to 5 Speed Case : FS5W71B : Reverse Switch Modification

Maybe it's from one of the 4 cylinder NAP? ZAP? ... NAPS-Z twin plug engines. Apparently they were vertical. Did you measure the length? That's another possible difference. Gear ratios might be interesting also. From the cloud. I don't know much, just remember them from the wrecking yard in the small trucks. - https://en.wikipedia.org/wiki/Nissan_NAPS https://en.wikipedia.org/wiki/Nissan_A_engine

-

Question on seat mechanism cover application

carpartsmanual shows that the change is at Jul/Aug 73. So, they might be right. http://www.carpartsmanual.com/datsun/Z-1969-1978/body-260z-280z/2-seater/seat-slide http://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/seat-slide/type-2-reclining-seat

- Timing Off Runs Bad

-

Timing Off Runs Bad

I forgot who made the universal base plates for the distributors. They're a member. That opens up options. For what it's worth, the brand name "Mallory" doesn't mean much for what you're trying to do. It might have some collection value, if it is an actual Mallory-made product from the past. But really, it's two advance mechanisms and a way to distribute the spark. Many ways to get that done. You might put a set of points back in while you're thinking. Then you can get on with carb tuning. Points work pretty well, they've been around for years.

-

Timing Off Runs Bad

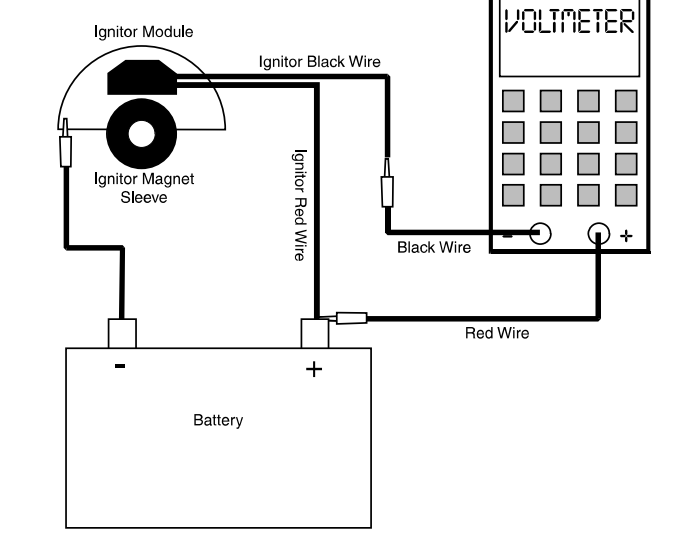

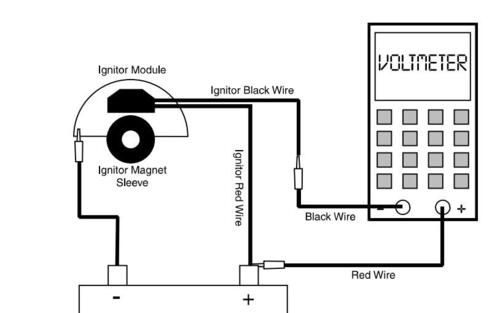

You can see by their diagram that the module grounds through the distributor body and the mounting screws to get to the engine block and complete the circuit . Might be that by loosening all of the various mounting bolts you lost your ground. Attach a wire directly from the distributor body if you want to be sure the module has a good ground. It's actually the most important one for spark strength.

-

Pertronix Ignitor I test methods

-

Timing Off Runs Bad

I found a test method for the module itself on Summit Racing's site. Worth reading... https://static.summitracing.com/global/images/instructions/pnx ignitor i tests.pdf

-

Timing Off Runs Bad

Bummer. Could be that you just lost a connection somewhere. Get out your meter. Don't overlook grounds. The Ignitor I is susceptible to overheating if the key is left on too long. Hopefully that's not what happened. https://images.carid.com/pertronix/products/pdf/1183-installation-instructions.pdf "2. Leaving the ignition “ON” with the engine “OFF” for an extended period could result in permanent damage to the Ignitor."

-

Timing Off Runs Bad

Did you try the coil main wire to check for spark? Maybe your ignition system is weak or dying and that's why you 've been having problems. You shouldn't be able to get a full twist on the distributor without one magnet at least passing by the sensor. You should be able to generate a spark. The twist is not meant to line up the rotor, it's meant to move the sensor past a magnet, to generate a spark. Make a spark then see if you can get the rotor pointed at a terminal.

-

Timing Off Runs Bad

Here's an old thread showing the green tape and the magnets underneath. There are six magnets. Might just help you absorb all that's been written so far. We're still at trying to get spark to happen on the #1 plug wire when #1 piston is at about 10 degrees before TDC on its compression stroke. You've pretty much covered all of the separate issues, just need to to put them together.

-

Timing Off Runs Bad

You could get everything aligned and set up the coil's center wire close to a ground where you can see the spark. Then turn the key on and twist the distributor until a spark happens. You'll be moving the sensor past a magnet instead of vice versa. Move it around until the spark happens where you like it and put your #1 plug wire at the proper spot on the cap. You should be close then.

-

Timing Off Runs Bad

You're working on a modified system so knowledge of how the ignition system works would help you a lot. Even if you installed the distributor and oil pump shaft exactly as Nissan instructs, the odd parts in the distributor will probably be off. You have Nissan, Mallory and Pertronix all combined. The Pertronix is a Hall effect sensor so you can use a meter to determine when the magnet passes the sensor. But...more knowledge required. If you remove the rotor and take a picture of the top of the magnet ring the position of the magnet might be apparent. It's important. And, just in case you bumped something, the gap between magnet and sensor needs to be right. It can cause sporadic spark if it's not.

-

Timing Off Runs Bad

Don't forget that the spark happens when the magnet on the shaft passes by the Pertronix sensor. One more thing to line up. Trigger, rotor, compression stroke on #1, plug wire. The magnets have been known to fall off.

-

Z's on BAT and other places collection

Early low number Series(?)1 survivor(?) automatic 1970. Should be interesting. https://bringatrailer.com/listing/1970-datsun-240z-90/

-

1983 280zx turbo engine

You could probably pull from the top of the open block with a pump like that.