Everything posted by Zed Head

-

No headlights and blinkers.. Help an electrical idiot!

Have you checked power in to the fuse box? I don't know the early wiring well but if it was a 280Z you'd be checking the fusible links. The 73 240Z electrical chapter is surprisingly oblique and unhelpful. Also, as SteveJ inferred on the flashers, voltage can be present but current not guaranteed. I would rig up a test light that draws a small amount of current, for your kind of problem. Many people make up their own with a tail bulb or halogen head lamp. Two wires with a bulb in the middle. Measure voltage then hit it with the test light. If the light doesn't light, there's probably a break opening in the circuit somewhere, due to heat. The meter doesn't pull enough to cause it. If it does light, but not when the correct circuit is connected, then it's probably a ground problem. Just some thoughts on breaking the problem in to smaller pieces. p.s. I know that the backs of the 240Z fuse boxes can get pretty messed up. Problem not visible unless you pull the box up.

-

To shim or not to shim?

I'd go with the How to Rebuild advice, to start. The cam tower bolt torque spec mistake is well known, but seems to be the only significant one in the whole book. Put things together without fully torquing, if you have the time, and you'll be able to tell if you're going to have issues. Most of the shimming and work involved is for the purpose of getting the chain to do its thing without problems. Jeff G's advice is based on the principles of how things are supposed to be, a lot of advice is based on how somebody else did it and it "worked" (p.s. not directed at anyone on the site just the world in general). You'll probably end up in between, I'd guess. I think that 108 mm is the factory spec for head thickness. It converts to 4.25 inches. Significant figures and all that stuff. I think that lash pad height might be another reason to shim. If the top of the head was shaved, the cam towers and cam will be lower. So, if my guess is right, that's a whole separate reason for tower shims, after the chain considerations. I've not rebuilt a complete engine though, my engine rebuilding has been in my head and the internet, so I could be way off. But these are the things that crop up.

-

New to me, 280Z...

Barefootdan's engine was in much worse shape than yours appears to be. Don't get too far ahead in assuming major problems. A loose spark plug can cause a miss, but stuck valves or shot piston rings cannot cause a loose spark plug. Oll, gas, or moisture on the plug threads of a plug is not a surprise, the gases creep in to the threads and condense there. Put a clean set of plugs in and give the engine a good tuneup before assuming terrible things. The pictures show that a PO did some "hacking". The PCV hoses are not correct, the crankcase is open to the atmosphere. If the PO did not know about the hose under the intake manifold where the valve is the intake manifold might have a major leak. 76 has the fuel pump relay contact in the AFM and the AFM needs all of the air entering the engine to pass through it. Low air flow can kill the fuel pump power.

-

battery drain

Get this guy back on it. He probably has the tools, maybe, or can help you figure things out. And, big picture, your grandson might get more out of completing your project than just driving it. Who knows. I see potential surface rust plus dry seals here... But don't see the need to pull the engine.

-

battery drain

You're in a zone where you have to use some of your own gut feel. If you have a piece of tube that will fit tightly over the tip of the valve you could slip that over the valve tip so that you can hang on to it. Remove that rocker arm and see if you can rest the valve on the piston top without dropping it all the way in. Pull the valve up and spin it to see if it's bent. Really though, you're just assessing damage at this point. Even if you want to put it back together you'll need a valve spring compressor. If you don't have plans to do the work yourself you might be best off to have a pro look at it and give you an assessment. A pro with a bore scope could take a look and tell you there's piston damage, maybe cylinder head damage. Today's borescopes are inexpensive and powerful. You could learn a lot without taking it apart. If the valve head had been destroyed and come apart I'd expect the sparkplug to have been damaged as the pieces bounced around. It seems like maybe the valve took one hit, got bent, got stuck up in the guide, and the noise was the rocker rattling off of the cam lobe as the engine kept running. You're most likely going to have to remove the head, it's just a matter of how much you want to do before making that decision.

-

78 Z - Water Temperature Switch - Blue Wire - Help!

It has the 78 fuel rail. But many of the factory hose clamps have been replaced, so somebody has definitely had those parts off in the past. Typical mystery motor. You can piecemeal things, or do a thorough tuneup in one shot. You'll probably end up doing everything by the time you're done. Compare mileage to valvetrain condition and you can probably see if there is $8000 in there. There are other external clues too.

-

New to me, 280Z...

Looks like you have bigger wider wheels also. The wheels on the Z's sit forward in the wheelwells. It bothers some people and they try to center them, but that takes a lot of work.

-

battery drain

If you are super super lucky. He's saying to find a way to hold the valve stem up so it doesn't drop in to the cylinder if the piston is down. You could also rotate the engine to bring the picton up so that it will hold the valve up while you collect those parts that are scattered around. Or you could remove the spark plug and fill the chamber with rope or tubing. Many tricks. Don't rotate the engine until you have a plan. In the meantime - have you removed the spark plug yet? If the electrodes are all smashed up that means there's been valve head damage and the head will have to come off. You can also shine a light in to the hole to see if the piston is up. You can learn a lot just by removing a spark plug.

