Everything posted by Zed Head

-

Somethings wrong...

Can you give more detail on the "rumble" noise? I got: a rumbling noise, a lack of power under load, and sudden engine dying, as the three main symptoms. Have you checked the air filter and housing? Maybe a rodent moved in. I've seen 'em do it. It's a great home, with a private entrance. Wasn't the engine suddenly dying one of the original problems?

-

Melted wire coming off alternator

I probably wasn't very clear in what I meant. I think that there are other ways to tell if you have a regulated or non-regulated alternator, without taking it apart. The marks on the outside of the case, or the shape of the case, or even just measuring what the wires supply. You can easily supply a new "S" wire with a jumper directly to the battery positive. Just for a test. Most melted wires are caused by battery amperage (edit - had voltage), not alternator. The battery is a huge reservoir of amps waiting to get out and cause damage.

-

Electric fuel pump conversion question

Nada for moi?

- CLSD R200

-

apples to apples, dust to dust

I saw the comment about you in the other thread and thought "what compelled him (the commenter) to make that comment, in that manner, referring to grannyknot?" It was completely unnecessary to his point to include you in his comment. Plus, he must know he wasn't welcome in the thread. It was flowing nicely. The internet is a strange place, full of strange people. Edit - tried to find the comment but can't. Maybe Mike got rid of it. Good...

-

Melted wire coming off alternator

Sorry to destroy your joy. Don't take this wrong, but I think that your energy might be misdirected. There are other, easier, ways to determine if your alternator is internally regulated. Also, easy ways to determine if a shorted wire caused the melt. Love the effort, just might benefit from being repointed. I do have my own disassembled alternator in the garage though, and an old thread describing how I was looking at the wrong diodes. I was on your path. That memory led me to the Rockauto picture. I have a replacement regulator (like the picture but just the regulator) in my garage (they're cheap), that I never installed because that wasn't the problem.

-

CLSD R200

Good point. He must have confused his turbos. And missed a year. Nissan only used the CLSD in the 86-89 300ZX turbo cars. Not the 280ZX turbos. The other somewhat popular option is the OBX diff. It's a knockoff though and takes some extra work to get working properly.

-

Electric fuel pump conversion question

Whoa.... I broke a sweat just reading those two posts. And we're in the middle of an ice-storm. He could also just carry a can of starting fluid.

-

240z Backfiring at idle and any rpm HELP

Since you don't know the history, and it doesn't run well enough to tune, your best path is to verify that the various rotating parts are timed correctly. Hatepotholez is going through the same situation and just found that his damper pulley might have slipped, for example. I would start with the ignition timing mark on the damper pulley at zero and verify that the cam shaft is in the proper orientation, the rotor in the distributor is pointing at the correct electrode, and the plug wires are properly placed. 1-5-3-6-2-4, counterclockwise, like site's picture. Then rotate the engine by hand and check valve lash, correcting any that are off. The older engines are known for worn valve seats due to unleaded fuel. That could cause some backfires, or popping back through the intake (some people call that front-fire, I think). They're also known for throwing lash pads, which would cause the valve not to open fully. Anyway, you've spent enough time on it to justify starting from zero. Set all of those things once, and you won't have to wonder about them.

-

240z Backfiring at idle and any rpm HELP

Try to get more methodical. I don't see valve lash adjustment on your list. That's the first item in the later years Engine Tune Up chapters. Borrow a timing light and actually set the timing to where it should be so that you don't fix the problem but still have the symptoms because the timing is wrong. Use a meter and measure voltage at the ballast. Measure resistance of the resistor. Find out what the other end of that hose was connected to. Better to know than guess. Seriously.

-

Electric fuel pump conversion question

He's just asking how to be sure the pump will supply his carbs so that his engine will start and run. Once the carb's float bowls get filled after the first start it will probably be fine. It will start on float bowl fuel. BUT, study the FSM description closely again. Usually Nissan bypassed the RPM or oil pressure or AFM (for EFI engines) control when the key is at Start. So there might not actually be a problem. SteveJ is a 260Z guy. He might know. @SteveJ.

- CLSD R200

-

Melted wire coming off alternator

What does tl dr mean again? I always forget. I think it would be on the other side. Compare the curve on the brushes.

- L28 Stroker Build - I need your advice :-)

-

[2017] What Did You Do To/with Your Z Today?

