Everything posted by Zed Head

-

Putting in a replacement L-28

That's a good summary. The aftermarket guys probably went cheap on their design and just grind the tip in to the bottom of the hole or let it sit above the bottom, not contacting. I was wondering about the washer also. No point to it if the sensor tip is supposed to make contact.

-

Car will not start

Engine spins way faster than it should. Like there's no compression. Have you ever measured cylinder pressure? I posted this picture of your cam lobe earlier. It looks like wear on the base circle which should not happen. Like there's no valve lash. Who last adjusted valve lash on the engine? Looks and sounds like the valves are all hanging open.

-

Putting in a replacement L-28

I agree. But thanks for clarifying, I think that you are right, Obviously. Now that you bring it up, I do remember the bottom "spinny" portion on the ZX parts. So, maybe, probably, it's just a one-way possibility. You can put a Z sensor in a ZX hole but you can't put a ZX sensor in a Z hole. Or maybe you can't do either, although I think that Av8ferg did, if I read his words correctly. He should be just fine, right? I was surprised at the prices. Things are getting expensive in Z world. So, a one-way swap, Z part in ZX hole, looks reasonable. Might help the wrecking yard and CL searches also.

-

New Oil Pump Installed, now hearing noise from engine?

If you read Diseazd's thread you'll see that he was too. That was the point - the MSA recommendation did not work correctly.

-

Putting in a replacement L-28

The main reason I let them know is so that they don't have a problem that goes on for months or years, damaging their business, because they did not know about it. They've been around since land lines but things are changing. Trying to help them keep up.

-

New Oil Pump Installed, now hearing noise from engine?

These two were at the very end of the search I posted. Searching is definitely more difficult than it used to be. Hard to find the right place then get it to do what you want it to do. I used the CZCC function this time but usually I just use Google and "site:classiczcars.com"

-

Fusible Links Smoking

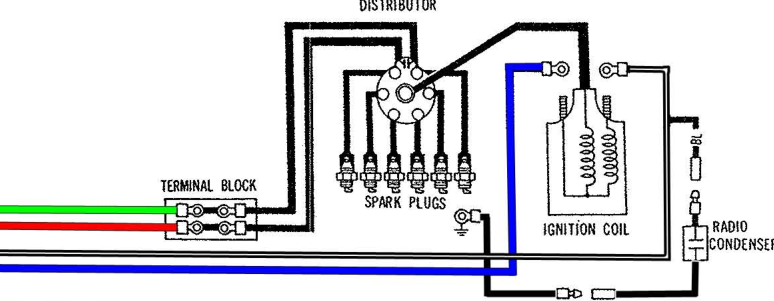

That box is the junction point for the wires from the distributor to the wires from the ignition module. With the factory setup there would have been a green and red wire from the distributor connected there too. On a reman distributor the wires are blue. Since your ignition module is connected to your distributor in the engine bay, and the ignition module inthe cabin is disconnected, the wires at the 6 sided box aren't connected to anything. They can just sit there. Here's the 78 wiring diagram that somebody colorized. They don't show the full shape of the terminal block.

-

Putting in a replacement L-28

The resistance versus T is the same. Fitment would be the issue, I'd guess. Might be that Nissan just modified the connection part because it had a tendency to fall apart like mine did. From the 1980 EFI book.

-

Putting in a replacement L-28

Other manufacturers have moved to dry cylinder head temperature sensors. I have a Ford that has one and they actually use the reading for the "coolant temperature" gauge in the dash. And, it turns out, they just set the needle in the middle if the temperature fits within a wide range. Anyway, on the Z's Nissan went to the head sensor with the P79 and P90 heads in the ZX's. They look almost identical. The part numbers differ by one digit. Actually, now I see the difference. But I think that they have the same thread and can be interchanged. I accidentally pulled the guts out of one of mine trying to remove the connector. It's just a dry hole with a thermistor and silicone gel inside.