-

78 Z - Water Temperature Switch - Blue Wire - Help!

Hiccups and loss of power, backfiring, bucking....those are the typical signs of running lean. A common problem with the old EFI systems. Not really clear why, maybe old electronics, different fuel, maybe the system was tuned to perfection for fuel economy. But there's a common fix for it, the potentiometer that I mentioned. But, before that, fuel press ure is critical to correct performance. You have to measure it, there's no easy way to tune around it. It has to be right. There is just a long list of small things that need to be done to get the engines running right. People rarely resurrect one of these old cars and are happy with the way it runs. Here's that fix, for after you check the other stuff. Get those engine and head numbers, just for kicks. There is a wide range of possible combinations that you might have. http://www.atlanticz.ca/zclub/techtips/tempsensorpot/index.html

-

78 Z - Water Temperature Switch - Blue Wire - Help!

Not clear which wire is "missing completely". I have a vague memory of a red wire being part of the coolant temperature sensor harness. It has two bullet connectors in between it and the ECU. (It's where people tap in to add a potentiometer). The best thing to do is to work through the EFI system tests, and give the engine a complete tuneup. Find the engine and head numbers and it might help ID the engine. 78 has the N47 head, everything before has the N42 head. The engine serial number will give an idea of year of manufacture. Engine swaps are very common. The N47 head wouldn't have come with the switch in the thermostat housing. The N42 head would have. Here are the links to the two books you'll need for the electrical testing and tuneup. Do the testing at the ECU plug and measure real numbers not continuity. Good luck.

-

battery drain

Ouch. That might be the disaster you feared. Even the valve seal came off. Odds are high that the valve hit the top of the piston. Hard to imagine a scenario where it didn't. Pull that spark plug and see what you find.

-

battery drain

@cgsheen1 might be able to help you out. He has a business, Sakura Garage (pasted the link below), that should be close to you. I assume that there will be charges, of course, but I'm sure you'll get an honest assessment. Sometimes a rocker arm can pop off and make a lot of noise but with no real damage. @Barefootdan just had that problem, and his engine survived. Surprisingly common with these engines, from what I've seen on the forums. Good luck. https://www.sakuragarage.com/

-

Fusible Links Smoking

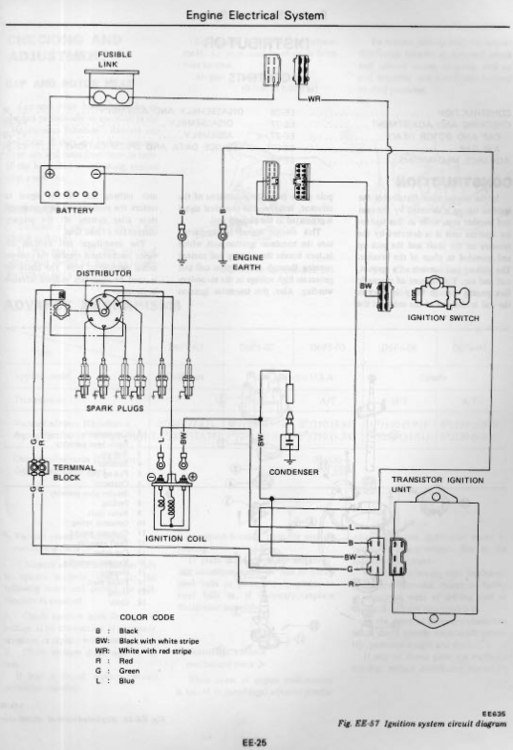

This might help. I only see four other things that could be connected directly to ground, or have an internal short. The diagram does have an odd parallel circuit in it, for anyone that likes a puzzle. Many ways to figure out a problem.

-

1979 280zx

I seem to recall that you might have a 75 280Z. If so, the diff bolt pattern will be your problem. But, you might try a parts wanted ad on the site. There are forum members with part hoards that might have one. Tell people what you're trying do and they might have suggestions. Your posts seem to be a series of random questions.

-

1979 280zx

The drive shafts (2 of them on each car) will, but the propeller shaft (one on each car) won't. The engine, differential, and transmission are all interchangeable. Various relays. Some front end parts. Wheels.

-

battery drain

Spark plugs on the Z engines are about the easiest you'll find anywhere to remove and inspect. If they're dry you'll know more, if they're wet you'll know more. Why wait?

-

battery drain

p.s. if I recall right it's a 74 260Z with carbs. So many electrical problems it's hard to keep track... Pull a spark plug and check for wetness. With carbs, when you smell fuel it usually means that flooding/fouling has occurred. Might be because you didn't have spark, maybe. But even if you solve the spark problem, if it exists, flooding will still stop it from starting.