This is my favorite part of the story from your Fiddling page - " That was when Michael went looking around in the shed. He came back out with the aftermarket AC evaporator. It had the TIU attached to the backside of the bracket that held the evaporator in place. " The full size cool-looking aluminum finned 260Z TIU? Maybe he thought it was overheating...

-

[2017] What Did You Do To/with Your Z Today?

Alright, I read the story. Now I feel right and wrong at the same time. Looks like you could have used some "O" of OCD - " Unfortunately I didn’t do much besides glance at it. (Keep that in mind.) " I'm impressed overall, that you were able to mentally assemble a tool inventory and get them all packed up and out there. Most of us would have come up at least a tool short. Kudos.

-

[2017] What Did You Do To/with Your Z Today?

Isn't the ballast bypassed during Start? So, it would be a running problem, not a starting problem. Sorry, I have OCD without the O. Can't help it.

-

Clean '73 240Z at a Very Low Price!

And? @fishingchampion

-

OE camshaft and cam gear markings?

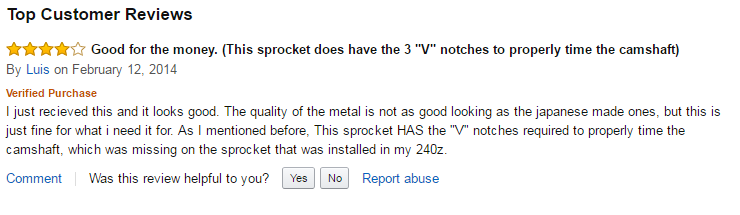

I remembered some past comments about sprockets that didn't have a notch. I thought that they were Cloyes brand so I searched around and found a comment on Amazon about the S462, which is the L6 sprocket. The comment doesn't support that it was Cloyes but does mention that he had a sprocket with no notch. So they are out there. Probably just an oversight or a manufacturing mistake. The sprocket is fairly easy to replace (if you don't drop the chain). If you have a used one with the notch, it might be worth a few minutes to swap them out, just to see.

-

OE camshaft and cam gear markings?

By the way, I always talk about the notch and groove because I have a 76 L28, a 78 L28 and a 1980 L28 and they all have the notch and groove. There are probably 240Z guys out there who don't know what I'm talking about and have always used the shiny links and/or counting to 42. Seems like there should be another way using cam lobe position, a little more precise than "pointing up", if you don't have the notch and groove.. Not sure exactly what it would be though. Actually, in motorman7's thread, he does point the locating dowel up (but the motor is tilted so...?). So that might be a good method. Remove the bolt and washer and you should see the locating dowel hole. Easier than removing the front cover. Even if the motor is tilted, if you align the crankshaft keyway with the locating pin, that's very close to right. The number might be visible also from behind the washer, but you won't know if it's stamped directly over the locating dowel hole.

-

OE camshaft and cam gear markings?

I think that I implied this in your other thread - it looks like Nissan didn't use the notch and groove on the early engines. That's why the early procedure calls for counting 42 links during installation, or using shiny links, and they don't talk about the notch and groove. The notch and groove are an easier way to confirm proper installation and to monitor chain stretch, that they apparently added later. Here's a thread that has an excellent picture of the notch (the second picture), but uses the link counting method for installation. It's confusing if you have an early engine. It's not clear which engine motorman7 is working on...

-

HELP PLEASE

The CHTS is in the vicinity. If it's connected, a meter reading at the ECCS connection would be worthwhile. I'm all about taking measurements before replacing anything. It's cheaper.

-

HELP PLEASE

Did you work on anything at all in the engine bay? Sounds like you knocked the CHTS plug loose. You'd think that the filter should have caught any crud that was stirred up. A fuel pressure measurement would tell if the fuel supply is correct.

-

Crazy weather

Woke up to teen temperatures a week ago. Today, teens. Record low. The snow (that really shouldn't be here) is not melting.

-

Re: Master Cyl - to bleed or not to bleed after replacing Master-vac

With a bench bleed you can do both front and back at the same time and use hoses run back up in to the reservoirs instead of plugs. You're not trying to build any pressure just to move the piston through its stroke so that it pushes all air out the bleed ports. When you're doing it you want to pay attention to where the outlets are and orient them upward so the air bubbles will be there. Not positive but I think that I "bench" bled mine while it was connected to the hydraulic lines in the car but not bolted tightly to the booster. So that I could put som etilt on it. You can also tilt the car to get the parts at the high point. It's all about the air bubbles. Be the bubble.