-

Putting in a replacement L-28

@Joseph@TheZStore @Greg@TheZStore @James@TheZStore @zcardepot.com

-

Putting in a replacement L-28

Hope you guys don't mind, I'm going to "at" the MSA guys and ZCD. ZCD never responds but I think that he does read the posts. The guys at MSA usually respond, and seem to address issues. The penny-saving on shipping seems like a new one though. @Joseph@TheZStore @Greg@TheZStore @James@TheZStore

-

Putting in a replacement L-28

Nissan used BSPT on their tapered plumbing fittings. You could probably take the old piece that fits in the hole and "machine" it to look better. Chop the connector off. I think that they all have a sealed well inside for the actual sensing element. Or maybe find a plug on McMaster Carr. Check/uncheck the boxes on the side to change the display. https://www.mcmaster.com/standard-pipe-fittings/thread-type~bspt/brass-and-bronze-pipe-and-pipe-fittings/type~plug/ The straight thread is probably BSPP. https://www.ralstoninst.com/news/story/the-difference-between-npt-bspp-and-bspt-seals

-

battery drain

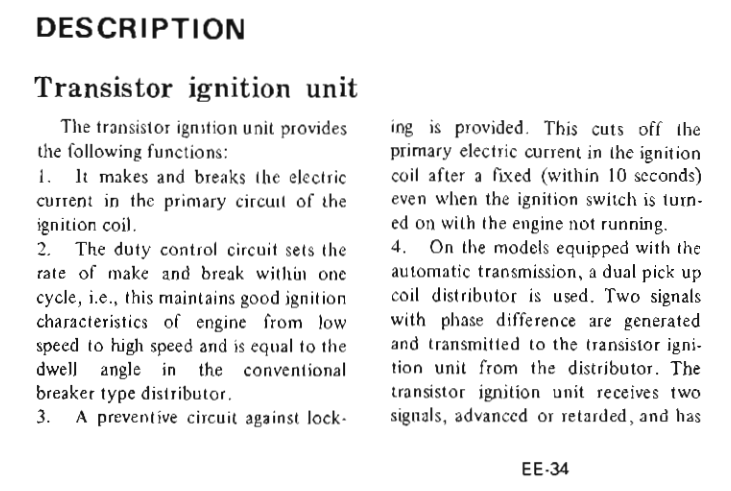

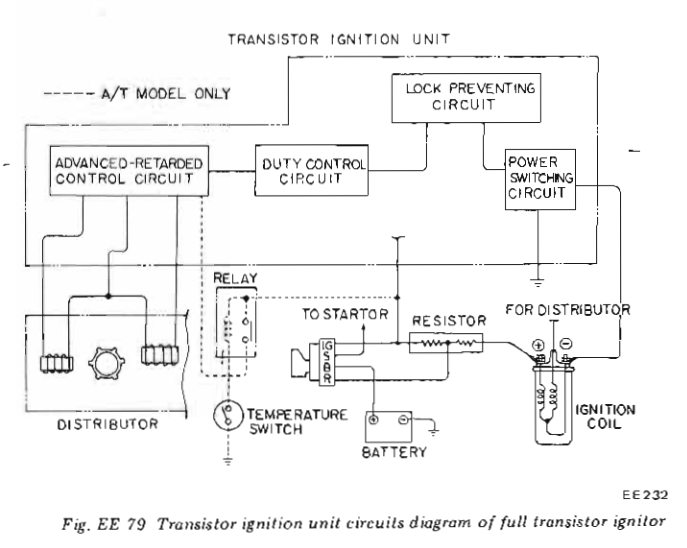

It says "lock preventing". I know it's just a translation error. Interesting though. There are better terms - current lockout? Current cut?

-

battery drain

If you have the factory ignition module you should see battery voltage minus resistance drop, then it should go to battery voltage after 10 seconds (no current). For what it's worth. Not really sure why they call it "locking".

-

New Oil Pump Installed, now hearing noise from engine?

https://www.classiczcars.com/search/?&q=damper&author=Diseazd&search_and_or=and&sortby=relevancy

-

battery drain

- battery drain

Shouldn't this be first? You can't have a voltage drop unless current is flowing. If you're seeing a drop at the ballast resistor that narrows things down to the ignition system. Except for the wires that are there as part of a terminal block. Nissan put extra terminals on the ballast that have nothing to do with ignition. Really though, if the problem is the battery dying with the key off, you shouldn't be looking for a voltage drop. You should just be looking for voltage. There shouldn't be any voltage at the ballast resistor with the key off. If anyone wants to summarize what the "current" problem is, feel free. I assumed it's still the battery dying.- New Oil Pump Installed, now hearing noise from engine?