-

Ignition Coil Exploded!!

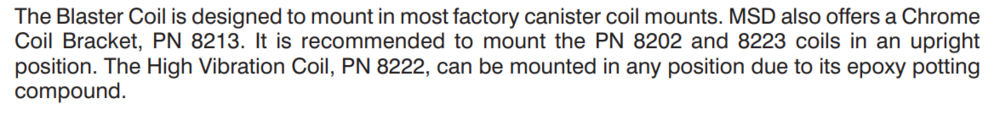

Some coils have instructions to mount them straight up, not sideways. Maybe there's a reason. It would be interesting to see if there are any ID marks on it. https://www.cpperformance.com/instructions/120-8202.pdf

-

Fusible Links Smoking

The Engine Electrical chapter shows all of the pins that you can check at the plug for a short to ground. If it was me I'd just unplug that plug, set my meter to beep for continuity and poke, poke, poke. The beep will be the problem circuit. Edit - actually, the beep would not be the best signal. You'll get a beep through the relay solenoid. Best to read resistance. The one close to zero is the problem. Then find that pin in the wiring diagram and follow it out. Here's another circuit, after the relay. If you find that the ignition relay itself is good then check each pin after the ignition relay. The relay will pass plenty of current to blow those fuses.

-

Fusible Links Smoking

-

Fusible Links Smoking

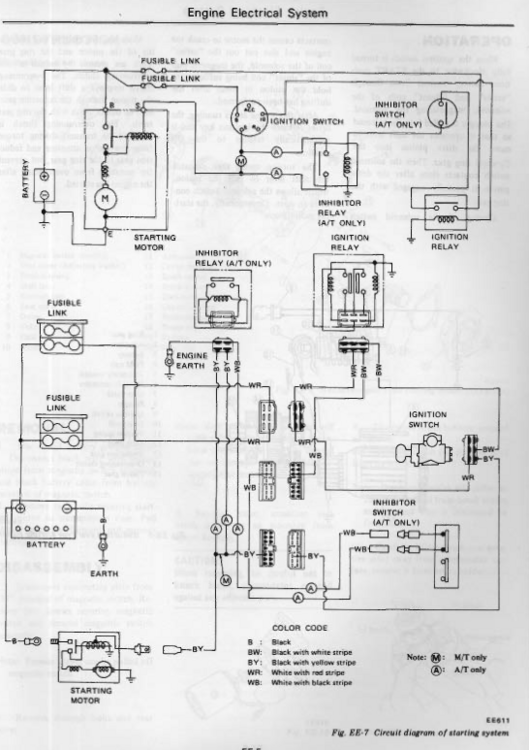

Don't go bigger on the fuses. There's nothing on the Z's that will pull 40 amps through one circuit, I think. You must have a short circuit after the ignition switch. Could be the ignition/accessory relay or something after it like the ignition system (coil, etc.). If your car was or is an automatic there are two inhibitor devices that could be shorting. The simplest starting point is at the plug to the ignition switch. Unplug it and check the black with white stripe for continuity to ground and the same for the black with yellow stripe. That will split the system in to two parts. You have a dead short after the switch. SteveJ just posted. Better see what he said...looks rational (of course). So, there's two separate things that you can do to narrow things down.

-

Ignition Coil Exploded!!

Might be that the engine was hotwired, or the PO tried to hotwire it and did it wrong. Might be that the PO replaced fusible links with full gauge wire. Lots of "might be's". If you had a coil blow up just by connecting the battery, that's a sign of major wrongness. Better get a meter and start using it. You really really don't want to smoke the wiring in the harness. You can test everything you need to test without connecting most of it. You don't need a coil yet. You don't even have enough information to choose a correct one. Also, Nissan did not use the standard red for positive, black for negative on their battery cables. Make sure you know which is which. The colors won't tell you anything. Good luck.

-

Ignition Coil Exploded!!

Was the engine running, or the key on? I'd guess the P.O. connected the blue coil negative wire to a ground terminal or shorted it out by accident, you turned the key on, the coil overheated and popped it's top. Is that a Blaster or did the PO just paint the stock coil red? Download the 1980 EFI book, and the Factory Service Manual if you want to figure things out quickly. Replace and hope doesn't do well on the EFI cars. No offense intended. If the PO bypassed the ballast resistor then he/she probably did something with the ignition module. Might even have a ZX distributor on there.

-

The Pinnacle of Ignition Technology!

Looks like you can still find NOS stuff out there. I'd pick a few links but the Google page has too much good stuff to choose just a few. https://www.google.com/search?q=heathkit+cp-1060&rlz=1C1SQJL_enUS862US862&oq=heathkit+cp-1060&aqs=chrome..69i57.13132j0j15&sourceid=chrome&ie=UTF-8

-

Pushing for more HP on the L28