You might check the tightness of the damper on the crankshaft snout. People often use the wrong combination of washer and bolt and end up torquing the bolt in to the nose of the crankshaft without actually clamping the damper down. Bolt too long, in effect. The key will keep the damper from spinning but it can still wobble around and cause damage. I think that @Diseazd might have a picture, if my memory is right. And, if you have AC, the AC belt idler pulley bearing is known for going bad and making noise.- battery drain

The 7.2 volts could mean a grounded circuit, either after the ballast or the coil, maybe at the ignition module or along the way to the module. If you had points I'd say check that your points weren't closed. Edit - p.s. the coil, or the ballast, or wires in the vicinity should be warm if current is flowing, giving that big of a voltage drop. Just spitballing. Hard to get a good grasp on the overall picture.- Fusible Links Smoking

It is. It's a on a branched circuit, and 1978 has a nice protected plug. Just unplug it and let it hang. OR, disconnect the FAST module and reconnect the original one. Not really clear why the FAST module was purchased and installed. Might be a clue there. The 1978 ignition module is pretty good.- Car will not start

You need to give more detail on how you tried and what, exactly, happened. Might be you turned the key, heard a click, and quit.- Car will not start

Pretty sure that one of these magnets (red) needs to be in the middle of the sensor (purple). There are other tricks a person can do with wires and voltage and turning the shaft but I think it would be a bit much for this thread. Turn the distributor body until one of those magnets is centered and you will be about as close as you can get for an initial start.- Car will not start

Check the trigger on the Pertronix first. I don't know how to do it, but it's important. I did some Google but the instructions are all for people who had a running engine before they swapped points. Can't find any "starting from scratch" instructions. It's probably as simple as lining up some marks on the sensor and magnet but I've never had one so don't know. If you do that you and confirm that the rotor is pointed at #1 plug wire then you'll have everything pointing where it should be pointing and it should start. Assuming...- Car will not start

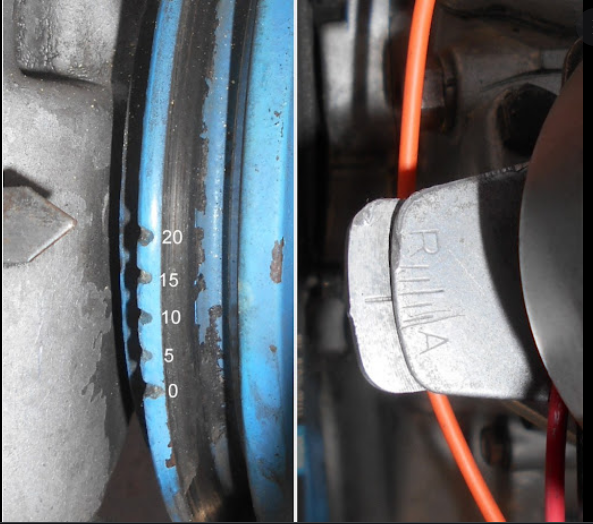

Nissan used both sides on the early cars. I think it had to do with air conditioning. That's about where you want to be. Now you just need to make sure that the Pertronix trigger is just about to trigger. If you had points or a 280Z system it would be pretty simple but Pertronix is a bit different, with the magnet.- Car will not start

I found this picture on the Google. (It's from zcar.com but it doesn't exist in the original post, so I won't link it). The picture on the left is of the bottom pulley on the front of your engine. You should be able to see if from the passenger side of the car. Shine a bright light down there and look. Those are your ignition timing marks. The picture on the right is of the distributor base. Nissan put degree marks right on the base of the distributor. Yours will probably be off because you have Pertronix now but they should be close. See if yours is between the A and the center mark. p.s. you don't have to remove anything or turn any bolts except for the screw that locks the distributor body down. - battery drain

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.